Hilti CP 651N Firestop Cushion Data Sheet

advertisement

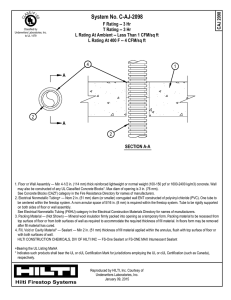

Data Sheet HILTI CP 651N Firestop Cushion The enclosed pages are taken from the Hilti Firestop Systems Manual Edition April 2011 Supported by additional standard details For Material Safety data sheets visit the technical library at www.hilti.co.uk/cfs Hilti (Gt Britain) Ltd TECHNICAL ADVISORY SERVICE TELEPHONE 0161 886 1144 Quality Management System Certification Standard: ISO 9001:2008 Issued by: The Swiss Association for Quality and Management Systems SQS. Registration No: 12455 (The current certificate can be downloaded from www.hilti.co.uk) Field of activity: Market Organisation. Note: The certificate of Hilti (Gt. Britain) Ltd. is a sub-certificate to the master certificate of Hilti Aktiengesellschaft,FL-9494 Schaan with the field of activity: Research, Development, Manufacturing, Sales and Service. Hilti (Gt. Britain) Limited, Telephone: 1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY 0800 886 100 Data Sheet Don’t just use Hilti Firestop Products, use our Hilti Accredited Firestop Contractors It is the combination of a quality conscious and third party accredited manufacturer working in close co-operation with a selected group of third party accredited installers that can offer you the best value. Here are some of the benefits available to you by using this co-operation: Reduce your liability; liability that comes from poor or incorrect installation and performance of products. Efficient Project Management based on the co-operation of a specialised manufacturer with a specialist contractor Commercially designed, effective Fire Protection solutions rd Products that adhere to 3 party product conformity schemes such as FM, UL and Certifire. These approvals are an assurance of product and manufacturer quality, they can also have an influence on the building insurance premium reducing the service costs of the building. Solutions that have been tested for long term performance. Solutions that offer business continuity and protections of premises. Certification of conformity of work completed. Installation work audited by FIRAS on site to ensure compliance with manufacturers’ recommendations and Building regulations. Installer with site based manufacturer support. Installer having available site based manufacturers support when needed. Clear and comprehensive documentation of installation. Comprehensive support documentation for proposed solutions. Clarity and assistance understanding the role of Passive Fire measures in modern building construction. Product Accreditation Hilti Firestop Systems have been certified by a wide variety of international bodies, such as FM, UL, Certifire and iBMB As part of this process products are monitored on an on-going basis so you can have absolute confidence in the quality and standard of the product you are specifying. Installation Accreditation Hilti-Accredited Firestop Contractors are also third party certified (e.g. FIRAS or LPCB). This means that they work to agreed industry standards, employ trained operatives and are subject to on-site audits and inspection of representative samples of the work carried out to ensure compliance with manufacturers’ recommendations and Building Regulations Further details about Hilti accredited Firestop Contractors and the support that we can offer you can be obtained by telephoning Freephone 0800 083 8889 (GB only). Association for Specialist Fire Protection Hilti is proud to support and be a member of The Association for Specialist Fire Protection (ASFP) ASFP Vision To offer the industry it serves with: Knowledge / guidance on all aspects of ‘built-in’ fire protection Technical support / impartial advice