Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Refrigerant Leak Detection System Installation Instructions

Table of Contents

Introduction ......................................................................................1 Hardware Specifications ..................................................................3 Functional Overview ......................................................................10 Panel Installation ............................................................................29 Sensor Installation..........................................................................30 Horn/Strobe installation .................................................................32 Wiring the System..........................................................................33 Checking Installation .....................................................................38 Recommended Gas Alarm Settings ...............................................38 Maintenance ...................................................................................39 Model & Part Numbers ..................................................................41 Introduction

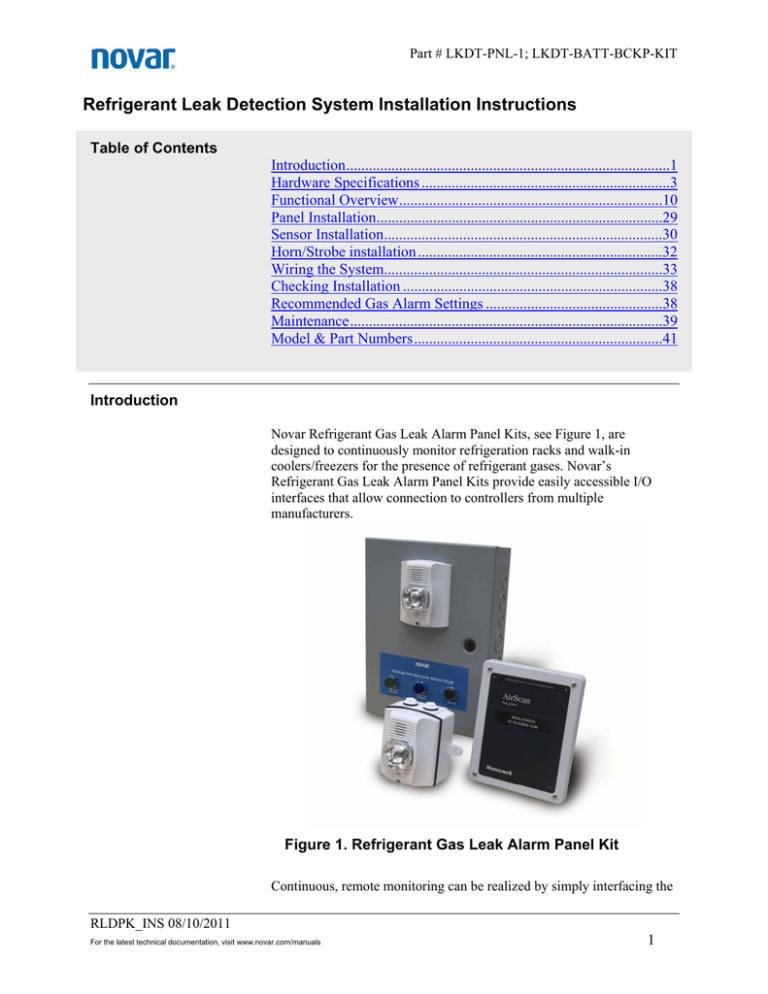

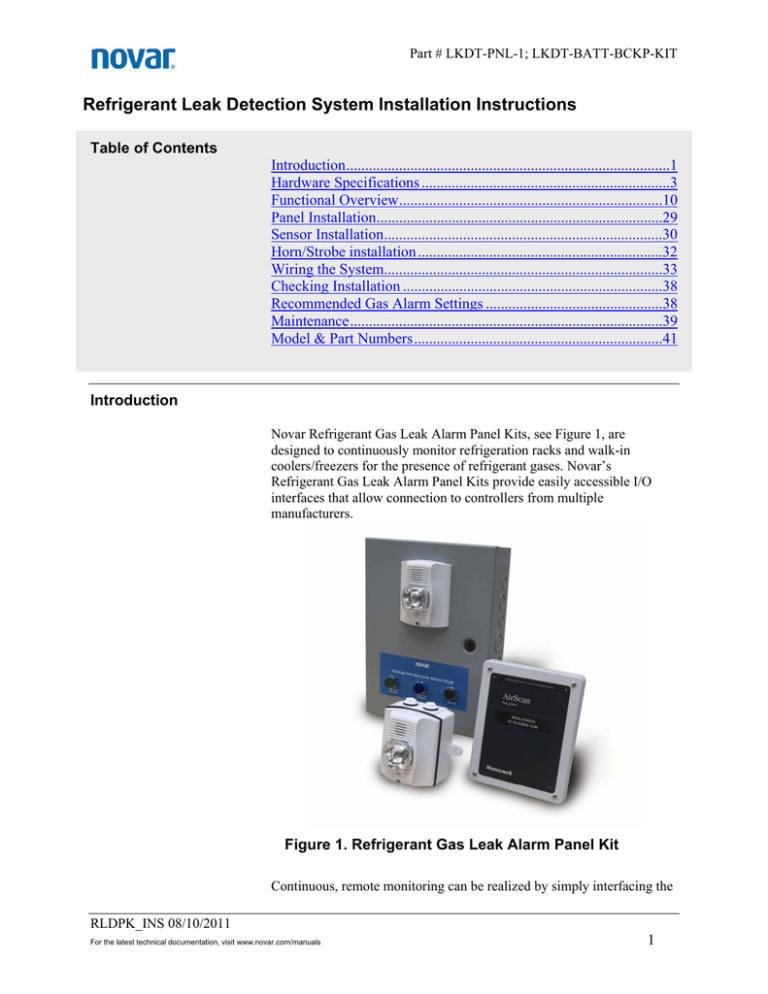

Novar Refrigerant Gas Leak Alarm Panel Kits, see Figure 1, are

designed to continuously monitor refrigeration racks and walk-in

coolers/freezers for the presence of refrigerant gases. Novar’s

Refrigerant Gas Leak Alarm Panel Kits provide easily accessible I/O

interfaces that allow connection to controllers from multiple

manufacturers.

