Specifications

advertisement

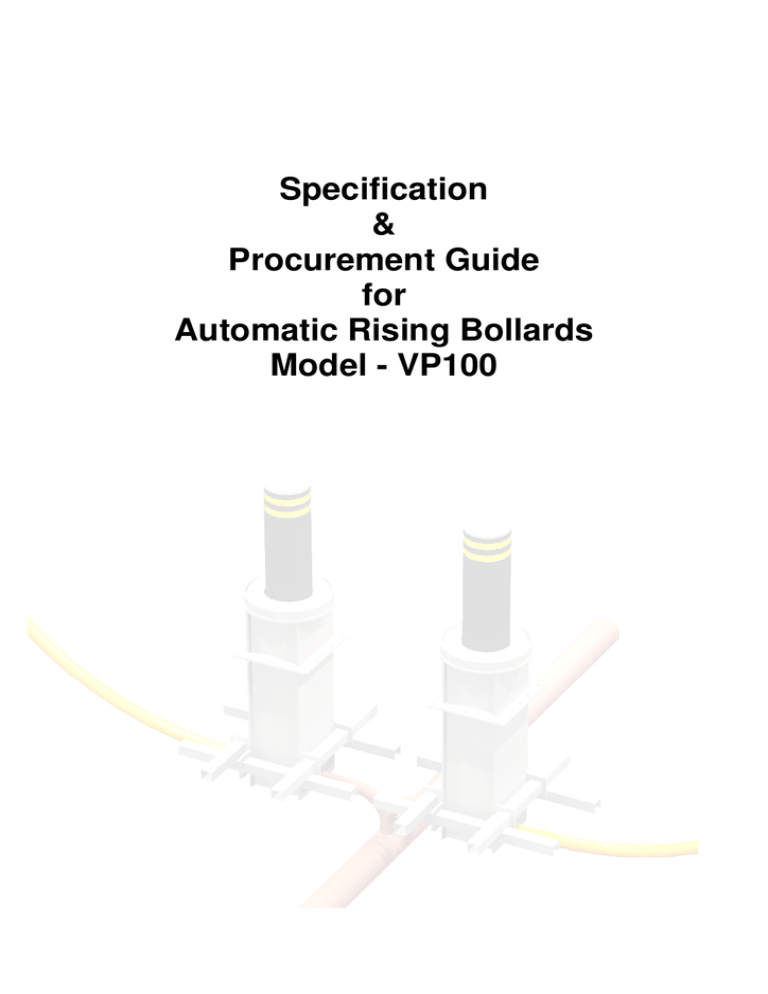

Specification & Procurement Guide for Automatic Rising Bollards Model - VP100 Contents 1.0 Scope ....................................................................................................... 2 2.0 System Configuration………………………………………………………. ... 2 2.1 Bollard(s)………………………………………………………………… .. 2 2.1.1 Single Bollard………………………………………………………………2 2.1.2 Multiple Bollards…………………………………………………………. 2 2.2 Bollard Construction……………………………………………………... 2 2.3 Bollard Height…………………………………………………………….. 2 2.4 Bollard Dimensions………………………………………………………. 2 2.5 Hydraulic Pump(s) & Circuit…………………………………………….. 2 3.0 Control & Logic Circuits………………………………………………………. 3 3.1 Control Circuit…………………………………………………………….. 3 3.2 Voltage……………………………………………………………………. .3 3.3 Control Cabinet…………………………………………………………… 3 3.4 Inhibit Loop………………………………………………. 3 4.0 Peripheral Control Equipment…………………………………………………3 5.0 Performance…………………………………………………………………… 3 5.1 Experience………………………………………………………………… 3 5.2 Speed of Operation………………………………………………………. 4 5.3 Frequency of Operation………………………………………………….. 4 6.0 Environmental Data…………………………………………………………… 4 6.1 Extremes in Temperature……………………………………………….. 4 6.2 Rainfall……………………………………………………………………. 4 7.0 Quality Assurance…………………………………………………………….. 4 7.1 Testing…………………………………………………………………….. 4 7.2 Shipment………………………………………………………………….. 4 8.0 Warranty……………………………………………………………………….. 5 9.0 Manufacturer's Data……………………………………………………………5 9.1 Drawings & Installation data…………………………………………….. 5 10.0 Disclaimer……………………………………………………………………… 5 11.0 Procurement Details………………………………………………………… 5 1.0 Scope The specification defines the procurement of an Automatic Hydraulic Rising Bollard System, Model VP100, comprising of one, two, three or four vertical rising bollards operating independently or in sets of two, three or four, a hydraulic pump(s), control cabinet containing the controls and logic circuits and options as defined herein. 2.0 System Configuration 2.1 Bollard(s) The system shall have a total of (enter quantity) bollard(s) installed 2.1.1 Multi bollards operating in sets. The bollard system shall have (enter quantity) bollards operating together as a set. Each set of bollards shall have its own controls and operate independently of other systems. 2.1 Bollard Construction. The bollard shall be a below ground assembly consisting of a square outer casing complete with cable and drainage duct oulets and an inner bollard of heavy steel cylindrical tube and an aesthetic polymer sleeve capable of being raised above ground into the raised position. In the raised position the bollard shall present a formidable obstacle to approaching vehicles. Upon impact, forces shall first be absorbed by the inner bollard and then transmitted to the outer casing and foundation. 2.3 Bollard Height Height of the bollard in the raised position shall be 700mm as measured from ground level to the top of the inner bollard. 2.4 Bollard Dimensions Outer Casing: 250mm x 250mm x 1100mm Inner Bollard: 168mm diameter Aesthetic Sleeve: 200mm outside diameter to slide fit over the inner bollard complete with two 50mm yellow reflective bands. If Stainless steel is the preferred finish the finished diameter will be 168mm 2.5 Hydraulic Pump(s) & Circuit Each bollard either working individually or working in multiples shall have its own individual hydraulic pump situated above ground and within the main control cabinet. The hydraulic circuit shall include all necessary control logic, hydraulic hoses, quick release connectors and valves. Normal operation will allow the bollards to lower in the case of a power fail. In security applications the hydraulic circuit must be flexible enough to allow the bollards to remain in the raised position in power fail. This must be specified at the time of order. 3.0 Control & Logic Circuits ATG Access | CoBaCo House | North Florida Road | Haydock | Merseyside | WA11 9TP 3.1 Control Circuit. A control circuit shall be provided to interface between the bollard(s) and the hydraulic pump(s). This circuit shall contain all relays, timers and other devices necessary for all the operations of the system as defined. All control equipment shall be situated above ground and within the main control cabinet 3.2 Voltage The control circuit shall operate from a 240 volt, 50Hz single phase supply. An internal transformer shall reduce this to 24VC for all external devices. 