Direction through industry authority AGE TESTED Hilti (Gt. Britain) Limited, Telephone: 1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY 0800 886 100 CP 651N AGE TESTED Contents Hilti Firestop Systems Manual Pages for Hilti CP 651N FS 011 - 02 FS 066 - 01 Hilti CP 651N Metal Trunking – Solid wall – Drywall – (Pillows) Hilti CP 651N Plastic Pipe – Cables - Solidwall 30 YEARS Data summary Data summary Data summary Additional Properties of CP 651N seals CP 651N - Firestop Cushion – BREEAM Criteria summary CP 651N - Firestop Cushion - NBS specification clauses 30 YEARS Material Safety Data Sheets and CAD files of the standard details FS ***-** can be downloaded from the technical library at www.hilti.co.uk/cfs Revision History May 2011 July 2011 May 2013 First release Data summaries added, inappropriate standard details removed. Update Hilti (Gt. Britain) Limited, Telephone: 1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY 0800 886 100 Hilti Firestop Systems Hilti Firestop Systems Firestop cushion CP 651 N Technical Information Ready-to-use firestop intumescent cushion Applications Technical data Applications for permanent of temporary seal in floors and walls Installations where frequent changes may be required CP 651 N Up to 4 hours Fire rating Dust free applications in switch or computer rooms Concrete, Masonry, Drywall Base materials Cable trays and inside cable trunking PVC pipes up to 50mm Density ~0.35 g/cm³ Colour White Up to 58db Acoustics performance Advantages Excellent for laying new cables Tear-resistant and dust-free pillows for dust-free rooms Easy installation without use of a special tool The following dimensions must be observed when installing firestop cushions: Size Wall Floor Width x Height 1200x1500mm 700mm x unlimited Min. building component thickness 100 mm 150 mm Min. distance of cable run from opening 40 mm 40 mm Min. distance between cable trays (horizontal) 0 mm 0 mm Min. distance between cable trays (vertical) 80 mm 80 mm Min. distance between openings 200 mm 200 mm Max. cable loading (as % of opening size) 60 % 60 % Re-usable, economical in use A flexible system (temporary or permanent firestop) Also for use in drywall Uneffected by water or mild frost EN 1366-3 Max. opening size For more standard details and technical information register online at the Hilti Firestop Design Centre at www.hilti.co.uk/cfs Installation instructions for CP 651 N Notice • Ordering Item number Before handling, read Material Safety Data Sheet and product label for safe usage and health information. Opening Order description Package Contents Dimensions (LxWxH) Package Quantity Firestop cushion CP 651 N-L 6 x CP 651N firestop pillow (large) 300 x 170 x 30 mm 6 pc Firestop cushion CP 651 N-M 15 x CP 651N firestop pillow (medium) 300 x 80 x 30 mm 15 pc 00382625 2. Cushion arrangement without cables running through wall partition. Firestop cushion CP 651 N-S 30 x CP 651N firestop pillow (small) 300 x 40 x 30 mm 30 pc 00382624 3. Cushion arrangement with cables running through wall partition. 00382626 1. Clean the opening. Cables and cable supporting structures must be installed and fastened in compliance with standards. 4. For floor openings fasten wire mesh in placewhen closing the opening. The following points when installing the cushions: • Insert the first layer of CP 651 N underneath the cables if possible. • Overlap (> 20 mm) • Shift next layer 1/2 width of cushion (stretcher bond). • Seal off the opening with CP651 N tightly. • If cable penetration must carry permanent identification mark in the form of an installation plate. Enter the appropriate details on the installation plate and mount it in a visible position beside the cable penetration. 