Figure 1. Refrigerant Gas Leak Alarm Panel Kit

Continuous, remote monitoring can be realized by simply interfacing the

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

1

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Refrigerant Gas Leak Alarm Panel (RGLAP) to any Executive Controller

using any standard I/O module supporting a 4-20mA interface.

Continuous, off-site monitoring can be realized by simply interfacing the

Novar Refrigerant Gas Leak Alarm Panel to an 8IM Module or Rack

Input Module and an Executive Controller.

The Novar Refrigerant Gas Leak Alarm Panel Kit is a stand-alone, onezone, refrigerant-gas-detection system which consists of the following

components:

Novar Refrigerant Gas Leak Alarm Panel

Figure 2. Novar Refrigerant Gas Leak Alarm Panel

Honeywell/Manning AirScanTM IR Refrigerant Sensor

Figure 3. Honeywell/Manning AirScanTM IR Refrigerant Sensor

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

2

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

System Sensor Horn/Strobe Audio/Visual Alarm

Figure 4. System Sensor Horn/Strobe Audio/Visual Alarm

Battery Backup Panel

Figure 5. Battery Back-up Panel

Hardware

Specifications

Refrigerant Gas

Leak Alarm Panel

Enclosed Fuse Holder (600V, 30A) (F1):

Indicating: No

Poles: One

Amperage: 30A

Case: Thermoplastic

Torque Rating: 17.7in/lbs

Wire Range: #8-#14 AWG CU

Fuse Size: 13/13"DIA x 1.5"

Fuse: ATDR

120VAC-to-24VDC, 2.5A, Class 2 Power Supply Module (PS-1):

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

3

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Type: 24V/2,5A

Input

Rated Voltage Vin: 100VAC to 240VAC

Voltage Range: 85VAC to 264VAC

Line Frequency Range: 47Hz to 63 Hz

Mains Buffering: > 40 ms

Rated Current Iin: 1.22A to0.66A

Output

Rated Voltage Vout: 24VDC

Residual Ripple/Spikes: < 200/300mVpp

Setting Range: 22.2VDC to 26.4VDC

Rated Current Iout: 2.5A

Current Limitation: 3.4A typ.

Efficiency at Full Load: 87% typ.

Environmental Conditions

Transportation and Storage Temperature: -40°C to +70°C

Ambient Temperature During Operation:-20°C to +55°C

Degree of Protection:IP 20

Pollution Degree Environment:2

Humidity Rating:Climate category 3K3 acc. to EN 60721, relative air humidity

5...95 %, without condensation

EMC Interference Emission:EN 50081-1, class B acc. to EN 55022

EMC Interference Immunity:EN 61000-6-2, EN 61000-4-2/-3/-4/-5/-6/-11

Safety

Protection Class:Class II (without protective earth PE)

Galvanic Isolation Primary/Secondary:SELV output voltage acc. to EN 60950

and EN 50178

AC Fail Relay (RLY-2):

Coil Voltage:120VAC

Poles:DPDT

Contact Amperes:20A

Features:Locking Push Button = M4

Bi-Polar LED

Relay Module (RLY-1):

Coil Voltage:24VDC

Poles:3PDT

Contact Amperes:15A

Features:Locking Push Button = M4

Bi-Polar LED

Terminal Block Style Connectors (TB-1):

Torque Rating:4.2in/lbs

Wire Range:22-12 AWG STR (copper wire 60°C)

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

4

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Honeywell Manning

Dual Alarm Relay

Module

Power Supply Requirements: +18 to +26 VDC

Power Supply Current: 120 mA Max

Operating temperature: -10° F to +120° F

Humidity Conditions: 0% to 95% RH non-condensing

Relay Contacts: Isolated 5A @ 125 VAC / 100 VDC

Set point Adjustment: 33%/100% full-scale (20 mA) and 50%/100%

full-scale (20 mA)

Built-in hysteresis: 2-second time delay for both On/Off transitions

Dimensions: 8.5” high x 8.5” wide x 2.5” deep

LED Status Indicators (Internal): Power (green), Low Alarm (yellow),

High Alarm (red)

Connectors: Screw terminal type 22-gauge to 18-gauge stranded copper

Maximum distance from controller: 1000 feet

Load Resistor: 50Ω to 400Ω

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

5

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

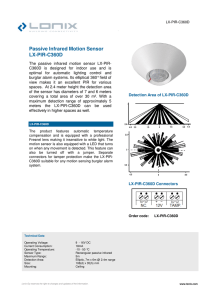

Honeywell Manning

AirScanTM iR

Refrigerant Sensor

Figure 6. Honeywell Manning AirScan iR Specifications

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

6

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

System Sensor

Horn/Strobe

Audio/Visual Alarm

Figure 7. System Horn Strobe Specifications

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

7

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Fire-Lite CHG-75

Battery Charger:

Primary (AC) Power - TB1, Terminals 1 (Hot), 2 (Neutral) & 3 (Earth)

120VAC, 60Hz, 2.05A maximum

220/240VAC, 50Hz, 1.14A maximum (JP1 cut)

Fuse F1 - 6.25A (slow blow 3AG)

Wire size: Minimum 14 AWG with 600 volt insulation

Secondary Power (Battery) Charging Circuit - TB2, Terminals 1 (+) & 2 (-)

Supports lead-acid batteries only

Float Charge Voltage: 27.6VDC

Maximum Charge Current: 4.5A (peak)

Maximum Battery Capacity: 75AH

Supervised and Current-limited: F2 – 15A replaceable fuse

24 VDC Secondary (Battery) Input Power

The CHG-75 current consumption from the battery is as follows:

• During AC Loss: 60mA

• With AC Present: 0mA

Note: use these values in battery calculations for host FACP

Battery Output - TB2, Terminals 3 (+) & 4 (-)

