AHF

advertisement

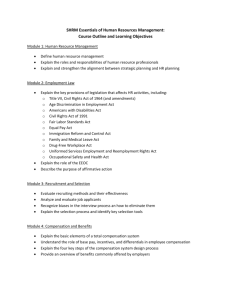

Active Harmonic Filters 2 Consumers of electricity often suffer from poor power quality • Machines stop, power packs burn out, and power outages paralyze the entire company. – Many consumers used in industrial production cause massive disruptions in the mains supply. – In Germany, for example, damages from production downtimes amount to billions each year. With increasing tendency! Power Quality – Sources of disturbances • • • • • Fast transients on the mains voltage side Flattening of sine mains voltage Switching power supplies Welding machines UPS Motor drives Converters with controlled rectifiers DC controllers for DC drives Old AC drives with thyristor power converter technology Induction furnaces up to sev. sec. 3~ asymmetric 1µs up to sev. ms Voltage dip Slow voltage changes Fast voltage Short-term Long-term Flicker interruption interruption changes Intermittent overvoltage UL-N Transient overvoltage UL-N - Frequency - Harmonic oscillations - Inter-harmonics June 2009 - Signal voltages Power Quality – The effect • 1-phase: PCs, monitors, printers, microwave ovens, TVs, electronic fluorescent lamp ballasts... Power Quality – The effect • 3-phase: motor drives, converters, UPS systems, induction furnaces, welding machines… Frequency converter: input current UPS: input current Frequency converter: current harmonics UPS: current harmonics Network disruptions – Common solutions • Harmonic compensation – Passive filters for individual harmonics (trap filters) or individual non-linear loads (e.g. for 6-pulse rectifiers) • Reactive power compensation – De-tuned capacitor banks – Dynamically slow – Resonances may occur Mains Medium voltage Low voltage These systems can only be designed in a passive manner, i.e. for a specific error source, and do not actively adapt to the situation. Consumers: - Power converters - Drives De-tuned PFC Principle of operation mains compensation current CTs load Principle of operation mains compensation current CTs neutral load Active harmonic filters • Active compensation of harmonic currents – Digital control technology with FFT analysis • • • • • • Dynamically fast Entire frequency spectrum compensated up to the 49th order Application: welding machines, induction furnaces, … FFT decomposes the current into its frequency components Possible to individually compensate for each harmonic Application: continuous loads, all types of motor drives • Active compensation of reactive power – Responds with almost no delay and without resonance – Optionally selectable Active Connection diagram Current transformers can be placed upstream or downstream of the filter Network Uncompensated load Compensated load OmniWave Active Dimensioning • Dimensioning – Sum up the nominal input currents of the consumers that need compensation. – Compensation current: 35% of the nominal input current must be compensated for (B6 rectifier bridges with 3% AC reactors) – Objective: <5% THD-I • Filter selection – Smaller individual non-linear consumers: • Group non-linear loads on a sub distribution bus • Completely compensate them with OmniWave Active – Large individual non-linear consumers: • Connect one or more OmniWave Active in parallel – Total system: • Completely compensate the installation with one or more OmniWave Active in a central location OmniWave Active Application example: B6-load OmniWave Active controller „ON“ Response time (example for 2phase welding process) line current (max. 110A) OmniWave Active current (immediate response) Welding current (max. 280A) OmniWave Active Application example: AC drive mix • • • Application: Load type: Comp. system: Compensation of harmonic oscillations and reactive power Motor and converter load in switching operation PFC (without series reactors) OmniWave Active Product range OmniWave Active 30A/50A (3-wire) Wall mounting or cabinet integration possible IP54 degree of protection if installed in a cabinet ~30% volume compared to tradition active harmonic filters Only 47kg OmniWave Active 30/60A (4-wire) Low audible noise emission Superior EMC Level OmniWave Active 100A/120A (3-wire and 4-wire) Only slightly larger and heavier than their little brothers Most popular type, always the perfect fit IP54 degree of protection if