General Arrangement - Cooper Crouse

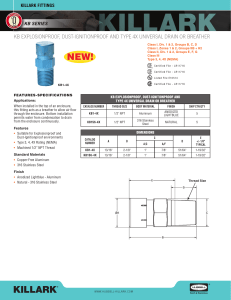

advertisement

CONTENTS

INTRODUCTION

Company Profile

QUALITY CERTIFICATE

EN ISO 9001: 2000.

NEXT - Steel Enclosure Range

Product specification.

Product technical parameters.

General arrangement drawing.

Ex-Cell - Steel Enclosure Range

Product specification.

Product technical parameters.

General arrangement drawing.

STB - Steel Enclosure Range

Product specification.

Product technical parameters.

General arrangement drawing.

HVB - Steel Enclosure Range

Product specification.

Product technical parameters.

General arrangement drawing.

Kestrel – GRP Enclosure Range

Product specification.

Product technical parameters.

General arrangement drawing.

Enclosure Product Range Size Chart

Customised Enclosure Services

Cooper Crouse- Hinds UK Ltd. is an EN ISO 9001: 2000 registered company manufacturing a range of high

quality and robust junction boxes, enclosures and custom electrical assemblies. These have been designed and

engineered to meet the requirements of both the most demanding hazardous area, marine and heavy industrial

environmental applications.

With over 30 years of experience in the design, engineering and manufacture of enclosures and custom electrical

assemblies, Cooper Crouse-Hinds provides proven, tried and tested solutions using quality materials and

processes to provide products to endure the toughest environmental conditions for project and installation

requirements.

Our core manufacturing expertise is in the manufacture of metallic fabricated enclosures in both steel and various

grades of stainless steel. These enclosures are available in options of different material finishes including electropolished, powder coated or natural finish, depending on the material and application.

The enclosure product lines are designed and ATEX certified for hazardous areas, UL certified for heavy industrial

applications and are used predominantly in the very demanding petro-chemical, pharmaceutical, food process and

utilities market sectors.

As a result of this our enclosure have the inherent benefits of a high degree of ingress protection (IP) to

environmental characteristics such as ingress of water and dust. The ingress protection (IP) of all of our product

line is IP66 (water & dust), additionally our enclosure product lines have an impact resistance of a minimum of 7Nm

to maintain IP66.

The Crouse-Hinds enclosure product line is renowned worldwide for quality, performance, longevity, and value.

This reflected by an impressive portfolio of global customers that include the majority of major; oil companies and

pharmaceutical companies worldwide.

In addition to our standard range enclosure products we also manufacture many customised enclosure products for

OEM customers that require an enclosure to meet a defined specification. These maybe variations on a standard

product range to accommodate a customer’s products or assemblies; alternatively it could be a custom design for a

specific application.

At Crouse-Hinds we also undertake sub-contract works using our highly skilled and motivated work force in our

modern production facility that has a comprehensive plant portfolio to provide a number or combination of services,

these include:

Design & Engineering.

Punching & Forming.

Welding

Electro-polishing (Stainless Steel)

Polyester Powder Coating.

Electrical Sub-Assembly.

C E R T I F I C A T E

DQSGmbH

DeutscheG€€tlschaft alr ZertfizigunS von Managenentsyatamon

herebycertifiesthat the company

/

GOOPERCrouse-Hinds

Oouse-HindsGmbH

COOPER

26

SenatorschwaE-Ring

59494Soest

withthe organEational

univsites as listedin the annex

for the scope

productjon

ProtectedPrcductsandSystems

Development,

andsalesof Explooion

and hazadousareaapplications,

for bothnonhazardous

standardandcustombuildenclosures

Emergency

Ughtingsand Emergency-Lrenungsystems

andmaintains

a

hasimplemented

System.

QualityManaglement

in a rcport,hasledfiedthat this

Anaudit,documented

qualitymanagement

systemfulfillstho requiEments

of the followingstandard:

DIN EN ISO9OO1: 20OO

December

2000 editron

thi6 certincateis vahduntil

2004-09-26

Ceftific€teRegstrationNo-

000,|:,1QM

F-dnkfurtam ldain

2005'0927

{^'ttt

ls, iu. M, Dcdrsel

MANAGING

OIRECTOfiS

l{}Net

0$043

Franktunan Man, Arglst'Schdnz-St?6e 21

@

Annex to Certificate Registration No.: (X)O4:11QM

>age117

Crouse-HindsGmbH

COOPER

Senator-Sch\,!€t_Ring26

59494 S'oest

CooperCrouse-HindsGmbH

GooperClouse-HindsAS

Neuerweg - Nord 49

D-69412Ebebach

Hus€bysletta9

N'3412 Uestranda

NOlwegen

CEAGNotlichtslrstemo GmbH

Cooper Crouse-Hinds(UK) Ltd.

26

Senator'SchwarE-Ring

D"59494 Soest

llarardous Arca Divialon

ljnit G, Quinnclose

SevenStars IndustnalEstat4whitley

coventry

CV34LH

England

CooperCrouse-HindsGmbH

CooperClouse-HindsB.V.

BuBmatten

10-12

D'77815B0huBaden

P.O.Box1(]23

NL-3004EHRotterdam

TheNetherlands

CoopelCrouse-HindsS.A.

CooperClouse-Hinds

Avda.SantaEulalia,290

ES-O8223Tenassa(Barcelona)

Spain

B.V.

BFnch of CooperCrcuse-Hinds

Registercd

GemeenGplein26

B-3010lGsseLo

Belgum

(UK)Ltd.

CooperCrouse-Hinds

EncloaureDMslon

Do.set Road

Sheemess,

KentlVE121 LP

EnEland

Thisannexis onlyvalidin connection

with the above-mentionedcenificate.

Cooper Crouse-Hinds are premier manufactures of high quality and robust enclosure solutions and

assemblies configured to meet the requirements of the most demanding hazardous area and industrial

environmental applications. With over 30 years of experience in the design, engineering and

manufacture of enclosure solutions, Cooper Crouse-Hinds provides, tried and tested solutions to meet

the toughest project and installation needs.

The NEXT range is an “ATEX certified” heavy-duty enclosure solution fully compliant with the impact,

thermal and ingress protection requirements of EN50014. These are available in a wide range of sizes

to meet a diverse range of applications.

With our customizing service fittings such as cable glands, breather drains and blanking plugs can be

provided and fitted as specified. Additionally appropriately certified components such instrument

transmitters and field-bus modules maybe fitted to provide fully certified OEM solutions.

