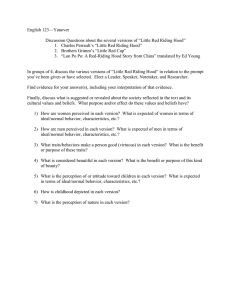

CORE Protection Manual

advertisement