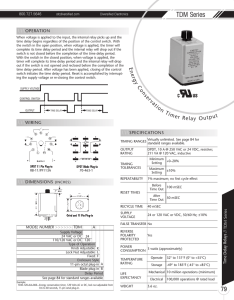

Solid State Relays

advertisement