Instrumentation Electrical Installation

advertisement

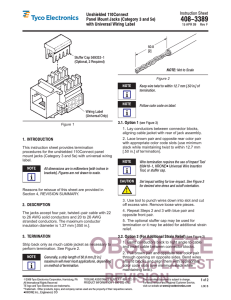

Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 SECTION INDEX Document #: CS17002 Revision Date: 10/01/2015 Page: 1 of 21 Effective Date: 11/04/2015 SHEET NO. PART 1 - GENERAL.................................................................................................................... 2 1.01 CODES AND STANDARDS..................................................................................... 2 1.02 SCOPE ........................................................................................................................ 2 1.03 DRAWINGS ................................................................................................................ 3 PART 2 - PRODUCTS................................................................................................................. 3 2.01 GENERAL ................................................................................................................... 3 2.02 ANALOG SIGNAL CABLE........................................................................................ 4 2.03 FOUNDATION FIELDBUS CABLE......................................................................... 5 2.04 AS-INTERFACE CABLE........................................................................................... 5 2.05 PROFIBUS CABLE.................................................................................................... 5 2.06 DEVICENET ............................................................................................................... 6 2.07 ETHERNET................................................................................................................. 6 2.08 FIBER OPTIC CABLE............................................................................................... 7 2.09 POWER AND DISCRETE SIGNAL WIRING ........................................................ 7 PART 3 - EXECUTION.............................................................................................................. 13 3.01 GENERAL ................................................................................................................. 13 3.02 INSTRUMENT WIRING .......................................................................................... 14 3.03 BUS NETWORKS.................................................................................................... 15 3.04 PANELS AND JUNCTION BOXES....................................................................... 17 3.05 CONDUIT .................................................................................................................. 17 3.06 INTRINSICALLY SAFE WIRING........................................................................... 18 3.07 FIBER OPTIC CABLE............................................................................................. 18 3.08 TESTING AND CALIBRATION.............................................................................. 19 Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 Document #: CS17002 Revision Date: 10/01/2015 Page: 2 of 21 Effective Date: 11/04/2015 PART 1 - GENERAL 1.01 1.02 CODES AND STANDARDS A. National Electric Code (NEC) and National Fire Protection Association (NFPA) standards B. Instrument Society of America (ISA) Standard RP 12.6 C. American National Standards Institute (ANSI) / API RP 551 – Process Measurement Instrumentation D. ANSI / API RP 554 Pt 1 – Process Control Systems Functions and Functional Specification Development E. ANSI / API RP 554 Pt 2 – Process Control Systems – Process Control System Design F. ANSI / API RP 554 Pt 3 – Process Control Systems – Project Execution and Process Control System Ownership G. Site Standard Instrument Installation Detail Drawings SD-00-#### H. Site Engineering and Construction Specifications 1. CS16111 – Conduits 2. CS17001 - Instrumentation Mechanical Installation SCOPE A. This specification covers the following work. 1. 2. Provision of cabling and/or wiring necessary to wire the following items: a. Instruments b. DCS Equipment c. Control Panels d. Junction Boxes Provision of raceways, fittings and supports. