Magnetics 2013 Dysprosium

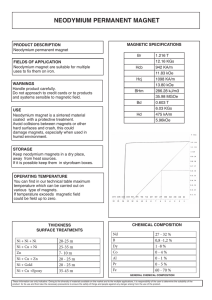

advertisement

Magnetics 2013 Dysprosium-free rare earth magnets Orlando, February 6-8 Presenter: Jim Herchenroeder Vice President Vision and Values VISION To be the world class Rare Earth products and technology company recognized for its ETHICS Our VALUES: ETHICS Excellence, Trust, Honesty, Integrity, Creativity and Safety 2 Outline • Hot pressed fully dense Dy-free MQ2 magnets – Introduction – Grain size advantage of MQ2 – Case study: 4-pole PMDC Motor • Isotropic bonded MQ1 magnets – High flux MQ1 magnets 3 DY-FREE MQ2 HOT PRESSED FULLY DENSE MAGNETS 4 Manufacturing Process Jet Casting MQ2 Magnet Cold Press MQ2 Magnet Hot Press Cold pressed magnet insertion stage Magnet pressing stage Unloading of hot pressed magnet Grind to Tolerance Coating Permanent Magnet Materials: Magnet Curves 1.4 1.2 1.0 0.8 MQ3 Sintered Neo (43SH) MQ2 J(T) SmCo 0.6 0.4 MQA-38-14 (Injection Molded) Sintered Ferrite MQP-16-9HD 0.2 0.0 -2400 -2000 -1600 -1200 H (kA/m) -800 -400 0 6 Grain size • MQ2 has smaller grain size which makes high HcJ possible – MQ2 makes higher HcJ than sintered Neo at lower Dy concentration 1 Sintered Neo Grain There are 106 MQ2 grains for every 1 sintered Neo grain Sintered Neo Comparison • Isotropic MQ2 has naturally lower β – Sintered Neo uses HRE to lower the temperature coefficient of HcJ 8 Sintered Neo Comparison • • • • Higher HcJ (grain size) and lower β (isotropic) combine to give much better temperature stability than sintered Neo MQ2 saves 5-7% Dy in the magnet reducing magnet cost MQ2 is a cost effective solution at temperatures above 125°C Cost/flux ratio in MQ2 can be reduced by half compared to sintered Neo because HRE are not needed Value of MQ2 At high temperatures, MQ2 has a higher value than sintered neo Cost per unit of flux Sintered Neo MQ2 Operating temperature 10 TEMPERATURE STABILITY Magnet 25°C HcB Br 50°C HcB Br 75°C HcB Br 100°C HcB Br 125°C HcB Br 150°C HcB Br 175°C HcB Br 200°C % Dy [kOe] [kG] [kOe] [kG] [kOe] [kG] [kOe] [kG] [kOe] [kG] [kOe] [kG] [kOe] [kG] MQ2-16-125 7.5 8.5 7.2 8.4 7.0 8.2 6.6 7.9 6.2 7.7 5.7 7.3 5.0 7.0 0 MQ2-14-150 7.1 8.0 6.8 7.9 6.6 7.7 6.4 7.5 6.1 7.2 5.7 7.0 5.4 6.7 0 MQ2-14-175 7.2 8.0 6.9 7.8 6.7 7.6 6.4 7.4 6.1 7.2 5.7 6.9 5.3 6.6 0 MQ2-13-200 6.9 7.7 6.7 7.6 6.5 7.4 6.3 7.2 6.0 7.0 5.7 6.7 5.4 6.5 2.5 H (kOe) • MQ2 has good stability up to 175°C without Dy B (kG) 8 -10 -7.5 -5 -2.5 0 1.0 MQ2-13-200 MQ2-14-150 MQ2-14-175 MQ2-16-125 0.8 125oC 150oC 6 0.6 175oC 4 0.4 175oC 0.2 2 0 -1000 J (T) -12.5 10 0.0 -800 Straight line B-H curve at respective temperature -600 -400 H (kA/m) -200 0 11 Temperature stability for high temperature applications Electric Vehicle Motors Engine Cooling Fans AC Compressors Under-the-hood Applications Irreversible Flux Loss (%) 0.0 -1.0 -2.0 -3.0 -4.0 MQ2-14-150 MQ2-14-175 MQ2-13-200 -5.0 0 100 200 300 400 500 600 700 800 9001000 Time (hours) @200oC MQ2 magnets (PC=2) retain 98% flux after 1000 hours at 200oC without dysprosium 12 Corrosion • • Magnet Type Initial Mass (g) Final Mass (g) Loss (%) 35H 35SH 35UH MQ2-16-125 MQ2-14-150 MQ2-14-175 MQ2-13-200 5.02 5.03 5.10 18.22 18.25 18.10 18.14 4.97 4.98 5.08 18.21 18.25 18.09 18.14 -0.98% -0.86% -0.39% -0.02% -0.01% -0.04% -0.01% Surface Loss Area (cm2) (mg/cm2) 4.30 4.29 4.29 8.51 8.58 8.58 8.48 -11.43 -10.108 -4.64 -0.47 -0.15 -0.77 -0.21 Sintered neo magnets show 10-50 times the corrosion as MQ2 85%RH/85°C for 4 weeks MQ2-14-150 N35SH 13 Case Study: 4-pole PMDC Motor • To illustrate the technical and economic benefits of utilizing bonded neo as compared to sintered neo Benchmarked 4-pole PMDC Motor with Sintered Neo (4% Dy) Dy-free MQ2 Electromagnetic Design 14 Case Study: 4-pole PMDC Motor Benchmarked and Redesign Motor Comparison Parameter Benchmarked Redesigned Type of Magnet 4-Pole, Sintered Neo (N27 SH/N30SH) 4-Pole, MQ2-14-150 (8-Arcs) Dy (%) 4.14 0 Overall diameter of the motor (mm) 44.10 44.10 Length of the motor (mm) 15.50 16.50 Length of airgap (mm) 0.57 0.57 Total copper weight (gm) 28.09 33.60 Total magnet weight (gm) 18.47 26.00 Total motor weight (gm) 151.35 168.10 Current at 80 mN-m (A) 14.76 14.05 Efficiency at 80 mN-m (%) 64.15 64.92 15 Case Study: 4-pole PMDC Motor Benchmarked and Redesigned Motor Performance Torque-efficiency and torque-output power characteristics Torque-speed and torque-current characteristics 16 Case Study: 4-pole PMDC Motor Benchmarked and Redesign Motor Comparison Benchmarked 4-pole PMDC Motor with Sintered Neo (4% Dy) Dy-free MQ2 Electromagnetic Design 17 Case Study: 4-pole PMDC Motor Comparison of the Benchmarked and Redesign Motors Sintered Neo magnet N30SH 18 MQ2 Summary • Ideal for applications that require high performance at elevated temperature. • MQ2 magnets provide excellent temperature stability – With no presence of heavy rare earths like Terbium and Dysprosium. 19 HIGH FLUX MQ1 ISOTROPIC BONDED MAGNETS 20 About high flux MQ1 • Achieve the highest flux for isotropic bonded materials • Utilize high density MQP grades – Designed specifically to allow for higher compaction – MQP-16-9HD and MQP-15-9HD (other high density grades are also available) • Offer 10-15% higher BHmax than standard MQ1 magnets 21 High Flux MQ1 Magnet Performance Comparison – PC=2 Cylinders Powder Type Density (g/cm3) 6.0 MQEP16-9HD MQEP15-9HD OD Height Weight (mm) (mm) (g) 9.792 6.45 2.920 Br (kGs) 7.03 Hc (kOe) 5.81 Hci (kOe) 8.92 BH(max) (MGOe) 10.28 6.4 9.813 6.45 3.139 7.59 6.11 8.81 11.72 6.0 9.800 6.45 2.916 6.97 5.74 9.28 10.04 6.4 9.831 6.45 3.140 7.52 6.04 9.14 11.35 8 • 7 6 16-9HD-6.0g/cc 4 16-9HD-6.4g/cc 15-9HD-6.0g/cc 3 15-9HD-6.4g/cc 2 1 0 -10 -9 -8 -7 -6 -5 -4 H (kOe) -3 -2 -1 0 B/J (kGs) 5 • • BHmax increased by 1314% from 6.0g/cm3 to 6.4g/cm3, tested by standard cylinder magnet of PC=2 Similar results by 15-9HD and 16-9HD Proprietary pressing techniques to achieve 6.4g/cm3 compact density' 22 High Flux MQ1 Visual Appearance • Ring magnet for automotive seat motor [Φ33.7 x Φ30.7 x H25.4mm] Commercially Available MQP-B+ (5.9g/cc) Magnequench MQP-169HD (6.4g/cc) High Flux MQ1 Case Study • Flux per pole improve by 13.6% MQP-16-9HD @6.4g/cc MQP-B+ @5.9g/cc Flux/pole (mWb) 58.85 51.77 Speed = 500 RPM Back-emf constant (mV/rpm) 3.717 3.427 Speed = 2000 RPM Back-emf constant (mV/rpm) 3.717 3.404 Speed = 2500 RPM Back-emf constant (mV/rpm) 3.727 3.412 24 Magnet Peak Efficiency (%) MQP-16-9HD @ 6.4g/cc 50.63 Torque-Speed & Torque-Current MQP-B+ @ 5.9g/cc 47.64 High Flux MQ1 Motor Performance Torque-Power & Torque-Efficiency MQ1 magnets at 6.4g/cc density offer performance that is comparable to commercially available HDDR magnets. 25 DISCUSSION QUESTIONS? 26