Using the highest quality materials and design benefits the NEXT enclosure range is the industry

benchmark for quality and performance enclosure solutions for both electrical and instrumentation

applications.

The retained stainless steel slotted

hex bolt fastenings provide a rapid

means of achieving high integrity

ingress protection (IP) of 66 for

reliable & rapid environmental

protection.

The high integrity “single piece”

sealing gasket for superior ingress

protection (IP) of 66 and excellent

recovery and re-sealing properties for

continuous environmental protection.

Material / Finish Options

An integral drainage channel

prevents liquids or other solids

contaminates from running in or

falling into the enclosure when

the door is opened, and to minimize

gasket path contamination.

An integral external & internal

feed through brass earth / ground

stud assembly enables rapid and

reliable protective earth / ground

connection mounted on the side of

the enclosure for ease of access.

316L Stainless Steel (1.4404 to EN 10088) with superior “corrosion resistant” electro chemical polish.

Sheet Steel - Polyester powder coated to RAL 7032.

Gasket Material

Door Fixing

High integrity “one piece” closed cell chloroprene or optional silicone gasket.

Detachable hinged door, stainless steel hinges with captive stainless steel hex fastening screws.

Enclosure Mounting

Equipment Mountings

Gland Plates

Enclosure Earth

4 x external welded lugs, 11mm Ø holes / slots.

4 x stand off pillars 9mm Ø, 25mm high, tapped M6 x10, for rail or mounting plate.

Optional 3mm thick gland plates available in bottom, top, left and right configurations.

M10 internal / external brass earth stud assembly M6 internal stud on lid & painted gland plates.

Certified Ingress Protection (IP) Rating

IP66 to EN60529.

Certified Operating Temp Range

Chloroprene gasket

Optional Silicone gasket

Certified Ambient Temp Range

Chloroprene gasket

Deluge Test (Shell)

Spec. No. DTS 01.

-45°C (-49°F) to +80°C (176°F)

-65°C (-85°F) to +135°C (-275°F)

-45°C (-49°F) to +40°C (104°F) for T6.

-45°C (-49°F) to +55°C (131°F) for T5.

Optional Silicone gasket

-65°C (-85°C) to +40°C (104°F) for T6.

-65°C (-85°F) to +55°C (131°F) for T5.

Certified Impact Resistance

Certification

7 J (Nm) to EN 50014.

ATEX ll 2 GD EEx e II T6 or T5. (KEMA99ATEX3172X).

GOST-R.

AEx Class 1 Zone 1 AEx e II T6.

cULus toUL50 / C22.2 no. 94-M91, types 3S, 4X.

Germanischer Lloyd.

Enclosure / terminal assemblies configured to meet clients specification within certification parameters.

Refer to our website: www.enclosures-crouse-hinds.uk.com for further company & product information.

REV. 0205

NEXT ENCLOSURE TECHICAL DATA

DIMENSIONS IN MM

(HEIGHT X W IDTH X DEPTH)

229 x 152

x 130

260 x 260

x 160

260 x 260

x 205

306 x 306

x 160

306 x 306

x 205

380 x 260

x 160

380 x 260

x 205

458 x 382

x 160

458 x 382

x 205

480 x 480

x 205

500 x 350

x 205

620 x 450

x 205

740 x 550

x 205

762 x 508

x 205

860 x 640

x 205

914 x 610

x 205

980 x 740

x 205

FIXING CENTRES

152 x 208*

170 x 316

170 x 316

20 3 x 361*

20 3 x 361*

250 X 316

250 X 316

305 x 437*

305 x 437*

327 x 535*

350 x 406

450 x 506

540 x 606

508 x 564*

570 x 696

559 x 666*

700 x 796

CCH PART NUMBER

NXT221513

NXT262616

NXT262620

NXT303016

NXT303020

NXT382616

NXT382620

NXT453816

NXT453820

NXT484820

NXT503520

NXT624520

NXT745520

NXT765020

NXT866420

NTX916120

NXT987420

"TB" SIZE CROSS REFERENCE

TB 10 -130

NONE

NONE

TB11 -150

TB11 - 200

NONE

NONE

TB12 - 150

TB 12 - 200

TB 12A - 200

NONE

NONE

NONE

TB 13 - 200

NONE

TB14 -200

NONE

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

3.25

5.50

5.50

7.00

7.00

7.00

7.00

9.75

9.75

10.40

10.50

17.00

30.40

23.50

29.00

31.00

38.00

129

52

149

72

160

160

180

180

160

160

180

180

206

206

226

226

206

206

226

226

280

180

300

160

280

180

300

160

358

282

378

302

358

282

378

302

380

380

400

400

400

260

420

270

520

350

540

370

640

450

660

470

662

408

682

428

760

540

780

560

814

510

834

530

880

640

900

660

58 x 108

58 x 108

58 x 108

214 x 80

114 x 80

114 x 80

214 x 124

114 x 124

114 x 124

261 x 80

214 x 80

261 x 80

261 x 124

214 x 124

261 x 124

214 x 80

214 x 80

214 x 80

214 x 124

214 x 124

214 x 124

337 x 80

337 x 80

337 x 80

337 x 124

337 x 124

337 x 124

404 x 124

337 x 124

404 x 124

304 x 124

304 x 124

304 x 124

404 x 124

404 x 124

404 x 124

504 x 124

504 x 124

504 x 124

404 x 124

594 x 124

594 x 124

594 x 124

2 x (304 x 124)

2 x (304 x 124)

566 x 108

566 x 108

566 x 108

2 x (304 x 124)

2 x (404 x 124)

2 x (404 x 124)

TOP & BOTTOM

M16

M20

M25

M32

M40

M50

M63

6

3

2

1

0

0

0

20

10

6

3

3

2

0

28

15

12

6

5

2

2

26

14

8

4

3

3

0

34

20

15

8

6

3

2

20

10

6

3

3

2

0

28

15

12

6

5

2

2

29

18

10

6

5

4

0

46

26

21

11

9

4

3

53

30

24

14

11

5

4

40

24

18

10

7

4

3

53

30

24

14

11

5

4

60

39

30

18

13

6

5

53

30

24

14

11

5

4

82

47

39

20

17

7

6

72

42

24

18

8

7

6

80

48

36

20

14

8

6

LEFT

M16

M20

M25

M32

M40

M50

M63

6

3

2

1

0

0

0

9

6

3

2

1

1

0

18

9

5

4

2

1

1

20

10

6

3

3

2

0

28

15

12

6

5

2

2

20

10

6

3

3

2

0

28

15

12

6

5

2

2

29

18

10

6

5

4

0

46

26

21

11

9

4

3

46

26

21

11

9

4

3

40

24

18

10

7

4

3

53

30

24

14

11

5

4

60

39

30

18

13

6

5

82

47

39

20

17

7

6

80

48

36

20

14

8

6

72

42

24

18

8

7

6

106

60

48

28

22

10

8

RIGHT

M16

M20

M25

M32

M40

M50

M63

6

3

2

1

0

0

0

9

6

2

3

1

1

0

18

9

5

4

2

1

1

26

14

8

4

3

3

0

34

20

15

8

6

3

2

20

10

6

3

3

2

0

28

15

12

6

5

2

2

29

18

10

6

5

4

0

46

26

21

11

9

4

3

53

30

24

14

11

5

4

40

24

18

10

7

4

3

53

30

24

14

11

5

4

60

39

30

18

13

6

5

82

47

39

20

17

7

6

80

48

36

20

14

8

6

72

42

24

18

8

7

6

106

60

48

28

22

10

8

(Vert. X Horiz.)