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 1.03 Document #: CS17002 Revision Date: 10/01/2015 Page: 3 of 21 Effective Date: 11/04/2015 DRAWINGS A. Perform all work in compliance with the mechanical, instrument, and electrical drawings provided by vendors and the Work Sponsor (the person responsible for completing the requested work). The instrumentation application is shown on the Piping and Instrument Diagrams (P&ID's) in standard ISA format. Each item is listed in the instrument index as provided by the Work Sponsor and is further identified by an Instrument Specification Sheet and a Wiring Diagram. B. Installation is to be completed as shown on the Site Standard Instrument Installation Detail Drawings furnished for each type of field mounted device. The instrument location and routing plans show the desired location of the instrument hardware and junction boxes. If field conditions make indicated arrangements impossible or impractical, the Contractor is to submit a written request for deviation to the Work Sponsor with sketches or drawings, if required for clarification, and proceed only after receiving written approval by the Work Sponsor. The Installer (Contractor or BASF Technician) shall verify actual conditions in the field and is to supply measurements necessary for the proper installation of his work. PART 2 - PRODUCTS 2.01 GENERAL A. Refer to Division 16, Electrical Specifications for more details on Basic Materials and Methods. B. Single conductors shall be copper cable of concentric, Class B stranded, annealed copper. C. With the exception of those listed under 2.02 through 2.07, cable insulation shall be manufactured according to both the National Electrical Manufacturer’s Association (NEMA) and the Insulated Cable Engineers Association (ICEA) standards for 600 volts at 100% insulation level suited for a minimum of 90 C for normal operation, 130 C for emergency overload operation, and 250 C for shortcircuit operation as per ICEA Pub. No. S-66-524 and NEMA Pub. No. WC7-1971. D. Cables shall be suitable for installation in conduits, ducts, or other raceways in wet or dry areas. THHN – 90 C dry and damp locations; THWN – 75 C dry and wet locations, and XHHW – 90 C dry and damp locations – 75 C wet locations; TFFN – 90 C dry and damp locations only used for 16 gauge control wiring. E. All wire and cables exposed to 480Vac wiring shall have an insulation rating of 600V. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 2.02 Document #: CS17002 Revision Date: 10/01/2015 Page: 4 of 21 Effective Date: 11/04/2015 F. All cables installed in cable tray shall be Tray Cable (TC) or Power Limited Tray Cable (PLTC) cables and shall be suitable for installation in a Class I, Division 2 area classification. G. Instrumentation cable shall comply with all applicable standards (latest revisions) of the Underwriter’s Laboratories (UL), National Electrical Code (NEC) of the National Fire Protection Association (NFPA), NEMA, Canadian Standards Association (CSA) and Insulated Cable Engineers Association (ICEA). H. Manufacturers shall be Belden or approved equal. ANALOG SIGNAL CABLE A. All 4-20 mA signals are to be twisted shielded pairs, stranded, copper conductors, tinned with red and black conductors. Red shall be positive and black negative. 100 percent coverage aluminum foil-polyester tape shield (static and magnetic shielding) shall be used. Jacket shall be polyvinyl chloride or equivalent with thickness as required by cable size. Insulation shall be 80 C-rated polyvinyl chloride; 300VAC minimum; 600VAC where required by NEC 725.26. The cable used shall be: 1. AWG #22 Belden 9322 (300V, PLTC rated) or equivalent for cable tray. 2. AWG #22 Belden 9462 (300V rated) or equivalent for conduit. 3. AWG #18 Belden 9341 (600V, TC rated) or equivalent for wire run in cable tray or conduit to 480Vac Motor or Heater Controller. B. Frequency, millivolt, and pulse type signals shall also use this cable. C. All RTD or 3-wire signals are to be twisted shielded triads, stranded, copper conductors, tinned with red, white and black conductors. 100 percent coverage aluminum foil-polyester tape shield (static and magnetic shielding) shall be used. Jacket shall be polyvinyl chloride or equivalent with thickness as required by cable size. Insulation shall be 80 C-rated polyvinyl chloride; 300VAC minimum; 600VAC where required by NEC 725.26. The cable used shall be: D. 1. AWG #18 Belden 1036A (300V, PLTC rated) or equivalent for cable tray. 2. AWG #18 Belden 8770 (300V rated) or equivalent for conduit. Multi-pair cables shall have individually twisted and shielded pairs with an overall shield and stranded copper conductors. Gauge size shall follow listing above. 100 percent coverage aluminum foil-polyester tape shield (static and magnetic shielding) shall be used. Jacket shall be polyvinyl chloride or equivalent with thickness as required by cable size. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 Document #: CS17002 Revision Date: 10/01/2015 Page: 5 of 21 Effective Date: 11/04/2015 E. Multi triad cables shall have individually twisted and shielded triads with black, white, and red conductors, overall shield and # 18 stranded copper conductors. 