Provides battery backup connection to other loads

Current-limited: F3 – 15A replaceable fuse

SLC (Signal Line Circuit) Connector - TB3, Terminals 1(B+), 2(A+), 3(B-) & 4(A-)

Voltage

24VDC nominal, 27.6VDC maximum

Maximum Loop Current

400mA (short circuit) or 100mA (normal)

Maximum Loop Resistance

40ohms

Supervised and Power-limited

Trouble Contact Rating - TB4, Terminals 1 (C), 2 (NO) & 3 (NC)

Fail-safe Form-C Relay Contacts

Rated for 2A @ 30VDC (resistive)

BAT-12260 26AHR

Lead Acid Battery:

Nominal voltage: 12VDC

Nominal capacity (20 hr): 26.0AH

Dimensions

Total height 125 mm (4.92")

Container height 125 mm (4.92")

Length 166 mm (6.54"); width 175 mm (6.89")

Weight

Approximately 8.80 kg (19.40 lbs)

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

8

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Container material: UL94HB ABS, UL94V-0 ABS.

Internal resistance (25°C, 77°F): ~ 10 m.

Discharge capacity under different temperatures

40°C: ~ 102%

25°C: ~ 100%

0°C: ~ 85%

Capacity 25°C/77°F

20hr @ 1.3A: 26.0AH

5hr @ 4.16A: 20.8AH

1hr @ 15.6A: 15.6AH

1C @ 26.0A: 13.0AH

Charging voltage (25°C, 77°F)

Standby use: 13.65V ± 0.15V

Cycle use: 14.7V ± 0.3V

Maximum discharge current: 300A (5 sec)

Maximum charging current: 7.8A

Self-discharge residual capacity (25°C, 77°F)

After 3 months: ~ 90%

After 6 months: ~ 82%

After 12 months: ~ 70%

Piezoelectric

Trouble Buzzer:

Sound level Category

: Medium Sound Level

Mode of Operation: Slow Pulse

Voltage Rating: 6 to 28VDC

Frequency Range: 1900 Hz ±300 Hz

Loudness (Min. Voltage): 60 dB(A) min. @ 2 FT and 6VDC

Loudness (Max Voltage): 75 dB(A) min. @ 2FT and 28VDC

Current Draw

5 mA Max @ 6VDC

23 mA Max @ 28VDC

Min Pulse Rate (PPS): 0.5 @ 6VDC

Max Pulse Rate (PPS): 2.0 @ 28VDC

Duty Cycle (%): 50 (Approx)

Storage Temperature: -40°F to 185°F (-40°C to +85°C)

Operating Temperature: -22°F to 149°F (-30°C to +65°C)

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

9

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Weight (Typical): 2.1 oz (59 g)

Housing: 6/6 Nylon, Color Black

Functional

Overview

The Novar Refrigerant Gas Leak Alarm Panel kit consists of a Novar

Refrigerant Gas Leak Alarm Panel, a Honeywell/Manning AirScanTM IR

infrared refrigerant gas sensor, and a Spectrometry Advance System

Sensor horn/strobe audio/visual alarm. An optional 24VDC Battery

Backup Panel is also available if required by the customer or local

authority. Figure 8. is a block diagram of the system.

Continuous, off-site monitoring can be accomplished by simply

interfacing the Novar Refrigerant Gas Leak Alarm Panel to either a

Novar 8IM or Rack Input Module and an Executive Controller.

Interfacing to an 8IM Module is implemented by connecting the 4mA-to20mA current-loop output (CNT-SIG and CNT-GND) to one of the 8IM

Module’s current inputs. For Rack Input Module implementation, one of

the three normally-open, dry-contact outputs provided (ALARM #1NO /

ALARM#1COM, ALARM #2NO / ALARM#2COM, or ALARM #3NO

/ ALARM#3COM ) should be used.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

10

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 8. System Block Diagram

Refrigerant Gas

Leak Alarm Panel

The Novar Refrigerant Gas Leak Alarm Panel consists of the following

components (See Figure 9):

Enclosed Fuse Holder (F1)

120VAC-to-24VDC, 2.5A, Class-2 Power Supply Module

(PS-1)

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

11

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

AC Fail Relay Module (RLY-2)

Honeywell/Manning Dual Alarm Relay Module (RDARM)

Relay Module of Three Normally-Open, Dry Contacts

(RLY-1)

Terminal Block Style Connector for Outside Connections

(TB-1)

Three Status Lamps (located on the center, lower front of

the panel)

SpectrAlert® Advance System Sensor Horn/Strobe

Audio/Visual Alarm

Figure 9. RGLAP Inside View

Enclosed fuse holder (F1), class-2 power supply module (PS-1), AC fault

relay module (RLY-2), relay module (RLY-1), and terminal connectors

(TB-1) of the Novar Refrigerant Gas Leak Alarm Panel are all mounted

on 1-3/8 inch (35mm) wide DIN rail.

The Honeywell/Manning Dual Alarm Relay Module (RDARM) is

mounted with threaded standoffs and nuts at each corner of the board.

The SpectrAlert® Advance System Sensor Horn/Strobe Audio/Visual

Alarm is snap-fitted to a four-screw-mounted base-plate at the top center

of the panel door.

For ease of installation, all modules and terminals have wire-cage and

screw connections (Figure 10).

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

12

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 10. Wire-cage screw connections

The enclosed fuse holder F1 (see Figure 11) contains a 600V, 30A fuse

which is easily replaceable by use of a fuse lift-handle system. If an overcurrent fault should occur within the system, the fuse will open removing

the system from the 120VAC power line. One replacement fuse is

mounted inside the panel at the lower right (see Figure 11).

