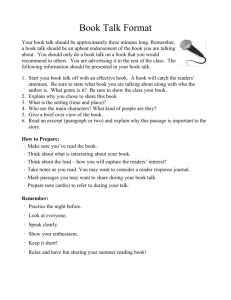

BUDGETARY OFFER FOR REMOVAL, SUPPLY

advertisement

CHENNAI PORT TRUST NOTICE INVITING BUDGETARY OFFER MEE/VA1/115/2015/Dy.CME (OH) BUDGETARY OFFER FOR REMOVAL, SUPPLY, COMMISSIONING OF MOUNTING, 1 No. DOUBLE TESTING HOOK AND QUICK RELEASE MOORING HOOK (QRMH) UNIT, INTEGRAL CAPSTAN AND REMOTE CONTROL TYPE AT BD -III POINT NORTH SIDE IN OIL DOCK. Submission on or before : 31.01.2016 To the address of : Office of the Dy.Chief Mechanical Engineer (OH) Chennai Port Trust Royapuram, Chennai – 600 013. ‘D’ BUDGETARY OFFER FOR REMOVAL, SUPPLY, MOUNTING, TESTING AND COMMISSIONING OF 1 No. DOUBLE HOOK QUICK RELEASE MOORING HOOK (QRMH) UNIT, INTEGRAL CAPSTAN AND REMOTE CONTROL TYPE AT BD -III ‘D’ POINT NORTH SIDE IN OIL DOCK. TECHNICAL SPECIFICATION SCHEDULE – ‘A’ GENERAL The Trust has proposed to carry out the works of removal of existing old (QRMH) and supply new QRMH, mounting, testing and commissioning of 1 No. Double Hook Quick Release Mooring Hooks Unit, Integral Capstan and Electric remote control system at BD-III ‘D’ Point North Side in Oil Dock. A detailed technical specification and terms & conditions as mentioned below : SCOPE OF WORKS: 1) The firm shall remove the existing Mooring Hook unit and its assembly at BD-III ‘D’ point North Side including capstan motor and electrical controls. While removing existing mooring hook unit assembly, the firm shall ensure that no damage / disturbance to the existing reinforcement of the Deck slab structures and adjacement slab. Note: The firm should remove existing mooring hook unit after successfully commissioned the new QRMH unit and which shall installed at a new location adjoining to the existing Mooring Hook as instructed by Trust Engineer. 2) Supply of 1 No. Double Hook Quick Release Mooring Hook (QRMH) unit, integral capstan and electric remote control system along with anchor bolts, washers, nuts, base plates and mounting template for proper mounting. 3) The firm shall mount the Anchor Bolts, base plates, washers & nuts, etc. with the help of template of the Quick Release Mooring Hook (QRMH) unit. For this purpose, necessary concrete mixture may be used for fixing of the base plate and anchor bolts and bonding may be ensured according to the Pull Load. 4) The firm shall ensure that while re-doing the concrete work after fixing the new QRMH necessary chemical bonding agents shall be used for old and new concrete structure and surface hardeners shall be used for water proofing. 5) After Anchor Bolts mounted; the firm shall install the new 1 No. Double Hook Quick Release Mooring Hook (QRMH) unit assembly with proper installation procedure furnished by the manufacturer. 6) For operation of the equipment, the firm shall connect the power cables with the QRMH assembly unit. 7) The firm shall conduct the pre-test before commissioning of the QRMH in the presence of Trust Engineer. 8) The firm shall collect the existing old removed items of Mooring Hook, Capstan Motor, etc. loading & unloading and transport to Trust RSA yard by their own arrangements. SUPPLY OF MATERIALS All the materials required for carrying out the works shall have to be supplied by the firm. All materials must be suitable and certified by third party or independent international classification authority such as IRS, BV, DNV or any Classification Society who is a member of International Association of Classification Society for use in an Oil Jetty to handle Crude oil (Class A - Petroleum Product). The trust will arrange for inspection by third party agencies and cost of inspection will be borne by the Trust. The tenderer shall agree for this clause. The designed life of the QRMH shall be not less than 20 years. SIZE OF TANKERS TO BE HANDLED The sizes of Tankers to be handled are as given below: LOA : 140 – 275 mtrs. ; Beam: 25 – 50 mtrs. ; The maximum size of the vessels being berthed ranges from 1,50,000 to 1,60,000 DWT tankers. (Displacement 2,00,000 T) QUICK RELEASE MOORING HOOKS (QRMH) The Double Hook Quick Release Mooring unit shall be installed at BD-III at ‘D’ point north side in Oil Jettty. Along with the installation of QRMH, the dolphin jetty edges need to be smoothened (sharp jetty edges to be rounded of with roller fittings which can withstand mooring ropes to avoid damage to the Ship’s mooring ropes / wires while berthing). The design and SWL of the QRMH shall be suitable for the above size of vessels and in conformity with IS : 4651 code of Practices for Marine Installation requirements. Each hook of the assembly shall not be less than 150T of Safe Working Load (SWL). The release mechanism shall be of remote control type. The QRMH shall be positioned on the Oil Jetty in consultation with the Civil Engineering Department of Chennai Port Trust so as to avoid any damage to the reinforcement of the Deck Structures. Assembly of Quick Release Mooring Hooks shall be installed approximately at the central location of the sea-facing side and at a distance of approximately ¼ th of the width of the Dolphin from the Sea-facing side. The QRMH shall have the following features : • Integral capstans • Remote control system • Mooring load monitoring system • Electrical insulation • Dust protection covers • Anti rope slip devices (keepers) • Special coatings • Special low temperature executions • Customized designs The case bases and hooks provided shall be