100 percent coverage aluminum foil-polyester tape shield (static and magnetic shielding) shall be used. Jacket shall be polyvinyl chloride or equivalent with thickness as required by cable size. F. Standard thermocouple extension cable shall be #20, shielded, PLTC, 300V, solid conductors, rated for 105°C with PVC insulated conductors and a PVC jacket. In applications where the thermocouple cable is exposed to temperatures exceeding 105°C, provide a high temperature extension cable rated for 200°C with FEP insulated conductors and a FEP jacket. Provide Belden cables as specified below or Site approved equal: Belden Cable Types: Type (+) E Purple J White K Yellow T Blue *This cable is 2/C #16 2.03 200°C 83955 83950 83952 83954 All Foundation Fieldbus cables shall be #18 AWG, shielded, PLTC, 300V, 80 C minimum, orange PVC cable with orange and blue conductors. Use orange for positive and blue for negative. 100 percent coverage aluminum foil-polyester tape shield (static and magnetic shielding) shall be used. Use Belden #3076F or equal cable. AS-INTERFACE CABLE A. 2.05 105°C 1101A* 3111A 3112A 3113A FOUNDATION FIELDBUS CABLE A. 2.04 (-) Red Red Red Red All AS-I cables shall be #16 AWG, unshielded, PLTC, 300V, 80 C minimum rated yellow PVC cable with brown and blue conductors. Use brown for positive and blue for negative. Use Turck model 254 or equal cable. PROFIBUS CABLE A. All Profibus DP cables shall be #22, shielded, 600V, PLTC, 75 C minimum violet PVC cable with red and green solid copper conductors. Use green for signal A and red for signal B. 100 percent coverage aluminum foil-polyester tape shield (static and magnetic shielding) plus a tinned copper braid shield (65% coverage) shall be used. Use Belden model 3079A or equal cable. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 2.06 2.07 Document #: CS17002 Revision Date: 10/01/2015 Page: 6 of 21 Effective Date: 11/04/2015 DEVICENET A. Devicenet trunk and drop cables used for motor control shall be Class I thick cable, 2 pair, shielded, 600V, TC, with a gray PVC jacket. One pair shall be used for power and shall be #16, shielded with red and black conductors. Red shall be positive and black negative. The data pair shall be #18, shielded with white and blue conductors. White shall be CAN-H and blue CAN-L. Use Belden model #7896A or Site approved equal. B. Devicenet trunk cables used for field networks shall be Class 2 thick cable, 2 pair, shielded, 300V, TC, with a yellow CPE jacket. One pair shall be used for power and shall be #15, shielded with red and black conductors. Red shall be positive and black negative. The data pair shall be #18, shielded with white and blue conductors. White shall be CAN-H and blue CAN-L. Use Belden model #3082A or Site approved equal. C. Devicenet drop cables used for field networks shall be Class 2 thin cable, 2 pair, shielded, 300V, TC, with a gray PVC jacket. One pair shall be used for power and shall be #22, shielded with red and black conductors. Red shall be positive and black negative. The data pair shall be #24, shielded with white and blue conductors. White shall be CAN-H and blue CAN-L. Use Belden model #3085A or Site approved equal. ETHERNET A. Use Commscope model 5ES4 or Site approved equal four pair, twisted, shielded cable for the Cat 5e cables on the Delta V network. Use a light blue and black color jacket for the primary and secondary networks respectively. B. Use multi-mode 62.5/125 micron fiber-optic cable for the fiber runs on the Delta V network. Install six fiber cables in all main runs between Delta V cabinet locations. C. Use RJ45 plastic or metal enclosed connectors for the Delta V connections per the following. 1. Controller to Switch – Straight through with metal enclosed grounded connectors on both ends. 2. Workstation to Switch – Straight through with a metal enclosed grounded connector on the switch and isolated, plastic enclosed connector on the workstation. 3. Switch to Switch – Can use cross-over cable but stay with straight through cable for standardization because auto sensing ports on switch correct for this issue. Use a metal enclosed grounded connector on the fiber/CAT5 switch and an isolated, plastic enclosed connector on the CAT5 only switch. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 4. 2.08 Page: 7 of 21 Effective Date: 11/04/2015 Wall Plates – Metal enclosed grounded female connector and metal enclosed grounded male connector plugged in to wall plate; other end of cable plastic or metal depending on device to which it connects (see above). FIBER OPTIC CABLE A. Fiber optic SMA/SMA NIR 600 um patchcord 1. 2. 3. 