NOTE : 123* - Subtract 30mm when no side gland plates

MATERIAL THICKNESS

BODY

DOOR

WEIGHT IN KG.

(EMPTY ENCLOSURE)

TERMINAL MOUNTING RAIL

RAIL FIXING CENTRE

RAIL LENGTH

VERT

HORZ

VERT

HORZ

AVAILABLE GLANDING AREA

TOP & BOTTOM

LEFT

RIGHT

MAXIMUM ENTRIES

TERMINAL CONTENT

Terminal Type (thk)

Row Orientation

WDU 2.5 (5)

VERT

1 x 21

2 x 27

2 x 27

2 x 36

2 x 36

2 x 51

2 x 51

2 x 67

2 x 67

3 x 71

3 x 75

4 x 99

5 x 124

3 x 128

6 x 147

5 x 158

6 x 171

WDU 4 (6)

VERT

1 x 17

2 x 23

2 x 23

2 x 30

2 x 30

2 x 43

2 x 43

2 x 56

2 x 56

3 x 59

2 x 63

3 x 83

4 x 103

3 x 106

5 x 123

5 x 132

6 x 143

WDU 6 (8)

VERT

1 x 13

1 x 17

1 x 17

2 x 23

2 x 23

1 x 32

1 x 32

2 x 42

2 x 42

3 x 44

2 x 47

3 x 62

4 x 77

3 x 80

5 x 92

4 x 99

5 x 107

WDU 10 (10)

VERT

1 x 10

1 x 13

1 x 13

2 x 18

2 x 18

1 x 25

1 x 25

2 x 33

2 x 33

3 x 35

2 x 37

3 x 49

4 x 61

3 x 64

4 x 73

4 x 79

5 x 85

SAK 2.5 (6)

VERT

1 x 17

2 x 23

2 x 23

2 x 30

2 x 30

2 x 43

2 x 43

3 x 56

3 x 56

4 x 59

3 x 63

4 x 83

5 x 103

4 x 106

6 x 143

5 x 132

8 x 143

SAK 4 (6.5)

VERT

1 x 16

2 x 21

2 x 21

2 x 28

2 x 28

2 x 39

2 x 39

3 x 51

3 x 51

4 x 55

3 x 58

4 x 67

4 x 95

4 x 98

5 x 113

5 x 121

7 x 132

SAK 6 (8)

VERT

1 x 13

2 x 17

2 x 17

2 x 23

2 x 23

2 x 32

2 x 32

3 x 42

3 x 42

4 x 44

3 x 47

3 x 62

4 x 77

4 x 80

5 x 92

5 x 99

6 x 107

SAK 10 (10)

VERT

1 x 10

2 x 13

2 x 13

2 x 18

2 x 18

2 x 25

2 x 25

3 x 33

3 x 33

4 x 35

3 x 37

3 x 49

4 x 61

4 x 64

5 x 73

5 x 79

6 x 85

NOTES : -

1. The information provided is based on the physical constraints of the enclosure.

2. This information is for guidance purposes only.

Please refer to the certificate for hazardous area applications.

Cooper Crouse-Hinds UK Ltd reserves the right to make any necessary changes without notice

PLEASE REFER TO SEPARATE DATA SHEET FOR "LANDSCAPE" SIZES.

REV. 0205

NEXT - LANDSCAPE ENCLOSURE TECHNICAL DATA

DIMENSIONS IN mm

(HEIGHT X WIDTH X DEPTH)

306 x 350

x 205

380 x 450

x 205

458 x 550

x 205

500 x 640

x 205

FIXING CENTRES (Vert. X Horiz.)

203 x 405

250 x 506

305 x 606

350 x 696

NXT303520

NXT384520

NXT455520

NXT506420

1.5

1.5

1.5

1.5

1.5

1.5

2.0

2.0

7.7

10.6

14.9

20.9

206

250

226

270

280

350

300

370

358

450

378

470

400

540

420

560

304 x 124

214 x 124

258 x 124

404 x 124

214 x 124

214 x 124

504 x 124

334 x 124

334 x 124

594 x 124

404 x 124

404 x 124

M16

M20

M25

M32

M40

M50

M63

40

24

18

10

7

4

3

53

30

24

14

11

5

4

60

39

30

18

13

6

5

82

47

39

20

17

7

6

LEFT

M16

M20

M25

M32

M40

M50

M63

28

15

12

6

5

2

2

28

15

12

6

5

2

2

44

26

21

11

9

4

3

53

30

24

14

11

5

4

RIGHT

M16

M20

M25

M32

M40

M50

M63

34

18

15

8

6

3

2

28

15

12

6

5

2

2

44

26

21

11

9

4

3

53

30

24

14

11

5

4

Terminal Type (thk)

Row Orientation

WDU 2.5 (5)

VERT

3 x 36

4 x 36

5 x 67

6 x 75

WDU 4 (6)

VERT

2 x 30

3 x 36

4 x 56

5 x 63

WDU 6 (8)

VERT

2 x 23

3 x 30

4 x 42

5 x 47

WDU 10 (10)

VERT

2 x 18

3 x 23

4 x 33

4 x 37

CCH PART REFERENCE

MATERIAL THICKNESS, mm

BODY

DOOR

WEIGHT IN Kg (Empty)

TERMINAL MOUNTING RAIL

RAIL FIXING CENTRES

VERT

HORZ

VERT

HORZ

OVERALL RAIL LENGTH

AVAILABLE GLANDING AREA

TOP & BOTTOM

LEFT

RIGHT

MAXIMUM ENTRIES

TOP & BOTTOM

TERMINAL CONTENT

Please refer to NOTES on main data sheet for NexT enclosures

NEXT ENCLOSURE TECHICAL DATA

(Imperial)

ALL DIMENSIONS IN INCHES

(HEIGHT X W IDTH X DEPTH)

REV.0205

9.02 x 5.98

x 5.12

10.24 x 10.24

x 6.3

10.24 x 10.24

x 8.07

12.05 x 12.05

x 6.3

12.05 x 12.05

x 8.07

14.96 x 10.24

x 6.3

14.96 x 10.24

x 8.07

18.03 x 15.04

x 6.3

18.03 x 15.04

x 8.07

18.9 x 18.9

x 8.07

19.69 x 13.78

x 8.07

24.41 x 17.72

x 8.07

29.13 x 21.65

x 8.07

30 x 20

x 8.07

33.86 x 25.2

x 8.07

35.98 x 24.02

x 8.07

38.58 x 29.13

x 8.07

(Vert. X Horiz.)