5. Cushion arrangement in floor. Seal gaps between cables and CP651 N with CP606 if required (please refer to approval). 6. Wrap cable/ cable tray resp. pipes running through opening with CP651 N-L if required (please refer to approval). 7. Fasten identification plate in pace (if required). Inspection • 9LVLWWKH+LOWL)LUHVWRS'HVLJQ&HQWUH5HJLVWHUWRGD\DWZZZKLOWLFRXNFIV +LOWL2XWSHUIRUP2XWODVW Check that the cushions have been installed in compliance with regulations. Hilti Firestop Systems Hilti Firestop Systems Firestop cushion CP 651 N Technical Information Ready-to-use firestop intumescent cushion Applications Technical data Applications for permanent of temporary seal in floors and walls Installations where frequent changes may be required CP 651 N Up to 4 hours Fire rating Dust free applications in switch or computer rooms Concrete, Masonry, Drywall Base materials Cable trays and inside cable trunking PVC pipes up to 50mm Density ~0.35 g/cm³ Colour White Up to 58db Acoustics performance Advantages Excellent for laying new cables Tear-resistant and dust-free pillows for dust-free rooms Easy installation without use of a special tool The following dimensions must be observed when installing firestop cushions: Size Wall Floor Width x Height 1200x1500mm 700mm x unlimited Min. building component thickness 100 mm 150 mm Min. distance of cable run from opening 40 mm 40 mm Min. distance between cable trays (horizontal) 0 mm 0 mm Min. distance between cable trays (vertical) 80 mm 80 mm Min. distance between openings 200 mm 200 mm Max. cable loading (as % of opening size) 60 % 60 % Re-usable, economical in use A flexible system (temporary or permanent firestop) Also for use in drywall Uneffected by water or mild frost EN 1366-3 Max. opening size For more standard details and technical information register online at the Hilti Firestop Design Centre at www.hilti.co.uk/cfs Installation instructions for CP 651 N Notice • Ordering Item number Before handling, read Material Safety Data Sheet and product label for safe usage and health information. Opening Order description Package Contents Dimensions (LxWxH) Package Quantity Firestop cushion CP 651 N-L 6 x CP 651N firestop pillow (large) 300 x 170 x 30 mm 6 pc Firestop cushion CP 651 N-M 15 x CP 651N firestop pillow (medium) 300 x 80 x 30 mm 15 pc 00382625 2. Cushion arrangement without cables running through wall partition. Firestop cushion CP 651 N-S 30 x CP 651N firestop pillow (small) 300 x 40 x 30 mm 30 pc 00382624 3. Cushion arrangement with cables running through wall partition. 00382626 1. Clean the opening. Cables and cable supporting structures must be installed and fastened in compliance with standards. 4. For floor openings fasten wire mesh in placewhen closing the opening. The following points when installing the cushions: • Insert the first layer of CP 651 N underneath the cables if possible. • Overlap (> 20 mm) • Shift next layer 1/2 width of cushion (stretcher bond). • Seal off the opening with CP651 N tightly. • If cable penetration must carry permanent identification mark in the form of an installation plate. Enter the appropriate details on the installation plate and mount it in a visible position beside the cable penetration. 5. Cushion arrangement in floor. Seal gaps between cables and CP651 N with CP606 if required (please refer to approval). 6. Wrap cable/ cable tray resp. pipes running through opening with CP651 N-L if required (please refer to approval). 