Figure 11. Fuse placement

The 120VAC-to-24VDC power supply (PS-1 in Figure 12) sources

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

13

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

+24VDC@2.5A to all components of the system.

120VAC line power is supplied to the module through two wire-cage and

screw terminals. One terminal (L1) connects to line voltage through fuse

module F1; the other (Neutral) through the TB-1 terminal block

connector.

Figure 12. 24VDC power supply

The AC fail relay (RLY-2 in Figure 13) prevents system power failure if

a power-line loss should occur by switching from the 120VAC-to24VDC power supply to the optional +24VDC Battery Backup Panel if

installed. Battery Backup Panel connections are made at TB-1 BATT(+)

and BATT (-). If a power outage should occur, the Battery Backup

option will allow the Refrigerant Gas Leak Alarm Panel to continue

normal operation for twenty-four hours and then be capable of operating

in alarm mode for five minutes if a refrigerant leak should occur during

the power outage. The AC fail relay has both mechanical and LED status

indicators and a locking push button.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

14

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 13. Power system failure prevention

Output from the Honeywell/Manning AirScanTM IR infrared refrigerant

gas sensor is input to a Honeywell/Manning Dual Alarm Relay Module

(Figure 14). The Dual Alarm Relay Module is a 4mA-to-20mA, feedthrough device designed to provide remote dual stage alarm relay outputs

and can be used with any Honeywell/Manning Systems gas sensor.

Setpoint adjustment is by a two-position switch, allowing standard trip

levels of 33% / 100 % full scale trip levels or 50 % / 100% full scale. The

2A@24VDC SPDT relays are unpowered in normal state. Three LED's

located at the center of the module indicate status of power (green), low

alarm (yellow), and high alarm (red).

Figure 14. Relay module

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

15

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Connections are made to the Dual Alarm Relay Module (RDARM) from

panel terminal blocks TB-1 (CNT-SIG, CNT-GND, SEN-GND, SEN24V, and SEN-GND) through two board mounted connector blocks, one

providing gas sensor +24V power, ground, and 4mA-to-20mA signal

input; the other providing control panel +24V power, ground, and 4mAto-20mA control signal.

NOTE!

In the event that offsite monitoring will not being utilized (not

connected to a Novar 8IM Module), to enable the alarm

function of the alarm panel a properly sized (wattage), 50Ω to

400Ω resistor must be connected between terminals CNT-SIG

and CNT-GND. If this is not done, the Dual Alarm Relay

Module will not alarm in the event of a detected gas leak.

The Relay Module (RLY-1 in Figure 15) provides three normally-open,

dry contacts which are used for auxiliary monitoring of alarms or

external equipment interfacing. The relay has both mechanical and LED

status indicators and a locking push button.

Figure 15. Relay module

Three status lamps are located on the lower front of the panel (Figure

16). After the 120VAC power is applied, the left-side green status lamp

will be illuminated. The center blue 24VDC power status lamp is

illuminated with the presence of either battery-backup power or the

24VDC power supply. The right-side red alarm status lamp is

illuminated only during an alarm.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

16

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 16. Alarm Panel

Upon detection of a refrigeration gas leak, the alarm status lamp is

illuminated by the Dual Alarm Relay Module’s low-alarm relay, which

also activates the SpectrAlert® Horn/Strobe Alarm, causing the strobe to

flash at a one-hertz rate and the horn to sound.

NOTE!

Alarms are automatically silenced when the detected refrigerant

has dissipated in the area being monitored and the gas sensor

sampling chamber has been cleared. Provision is made for the

addition of external strobe/horn devices at connector terminals

H/S 24V and H/S GND.

Manning AirScanTM

IR

The Honeywell Manning AirScanTM IR infrared sensor (Figure 17) is a

microprocessor-based sensor that is selective to refrigerants and provides

years of service at the highest level of accuracy and reliability. This

highly versatile sensor features SensorCheckTM, a unique technology that

continuously monitors sensor performance that enables it to provide

worry-free performance throughout the life of the sensor. A true

“diffusion” design sensor, the Honeywell Manning AirScanTM IR sensor

does not require pumps or filters and allows all points of gas detection to

be monitored perpetually, unlike sample draw systems.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

17

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 17. Air Scan

Gas detection by the infrared method is based on the principle that most

gases absorb infrared energy at a characteristic frequency. In this

instrument, a broad band infrared source emits energy which is then

band-pass filtered to produce a narrow range of frequencies characteristic

of the refrigerants’ (CFC/HCFC/HFC) absorption spectra.

Any refrigerant in the gas sample cell (Figure 18) selectively absorbs

energy reaching the detector. This reduction in energy is detected,

amplified and sent to the signal processing portion of the system.

The Honeywell Manning AirScanTM IR Sensor line is a three-wire, 4mAto-20mA sensor for two bands of refrigerants available in a range of 0—

3,000ppm, but can be adjusted for lower ranges, if required. The lowband or R-404a infrared sensor reacts to R-123, R-134a, R-404a and R507. The high-band or R-22 Honeywell/Manning AirScanTM IR sensor

reacts to R-22.

Figure 18. Sample cell

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

18

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Internal compensation for environmental changes allows the sensor to

automatically adapt to fluctuating temperature and humidity conditions.

Every two seconds SensorCheckTM technology monitors the AirScanTM

IR source and ensures that the dual channels are functioning properly. A

notification signal will be transmitted if any of several performance

parameters are not met.

Monitoring equipment must be configured to indicate a fault if the signal

is less than 1.5mA. All signals over 20mA must be considered a high gas

concentration.

Honeywell Manning infrared sensors are normally long-lived (5 years

plus), unless physically damaged or wetted with water or other liquid.

Power and signal connections for the Honeywell Manning AirScanTM IR

are made through a wire-cage and screw connector (see Figure 19).

