Hydrometallurgy at CTH

advertisement

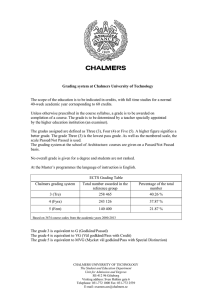

5/22/2015 Chalmers University of Technology Hydrometallurgy at CTH Hydrometallurgy Seminar March 7th 2015 Chalmers University of Technology Sweden Göteborg • • • • • • 12 campuses in the middle of Gothenburg 8 departments 41 Master’s programs all taught in English 11 800 students 1 200 PhD students ~40 % of Sweden’s graduate engineers/architects educated at Chalmers 1 5/22/2015 Chalmers University of Technology Chalmers University of Technology Short history of Nuclear Chemistry & Industrial Materials Recycling • 1947 – Nuclear Chemistry founded as “Atomkommitténs kärnkemilaboratorium”. Headed by Karl Erik Zimen and later Roland Lindner • 1989 – Jan-Olov Liljenzin new professor • 2001 – Lembit Sihver new professor • 1963 – Department of Nuclear Chemistry formed, Jan Rydberg first full professor • 2007 – Industrial Materials Recycling formed, Christian Ekb f Ekberg fifirstt professor • 2012 Jan Rydberg (1923-2015) – Christian Ekberg professor in Nuclear Chemistry 2 5/22/2015 Chalmers University of Technology Nuclear Chemistry/Industrial Materials Recycling personnel Seniors: 7 Ph.D. students: 15 Emeretii: E tii 1 Other: 2 Chalmers University of Technology Personnel Seniors Christian Ekberg Gunnar Skarnemark Britt-Marie Steenari Mark Foreman Christer Forsgren Henrik Ramebeck Kastriot Spahiu Henrik Glänneskog Stefan Allard Dan Costin Burcak Ebin Anna Gustafsson Stellan Holgersson Martina Petranikova T d R Teodora Retegan Rickard Ylmen Jan-Olov Liljenzin head of unit (part time, retired) (part time, STENA) (part time, FOI) (part time, SKB) (part time, Vattenfall) radiation protection (post doc) (post doc) (post doc.) Professor Professor Professor Assoc Prof Assoc. Adj. Professor Adj. Professor Adj. Professor Dr Dr Dr Dr Dr Dr Assist. Prof A Assoc. P Proff Dr Prof Em PhD students Lovisa Bauhn Isabelle Dubois (with KTH) Marino Gergoric Toni Gutknecht Jenny Halleröd Marcus Hedberg Filip Holmberg Ivan Kajan Mikael Karlsson Sravya Kosaraju Henric Lassesson Artem Matyskin Aneta Sajdova Jinfeng Tang S Sabrina b i Ti Tietze t Sandra Tostar Cristian Tunsu Michail Tyumntcev Jianxu Yang Aneta Sajdova Lic.Eng. Lic.Eng. M.Sc. M Sc M.Sc. M.Sc. Lic.Eng. M.Sc. M.Sc. M.Sc. Lic.Eng. Lic.Eng. M.Sc. M.Sc. M.Sc. Fil Fil.Lic. Li Lic.Eng. Lic.Eng. M.Sc. Lic.Eng. M.Sc. 3 5/22/2015 Chalmers University of Technology Nuclear Chemistry & Industrial Materials Recycling Chalmers University of Technology Competence areas • • • • • • • • • • • Aqueous q chemistry, y, thermodynamics y Radiation protection Handling of substantial amounts of radiactive material Specialised in alpha active material Organic synthesis Detection of ionising radiation Radiation chemistry and radiation biology Separation processes Design of equipment for separation processes Statistics and uncertainty analysis Processes for materials recycling 4 5/22/2015 Chalmers University of Technology Equipment overview Autoradiograph Alphaspectrometers t t HPGe:s – manual and automated systems NaI:s – manual and automated systems SiLi Liquid scintillation counters AKUFVE (Ti & PEEK) Surface tension meter ICP-MS/OES Mixer-settlers Gas-MS Titrators Potentiostat SEM-EDX XRD Particle sizer UV/VISspectrometers TOC-analyzer BET-analyzer IonChromatograph (anion-, cation-, organic-columns) Chalmers University of Technology Mixer-settlers A modular mixer‐settler‐system was developed and originally used for hot tests of the CTH‐process for partitioning. The volume of the mixing chamber is approximately 30 mL while the settler has a volume of approximately 100 mL. The impeller of the mixer is made of PVDF while the rest of the mixer‐settler can be built of e.g. PVDF or plexiglass. The level of the phase boundary surface is controlled by electronic level meters based on conductivity measurements. The picture shows a newly designed mixer settler 5 5/22/2015 Chalmers University of Technology AKUFVE Ti-AKUFVE 1. Centrifuge 