7. Fasten identification plate in pace (if required). Inspection • 9LVLWWKH+LOWL)LUHVWRS'HVLJQ&HQWUH5HJLVWHUWRGD\DWZZZKLOWLFRXNFIV +LOWL2XWSHUIRUP2XWODVW Check that the cushions have been installed in compliance with regulations. Hilti Firestop Systems Hilti Firestop Systems Consumption guide The following numerical values can only be taken as a rough guideline. The actual number of cushions which will be required, will vary according to a number of conditions including opening size, wall or floor thickness, as well as the shape of the opening. Wall assembly Cable penetrations through walls covering all cable diameters Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.4 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Cushion 0 3 6 8 16 32 65 80 96 128 160 182 215 257 298 CP 651N-L Cable load 0% 1 2 2 2 4 7 15 19 23 29 36 47 54 61 68 CP 651N-M Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.4 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Cushion – – 5 7 15 23 51 64 74 92 119 136 164 189 218 CP 651N-L Cable load 30% – – – – 2 1 4 1 3 2 6 3 14 5 13 5 16 7 20 8 25 10 31 11 38 12 43 12 48 15 CP 651N-M CP 651N-S 4 3 1 2 2 3 6 8 9 11 13 15 16 18 21 CP 651N-S Cable load 10% – – – 3 2 2 5 2 1 8 2 1 18 3 2 31 6 3 63 13 6 76 16 7 90 20 8 118 26 10 148 32 12 169 39 13 201 48 15 232 55 16 278 61 19 CP 651N-L CP 651N-M CP 651N-S – – – – 12 20 36 40 52 66 78 86 109 120 136 CP 651N-L Cable load 60% – – – – – – – – 4 2 5 3 9 4 11 4 12 6 13 6 18 8 24 9 31 10 36 10 41 12 CP 651N-M CP 651N-S Cable penetrations through walls with cable diameters ≤ 16 mm Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.4 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Cushion 0 3 6 8 16 32 65 80 96 128 160 182 215 257 298 CP 651N-L Cable load 0% 1 2 2 2 4 7 15 19 23 29 36 47 54 61 68 CP 651N-M 4 3 1 2 2 3 6 8 9 11 13 15 16 18 21 CP 651N-S – 3 5 8 17 29 59 72 86 105 144 164 180 206 269 CP 651N-L Cable load 10% – – 2 2 2 1 2 1 3 2 6 3 13 6 16 7 20 8 26 10 32 12 39 13 48 15 55 16 61 18 CP 651N-M CP 651N-S 9LVLWWKH+LOWL)LUHVWRS'HVLJQ&HQWUH5HJLVWHUWRGD\DWZZZKLOWLFRXNFIV Cable penetrations through walls with cable diameters ≤ 16 mm Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.4 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Cushion – – 4 6 11 23 45 56 67 82 112 128 158 181 208 CP 651N-L Cable load 30% – – – – 2 1 3 1 3 2 6 2 11 4 13 5 16 6 20 8 25 9 33 11 39 11 43 12 48 15 CP 651N-M CP 651N-S – – – – 9 14 26 33 41 54 65 76 87 104 121 CP 651N-L Cable load 60% – – – – – – – – 5 3 5 3 8 4 11 4 12 6 13 6 18 8 24 9 31 10 36 10 41 12 CP 651N-M CP 651N-S Floor assembly Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Cushion 0 0 3 5 9 20 30 42 52 63 73 CP 651N-L Cable load 0% 1 2 3 4 5 10 15 21 26 31 36 CP 651N-M 1 3 2 2 2 4 8 9 12 14 16 CP 651N-S – 1 2 5 11 22 32 46 57 69 81 CP 651N-L Cable load 10% – – 2 3 4 3 3 2 5 2 10 4 14 8 18 8 21 10 23 12 25 15 CP 651N-M CP 651N-S Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Cushion – – 3 6 9 18 26 34 42 49 57 CP 651N-L Cable load 30% – – – – 2 2 2 2 4 3 7 4 11 5 15 6 18 8 22 10 26 12 CP 651N-M CP 651N-S – – – – 7 12 18 24 28 33 39 CP 651N-L Cable load 60% – – – – – – – – 3 1 4 2 6 3 8 5 10 6 13 7 15 9 CP 651N-M CP 651N-S +LOWL2XWSHUIRUP2XWODVW Hilti Firestop Systems Hilti Firestop Systems Consumption guide The following numerical values can only be taken as a rough guideline. The actual number of cushions which will be required, will vary according to a number of conditions including opening size, wall or floor thickness, as well as the shape of the opening. Wall assembly Cable penetrations through walls covering all cable diameters Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.4 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Cushion 0 3 6 8 16 32 65 80 96 128 160 182 215 257 298 CP 651N-L Cable load 0% 1 2 2 2 4 7 15 19 23 29 36 47 54 61 68 CP 651N-M Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.4 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Cushion – – 5 7 15 23 51 64 74 92 119 136 164 189 218 CP 