2.09 Document #: CS17002 Revision Date: 10/01/2015 FiberTech Optica Ultra low OH fiber: part # AS600/660IRPIT or equivalent a. Pure silica core: 600 um +/- 2% b. Fluorine doped silica clad: 660 um +/- 2% c. Polyimide coating: 690 um +/- 3% d. Nylon jacket: 1000 um +/- 5% e. Numerical aperture: 0.22 +/- 0.02 f. Operating wavelength: 350 to 2400 um g. Temperature resistance: -40 C to + 150 C h. Attenuation @ 1385 nm: < 12.55 dB/km i. OH content @ 1385 nm: < 0.2 ppm Terminations: a. Standard SMA-905 connector on both ends reinforced with metal sleeve b. Sleeve dimension: 40 mm long x 7 mm OD c. The stainless steel sleeve is installed in order to release the pressure over the connector during the pulling process. Sheathing: Black PVC-furcation tube, 3.8 mm OD POWER AND DISCRETE SIGNAL WIRING A. Use individual conductors in conduit. B. Wire size #14 to #10 shall be stranded type THHN/THWN. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 Document #: CS17002 Revision Date: 10/01/2015 Page: 8 of 21 Effective Date: 11/04/2015 C. Wire size #18 and #16 shall be stranded type TFFN. D. Single conductors shall conform to the following color code (for striped wires, several pieces of tape at both ends colored the same color as the stripe can be used to replace the stripes): 1. 12 and 24VDC bussed field power from DCS cabinet to field instruments where polarity is an issue: Blue = Positive (+) Blue with White Stripe = Negative (-) 2. 120VAC bussed field power from DCS cabinet to field instruments: Black = Line (L) White = Neutral (N) 3. 24VDC discrete signals circuits: Input: Blue = Line Fused Supply Blue with Black Stripe = Switched Hot from Device Output: Blue = Output to Device Blue with White Stripe = Return 4. 120VAC discrete signal circuits: Input: Red = Line Fused Supply Red with Black Stripe = Switched Return Output: Red = Output to Device White = Neutral Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 Document #: CS17002 Revision Date: 10/01/2015 Page: 9 of 21 Effective Date: 11/04/2015 5. Discrete Valve Control Wiring, On-Off and 3-way, 120VAC (preferred): Red = switched hot to solenoid White = neutral to solenoid Black = hot to confirm switches Yellow = confirm close, 3-way position A, cam farthest from the valve Orange = confirm open, 3-way position B, cam nearest to the valve 6. Discrete Valve Control Wiring, On-Off and 3-way, 24VDC: Blue = Output to solenoid Blue with White Stripe = Return from solenoid Black = hot to confirm switches Yellow = confirm close, 3-way position A, cam farthest from the valve Orange = confirm open, 3-way position B, cam nearest to the valve 7. Motor Control Three Wire Control Red = hot to stop button Black = terminal 2 of holding coil Blue = terminal 3 of holding coil Green = switch casing ground* Two Wire Control Red = hot to switch Blue = return from switch Green = switch casing ground* * Not required if phase conductors and control wires are in the same conduit and the switch casing ground is wired to the motor ground. DCS Motor Control IO Wiring Black = 1 to DCS stop (HS) (1 is short for MCC terminal 1) Red = DCS stop (HS) to 1A Black with red stripe = 2 to DCS start (HR) Blue = DCS start (HR) to 3 Yellow = 4 (or auxiliary contact terminal) to DCS run confirm (HI) White = DCS run confirm (HI) to X2* * When using As-i control the run feedback is a dry contact wired to the As-i module. In this case use an orange wire not a white wire connected to X2. E. Cables installed in cable tray shall conform to the following specifications: 1. DC Power 2/C #16 AWG, unshielded, stranded, copper conductors, tinned with red and black conductors, PLTC, 300V, 80 C grey PVC jacket. Use red for positive and black for negative. Use Belden 9410 or equal. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 2. Document #: CS17002 Revision Date: 10/01/2015 Page: 10 of 21 Effective Date: 11/04/2015 DC 2-wire Devices 2/C #22 AWG, unshielded, stranded, copper conductors, tinned with red and black conductors, PLTC, 300V, 80 C chrome PVC jacket. Use red for positive and black for negative. Use Belden 9407 or equal. 3. 12 or 24Vdc Powered Discrete Devices 3/C #22 AWG, unshielded, stranded, copper conductors, tinned with red, black and white conductors, PLTC, 300V, 80 C chrome PVC jacket. Use red for positive, black for negative and white for signal. Use Belden 9491 or equal. 4. 120Vac Powered Devices 3/C #16 AWG, unshielded stranded, copper conductors, tinned with black, white and red conductors, PLTC, 300V, 80 C chrome PVC jacket. Use black for hot, white for neutral and tape the red wire green for ground. Use Belden 9494 or equal. Note: If device is not protected by a 10 amp or less fuse, then use Belden 9495 for #14 wire if protected by a 15 amp breaker. 