2. Mixing vessel 3. Flow measurement 4. Sampling and mixing pumps 5. Heat exchanger 6. pH-electrode 7. Thermo element Chalmers University of Technology AKUFVE 6 5/22/2015 Chalmers University of Technology 3.5 30 3.0 25 2.5 lo g lo g (D ) 20 2.0 1.5 logB eta1 logB eta2 logB eta3 15 10 1.0 5 0.5 0.0 ‐6.0 ‐5.0 ‐4.0 ‐3.0 ‐2.0 ‐1.0 0.0 0 0.0032 log ([IS A ‐ ]) 0.00325 0.0033 0.00335 0.0034 0.00345 0.0035 1/T (K ‐11 ) Chalmers University of Technology SISAK • The H-centrifuge has a very short hold-up time and it is therefore also used to study short-lived nuclides and the transactinide elements. This technique is called SISAK. • The original H-33 centrifuge (120 mL volume/phase, 30 mL/s,phase) diminished to H-10 (12 mL/plase, 25 mL/s,phase) to H-0.3 (0.3 mL/phase, 3 mL/s,phase) • Selective extraction systems developed for 27 elements (from fifission i product d t or h i reaction ti product d t mixtures) i t ) heavy-ion • Detection techniques for very short-lived nuclides 7 5/22/2015 Chalmers University of Technology SISAK Chalmers University of Technology SISAK • • • • Most short-lived studied so far: 114Ru (T½ = 0.47 s) First identification of about 20 previously unknown nuclides Nuclear studies of about 80 short-lived nuclides Chemical studies of Rf, Db and Sg 8 5/22/2015 Chalmers University of Technology Use of solvent extraction at CTH Nuclear Chemistry Industrial Materials Research Fundamental research Nuclear Chemistry Industrial Materials Recycling Applied Research As part of other courses As dedicated course Education Chalmers University of Technology Education • • • • • KBT192 – Nuclear Chemistryy I KBT168 – Nuclear Chemistry II KBT200 – Radiopharmaceutical Chemistry KBT215 – Radioecology and Radioanalytical Chemistry KBT171 – Chemistry of Lanthanides, Actinides and Superheavy Elements • KBT195 – Solvent extraction 9 5/22/2015 Chalmers University of Technology Solvent extraction course • Lectures • Calculation Exercises • Laboratory project (separation of Co, Cu and Zn) – Batch extraction – AKUFVE extraction – Mixer-settler • Course divided in two tracks: – NE – POWRES – About 80% of the course is identical (thermodynamics, extraction systems, equipment, multistage extraction etc.) Chalmers University of Technology Solvent extraction course • NE-track – Uranium production – Reprocessing of nuclear fuel – Partitioning and transmutation – Other processes of interest in nuclear engineering • POWRES-track – Leaching of metal scrap and ashes – Methods for production and recycling of e.g. Cu, Co Co, Ni Ni, Zn Zn, Pt Pt, Rh Rh, lanthanides, … 10 5/22/2015 Chalmers University of Technology The connection SX – Nuclear Chemistry • Whyy have almost all SX chemists started as ((or still are)) nuclear chemists? Chalmers University of Technology The connection SX – Nuclear Chemistry • Whyy have almost all SX chemists started as ((or still are)) nuclear chemists? • The first large scale application of inorganic SX was in the field of nuclear technology (U production, reprocessing). SX chemistry studies are also rather easy if using radioactive tracers. 11 5/22/2015 Chalmers University of Technology The connection SX – Nuclear Chemistry • Whyy have almost all SX chemists started as ((or still are)) nuclear chemists? • The first large scale application of inorganic SX was in the field of nuclear technology (U production, reprocessing). SX chemistry studies are also rather easy if using radioactive tracers. • Knowledge and experience from the nuclear chemistry research group is implemented in the industrial materials research group – this gives added value Chalmers University of Technology Research 12 5/22/2015 Chalmers University of Technology Selected projects RECYVAL NANO SOE MAXIMA SEARCH g • lead-claddingfuel interactions • lead fuel interaction SKIN CINCH-II LISSEN COLABATS • Ra/Ba solubilities • EU teaching in NC • Li-ionbattery recycling • cobalt recycling from Li-ion SKB TALISMAN EREAN SACSESS • Simfuel surfaces • Int’l