5.98 x 8.19*

NOTE : 123* - Subtract 1.18"mm when no side gland plates

6.69 x 12.44

6.69 x 12.44

0.79 x 1.42*

0.79 x 1.42*

9.84 x 12.44

9.84 x 12.44

12.01 x 17.2*

12.01 x 17.2*

12.87 x 21.06*

13.78 x 15.98

17.72 x 19.92

21.26 x 23.86

20 x 22.2*

22.44 x 27.4

22.01 x 26.22*

27.56 x 31.34

CCH PART NUMBER

NXT221513

NXT262616

NXT262620

NXT303016

NXT303020

NXT382616

NXT382620

NXT453816

NXT453820

NXT484820

NXT503520

NXT624520

NXT745520

NXT765020

NXT866420

NTX916120

NXT987420

TB / TBX PART No. CROSS REFERENCE

TB 10 -130

NONE

NONE

TB11 -150

TB11 - 200

NONE

NONE

TB12 - 150

TB 12 - 200

TB 11 - 200

NONE

NONE

NONE

TB 13 - 200

NONE

TB14 -200

NONE

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

7.15

12.10

12.10

15.40

15.40

15.40

15.40

21.45

21.45

22.88

23.10

37.40

66.88

51.70

63.80

68.20

83.60

5.08

2.05

5.87

2.83

6.30

6.30

7.09

7.09

6.30

6.30

7.09

7.09

8.11

8.11

8.90

8.90

8.11

8.11

8.90

8.90

11.02

7.09

11.81

6.30

11.02

7.09

11.81

6.30

14.09

11.10

14.88

11.89

14.09

11.10

14.88

11.89

14.96

14.96

15.75

15.75

15.75

10.24

16.54

10.63

20.47

13.78

21.26

14.57

25.20

17.72

25.98

18.50

26.06

16.06

26.85

16.85

29.92

21.26

30.71

22.05

32.05

20.08

32.83

20.87

34.65

25.20

35.43

25.98

Top & Bot

LEFT

RIGHT

4.25 x 2.28

4.25 x 2.28

4.25 x 2.28

8.43 x 3.15

4.49 x 3.15

4.49 x 3.15

8.43 x 4.88

4.49 x 4.88

4.49 x 4.88

10.28 x 3.15

8.43 x 3.15

10.28 x 3.15

10.28 x 4.88

8.43 x 4.88

10.28 x 4.88

8.43 x 3.15

8.43 x 3.15

8.43 x 3.15

8.43 x 4.88

8.43 x 4.88

8.43 x 4.88

13.27 x 3.15

13.27 x 3.15

13.27 x 3.15

13.27 x 4.88

13.27 x 4.88

13.27 x 4.88

15.91 x 4.88

13.27 x 4.88

15.91 x 4.88

11.97 x 4.88

11.97 x 4.88

11.97 x 4.88

15.91 x 4.88

15.91 x 4.88

15.91 x 4.88

19.84 x 4.88

19.84 x 4.88

19.84 x 4.88

15.91 x 4.88

23.39 x 4.88

23.39 x 4.88

23.39 x 4.88

2 x (11.97 x 4.88)

2 x (11.97 x 4.88)

22.28 x 4.25

22.28 x 4.25

22.28 x 4.25

2 x (11.97 x 4.88)

2 x (15.91 x 4.88)

2 x (15.91 x 4.88)

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

3

2

2

0

0

0

0

11

4

4

3

2

0

0

17

12

7

5

2

2

2

13

5

4

4

3

0

0

20

15

8

7

3

2

2

11

4

4

3

2

0

0

17

12

7

5

2

2

2

18

7

6

5

4

0

0

27

21

11

9

4

3

3

33

26

14

11

5

4

3

24

18

10

8

4

3

2

33

26

14

11

5

4

3

41

32

18

14

6

5

4

33

26

14

11

5

4

3

48

39

21

17

7

6

5

47

24

20

8

7

6

5

48

36

20

16

7

5

4

LEFT

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

3

2

2

0

0

0

0

5

2

2

1

1

0

0

8

6

3

2

1

1

1

11

4

4

3

2

0

0

17

12

7

5

2

2

2

11

4

4

3

2

0

0

17

12

7

5

2

2

2

18

7

6

5

4

0

0

27

21

11

9

4

3

3

27

21

11

9

4

3

3

24

18

10

8

4

3

2

33

26

14

11

5

4

3

41

32

18

14

6

5

4

48

39

21

17

7

6

5

48

36

20

16

7

5

4

47

24

20

8

7

6

5

66

51

28

22

9

7

6

RIGHT

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

3

2

2

0

0

0

0

5

2

2

1

1

0

0

8

6

3

2

1

1

1

13

5

4

4

3

0

0

20

15

8

7

3

2

2

11

4

4

3

2

0

0

17

12

7

5

2

2

2

18

7

6

5

4

0

0

27

21

11

9

4

3

3

33

26

14

11

5

4

3

24

18

10

8

4

3

2

33

26

14

11

5

4

3

41

32

18

14

6

5

4

48

39

21

17

7

6

5

24

18

10

8

4

3

2

47

24

20

8

7

6

5

33

26

14

11

5

4

3

FIXING CENTRES

MATERIAL THICKNESS in mm

BODY

DOOR

WEIGHT IN POUNDS

(EMPTY ENCLOSURE)

TERMINAL MOUNTING RAIL

RAIL FIXING CENTRES

VERT

HORZ

VERT

HORZ

RAIL LENGTH

AVAILABLE GLANDING AREA

MAXIMUM ENTRIES

TOP & BOTTOM

TERMINAL CONTENT

Terminal Type (thk)

Row Orientation

WDU 2.5 (5)