5. 120Vac Discrete Devices 2/C #16 AWG, unshielded stranded, copper conductors, tinned with red and black conductors, PLTC, 300V, 80 C chrome PVC jacket. Use black for hot and red for neutral or input. Use Belden 9410 or equal. 6. 120Vac Powered Switches 4/C #16 AWG, unshielded stranded, copper conductors, tinned with black, red, blue and orange conductors, TC, 600V, 75 C black PVC jacket. Use black for hot, red for signal, tape the orange wire white for neutral and tape the blue wire green for ground. Use Belden 27338A or equal. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 7. Document #: CS17002 Revision Date: 10/01/2015 Page: 11 of 21 Effective Date: 11/04/2015 Discrete Valve Control Wiring, On-Off and 3-way, 120VAC 6/C #18 AWG, unshielded stranded, copper conductors, tinned with black, red, blue, orange, yellow and brown conductors, TC, 600V, 75 C black PVC jacket. Use Belden 27600A or equal with the following color code. Red = switched hot to solenoid Brown (Taped Green) = Ground Blue (Taped White) = neutral to solenoid(s) Black = hot to confirm switches Yellow = confirm close, 3-way position A, cam farthest from the valve Orange = confirm open, 3-way position B, cam nearest to the valve 8. Discrete Valve Control Wiring, On-Off and 3-way, 24VDC: 6/C #18 AWG, unshielded stranded, copper conductors, tinned with black, red, blue, orange, yellow and brown conductors, TC, 600V, 75 C black PVC jacket. Use Belden 27600A or equal with the following color code. Red = switched hot to solenoid Brown (Taped Green) = Ground Blue = negative to solenoid(s) Black = hot to confirm switches Yellow = confirm close, 3-way position A, cam farthest from the valve Orange = confirm open, 3-way position B, cam nearest to the valve 9. Discrete Valve Control Wiring, On-Off and 3-way, Dual Solenoid, 120VAC 7/C #18 AWG, unshielded stranded, copper conductors, tinned with black, red, blue, orange, yellow, brown and red/black conductors, TC, 600V, 75 C black PVC jacket. Use Belden 27327A or equal with the following color code. Red = switched hot to solenoid #1 Red with Black Stripe = switched hot to solenoid #2 Brown (Taped Green) = Ground Blue (Taped White) = neutral to solenoid(s) Black = hot to confirm switches Yellow = confirm close, 3-way position A, cam farthest from the valve Orange = confirm open, 3-way position B, cam nearest to the valve Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 10. Document #: CS17002 Revision Date: 10/01/2015 Page: 12 of 21 Effective Date: 11/04/2015 Discrete Valve Control Wiring, On-Off and 3-way, Dual Solenoid, 24VDC: 7/C #18 AWG, unshielded stranded, copper conductors, tinned with black, red, blue, orange, yellow, brown and red/black conductors, TC, 600V, 75 C black PVC jacket. Use Belden 27327A or equal with the following color code. Red = switched hot to solenoid #1 Red with Black Stripe = switched hot to solenoid #2 Brown (Taped Green) = Ground Blue = negative to solenoid(s) Black = hot to confirm switches Yellow = confirm close, 3-way position A, cam farthest from the valve Orange = confirm open, 3-way position B, cam nearest to the valve 11. 120Vac Motor Control – 3-wire 4/C #18 AWG, unshielded stranded, copper conductors, tinned with black, red, blue and orange conductors, TC, 600V, 75 C black PVC jacket. Use Belden 27326A or equal with the following color code. Red = hot to stop button Black = terminal 2 of holding coil Blue = terminal 3 of holding coil Orange (Taped Green) = switch casing ground 12. 120Vac Motor Control – 2-wire 3/C #18 AWG, unshielded stranded, copper conductors, tinned with black, red and blue conductors, TC, 600V, 75 C black PVC jacket. Use Belden 27334A or equal with the following color code. Red = hot to switch Blue = return from switch Black (Taped Green) = switch casing ground Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 13. Document #: CS17002 Revision Date: 10/01/2015 Page: 13 of 21 Effective Date: 11/04/2015 DCS Motor Control 7/C #18 AWG, unshielded stranded, copper conductors, tinned with black, red, blue, orange, yellow, brown and red/black conductors, TC, 600V, 75 C black PVC jacket. Use Belden 27600A or equal with the following color code. Black = 1 to DCS stop (HS) (1 is short for MCC terminal 1) Red = DCS stop (HS) to 1A Brown = 2 to DCS start (HR) Blue = DCS start (HR) to 3 Yellow = 4 (or auxiliary contact terminal) to DCS run confirm (HI) Orange (Taped White) = DCS run confirm (HI) to X2* Red with Black Stripe (Taped Green) = Ground * When using As-i control the run feedback is a dry contact wired to the As-i module. In this case use the orange wire color and do not tape it white. PART 3 - EXECUTION 3.01 GENERAL