superior corrosion resistance and have high tensile strength. The cast hooks with optimal throat size shall be supplied to minimise the rope wear. It shall have compact and strong hook design, double the yield strength of forged mild steel hook. It shall have release mechanism Fully protected release mechanism in a weatherproof and explosion proof enclosure. In main control room, controls shall be provided for operation of individual Quick Release Mooring Hooks (QRMH) as well as emergency operation of all the Quick Release Mooring Hooks (QRMH) simultaneously. Visual light indication shall be provided in the control panel to indicate the status of the Quick Release Mooring Hooks (QRMH). Control mechanism shall have On/Off/reset button arrangements to feed power supply to Capstan motors. A remote operating station shall be provided at a convenient point, preferably in control operation panel, so that in the event of emergency situation, all the Quick Release Mooring Hooks (QRMH) can be released promptly. All the equipment shall be capable of working under the following conditions:Voltage variation : + 10% The system shall have overload protection. The isolating switches shall be rated accordingly. CAPSTAN The capstan motor shall be of reversible with appropriate braking system and integrated type with the Quick Release Mooring Hooks (QRMH) units and shall have the following specifications: Nominal Line Speed - 30 Mtrs / min ; Line Pull Load - Not less than 3 MT Starting Pull Load - Not less than 6 MT The QRMH unit shall be equipped with an integral capstan. The capstan allows hauling in the mooring line in a safe and efficient way. The capstan motor shall have the following features. i) brake motor with reversible rotation ii) switch box with control equipment iii) motor starter iv) foot pedal for operating the capstan The capstan assembly shall be installed eastward of hooks so that the hooks are clear to rotate north & south to align with ship’s mooring lines. The electric motor shall comply with following specifications: Power shall be minimum : 15.0 kW Supply Voltage : 440 Volts, 3 Phase, 50 Hz RPM : 1500 rpm Motor Housing : TEFC (Totally enclosed Hazardous) Environmental Protection : Gas Group II-B Fan cooled Flame Proof motor for hazardous application Insulation class : F Space Heater : 240 volts, single phase space heater fitted. Brake holding torque : Holding torque equivalent to 150% of motor torque (reversible only) Brake operation : Automatically, spring applied brake with power “OFF” Maintenance (Bearings) : Bearings are grease packed and sealed for life Construction : Vertical Rated Working Time (appx.) : 1 Hour The capstans shall be equipped with rope guides to assist in leading the messenger line to the capstan head. The capstans should be driven through gearing system, grease lubricated for life. GENERAL REQUIREMENTS OF QRMH The mooring hooks shall be able to move in both vertical and horizontal planes and each one shall be designed to be released independently from the other. Vertical Hook Range : 0° to +45° from horizontal Horizontal Hook Ranges Double Mooring Unit : 90°/ 45° (left hook) 45° / 90°(right hook) Manual release operation of the quick release hooks and reset shall be possible with a minimum effort. The Removable Release Lever shall be placed in the proximity of the mooring hook. Release operation shall be possible locally or via the remote release system. Each hook shall be provided with a safety latch to prevent escaping of the mooring line. All hooks shall be of the fully dismountable type. Identification plates shall be provided in assembly indicating the name of the manufacturer, year of manufacturing, model number, Sl.No., Type and Safe Working Load (SWL) capacity of each hook and of the total assembly. LOAD CAPACITIES Double Hook Mooring Unit shall have 150 MT (SWL) and 225 MT Proof Load on each hook. STRUCTURAL STEEL SELECTION All structural steel selection shall be done in accordance with relevant standards. Hook body shall be cast steel. Cast steel parts shall be heat treated to relieve stress. Cast iron parts shall not be used. ANCHOR BOLTS The anchor bolts shall be supplied by the firm for mounting the QRMH unit suitable for existing concrete structure. It shall be made of hot dip galvanized surface. Complete with washers, bottom plates and nuts to be supplied along with supply. Templates of the anchor pattern marked with seaside arrows shall be provided for a correct positioning of the holes for the both. DIRECT ON LINE (D.O.L.) MOTOR STARTER AND FOOT SWITCH To operate the capstan of the mooring units shall be equipped with a Direct Online IP 65 protected reversible motor starter operated from a foot switch and a push button. The control box material shall be sea water resistant. A thermal overload relay & an emergency stop shall be provided complete with externally mounted reset button. Heavy duty protection shall be included for the local harsh environment and an internal heater element shall be provided. ELECTRIC REMOTE CONTROL SYSTEM Mooring unit shall be equipped with a remote control system. This system shall consists of : An electric release device, a hook status detection switch, a local hook release push button and a local control panel to operate the system. The electric release device shall consist of an electric actuator fully integrated into the hook