Figure 19. Screw connector

Sensor operation status is indicated by the blink pattern of seven LED’s

located in a vertical row on the right side of the sensor circuit board (see

Figure 20). LED status is differentiated by color and duration/pattern of

blink(s).

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

19

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

20

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 20. Sensor circuit board

After power-up, the green power LED is continuously on, both fault

LED’s are off, and the green source LED is blinking once every 2

seconds.

The green power LED is continuously ON once power is applied.

The yellow system LED indicates the following:

Continuous ON during normal filtered output run mode “dead band” from 4mA to 4.6mA

Slow blink during normal non-filtered output run mode

Fast blink indicating unit lost calibration data

Off during 4mA-to-20mA loop check

The yellow calibrate LED indicates the following:

Continuous momentary on for auto-zero mode activation

Slow blink for 4mA output calibration mode

Medium double blink indicates 4mA-to-20mA loop check

0.5mA (low)

Fast blink for span calibration mode and 4mA-to-20mA

loop check 22mA (high)

The red fault LED indicates the following (all scenarios produce a

0.5mA output):

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

21

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Continuous on indicates a failed source, low signal, or

circuit failure

Slow blink indicates the power supply 24VDC input

voltage is too low

Medium double blink indicates sensor is outside the

operating temperature range

Fast blink indicates the signal drifted below 4mA and needs

to be re-calibrated, only in non-filtered output run mode (no

dead-band)

The red mA fault LED attempts to output a 0.5mA. A fast blink indicates

4mA-to-20mA loop failure or load resistance too high.

The green source LED blinks once every 2 seconds to indicate when

source is energized and also that the source is not short circuited.

The green ATMOS LED is continuously on and indicates ATMOS

circuitry is active or adjusting the enclosure’s internal environmental

conditions for the sensor to function reliably.

The above description on LED indicators is very limited; See AirScan IR

Manual for full details.

Pushbutton S1 (Figure 21) is used to initiate the auto-zero function,

program the 4mA output calibration, and initiate the 4mA-to-20mA loop

test.

Figure 21. Pushbutton S1

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

22

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

System Sensor

SpectrAlert®

Horn/Strobe

Audio/Visual Alarm

The SpectrAlert Advance horns, strobes, and horn/strobes can be used

indoors or outdoors in wet or dry applications and can provide reliable

operation from −40°F to 151°F.

Figure 22. Honeywell Sensor SpectrAlert Horn/Strobe

Like the entire SpectrAlert Advance product line, these devices include a

variety of features that increase their application versatility while

simplifying installation. All devices feature plug-in designs with minimal

intrusion into the back box, which make installations fast and foolproof

while virtually eliminating costly and time-consuming ground faults.

All horns, strobes, and horn/strobes use a universal mounting plate with

an onboard shorting spring that tests wiring continuity before the device

is installed, protecting devices from damage.

The SpectrAlert Advance is housed in a NEMA 4X rated, 5.6” x 4.7” x

2.5 deep (without weather-proof back box) enclosure.

24VDC Battery

Backup Panel

The Battery Backup Panel (Figure 23) allows the Refrigerant Leak

Detection Panel to continue with normal operation for twenty-four hours

and then be capable of operating in alarm mode for at least five minutes.

The Refrigerant Leak Detection Panel transfers to the Battery Backup

Panel when 120VAC power is lost.

The Refrigerant Leak Detection Panel automatically returns to primary

power when the 120VAC power has been restored.

Simultaneously, when 120VAC power is lost, a 24VDC trouble audible

will sound (pulses on/off for one second) until the primary power has

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

23

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

been restored. The audible buzzer cannot be manually silenced.

Battery Backup Panel dimensions are 15.6” x 15.5” x 5.13”; weight is

approximately 60lbs with batteries.

The Battery Backup Panel consists of the following components:

Fire-Lite CHG-75 Battery Charger

Fire-Lite BB-26 Battery Box

Fire-Lite BAT-12260 26AH, Lead-Acid, Sealed Battery (2

required).

Piezoelectric Buzzer with Bracket Assembly

Figure 23. Battery Backup Panel

CHG-75 Battery

Charger

The CHG-75 battery charger (Figure 24) is designed to charge lead-acid

batteries that provide emergency standby power. Two 12V batteries

(BAT-12260) are used in series to supply a nominal 24VDC. The battery

charger is compatible with any lead-acid batteries with a rating of 25AH

to 75AH. The CHG-75 can be configured for 120VAC operation or

220/240VAC operation via jumper selection.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

24

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 24. Battery Charger

Two screw terminal blocks, one insulated located at the lower-left-side

of the module and one non-insulated located at the right-hand side of the

module, provide connection points for line power, battery, and RGLAP

+24VDC power out (see Figure 24 and Figure 25).

Figure 25. Wiring Board

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

25

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Line power connections Line, Neutral, and Ground enter the CHG-75

through the insulated, screw-terminal block located at the lower-left side

of the module. BAT-12260 + and - connections are made at the lower

two screw terminals located on the right-hand side of the module.

RGLAP +24VDC power out connections are made at the upper two

screw terminals located on the right-hand side of the module.

Status indication LEDs are provided on the CHG-75 circuit board to

monitor various charger conditions:

AC LED – green LED indicates AC power is present

Trouble LED – yellow LED turns on for charger troubles or

trouble indication from the Master Trouble Input

Low Battery LED – yellow LED turns on when the battery

voltage drops too low

Charging LED – yellow LED indicates battery is being

charged, turns off when the CHG-75 is trickle charging

Ground Fault LED – yellow LED turns on to indicate

ground fault on the charger

BB-26 Battery Box

The battery box is designed to contain two BAT-12260 12V, 26AH,

lead-acid, sealed batteries; a CHG-75 battery charger; and a piezoelectric

alarm buzzer with bracket assembly.

The CHG-75 module is located and mounted on four #4-40 threaded

studs. One #4-40 stud, located at the left side of the CHG-75 module, is

provided for battery box grounding.