A. Provide supervision and labor that has been qualified by training and experience to perform the activities. B. Ensure the physical mounting of an instrument is complete, prior to terminating conduit and wiring at the instrument. C. Refer to Division 16, Electrical Specifications for installation methods not listed below. D. During construction, wire pulls through conduit should be planned to be completed by the end of the contiguous working shifts. If a wire pull cannot be completed, the coiled wire must have an orange tag attached with the following information completed on the tag: CONSTRUCTION IN PROGRESS NAME: _________________ COMPANY NAME: _________________ DATE: __________________ PROJECT/WORK ORDER#: _____________________ THESE WIRES ARE NOT POWERED (INITIALS): ____________ The DATE entry is the first day the wire is left coiled up. Exception 1 below * applies. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 Document #: CS17002 Revision Date: 10/01/2015 Page: 14 of 21 Effective Date: 11/04/2015 If the coiled wire cannot be completely placed in conduit within three days, the coiled wire must be placed in an enclosure connected to the end of the conduit, with the CONSTRUCTION IN PROGRESS tag attached to the wire. Wires run to MCC or DCS IO cabinets shall be landed immediately if the electrical hardware is installed. If not landed before the end of the shift, attach a CONSTRUCTION IN PROGRESS tag to the wire or bundle of wires. Exception 1 below * applies. The CONSTRUCTION IN PROGRESS tag (and enclosure) should be removed only after the wires are landed on both ends. If a different work crew completes a wire pull, they should coordinate with the crew that left the CONSTRUCTION IN PROGRESS tag (and enclosure) before completing the wire pull. No power shall be applied to any wires until the installation of the wire and conduit is complete. *Exception 1. If construction is in a building or area that is shut down, these temporary measures are not required. Once the building or area is started up, these temporary measures must be implemented. 3.02 INSTRUMENT WIRING A. All Site and NEC color codes must be used unless written authorization to deviate from these codes is obtained from the Work Sponsor. B. The use of wire nuts is not permitted for instrument signal wiring. Soldered splices can be used with the written approval of the Work Sponsor. C. Use spade lugs under screwed terminals where pressure plates are not furnished. D. Do not run D.C. wiring in common conduit with A.C. wiring. E. Ground shields only at one end of the cable, preferably at the signal source. F. Cross analog signal circuits at right angles to AC circuits or D.C. inductive circuits. G. Label each end of wires and cable. These markers are to have printed wire and cable numbers as shown on drawings. H. Install bus networks per drawings paying particular attention to lengths. Inform Work Sponsor if cable length is longer than what the drawing specifies. Red-line the drawings with the installed cable length. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 I. 3.03 Document #: CS17002 Revision Date: 10/01/2015 Page: 15 of 21 Effective Date: 11/04/2015 Separate raceway systems shall be provided and run for the following types of instrument wiring. 1. 120 VAC Power and Signals 2. Analog, 24Vdc Power and Signals, Networks (AS-I, Foundation Fieldbus, Profibus, etc.) 3. Low Level (Load Cells, ph sensors, etc.) 4. Intrinsically Safe Signals 5. Communication Cables (Ethernet, Serial, RS3 Peerway, etc.) 6. SIS systems as documented in G-P-EI 201 M 7. EPA Regulated Systems as documented in Kankakee EHS list 6.01.01, Air Pollution Control Devices and Responsibilities. J. Instrument signals from field devices shall be grouped by type and routed to their respective destinations. Refer to wiring diagrams and I/O schematics for point-topoint wire terminations and for wire tagging information. K. Main conduit runs to an area, a junction box or local panel shall be sized for at least 15% spare cables or wires, and it is preferred to add all spare wires to main conduits during initial installation to avoid future risk to operations when pulling new wire through conduits that contain live instrument wires. If spare wires are not installed initially, future installation may require new conduit. The project manager or work sponsor (any party responsible for the installation) will determine if spare cables or wires are actually installed and, if they are, the required quantity. If installed these cables and wires shall be labeled at both ends with the location of the other end followed by SP and the spare number. The cables and wires shall be long enough at both ends to reach the furthest terminal. BUS NETWORKS A. General 1. Install bus networks as shown on the drawings. 