VERT

1 x 21

2 x 27

2 x 27

2 x 36

2 x 36

2 x 51

2 x 51

2 x 67

2 x 67

3 x 71

3 x 75

4 x 99

5 x 124

3 x 128

6 x 147

5 x 158

6 x 171

WDU 4 (6)

VERT

1 x 17

2 x 23

2 x 23

2 x 30

2 x 30

2 x 43

2 x 43

2 x 56

2 x 56

3 x 59

2 x 63

3 x 83

4 x 103

3 x 106

5 x 123

5 x 132

6 x 143

WDU 6 (8)

VERT

1 x 13

1 x 17

1 x 17

2 x 23

2 x 23

1 x 32

1 x 32

2 x 42

2 x 42

3 x 44

2 x 47

3 x 62

4 x 77

3 x 80

5 x 92

4 x 99

5 x 107

WDU 10 (10)

VERT

1 x 10

1 x 13

1 x 13

2 x 18

2 x 18

1 x 25

1 x 25

2 x 33

2 x 33

3 x 35

2 x 37

3 x 49

4 x 61

3 x 64

4 x 73

4 x 79

5 x 85

SAK 2.5 (6)

VERT

1 x 17

2 x 23

2 x 23

2 x 30

2 x 30

2 x 43

2 x 43

3 x 56

3 x 56

4 x 59

3 x 63

4 x 83

5 x 103

4 x 106

6 x 143

5 x 132

8 x 143

SAK 4 (6.5)

VERT

1 x 16

2 x 21

2 x 21

2 x 28

2 x 28

2 x 39

2 x 39

3 x 51

3 x 51

4 x 55

3 x 58

4 x 67

4 x 95

4 x 98

5 x 113

5 x 121

7 x 132

SAK 6 (8)

VERT

1 x 13

2 x 17

2 x 17

2 x 23

2 x 23

2 x 32

2 x 32

3 x 42

3 x 42

4 x 44

3 x 47

3 x 62

4 x 77

4 x 80

5 x 92

5 x 99

6 x 107

SAK 10 (10)

VERT

1 x 10

2 x 13

2 x 13

2 x 18

2 x 18

2 x 25

2 x 25

3 x 33

3 x 33

4 x 35

3 x 37

3 x 49

4 x 61

4 x 64

5 x 73

5 x 79

6 x 85

NOTES : -

1. The information provided is based on the physical constraints of the enclosure.

2. This information is for guidance purposes only.

Please refer to the certificate for hazardous area applications.

Cooper Crouse-Hinds UK Ltd reserves the right to make any necessary changes without notice

PLEASE REFER TO SEPARATE DATA SHEET FOR "LANDSCAPE" SIZES.

NexT - "Landscape" ENCLOSURE TECHNICAL DATA

(Imperial)

ALL DIMENSIONS IN INCHES

(HEIGHT X WIDTH X DEPTH)

REV. 0205

12.05 x 13.78

x 8.07

14.96 x 17.72

x 8.07

18.03 x 21.65

x 8.07

19.69 x 25.2

x 8.07

CCH PART NUMBER

NXT303020

NXT382620

NXT453820

NXT503520

FIXING CENTRES (Vert. X Horiz.)

15.94 x 7.99

19.92 x 9.84

23.82 x 12.01

27.4 x 12.99

1.5

1.50

1.5

1.50

1.5

1.50

1.5

1.50

17.0

23.2

32.7

46.1

8.11

9.84

8.90

10.63

11.02

13.78

11.81

14.57

14.09

17.72

14.88

18.5

15.75

21.26

16.54

22.05

11.97 x 4.88

8.43 x 4.88

10.16 x 4.88

15.91 x 4.88

8.43 x 4.88

8.43 x 4.88

19.84 x 4.88

13.15 x 4.88

13.15 x 4.88

23.39 x 4.88

15.91 x 4.88

15.91 x 4.88

MATERIAL THICKNESS in mm

BODY

DOOR

WEIGHT in lbs (empty)

TERMINAL MOUNTING RAIL

RAIL FIXING CENTRES

OVERALL RAIL LENGTH

VERT

HORZ

VERT

HORZ

AVAILABLE GLANDING AREA

Top & Bot

LEFT

RIGHT

MAXIMUM ENTRIES

TOP & BOTTOM

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

Gland

38

23

18

10

8

3

3

/ Hub

/ 21

/ 12

/ 10

/ 8

/ 4

/ 3

/ 3

Gland

52

32

26

13

11

5

4

/

Hub

29

16

13

11

/ 5

/ 4

/ 4

LEFT

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

26

15

12

6

5

2

2

/ 14

/ 8

/ 6

/ 5

/ 2

/ 2

/ 2

26

15

12

6

5

2

2

/ 14

/ 8

/ 6

/ 5

/ 2

/ 2

/ 2

42

26

21

11

9

4

3

/ 23

/ 13

/ 11

/ 9

/ 4

/ 3

/ 3

52

32

26

13

11

5

4

29

16

13

11

/ 5

/ 4

/ 4

RIGHT

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

2" NPT

2 1/2" NPT

32

20

15

8

3

2

/ 18

/ 10

/ 8

/ 7

/ 3

/ 2

26

15

12

6

2

2

/ 14

/ 8

/ 6

/ 5

/ 2

/ 2

42

26

21

11

4

3

/ 23

/ 13

/ 11

/ 9

/ 3

/ 3

52

32

26

13

5

4

/

/

/

/

/

/

/

/

/

/

Gland

64

39

33

17

14

6

5

/

Hub

36

20

17

14

/ 6

/ 5

/ 5

/

/

/

/

Gland

78

47

39

20

17

7

6

/

Hub

42

24

21

17

/ 8

/ 6

/ 6

/

/

/

/

/

/

/

/

29

16

13

11

4

4

TERMINAL CONTENT

Terminal Type / Orientation

WDU 2.5N (5)

VERT

3 x 36

4 x 36

5 x 67

6 x 75

WDU 2.5 (5)

VERT

2 x 30

3 x 36

4 x 56

5 x 63

WDU 4 (6)

VERT

2 x 23

3 x 30

4 x 42

5 x 47

WDU 6 (8)

VERT

2 x 18

3 x 23

4 x 33

4 x 37

Please refer to NOTES on main data sheet for NexT enclosures

NexT (NXT) Range Enclosure - General Arrangement

Width

Rail Fixing Pillars

Height

Fixing Centres (vertical)

3rd hinge and

lid fixing screw

added on sizes

62/45 and over

Depth

Fixing Centres (horizontal)

NexT Rev. 0704

3rd angle projection

Cooper Crouse-Hinds are premier manufactures of high quality and robust enclosure solutions and

assemblies configured to meet the requirements of the most demanding hazardous area and industrial

environmental applications. With over 30 years of experience in the design, engineering and

manufacture of enclosure solutions, Cooper Crouse-Hinds provides, tried and tested solutions to meet

the toughest project and installation needs.