The BB-26 box dimensions are 15.6" (39.62cm) wide, 15.5" (39.37cm)

high, and 5.125" (13.02cm) deep.

For installation wiring, the box is designed with one 1.125” diameter

(2.857cm) knockout located on the left-side top of the box; four identical

knockouts are located in both sides and the rear of the box.

Two mounting holes are provided at the top of the battery box for

installation of optional AM-1and VM-1 meters.

For installation mounting, the BB-26 battery box has two mounting holes

located in the back of the box (see Figure 26)

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

26

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 26. Battery Box

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

27

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 27. Mounting Diagram

Optional Ammeter

(AM-1) or Voltmeter

(VM-1)

Optional ammeter (AM-1) and voltmeter (VM-1) are available for the

CHG-75 battery charger. Meter ranges are 0A-to-10A and 0V-to-50V

respectfully. The meters indicate charge voltage and charge current. Both

meters are wired to the CHG-75 and mounted in mounting holes

provided in the BB-26 battery box.

BAT-12260

The BAT 12260 battery is a 12V, 26AH, lead-acid, sealed battery. Two

are required and are serially configured for a nominal output voltage of

24VDC.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

28

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Piezoelectric

Trouble Buzzer with

Custom Bracket

Assembly

A piezoelectric buzzer (Figure 28) is employed to sound a one-second

pulse rate, 70dB(A)@2Ft audible alarm when primary line power to the

Battery Backup and RGLP is lost. The alarm will sound until primary

power is restored and cannot be manually silenced.

Figure 28. Piezoelectric buzzer

The piezoelectric buzzer is mounted on a custom bracket which is

mounted to the CHG-75 module.

The buzzer is powered by the +24VDC battery source and is operated by

the CHG-75 module Form-C, trouble-relay contacts.

Panel Installation

This section covers the mounting of the Refrigerant Gas leak Alarm

Panel (RGLAP). It assumes that the work is being completed by an

engineer, technician, or service person that is performing control systems

installation.

Mounting and

Orientation

The Panel is to be mounted per the requirements of the Customer or

Authority having jurisdiction. The panel is to be mounted at a height

which allows appropriate access to the interior of the panel. When

mounting the panel to paneling or drywall, use hollow-wall anchors or

appropriate fasteners to insure that the assembly remains secure. The

panel should be on the outside of the space being monitored near the

entrance of that space.

Screw Locations

The RGLAP should be installed plumb and level and securely fastened to

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

29

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

a rigid mounting surface. The enclosure utilizes four mounting holes on

the back of the box (see Figure 29 below).

Figure 29. Mounting hole locations

Sensor Installation

This section covers the mounting of the Manning AirScanTM IR.

Mounting and

Orientation

Because each sensor can only “report” what it is seeing at the moment, it

is very important that the sensor be located where leaks are most likely to

occur. CFC/ HCFC/HFC vapor is heavier than ambient air, so in a room

with no air movement it will tend to settle. For quickest detection, mount

the sensor about one to two feet from the floor, close to the potential leak

source.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

30

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

If the primary application is the fastest possible leak detection, mount the

sensor near the potential leak sources. In doing this, be aware that the

indicated concentration may not be representative of personnel exposure

and easy access for the required calibration and maintenance could be

compromised.

General

Considerations:

Very Important:

Must be easily accessible for calibration and maintenance.

Always mount the sensor vertically.

Mount the sensor close to the potential leak source for

fastest possible leak detection.

Protect sensor from water, excessive humidity, and washdown.

Take air movement and ventilation patterns into account.

To prevent electrical interference, keep sensor and wire

runs away from mercury vapor lights, variable speed

drives, and radio repeaters.

Protect sensor from physical damage (fork lifts, etc.).

Do not mount the sensor over a door in a refrigerated area.

Sensor must be mounted vertically.

Never mount sensor flat on a ceiling.

Enter enclosure only through existing hole in bottom of

enclosure.

Always make a drip loop in the conduit.

Never mount sensor on a vibrating surface.

NOTE!

Mount sensor enclosures through the flange holes as shown in

Figure 30 and always mount vertically.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

31

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 30. Sensor Dimensions

Horn/Strobe

installation

This section covers the mounting of the Remote Horn and Strobe.

The Horn/Strobe is to be mounted per the requirements of the Customer

or Authority having jurisdiction.

An installed weatherproof back box should not be left without an

installed unit for extended periods of time to avoid water accumulation.

Mounting and

Orientation

The wall-mount back box shipped with these products must be mounted

with the internal post (Figure 31A) in the lower left corner.*Attach the

device mounting plate (Figure 31B) to the weatherproof back box

(Figure 31C) using the four non-painted screws (Figure 31D) included

with the product. Hook the tabs on the product housing into the grooves

on the mounting plate. Then, swing the product into position to engage

the pins on the device with the terminals on the mounting plate. Verify

that the tabs on the back of the device are fully engaged with the

mounting plate. Finally, secure the device to the mounting plate by

tightening the single screw attached to the front of the housing (Figure

31E). For tamper resistance, the captured screw may be replaced with the

Torx screw supplied with the device.

For conduit installation refer to the Proper Installation of SpectrAlert®

Advance Outdoor Audible Visible Appliances guide.

Screw Locations

The Horn and Strobe should be installed plumb and level and securely

fastened to a rigid mounting surface. The enclosure utilizes two flange

holes on the either side of the box (see Figure 31 below).

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

32

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 31. Horn Strobe details

Wiring the System

CAUTION!

All wiring must comply with local and national electrical

codes.

CAUTION!

Disconnect power before beginning installation. Failure to do

so can cause electrical shock or equipment damage.

NOTE!

This product should be installed by a trained and experienced

technician. Failure to follow these instructions carefully could

damage the product or cause unexpected system operation.