2. Do not exceed cable lengths shown on drawings without authorization from the Work Sponsor. 3. Do not substitute bus network connectivity components without authorization from the Work Sponsor. 4. Locate bus network local junction boxes as shown on the location plans and as close as possible to the connected devices. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 5. B. C. D. E. Document #: CS17002 Revision Date: 10/01/2015 Page: 16 of 21 Effective Date: 11/04/2015 Do not move devices or add additional devices to a network without authorization from the Work Sponsor. Foundation Fieldbus 1. Foundation Fieldbus networks require a terminator at each end. 2. If the cable lengths exceed what is shown on the drawing notify the Site Area Representative. Typically cable lengths are not an issue with this type of network. 3. Cut and tape shields at the field devices. AS-i 1. Cable lengths are critical with this type of network. If the total cable length on a given segment exceeds what is shown on the drawing notify the Work Sponsor. 2. Each AS-i segment must not exceed more than 100 meters of total cable length. 3. When mounting AS-I components in a panel or junction box be aware of the maximum temperature rating and allow spacing between components for heat dissipation. Profibus DP 1. Profibus networks require a terminator at each end. 2. All devices on a network must be set for the same baud rate as indicated on the drawings. Devicenet 1. All devices on a network must be set for the same baud rate as indicated on the drawings. 2. Use the cable shown on the drawings. 3. Each Devicenet network requires a terminating resistor at each end. 4. The maximum drop length must not exceed 20 feet. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 3.04 3.05 Document #: CS17002 Revision Date: 10/01/2015 Page: 17 of 21 Effective Date: 11/04/2015 5. If flat cable with insulation displacement connectors is used do not remove a connector once it is placed on the cable. If the device is moved install a new connector on the cable at the new location. 6. Do not re-use insulation displacement connectors. PANELS AND JUNCTION BOXES A. The contractor shall devise and provide stands, brackets, or other supports as necessary to securely mount panels and junction boxes. Acceptable designs are available from your Work Sponsor. B. Panels must be stored, handled, moved, and installed in an upright position. C. Anchor self supporting freestanding enclosed panels in place with anchor bolts. D. Conduits to all panels or junction boxes shall be supported independent of the panel or junction box. E. Do not support panels and junction boxes from equipment without prior written approval of the Work Sponsor. F. No panels or junction boxes may protrude into walkways or aisle ways. G. Install small wall mounted panels and junction boxes so that their centerlines are approximately 5’-3” from the floor. The top of the panel or junction box should not exceed 6’-6”. H. Install panels to provide adequate clearance to conform to the requirements of the National Electric Code. I. Clean welded joints between supports and structural steel and paint per Site Finished Paint specification. J. Paint supports per Site Finished Paint specification. CONDUIT A. Wherever a seal-off is to be poured, install an explosion proof union between the seal off and the device to permit later removal of the device for maintenance. B. Use watertight hubs for conduits entering enclosures mounted outside or in wash down areas. C. To prevent water from entering instruments and panels mounted outdoors or in hose down areas, conduits should run up to device and/or should enter through Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 Document #: CS17002 Revision Date: 10/01/2015 Page: 18 of 21 Effective Date: 11/04/2015 the side or bottom. Install low point combination drains and breather in conduit runs (Crouse-Hinds ECD18 or equal). 