infrastructure access • lanthanide recycling • recycling of nuclear waste SKB ASGARD Pilot plant REE recovery • Sorption modelling • nuclear fuel • NiMH batteries • Fluorescent lamp waste • recycling of In and REE • recycling of Li-ion batteries b tt i Chalmers University of Technology Selected projects RECYVAL NANO SOE MAXIMA SEARCH • lead-claddingg fuel interactions • lead fuel interaction SKIN CINCH-II LISSEN COLABATS • Ra/Ba solubilities • EU teaching in NC • Li-ionbattery recycling • cobalt recycling from Li-ion SKB TALISMAN EREAN SACSESS • Simfuel surfaces • Int’l infrastructure access • lanthanide recycling • recycling of nuclear waste SKB ASGARD Pilot plant REE recovery • Sorption modelling • nuclear fuel • NiMH batteries • Fluorescent lamp waste • recycling of In and REE • recycling of Li-ion b tt i batteries 13 5/22/2015 Chalmers University of Technology SOE (styrkeområde energi) - recycling HEV Li-ion Batteries (Sravya Kosaraju, Christian Ekberg, Britt-Marie Steenari, Stefan Allard) Chalmers University of Technology Process steps Li‐ion ba ery Blackmass Al‐ substrate Leaching black mass Mixer se ler Akufve 14 5/22/2015 Chalmers University of Technology Leaching – HCl 120 Recovery in leachate (%) 100 Al-FB 80 Al-SC Li-FB 60 Li-SC Fe-FB 40 Fe-SC P-FB 20 P-SC 0 0 1 2 3 c (M) 4 5 6 Chalmers University of Technology Solvent extraction Aq: q Li, Mn, Ni HCl in chloride media Org: Cyanex 272 (5%vol)/Solvent 70 120 Cyanex 272 100 80 %E • • %E, Li 60 %E, Mn %E, Ni 40 20 0 0 1 2 3 4 5 6 7 pH 15 5/22/2015 Chalmers University of Technology LiFePO4 Batteries Un-damaged Electrolyte Removal Discharge Sort basis State of charge &/damage Dismantle in Dismantle in fume hood Separate p Anodes & cathodes Anode Ultra‐sonication Medium:H2O Time1h, S/L 1:50 Electrochemically active material: active material: carbon Heat in O2 free atm carbon 200C Cu substrate Filter Anode Shortcircuited/ damaged Cathode Remnant H2O after ultra‐ sonication and filtration Acidify with HCl Dismantle in Ar‐atmosphere Removal of Electrolyte & built-up gas vaporizes Cathode Ultra‐sonication Medium:H2O Time1h S/L 1:50 Filter Al substrate Electrochemically active material: LiFePO4 SX, solvent70 (1M) Cyanex 272 Strip Organic phase PvDf free carbon powder Li separation Chalmers University of Technology • Colabats EU project on battery recycling (NiMH and Li ion) – Solvent Extraction from ionic liquids and related solvents – Solvent extraction from mixtures with very high ionic strengths – Both deep eutectics based on choline chloride (below) and true ionic liquids are being used 16 5/22/2015 Chalmers University of Technology ((Marino Gergoric, g , Mikhail Tyumentsev) y ) • Recycling of rare earths – RE permanent magnets – e.g. Sm, Co, Nd – Solvent extraction used; separation difficult due to similarities of chemical properties Chalmers University of Technology EREAN 17 5/22/2015 Chalmers University of Technology Recovery of rare earth elements from fluorescent lamp waste phosphor fractions (Cristian Tunsu, Teodora Retegan) Chalmers University of Technology Lamp phosphors based on REEs Tb Y Eu La Gd Phosphor Ph h type t Red phosphor Possible P ibl compounds d Y2O3∶Eu3+ Blue phosphors BaMgAl10O17∶Eu2+ (Sr,Ca,Ba)5(PO4)3Cl:Eu2+ Green phosphors CeMgAl10O17∶Tb3+ LaPO4:Ce3+,Tb3+ (Ce,Tb)MgAl11O19 (Ce Gd Tb)MgB5O10 (Ce,Gd,Tb)MgB Ce Standard lamp: 4-6 g phosphors powder (2% of the lamp’s mass). Cuif et al., 2005; Ronda et al., 1998; US Department of Energy, 2009; Raposo et al., 2003 18 5/22/2015 Chalmers University of Technology Hydrometallurgical approach: leaching + solvent extraction • Efficient Efficient leaching of Eu leaching of Eu and Y (>95%) with and Y (>95%) with diluted mineral acids, at room temperature; • The other four REEs (Ce, La, Tb and Gd) are harder to leach and require concentrated acids/temperature/ultrasound; • Because of this, selective leaching is possible; • Leaching is carried out using nitric acid solutions. Chalmers University of Technology Solvent extraction – Cyanex 923 • Mix of trialkyl phosphine oxides; readily available, commercial extractant; • Solvating extractant → no pH adjustment step → possibility of re‐ using the raffinate for subsequent leaching. • Fast extraction of REEs (< 1 min.); co‐extraction of Fe; Hg (slower kinetics 15‐20 min.); selective stripping possible; • Separation of light elements (Ce, La) from heavier ones (Tb) possible; • Diluents tested : TetraPropyleneHydrogenated Diluents tested : TetraPropyleneHydrogenated > kerosene > > kerosene > Tertbutyl benzene > 1‐octanol; • Scale up: mixer settlers. 