Refrigerant Gas

Leak Alarm Panel

The 120VAC-to-24VDC power supply (PS-1) sources +24VDC@2.5A

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

33

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

to all components of the Novar Refrigerant Leak Detection System

through Terminal Block 1 (TB1). 120VAC line power is supplied to the

module through two wire cage and screw terminals using 18 AWG. One

terminal (L1) connects to terminal 1 (on TB1) line voltage through the

fuse module; the other (Neutral) through the terminal block connector

terminal 2 (TB1). Connect the Earth Ground to terminal 3.

NOTE!

Refer to the wire diagram in the panel door pocket for further

detail.

NOTE!

In the event that offsite monitoring will not being utilized (not

connected to an Input/Output Module), to enable the alarm

function of the alarm panel a properly sized (wattage), 50Ω to

400Ω resistor must be connected between terminals CNT-SIG

and CNT-GND. If this is not done, the Dual Alarm Relay

Module will not alarm in the event of a detected gas leak.

Connecting to a

Novar system

The RGLAP is typically connected to a Novar 8IM Module, or other

input/output module. Connect TB1 terminals 6 (Signal), and 7 (Ground)

in the RGLAP (see Figure 32) to the 8IM module sensor input field

termination block. There are 8 screw terminals; the signal wire is to be

connected to the positive terminal and ground to the negative terminal on

the 8IM module.

Connecting to a

third party system

The RGLAP may be connected to an input/output device from other third

party suppliers designed to accept a 4mA-20mA signal. Connect TB1

terminals 6 (Signal) and 7 (Ground) in the RGLAP connect to the Third

party input/output module as specified by the manufacture.

The Novar Refrigerant Leak Detection System can be monitored by any

other manufacturer’s control equipment using the normally open dry

relay contacts provided in the RGLAP.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

34

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

NOTE!

In the event that offsite monitoring will not being utilized (not

connected to an Input/Output Module), to enable the alarm

function of the alarm panel a properly sized (wattage), 50Ω to

400Ω resistor must be connected between terminals CNT-SIG

and CNT-GND. If this is not done, the Dual Alarm Relay

Module will not alarm in the event of a detected gas leak.

Figure 32. Contactor Panel

Manning

AirScan™IR

NOTE!

Nearly all start-up problems are due to improper wiring or

monitor configuration. Please follow these guide-lines

carefully.

Always use three conductors, insulated, stranded, shielded copper cable.

Use only three conductor cable, not two cables of two conductor wire.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

35

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Do not pull sensor wiring with AC power cables. This will cause

electrical interference. Be sure there are no breaks or splices in sensor

wiring runs. If cable runs cannot be made without a splice, all

connections must be soldered. Soldering should be done using a rosin

flux to tie the connecting ends of sensor wires to ensure a positive and

long-lasting contact.

Ground the shield at the main control panel. Connect the shield wire in

the sensor terminal block labeled shield. Tape all exposed shield wire at

the sensor to insulate it from the enclosure.

All penetrations into a refrigerated room should be sealed to prevent

condensate from forming in the conduit and dripping into the sensor

enclosure.

Make drip loops for cables going into sensor housings. Follow the

special mounting instructions on the enclosure (…This End Up).

NOTE!

Circuit board mounted sensor provides a linear 4/20 mA output.

Monitoring equipment may have a maximum input impedance

of 500 ohms.

Cable Recommendation: Use #18/3 (Belden #8770) for cable runs up to

200 feet. Use #16/3 (Belden #8618) for cable runs up to 1,000 feet. Use

only the existing punched holes for connections to the sensor.

Connection to RGLAP: The sensor wires are connected to terminal

block 1 (TB-1 Figure 33) on terminals 8 (signal), 9 (24V) and 10

(Ground)

NOTE!

Allow the sensor to operate for 12 hours with the enclosure

sealed prior to testing the sensors. This will give the sensor

time to reach thermal equilibrium to the external and internal

temperatures while in operation. Because sensors are normally

located at a distance from the main unit, the test time required

and accuracy of the response checks will be improved if two

people perform the start-up procedures and use radio contact.

To avoid possible activation of the H/S both internal and

remote do not connect the signal wire during this period.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

36

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Figure 33. Wiring

Remote Horn/Strobe

The Horn/strobe can be wired (Figure 34) using #12 to #18 AWG. The

remote horn/strobe is connected to the RGLAP on terminal block 1

(TB1) on terminals 11 (24V), 12 (Ground).

Figure 34. Terminals

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

37

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Checking

Installation

Manning AirScan™

IR

NOTE!

Before applying power, make a final check of all wiring for

continuity, shorts, grounds, etc. It is usually best to disconnect

external alarms and other equipment from the sensor until the

initial start-up procedures are completed.

For detail in verifying proper operation of the Manning AirScan™ IR

sensor please reference section 3 of the Honeywell Installation and

Instruction manual Manning AirScan™IR Refrigerant Sensor 19546

AirScan™-IR-com

RGLAP HORN/STROBE

1.

2.

3.

4.

Apply 120 VAC

Verify the 120 VAC lamp is lit.

Verify the 24 VDC lamp is lit

Exposes the sensor to the recommended about of gas that is being

monitored per the Calibration manual (Refer to the AirScan

Calibration manual)

5. Verify that the RGLAP responses causing appropriate alarm

function (Horn/Strobe active and front panel alarm lamp is lit).

6. Allow alarm to clear before leaving

Recommended

Gas Alarm

Settings

User Configuration

Settings

Only the Dual Relay Module is capable of configuration. The user can

select one of two set point adjustments (left position: 33%/100% full

scale, right position: 50%/100% full scale).

Factory Defaults

The Dual Relay Module is factory pre-set for 33%/100% set point trip

levels.