system. The hook status detection switches shall be of an industrial, robust type. The control circuit shall be designed from generally available industrial switching gear. The release system shall be remotely operated installed in the control room. To operate the release system from a distance, a central remote control panel shall be provided with the following controls: - Individual hook release push button - Individual hook released indication signal lamp - Assembly release push button (all hooks of one mooring unit). - Master release push button (two step activity). - Emergency release push button (all hooks of the jetty). - Lamp test/reset push button. - Power on/off switch. - Power on indication. ELECTRIC PROTECTION All electrical accessories shall be provided suitable for installation at hazardous area. TESTING The QRMH units with capstan shall be completely assembled and tested for proper operation prior to shipment. Following manufacturing, each hook shall be tested for the following : - Proof load at 1.5 times the SWL - Release test at SWL An independent international classification authority such as IRS, BV or DNV must witness these tests. The hook shall be tested 1.5 times the SWL (Proof Load : 1.5 times SWL) GENERAL CONDITIONS 1) The firm shall inspect the site before quoting the rate. 2) The firm shall submit their rates as per the Schedule ‘A’ and Prices & Quantities in Schedule ‘A1’. 3) The firm shall erect the new QRMH unit at a new location adjacent to the existing Quick Release Mooring Hook Unit. 4) The Trust will not be responsible for any damage or loss of any of the materials and for any damage / accident to the Tenderer’s personel. 5) The firm shall arrange necessary watch and ward for their materials till the completion of work. 6) Essential Harbour entry Permit for the workers shall be arranged by the firm. 7) The contractor’s vehicle viz. van / lorry / cranes should fitted with spark arrester unit in the exhaust pipe of the vehicle. 8) The firm shall supply all the items with proper delivery challans. 9) The firm shall submit all test certificates and manuals / catalogues along with supply. 10) The firm shall arrange transportation facility for sending the dismantled old QRMH items to Trust RSA yard by their own arrangements. 11) The firm shall engage any lifting crane arrangement for installing QRMH by their own arrangement. 12) The firm shall comply the safety standards for welding works and shall arrange welding set if required at their own cost and obtain necessary fire permission from the Trust Fire Officer and Assistant Safety Officer. COMPLETION PERIOD i) The removal of the existing mooring hooks including capstan motor assembly unit shall be completed within 20 days of Allotted / Non-shipment days after successfully commissioned new QRMH unit assembly. ii) The complete civil works, Installation, Testing and Commissioning of QRMH shall be completed within 210 days from the date of receipt of order. EMPLOYEES STATE INSURANCE: The Contractor must ensure compliance of ESI Act, 1948 in respect of labourers engaged for the above work. The details of employees proposed to be engaged should be furnished before commencement of work. The payment to the Contractor will be released only on production of documentary proof for having paid ESI (Employer & Employee) Contribution for all the employees engaged for the said work. INSPECTION AGENCIES : The Trust will engage inspection agencies such as IRS, BV (or) DNV as third party to inspect the 1 No. double hook Quick Release Mooring Hook and inspection charges will be borne by the Trust. The Tender shall agree for this clause. GUARANTEE PERIOD The QRMH shall be guaranteed for a period of 12 (Twelve) Months from the date of installation and commissioning of the unit. CHIEF MECHANICAL ENGINEER CHENNAI PORT TRUST BUDGETARY OFFER FOR REMOVAL, SUPPLY, MOUNTING, TESTING AND COMMISSIONING OF 1 No. DOUBLE HOOK QUICK RELEASE MOORING HOOK (QRMH) UNIT, INTEGRAL CAPSTAN AND REMOTE CONTROL TYPE AT BD -III ‘D’ POINT NORTH SIDE IN OIL DOCK. SCHEDULE OF PRICES & QUANTITIES SCHEDULE – ‘A1’ Sl. No. 1. Description of Item Unit Quantity Labour Charges for Removal of No. existing Mooring Hook Unit assembly at BD-III, ‘D’ point north side in Oil Jetty as detailed in Schedule-A. Supply of Double Hook equipped No. Quick Release Mooring Hook (QRMH) Unit, integral capstan, Remote Control System Console in fully wired condition along with all instruments and accessories as per the Scope of Work as detailed in Schedule-A. VAT 3. 4. Labour Charges for installation and No. commissioning of double hook QRMH on the concrete arrangements made by Anchor bolts as detailed in Schedule-A at a new location. (Rs.) 01 % 01 / CST Labour Charges for mounting of No. Anchor bolts, base plates, washers & nuts, etc. for installation QRMH as detailed in Schedule-A. Amount (Rs.) Service Tax 2. Total Rate/Unit / Other duties, etc. 01 Service Tax % Service Tax % 01 5. Labour Charges for collection, loading and unloading of existing old dismantled mooring hook unit from BD-III to Trust RSA yard by their own arrangements. Service Tax % Sub-Total VAT / CST / Other duties, etc. Service Tax % Grand Total (Rupees _______________________________________________________ only inclusive of all the Central/State taxes, duties, Cess, transportation & insurance charges). CONTRACTOR’S SIGNATURE WITH SEAL