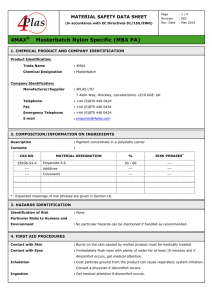

Product Portfolio

advertisement