Flexible Conduits and Fittings

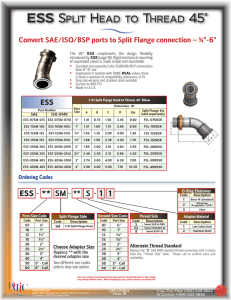

advertisement