The Ex-Cell range is an “ATEX certified” heavy-duty enclosure solution fully compliant with the impact,

thermal and ingress protection requirements of EN50014. These are available in a wide range of sizes

to meet a diverse range of applications.

With our customizing service fittings such as cable glands, breather drains and blanking plugs can be

provided and fitted as specified. Additionally appropriately certified components such instrument

transmitters and field-bus modules maybe fitted to provide fully certified OEM solutions.

Using the highest quality materials and design benefits the Ex-Cell enclosure range is the industry

benchmark for quality and performance enclosure solutions for both electrical and instrumentation

applications.

The ¼ turn lock or the retained

stainless steel slotted hex bolt

fastenings provide a rapid means

of achieving high integrity ingress

protection (IP) of 66 for reliable &

rapid environmental protection.

Material / Finish

The high integrity “single piece”

sealing gasket for superior ingress

protection (IP) of 66 and excellent

recovery and re-sealing properties for

continuous environmental protection.

An integral drainage channel

prevents liquids or other solids

contaminates from running in or

falling into the enclosure when

the door is opened, and to minimize

gasket path contamination.

An integral external & internal

feed through brass earth / ground

stud assembly enables rapid and

reliable protective earth / ground

connection mounted on the side of

the enclosure for ease of access.

316L Stainless Steel (1.4404 to EN 10088) with superior “corrosion resistant” electro chemical polish.

304 (1.4301 to EN 10088) Stainless Steel with superior “corrosion resistant” electro chemical polish.

Sheet Steel - Polyester powder coated to RAL 7032.

Gasket Material

High integrity “one piece” foam in place polyurethane gasket.

Optional Chloroprene closed cell sponge gasket.

Door Fastening

Chromium plated Zinc ¼ turn lock with stainless steel hinges (two latches fitted on sizes 50cm(20”) high and above)

(Double bit lock supplied as standard with other key options on request)

Captive stainless steel bolt door fastenings available on request.

(Optional factory fitted padlock hasp available on request)

Enclosure Mounting

Equipment Mountings

Gland Plates

Enclosure Earth

Certified IP Rating

Certified Ambient Temp Range

4 x external 3mm welded lugs11mm Ø holes / slots, vertical or horizontal.

4 x stand off pillars 9mm Ø, 25mm high, tapped M6 x10, for rail / mounting plate.

Optional 3mm thick gland plates available in bottom, top, left and right configurations.

M10 internal / external brass earth stud assembly M6 internal stud on lid & painted gland plates.

Certified IP66 to EN60529.

Polyurethane foam in place gasket -20°C (-4°F) to +60°C (140°F)

Chloroprene closed cell sponge gasket -40°C (-40°F) to +55°C (140°F)

Certified Impact Resistance

Certification

7 J (Nm) to EN 50014.

ATEX ll 2 GD EEx e ll T6. (PTB02ATEX1014)

GOST-R.

cULus toUL50 / C22.2 no. 94-M91, types 3S, 4X.

Enclosure / terminal assemblies configured to meet clients specification within certification parameters.

Refer to our website: www.enclosures-crouse-hinds.uk.com for further company & product information.

TECHNICAL DATA SHEET

Ex-Cell Range Enclosure

CCH PART NUMBER

DIMENSIONS OVERALL, mm

XLH 231513

XLH 262615

XLH 302015

XLH 303015

XLH 403015

XLH 404015

XLH 405015

XLH 504015

XLH 505015

XLH 604015

XLH 605015

XLH 606015

229 x 152

x 127

( 9" x 6" x 5" )

260 x 260

x 152

(10.2" x 10.2" x 6")

305 x 203

x 152

( 12" x 8" x 6" )

305 x 305

x 152

( 12" x 12" x 6" )

406 x 305

x 152

( 16" x 12" x 6" )

406 x 406

x 152

( 16" x 16" x 6" )

406 x 508

x 152

( 16" x 20" x 6" )

508 x 406

x 152

( 20" x 16" x 6" )

508 x 508

x 152

( 20" x 20" x 6" )

610 x 406

x 152

( 24" x 16" x 6" )

610 x 508

x 152

( 24" x 20" x 6" )

610 x 610

x 152

( 24" x 24" x 6" )

-----

-----

-----

C-SD12126SS6

---

C-SD16126SS6

A-16H1206SS6LP

C-SD16166SS6

A-16H1606SS6LP

--A-16H2006SS6LP

C-SD20166SS6

A-20H1606SS6LP

C-SD20206SS6

A-20H2006SS6LP

-----

--A-24H2006SS6LP

--A-24H2406SS6LP

Vertical

Horizontal

152

208

170

316

203

259

203

361

267

361

267

462

267

564

354

462

354

564

445

462

445

564

445

666

BODY

DOOR

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

2.35 kg

2.8 kg

3.4 kg

4.6 kg

5.7 kg

7.1 kg

8.5 kg

8.5 kg

10.2 kg

9.9 kg

11.8 kg

13.7 kg

129

52

149

72

160

160

180

180

205

103

225

123

205

205

225

225

306

205

326

225

306

306

326

326

306

408

326

428

408

306

428

326

408

408

428

428

510

306

530

326

510

408

530

428

510

510

530

530

108 x 58

108 x 58

214 x 80

114 x 80

156 x 80

156 x 80

261 x 80

156 x 80

261 x 80

261 x 80

337 x 80

261 x 80

464 x 80

261 x 80

337 x 80

337 x 80

464 x 80

337 x 80

337 x 80

464 x 80

464 x 80

464 x 80

562 x 80

464 x 80

M16

M20

M25

M32

M40

M50

M63

6

2

2

1

0

0

0

21

10

4

3

3

2

0

15

7

3

2

2

2

0

26

13

5

4

3

3

0

26

13

5

4

3

3

0

35

17

7

6

5

4

0

48

24

10

8

7

6

0

35

17

7

6

5

4

0

48

24

10

8

7

6

0

35

17

7

6

5

4

0

48

24

10

8

7

6

0

59

29

12

10

8

7

0

M16

M20

M25

M32

M40

M50

M63

6

2

2

1

0

0

0

11

5

2

2

1

1

0

15

7

3

2

2

2

0

15

7

3

2

2

2

0

26

13

5

4

3

3

0

26

13

5

4

3

3

0

26

13

5

4

3

3

0

35

17

7

6

5

4

0

35

17

7

6

5

4

0

48

24

10

8

7

6

0

48

24

10

8

7

6

0

48

24

10

8

7

6

0

Orientation in

Enclosure

VERT

1 x 21

2 x 27

1 x 36

2 x 36

2 x 56

3 x 56

4 x 56

3 x 77

4 x 77

3 x 97

4 x 97

6 x 97

VERT

1 x 17

2 x 23

1 x 30

2 x 30

2 x 47

3 x 47

4 x 47

3 x 64

4 x 64

3 x 81

4 x 81

6 x 81

(HEIGHT X W IDTH

X DEPTH)