installed in a cabinet Weight: 105/145kg OmniWave Active Product range OmniWave Active 200A/250A/300A Cabinet 800 x 2000 x 600mm (W x H x D) 3-wire and 4-wire technology available IP54 protection degree for industrial use Weight: 415/495 kg Air cooling, optional water cooling Internally encapsulated liquid cooling Ambient temperature: 0°C - 40°C continuous, 40°C - 55°C automatic de-rating 2%/K The industrial model is a real power pack OmniWave Active System architecture OmniWave Active controller OmniWave Active Controller platform • • • • • System architecture: – Power PC – eCOS real-time operating system – Synchronous 12-channel measured value recording, sampling rate 31µs Standard interfaces: – ModBus RTU (RS485), ModBus TCP/IP (Ethernet), CAN digital input/output – 2 free slots for additional cards Monitoring: – Device and module temperatures, precision < 1Kelvin – Mains voltage and phase – Asymmetric intermediate circuit – Failure memory Housing optimized for EMC Operating temperature range: -40°C to +55°C OmniWave Active (50A) Components OmniWave Active (300A) Mechanical design • System rack: – 800 x 2000 x 600mm (WxHxD) – IP54 protection class – Weight: 415/495kg • Cooling system: – Air cooling (integrated air/water heat exchanger) – Power loss: 7,500/8,500W – Optional water cooling – The acquired process heat can be used – > OmniWave Active is energy-neutral • Ambient temperature: – 0°C – 40°C continuous – 40°C – 55°C automatic de-rating 2%/K OmniWave Active (300A) Cooling system • Primary cooling: – – – – – – Water/air heat exchanger Fans Expansion reservoir and pump Control unit Coolant: water with Antifrogen Cooling performance: 6,500/7,500W • Interior cooling: – Air/air heat exchanger – Cooling performance: 1,000W OmniWave Active (300A) System concept • Module units: – – – – – CE, UL mains fuse unit Mains filter Converter unit Intermediate circuit modules Power output stages – Notch filter + absorption circuit – Control platform + HMI – Measured value recording • Serviceability: – Plug & Play module replacement – MTTR <15min AHF Viewer PC user interface • • • • • Based on Windows XP, multi-language interface Modbus serial line or TCP/IP protocol Data interface to common office applications System management Monitoring functions: – – – – – • Oscilloscope Data logger Transients monitoring FFT analysis Diagnosis, disruption analysis Parameterization functions: – Unit initialization – Firmware update OmniWave Active Features • • • • • • • • • Global or selective compensation of specific harmonics up to the 50th order Compensation for power factor, cos phi Multi-language control and display panel Menu-guided setting and selection of parameters AHF Viewer PC operation software Diagnosis and maintenance system Status display of current power quality Remote operation Can be used with a wide range of common current transformers 25 OmniWave Active Features and Benefits • • • • • • • • • • • • • • CE and UL conform > ready for worldwide use Fully digital > state-of-the-art technology Fastest control > immediate harmonic compensation 16kHz control cycle with notch filter > very quiet system Current transformer can be upstream/downstream of filter > simple integration Use of any current transformer > great flexibility Any type of device cascading > cost effective upgrades possible anytime High overload capability > excellent dynamic load compensation High-quality components > long maintenance intervals, MTBF up to 100,000h Fast commissioning > intuitive and easy Complete PC analysis tool > online network monitoring TCP/IP connection > remote maintenance possible German engineering > highest quality and reliability Worldwide organization > fast and local support Plug-and-play 3 simple steps to better power quality Measure Determine the supply points for OmniWave Active by precisely measuring the network load. Install Select the suitable current transformer and install OmniWave Active. Configure Commission OmniWave Active with just a few clicks. OmniWave Active is easy to cascade Up to five OmniWave Active units can be used in parallel Filters with different ratings can be combined Medium Voltage Harmonic Correction • 1000 kVA Harmonic Correction per module • for larger systems add modules to meet Harmonic requirements • Voltages up to 33kV