3.06 3.07 D. Do not support devices and conduit from equipment without prior written approval of the Work Sponsor. E. For instruments requiring removal for testing or calibration, provide a sufficient length of flexible conduit at the instrument no longer than 30” and within the limits of the National Electric Code to allow removal of the instrument without the need to dismantle the conduit system. F. EPA Regulated Systems should be in accordance with 3.02 Section I. No new wire shall be pulled through existing conduit going to an EPA regulated system. G. Refer to Site specification CS16111 for additional information regarding conduit materials and NEC code adherence for installation. H. Prior to pulling new instrument wires through existing conduit (cannot be done on conduit going to EPA regulated systems), the integrity of the conduit and contained wiring should be evaluated. The project engineer or work sponsor should be consulted if there is risk that pulling new wire could affect the integrity of existing wire. Condition of the conduit and existing wiring, how full the conduit is and will be after pulling the new wire, and the length and difficulty of the new pull should be considered. If the risk is evaluated to be unacceptable, new conduit should be installed. INTRINSICALLY SAFE WIRING A. Make installation of intrinsically safe wiring in accordance with ISA Recommended Practice RP12.6 latest edition. B. Wireways and conduit carrying intrinsically safe wiring will be color-coded blue at each end and at intervals not exceeding 6 feet. C. Intrinsically safe and non-intrinsically safe wiring will not be run in the same conduit. D. Intrinsically safe and non-intrinsically safe wiring will be at least two inches apart or separated by a grounded metal barrier within cable tray, wireway or enclosures. FIBER OPTIC CABLE A. Refer to the manufacturer’s literature to obtain the minimum bend radius and maximum tensile loading before installing fiber optic cable. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 3.08 Document #: CS17002 Revision Date: 10/01/2015 Page: 19 of 21 Effective Date: 11/04/2015 B. Conduits should be routed and pull boxes installed to stay within the limits of the cable. C. When pulling the fiber optic cable through conduit, it is important to ensure that a basket weave type grip of the correct size is used. To install the grip, the cable is fed through the basket weave portion of the grip, the sheath is removed, and the Kevlar yarns are separated from the other components of the cable. The remaining portions are cut back, and the yarns are tied off with a series of half hitches to the small eye inside of the basket weave. The grip is then covered with plastic tape from about six inches behind the basket weave to the free end of the grip so that the lays of tape overlap. The pull can begin after a swivel is attached between the pull line and the grip. The swivel is important because fiber optic cable is very light and the stranding of the pull line can induce a twist in the cable if the two are directly coupled under tension. D. If a pull is going to require lubrication, a suitable water based lubricant must be used. TESTING AND CALIBRATION A. Handle instruments with care to prevent loss of calibration. B. Refer to Site Engineering and Construction Specification CS17010 Instrumentation Checking Procedures for additional information. C. Conventional wire and cable required functional testing and operational checks. D. 1. Check continuity and terminations. 2. Check that all shields are only grounded at one location. 3. Check bus networks for terminating resistors when required. 4. Verify bus networks are within length and current limitations. Fiber Optic Cable 1. Perform end-to-end attenuation testing on each segment of fiber optic cable. Use wavelengths of 850 and 1300 nanometers for this test. 2. Perform OTDR (Optical Time Domain Reflectometer) testing on all cables before and after installation. Also test all splices and connectors. Use a high resolution OTDR for this testing. 3. Measure and record each transmitters output and the power levels at each receiver. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 4. Document #: CS17002 Revision Date: 10/01/2015 Page: 20 of 21 Effective Date: 11/04/2015 Document the results of all testing and turn over to the Work sponsor upon completion. Engineering and Construction Specifications Division 17 - Instrumentation Title: Instrumentation Electrical Installation Revision: 5 Document #: CS17002 Revision Date: 10/01/2015 Page: 21 of 21 Effective Date: 11/04/2015 Revision History Revision Date Page Description 0 07/19/10 All Original J. Shute 1 02/08/13 All Updated BASF Header. Reviewed, no changes made to content. J. Shute 2 01/30/14 7 Add Fiber Optic Cable section in Part 2 J. Shute 3 04/17/14 7 Add cabling details for wall plates J. Shute 4 09/22/15 15,18 5 11/04/15 15, 18 EPA Regulated Systems and Clarification of Best Practices Per NEC Code, Site Area Representative changed to Work Sponsor Clarify practices regarding conduit wire pulls and EPA Regulated Systems Initiator R. Arias R. Arias Approvals Prepared By: _____________________________________ Date: __________________ Process Control Engineer Approved By: _____________________________________ Date: __________________ TES Manager