( Imperial Conversion )

Hoffman Range Equivalent

"Concept" - CWS (Type 316L)

"Type 4X" - A4S (Type 316L)

FIXING CENTRES, mm

MATERIAL THICKNESS, mm

WEIGHT (empty)

kg

TERMINAL MOUNTING RAIL

RAIL FIXING CENTRES, mm

VERT

HORZ

VERT

HORZ

RAIL LENGTH, mm

AVAILABLE GLANDING AREA , mm

(with Gland Plates FITTED)

METRIC (150 deep)

TOP & BOTTOM

LEFT & RIGHT

MAXIMUM ENTRY GUIDE (Metric Glands)

TOP & BOTTOM

LEFT / RIGHT

TERMINAL CONTENT

Terminal Size

2.5 mm2

4 mm2

NOTES : -

6 mm2

VERT

1 x 13

1 x 17

1 x 23

2 x 23

2 x 35

3 x 35

4 x 35

3 x 48

4 x 48

3 x 61

4 x 61

6 x 61

10 mm2

VERT

1 x 10

1 x 13

1 x 18

2 x 18

2 x 28

3 x 28

4 x 28

3 x 38

4 x 38

3 x 49

4 x 49

6 x 49

16 mm2

VERT

1x9

1 x 11

1 x 15

2 x 15

2 x 23

3 x 23

4 x 23

3 x 32

4 x 32

3 x 40

4 x 40

6 x 40

1. The information provided is based on the physical constraints of the enclosure.

2. This information is for guidance purposes only.

XLH - Metric - 150

Sheet 1 of 2

Please refer to the certificate for hazardous area applications.

Cooper Crouse-Hinds UK Ltd reserves the right to make any necessary changes without notice

Rev. 0205

TECHNICAL DATA SHEET

Ex-Cell Range Enclosures

CCH PART NUMBER

DIMENSIONS OVERALL, mm

XLH 303020

XLH 403020

XLH 404020

XLH 405020

XLH 504020

XLH 505020

XLH 506020

XLH 604020

XLH 605020

XLH 606020

XLH 607620

XLH 765020

XLH 766020

XLH 767620

306 x 306

x 203

( 12" x 12" x 8")

406 x 305

x 203

( 16" x 12" x 8" )

406 x 406

x 203

( 16" x 16" x 8" )

406 x 508

x 203

( 16" x 20" x 8" )

508 x 406

x 203

( 20" x 16" x 8" )

508 x 508

x 203

( 20" x 20" x 8" )

508 x 610

x 203

( 20" x 24" x 8" )

610 x 406

x 203

( 24" x 16" x 8" )

610 x 508

x 203

( 24" x 20" x 8" )

610 x 610

x 203

( 24" x 24" x 8" )

610 x 762

x 203

( 24" x 30" x 8" )

762 x 508

x 203

( 30" x 20" x 8" )

762 x 610

x 203

( 30" x 24" x 8" )

762 x 762

x 203

( 30" x 30" x 8" )

-----

C-SD16128SS6

A-16H1208SS6LP

C-SD16168SS6

---

C-SD16208SS6

---

C-SD20168SS6

A-20H1608SS6LP

C-SD20208SS6

A-20H2008SS6LP

--A-20H2408SS6LP

C-SD24168SS6

A-24H1608SS6LP

C-SD24208SS6

A-24H2008SS6LP

C-SD24248SS6

A-16H2006SS6LP

--A-24H3008SS6LP

--A-30H2008SS6LP

C-SD30248SS6

A-30H2408SS6LP

C-SD30308SS6

A-30H3008SS6LP

Vertical

Horizontal

203

361

267

361

267

462

267

564

354

462

354

564

354

666

445

462

445

564

445

666

445

818

508

564

508

666

508

818

BODY

DOOR

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

1.2

1.5

5.8 kg

6.6 kg

8.1 kg

9.7 kg

9.7 kg

11.4 kg

13.2 kg

11.2 kg

13.2 kg

15.3 kg

18.3 kg

15.9 kg

18.3 kg

21.9 kg

206

206

226

226

306

205

326

225

306

306

326

326

306

408

326

428

408

306

428

326

408

408

428

428

408

510

428

530

510

306

530

326

510

408

530

428

510

510

530

530

510

662

530

682

662

408

682

428

662

510

682

530

662

662

682

682

(HEIGHT X W IDTH

X DEPTH)

( Imperial Conversion )

Hoffman Range Equivalent

"Concept" - CWS (Type 316L)

"Type 4X" - A4S (Type 316L)

FIXING CENTRES, mm

MATERIAL THICKNESS, mm

WEIGHT (empty)

kg

TERMINAL MOUNTING RAIL

RAIL FIXING CENTRES, mm

VERT

HORZ

VERT

HORZ

RAIL LENGTH, mm

AVAILABLE GLANDING AREA , mm

(with Gland Plates FITTED)

METRIC (200mm deep)

TOP & BOTTOM

LEFT & RIGHT

261 x 124

214 x 124 (L)

261 x 124 (R)

261 x 124

334 x 124

460 x 124

334 x 124

460 x 124

562 x 124

334 x 124

460 x 124

562 x 124

714 x 124

460 x 124

562 x 124

714 x 124

261 x 124

261 x 124

261 x 124

334 x 124

334 x 124

334 x 124

460 x 124

460 x 124

460 x 124

460 x 124

562 x 124

562 x 124

562 x 124

34

18

15

8

6

3

2

44

26

21

11

9

4

3

62

35

29

15

13

5

4

44

26

21

11

9

4

3

62

35

29

15

13

5

4

78

44

36

19

16

7

5

44

26

21

11

9

4

3

62

35

29

15

13

5

4

78

44

36

19

16

7

5

100

56

47

24

20

9

7

62

35

29

15

13

5

4

78

44

36

19

16

7

5

100

56

47

24

20

9

7

34

18

15

8

6

3

2

34

18

15

8

6

3

2

34

18

15

8

6

3

2

44

26

21

11

9

4

3

44

26

21

11

9

4

3

44

26

21

11

9

4

3

62

35

29

15

13

5

4

62

35

29

15

13

5

4

62

35

29

15

13

5

4

62

35

29

15

13

5

4

78

44

36

19

16

7

5

78

44

36

19

16

7

5

78

44

36

19

16

7

5

MAXIMUM ENTRY GUIDE (Metric Glands)