3.3 Control Cabinet The control panel shall be sufficient to house all the control circuits, hydraulic pump(s) and other devices for operation of the system that do not require external visibility (e.g. Radio Receiver) and shall be treated and finished in Black or Stainless Steel with high security locks. The control panel shall have a side access panel for a manual override system and a mains power supply isolator. The control cabinet dimensions shall be 950mm high x 760mm wide x 335mm deep. 3.4 Inhibit Loop The option of an inhibit loop may be installed around the rising bollard preventing the bollard from rising if a vehicle is detected. 4.0 Peripheral Control Equipment The final specification of devices required to operate the system will be discussed and issued at a later date but may include devices such as Key Pad, Intercom, Key Switch or Push Button. 5.0 Performance 5.1 Experience The manufacturer shall have over 500 systems installed and in operation for a minimum of 5 years with documented logs of all major components and design features. 5.2 Speed of Operation Normal speed of operation shall be capable of raising or lowering the bollards between 5-6 seconds when operated at a repetition rate not greater than ATG Access | CoBaCo House | North Florida Road | Haydock | Merseyside | WA11 9TP specified in 6.3. The control system shall be capable of reversing the bollard upward cycle at any time on a valid demand from the devices controlling the system. 6.2 Frequency of Operation The bollard shall be capable of 1000 up/down cycles per day. 6 Environment Data The bollard system shall operate satisfactorily under the following environmental conditions: 6.1 Extremes in Temperature The bollard system shall operate between the following temperatures. Normal Operating Temp for Control System: Maximum Operating Temp for Hydraulic Oil: Minimum Operating Temp for Hydraulic Oil: 40˚C to -15˚C 90˚C - 54˚C 6.2 Rainfall It is recommended the bollard outer casings are connected to a drain, if this is not practical then a natural soak away should be constructed. It is imperative to note that a natural soak away should only be considered if connection to a drain is not practical, the success of a natural soak away will be dependant on the ground conditions. 7 Quality Assurance The manufacture will be accredited to ISO 9001/2000 7.1 Testing Upon completion of the system build the bollard system will be fully tested at the manufactures facility. The client will be invited to the Factory Acceptance Test for signing off to verify functionality, operating speeds, workmanship and the finished colour is matched against the order placed. 7.2 Shipment The system will packaged in a sufficient manner for transport in the UK so that the risk to damage is minimal. Export shipments shall be crated and be of sufficient structural integrity to be lifted and transported by overhead crane or forklift truck without failure. 8 Warranty The system shall carry a full 12 months parts and labour warranty. The manufacturer must be able to extend the warranty to cover a 5 year parts and labour maintenance agreement at the placement of order if required by the client. ATG Access | CoBaCo House | North Florida Road | Haydock | Merseyside | WA11 9TP 9 Manufacturer’s Data 9.1 Drawings and Installation Data Method Statements, Risk Assessments, site specific layout and duct drawings shall be sent to the purchaser within four weeks of placing an order. A full operating manual will be issued on handover of the system. 10.0 Disclaimer Careful consideration must be devoted to the selection, design and location of an automatic rising bollard system in the same manner as any other product that may be used to close off a roadway. Care must be taken to ensure approaching vehicles and pedestrians are made fully aware that automatic rising bollards are in operation through appropriate signage. 11.0 Procurement Details The VP100 automatic hydraulic rising bollard system shall be purchased from ATG Access Ltd CoBaCo House North Florida Road Haydock Industrial Estate Haydock Merseyside WA11 9TP Ph: + 44 (0)1942 407700 Fax: + 44 (0)8456 759955 Contact: Gavin Hepburn – Sales & Marketing Director E-mail: sales@atgaccess.com Web: www.atgaccess.com ATG Access | CoBaCo House | North Florida Road | Haydock | Merseyside | WA11 9TP