651N-L Cable load 30% – – – – 2 1 4 1 3 2 6 3 14 5 13 5 16 7 20 8 25 10 31 11 38 12 43 12 48 15 CP 651N-M CP 651N-S 4 3 1 2 2 3 6 8 9 11 13 15 16 18 21 CP 651N-S Cable load 10% – – – 3 2 2 5 2 1 8 2 1 18 3 2 31 6 3 63 13 6 76 16 7 90 20 8 118 26 10 148 32 12 169 39 13 201 48 15 232 55 16 278 61 19 CP 651N-L CP 651N-M CP 651N-S – – – – 12 20 36 40 52 66 78 86 109 120 136 CP 651N-L Cable load 60% – – – – – – – – 4 2 5 3 9 4 11 4 12 6 13 6 18 8 24 9 31 10 36 10 41 12 CP 651N-M CP 651N-S Cable penetrations through walls with cable diameters ≤ 16 mm Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.4 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Cushion 0 3 6 8 16 32 65 80 96 128 160 182 215 257 298 CP 651N-L Cable load 0% 1 2 2 2 4 7 15 19 23 29 36 47 54 61 68 CP 651N-M 4 3 1 2 2 3 6 8 9 11 13 15 16 18 21 CP 651N-S – 3 5 8 17 29 59 72 86 105 144 164 180 206 269 CP 651N-L Cable load 10% – – 2 2 2 1 2 1 3 2 6 3 13 6 16 7 20 8 26 10 32 12 39 13 48 15 55 16 61 18 CP 651N-M CP 651N-S 9LVLWWKH+LOWL)LUHVWRS'HVLJQ&HQWUH5HJLVWHUWRGD\DWZZZKLOWLFRXNFIV Cable penetrations through walls with cable diameters ≤ 16 mm Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.4 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Cushion – – 4 6 11 23 45 56 67 82 112 128 158 181 208 CP 651N-L Cable load 30% – – – – 2 1 3 1 3 2 6 2 11 4 13 5 16 6 20 8 25 9 33 11 39 11 43 12 48 15 CP 651N-M CP 651N-S – – – – 9 14 26 33 41 54 65 76 87 104 121 CP 651N-L Cable load 60% – – – – – – – – 5 3 5 3 8 4 11 4 12 6 13 6 18 8 24 9 31 10 36 10 41 12 CP 651N-M CP 651N-S Floor assembly Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Cushion 0 0 3 5 9 20 30 42 52 63 73 CP 651N-L Cable load 0% 1 2 3 4 5 10 15 21 26 31 36 CP 651N-M 1 3 2 2 2 4 8 9 12 14 16 CP 651N-S – 1 2 5 11 22 32 46 57 69 81 CP 651N-L Cable load 10% – – 2 3 4 3 3 2 5 2 10 4 14 8 18 8 21 10 23 12 25 15 CP 651N-M CP 651N-S Opening (m2) 0.01 0.02 0.04 0.05 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Cushion – – 3 6 9 18 26 34 42 49 57 CP 651N-L Cable load 30% – – – – 2 2 2 2 4 3 7 4 11 5 15 6 18 8 22 10 26 12 CP 651N-M CP 651N-S – – – – 7 12 18 24 28 33 39 CP 651N-L Cable load 60% – – – – – – – – 3 1 4 2 6 3 8 5 10 6 13 7 15 9 CP 651N-M CP 651N-S +LOWL2XWSHUIRUP2XWODVW CP 651N Additional Properties of CP 651N – Firestop Cushion Property Test regime Fire BS EN 1366-3 ETA Acoustic EN ISO 20 140-10: 1992 BS EN ISO 1403:1995 EN ISO 20 140-10: 1992 EN ISO 20 140-10: 1992 Notes 58 dB Dnw 50 dB Rw Dn,e,wtest results obtained 58 dB Blank Dn,e,w, 57 dB Cables Ageing DIBT DAfSTB Fire test after ageing VOC LEED 2009 Chemical Resistance Contact Hilti Technical Advisory Service with details of type, concentration, duration and ambient temperature of exposure conditions LEED 3.0 6.6 g/l N.R Not relevant Meets standard Hilti (Gt. Britain) Limited, Telephone: 1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY 0800 886 100 CP 651N CP 651N –Firestop cushion - BREEAM criteria BREEAM Section Management construction site impact Health and wellbeing Energy Materials No power tools required for installation (no energy source required) Dust free installation Saves water during application No water pollution Low VOC* (air quality) No ozone depletion potential (ODP) Low global warming potential (GWP) Smoke and gas tightness Noise reduction Air tightness NA Avoidance of air infiltration Product Carbon Footprint or LCA Data Thermal insulation NA Recycling of packaging Waste Reuse of materials Re-penetration in existing opening (No waste) Product contributes to Green Building under this clause Not applicable for this product Product makes No contribution to green Building under this clause NA Hilti (Gt. Britain) Limited, Telephone: 1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY 0800 886 100 CP 651N CP 651N –Firestop cushion - NBS specification clauses This page is to be used in conjunction with the NBS Specification clauses in the introduction to the Hilti Firestop Specifiers Binder. Application: Imperfections of fit of building components and Service penetrations through fire rated walls and floors requiring treatment to reinstate the fire performance of said walls and floors P12 FIRE STOPPING SYSTEMS PRODUCTS 345 INTUMESCENT PILLOWS • Composition: sealed polythene bags contained within a glass fibre outer containing graphite and vermiculite granules that intumesce to provide a fire rated barrier for service penetrations in solid walls and floors and partition walls when packed into opening in layers. CP 651N use to Firestop inside cable trunking. • Tested to BS 476: Part 20: 1987 and BS EN 1366-3:2004. • Fire resistance: up to 4 hours • Age tested as defined in the DafStb guidelines, with subsequent fire testing. • Manufacturer: Hilti (Gt Britain) Ltd, 1Trafford Wharf Road, Manchester M17 1BY, Tel no 0800 886 100, Fax 0800 886 200. Website www.hilti.co.uk. - Product Reference: CP 651N Intumescent Cushions Hilti (Gt. Britain) Limited, Telephone: 1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY 0800 886 100 CP 651N Visit our web site at www.Hilti.co.uk/cfs to access our Firestop Design Centre Penetration product selector Interactive product selector for firestopping openings through walls and floors Other product features Find out more about the benefits of using Hilti firestop systems Joints product selector Interactive product selector for wall to wall, top of wall, curtain wall , floor to floor and floor to wall applications. Important note: All sales are subject to Hilti (Gt Britain) Ltd. “Terms and Conditions of Sale”. Copies of these “Terms and Conditions of sale” are available on request. All descriptions and illustrations in this publication are intended for guidance only and shall not constitute a “sale by description / picture”. All dimensions given are nominal and Hilti (Gt Britain) Limited may change the information, products and specifications from time to time for a variety of reasons, without prior notice. The information in this publication is provided “as is” at the date specified on the front cover. (Updates will not be issued automatically) This information is not intended to have any legal effect, whether by way of advice, representation or warranty (express or implied). Hilti (Gt Britain) Ltd accepts no liability whatsoever (to the extent permitted by law) if you place any reliance on this publication and you must do so at your own risk. RETURNS AND CANCELLATIONS Subject to condition 6.3 of the Company’s Terms and Conditions, Goods supplied pursuant to the Contract cannot be returned without the Company’s prior written authorisation. Duly authorised returns: • shall be sent to the Company’s premises at the Buyer’s expense; • may be subject to a handling charge of £10 or 20% Hilti Gt. Britain Ltd) of the value of the Goods, whichever amount is the greater; and • Must be in the same condition as originally supplied to the Buyer. • The Buyer may not cancel an order of the Goods including but without limitation, any Goods that involve special requirements of the Buyer once the order has been inputted onto the Company’s ordering system, without the prior written consent of the Company. Right of technical and programme changes reserved S.E&O; no liability accepted for printing errors or other deficiencies, earlier catalogues are thus rendered non valid. Hilti = registered trademark of Hilti Corp. Schaan Hilti (Gt. Britain) Limited, Telephone: 1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY 0800 886 100