The gas sensor has been calibrated at an altitude of 1,000 ft. above sea

level. For installations where the altitude is greater than 3,500 ft. above

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

38

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

sea level, it is necessary to recalibrate the sensor “span” during the initial

setup for more accuracy and reliability.

Calibration is accomplished by using a Manning “CK” Calibration Kit

for the specific gas to be detected. For information on Calibration kits

please refer to the Manning Calibration Kit Instruction and Calibration

Manual.

Maintenance

Manning AirScan™

IR

Expose each sensor to test gases monthly to verify that the sensor has a

normal response. This will also check the alarm lights and relay action of

the monitoring equipment.

NOTE!

It is essential that signal voltages be taken and logged on a

consistent basis at least monthly. Periodically, sensors should

be exposed to refrigerant sample and the results logged.

For proper operation it is essential that the test and calibration schedule

be adhered to. Honeywell Analytics recommends the following

maintenance schedule:

Calibration should be performed with certified calibration

gas every six months. Calibration kits are available from

Honeywell Analytics.

All tests and calibrations must be logged. It is highly

recommended that certified calibration gas be used every

six months.

NOTE:

For information on Calibration kits please refer to the Manning

Calibration Kit Instruction and Calibration Manual.

Interchangeability

The 404a and 407a gas sensors are interchangeable with any RGLAP,

provided it is used for monitoring the appropriate refrigerant gas.

Refrigerant Gas

Leak Alarm Panel

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

39

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Only the AC fuse is serviceable. A Replacement fuse will be included

with each panel. The Dual Relay Module and Indoor Horn/Strobe is also

field replaceable. All other hardware failures will require panel

replacement.

Outdoor

Horn/Strobe

No user serviceable parts. Failures will require Horn/Strobe

replacement.

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

40

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Model & Part

Numbers

The part numbers below should be used to order Novar parts.

OS/ Part No.

LKDT-404A-KIT-1

LKDT-407A-KIT-1

LKDT-PNL-1

815003000

M-700071

P2WHK-P

LKDT-BATT-BCKP-KIT

P2WH-P

BAT-12260-M

M-700124

Product

404a Refrigeration Leak Detector Panel Kit

407a Refrigeration Leak Detector Panel Kit

Refrigeration Leak Alarm Panel (no sensor-spare part)

404A Refrigerant Sensor

407A Refrigerant Sensor

Horn/Strobe, 24 VDC, Outdoor w/Back Box, White

Battery Back-up Unit w/Power Supply, Battery Cabinet, Trouble

Buzzer Assembly and (2) BAT-12260 Sealed Lead-Acid Batteries

Horn/Strobe, 24 VDC, Indoor w/o Back Box, White (spare part)

Battery, 12 VDC, 26 AHR, Sealed Lead Acid (spare part)

Dual Relay Module (spare part)

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

41

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

Regulatory Compliance

Refrigerant Gas

Leak Alarm Panel:

UL/ULC: UL-508A

CE

CE CE marking acc. to 2004/108/EG and 2006/95/EG

UL UL 508 (Listed, File E197259), UL 60950

(Recognized, File E151273), NEC Class 2 for 6EP13321SH42

FM Class I, Division 2, Groups A,B,C,D, T4

GL Approval for shipbuilding to Germanischer Lloyd

ABS Approval for shipbuilding to American Bureau of

Shipping for 6EP1322-1SH02 und 6EP1332-1SH42

ATEX ATEX94/9/EC Kat.3;Ex, nA IIC T3

UL 1638 (strobe) and UL 464 (horn)

UL Listed:

1638 (strobe)

464 (horn)

S4011 (chimes, horn strobes, horns)

S3593 (outdoor and alert strobes)

FM Approved:

3023572

MEA Approved:

MEA452-05-E

State of California State Fire Marshall:

7300-1653:187 (outdoor strobes)

7125-1653:188 (horn strobes, chime strobes)

7135-1653:189 (horns, chimes)

N/A

UL 1638 (strobe) and UL 464 (horn)

UL Listed:

1638 (strobe)

464 (horn)

24VDC Supply

Horn/Strobe Alarm:

Manning AirScanTM

IR Refrigerant

Sensor

System Sensor

Outdoor

Horn/Strobe

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

42

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

S4011 (chimes, horn strobes, horns)

S3593 (outdoor and alert strobes)

FM Approved:

3023572

MEA Approved:

MEA452-05-E

State of California State Fire Marshall:

7300-1653:187 (outdoor strobes)

7125-1653:188 (horn strobes, chime strobes)

7135-1653:189 (horns, chimes)

UL Recognized Components: files MH19884 (B & B

Battery), MH20567 (UPG, previously Jolt), MH20845

(Power-Sonic).

Battery Backup

Panel:

BAT-12260

Note:

The listings and approvals below apply to BAT Series Batteries. In some

cases, certain modules may not be listed by certain approval agencies, or

listing may be in process. Consult factory for latest listing status.

CHG-75 Battery

Charger

UL Listed

S1287

MEA

297-01-E

California State Fire Marshal

7315-0075:201 (power units)

UL Listed

Piezoelectric Buzzer

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

43

Part # LKDT-PNL-1; LKDT-BATT-BCKP-KIT

The material in this document is for information purposes only. The content and the product it describes

are subject to change without notice. Novar makes no representations or warranties with respect to this document.

In no event shall Novar be liable for technical or editorial omissions or mistakes in this document, nor shall it be liable

for any damages, direct or incidental, arising out of or related to the use of this document. No part of this document

may be reproduced in any form or by any means without prior written permission from Novar.

Copyright © 2011 by Honeywell International, Inc.. All Rights Reserved.

Novar

6060 Rockside Woods Blvd.,

Cleveland, OH 44131

Phone: 1.800.348.1235

www.novar.com

RLDPK_INS 08/10/2011

For the latest technical documentation, visit www.novar.com/manuals

44