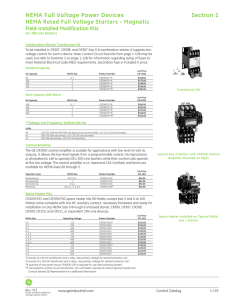

Standard Low Voltage Drive Products

advertisement