19 5/22/2015 Chalmers University of Technology SACSESS Grouped Actinide Extraction Process Research at Chalmers (Emma Aneheim, Christian Ekberg, Jenny Halleröd, Elin Löfström-Engdahl) Chalmers University of Technology 20 5/22/2015 Chalmers University of Technology Transmutation Chalmers University of Technology Transmutation requires separation from fission, corrosion and activation products solvent extraction At Chalmers we are working with a so called Grouped actinide extraction 21 5/22/2015 Chalmers University of Technology The research has two branches: 1. Process development 2. Basic Science An example of process optimization: exchange of the diluent cyclohexanone to the diluent phenyl trifluoromethyl sulfone An example of basic research: investigating the influence of extractant concentration on the rate of americium extraction. This feature is important for process development as well as separation of elements. Chalmers University of Technology Pilot plant – NiMH batteries Hydrometallurgical technology for recovery of metals from spent car NiMH batteries (Martina Petranikova, Irena Herdzik-Koniecko, Kristian Larsson, Britt-Marie Steenari, Christian Ekberg) 22 5/22/2015 Chalmers University of Technology Current state of HEVs technology • • • Road transport is responsible for 17-18% of global CO2 emissions from fossil fuel comb stion combustion. NiMH battery technology is most used in HEVs technology. Lifetime of the battery = lifetime of the vehicle (250 000 – 320 000km). Chalmers University of Technology Current state of NiMH recycling Mechanical pre-treatment Pyrometallurgical treatment Hydrometallurgical treatment REEs Umicore Rhodia slag 23 5/22/2015 Chalmers University of Technology Hydrometallurgical process developed at Chalmers 1. Dismantling of batteries 2. Leaching of electrode material with HCl 3. Solvent extraction using Cyanex 923 Chalmers University of Technology 1. Dismantling of batteries 2. Leaching of electrode material with HCl 3. Solvent extraction using Cyanex 923 24 5/22/2015 Chalmers University of Technology Chalmers University of Technology NiMH battery dismantling Toyota Prius Battery – before dismantling Battery modules (38) 1.4% 1.4% 0.6% 0.5% 19.8% 1.7% 74.6% Other components cables and copper aluminium modules plastic steel printed circiut boards other 25 5/22/2015 Chalmers University of Technology 1. Dismantling of batteries 2. Leaching of electrode material with HCl 3. Solvent extraction using Cyanex 923 Chalmers University of Technology Equipment L Leaching hi - glass reactor with double wall (with heating/cooling system) - volume: 2 or 5L - titration devices 26 5/22/2015 Chalmers University of Technology 1. Dismantling of batteries 2. Leaching of electrode material with HCl 3. Solvent extraction using Cyanex 923 Chalmers University of Technology • Extractant: Cyanex 923: mixture of trialkyl-phosphine oxides: R3P(O), P(O) R2R'P(O), R'P(O) RR'2P(O), P(O) R'3P(0) R = [CH3(CH2)7] - normal octyl, R'= [CH3(CH2)7] - normal hexyl • Solvent: kerosene (Solvent 70) • Equipment: - PVDF mixer-settlers (volume: 120 120, - electromagnetic pumps 500 ml) 27 5/22/2015 Chalmers University of Technology Principle of counter-current flow extraction Raffinate scrubbing Scrubbing liquor stripping regeneration organic flow regeneration Stripping liquor Chalmers University of Technology Thank you for your attention! 28