M16

M20

M25

M32

M40

M50

M63

TOP & BOTTOM

M16

M20

M25

M32

M40

M50

M63

LEFT / RIGHT

34

18

15

8

6

3

2

28 (L)

15 (L)

12 (L)

6 (L)

5 (L)

2 (L)

2 (L)

/

/

/

/

/

/

/

34 (R)

18 (R)

15 (R)

8 (R)

6 (R)

3 (R)

2 (R)

TERMINAL CONTENT

Terminal Size Orientation in Enclosure

2.5 mm2

VERT

2 x 36

2 x 56

3 x 56

4 x 56

3 x 77

4 x 77

6 x 77

3 x 97

4 x 97

6 x 97

7 x 97

4 x 128

6 x 128

7 x 128

4 mm2

VERT

2 x 30

2 x 47

3 x 47

4 x 47

3 x 64

4 x 64

6 x 64

3 x 81

4 x 81

6 x 81

7 x 81

4 x 106

6 x 106

7 x 106

6 mm2

VERT

2 x 23

2 x 35

3 x 35

4 x 35

3 x 48

4 x 48

6 x 48

3 x 61

4 x 61

6 x 61

7 x 61

4 x 80

6 x 80

7 x 80

10 mm2

VERT

2 x 18

2 x 28

3 x 28

4 x 28

3 x 38

4 x 38

6 x 38

3 x 49

4 x 49

6 x 49

7 x 49

4 x 64

6 x 64

7 x 64

16 mm2

VERT

2 x 15

2 x 23

3 x 23

4 x 23

3 x 32

4 x 32

6 x 32

3 x 40

4 x 40

6 x 40

7 x 40

4 x 53

6 x 53

7 x 53

NOTES : -

1. The information provided is based on the physical constraints of the enclosure.

2. This information is for guidance purposes only.

XLH - Metric - 200

Sheet 2 of 2

Please refer to the certificate for hazardous area applications.

Cooper Crouse-Hinds UK Ltd reserves the right to make any necessary changes without notice

Rev. 0205

TECHNICAL DATA SHEET

Ex-Cell Range Enclosure

IMPERIAL

CCH PART NUMBER

XLV 090605

XLV 120806

XLV 121206

XLV 161206

XLV 161606

XLV 162006

XLV 201606

XLV 202006

XLV 241606

XLV 242006

XLV 242406

DIMENSIONS OVERALL (inches)

(HEIGHT X WIDTH X DEPTH)

9" x 6" x 5"

12" x 8" x 6"

12" x 12" x 6"

16" x 12" x 6"

16" x 16" x 6"

16" x 20" x 6"

20" x 16" x 6"

20" x 20" x 6"

24" x 16" x 6"

24" x 20" x 6"

24" x 24" x 6"

-----

-----

C-SD12126SS6

---

C-SD16126SS6

A-16H1206SS6LP

C-SD16166SS6

A-16H1606SS6LP

--A-16H2006SS6LP

C-SD20166SS6

A-20H1606SS6LP

C-SD20206SS6

A-20H2006SS6LP

-----

--A-24H2006SS6LP

--A-24H2406SS6LP

10.24

3.50

13.24

5.50

13.24

9.50

17.24

9.50

17.24

10.00

17.24

14.00

21.24

10.00

21.24

14.00

25.24

10.00

25.24

14.00

25.24

18.00

BODY

DOOR

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

lbs

5.17 lbs

7.54 lbs

10.07 lbs

12.57 lbs

15.63 lbs

18.71 lbs

18.71 lbs

22.36 lbs

21.8 lbs

26.01 lbs

30.22 lbs

5.08"

2.05"

5.87"

2.83"

8.07"

4.06"

8.86"

4.84"

8.07"

8.07"

8.86"

8.86"

12.05"

8.07"

12.83"

8.86"

12.05"

12.05"

12.83"

12.83"

12.05"

16.06"

12.83"

16.85"

16.06"

12.05"

16.85"

12.83"

16.06"

16.06"

16.85"

16.85"

20.08"

12.05"

20.87"

12.83"

20.08"

16.06"

20.87"

16.85"

20.08"

20.08"

20.87"

20.87"

4.25" x 2.28"

4.25" x 2.28"

6.14" x 3.15"

6.14" x 3.15"

10.28" x 3.15"

6.14" x 3.15"

10.28" x 3.15"

10.28" x 3.15"

13.27" x 3.15"

10.28" x 3.15"

18.27" x 3.15"

10.28" x 3.15"

13.27" x 3.15"

13.27" x 3.15"

18.27" x 3.15"

13.27" x 3.15"

13.27" x 3.15"

18.27" x 3.15"

18.27" x 3.15"

18.27" x 3.15"

22.13" x 3.15"

18.27" x 3.15"

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

gland

6

2

2

1

0

0

0

/

/

/

/

/

/

/

/

hub

2

2

2

0

0

0

0

gland

9

7

3

2

2

2

0

/

/

/

/

/

/

/

/

hub

3

3

2

0

0

0

0

gland

16

13

5

4

3

3

0

/

/

/

/

/

/

/

/

hub

12

5

4

4

3

0

0

gland

16

13

5

4

3

3

0

/

/

/

/

/

/

/

/

hub

12

5

4

4

3

0

0

gland

21

17

7

6

5

4

0

/

/

/

/

/

/

/

/

hub

15

7

6

5

4

0

0

gland

30

24

10

8

7

6

0

/

/

/

/

/

/

/

/

hub

22

10

8

7

6

0

0

gland

21

17

7

6

5

4

0

/

/

/

/

/

/

/

/

hub

15

7

6

5

4

0

0

gland

30

24

10

8

7

6

0

/

/

/

/

/

/

/

/

hub

22

10

8

7

6

0

0

gland

21

17

7

6

5

4

0

/

/

/

/

/

/

/

/

hub

15

7

6

5

4

0

0

gland

30

24

10

8

7

6

0

/

/

/

/

/

/

/

/

hub

22

10

8

7

6

0

0

gland

36

29

12

10

8

7

0

/

/

/

/

/

/

/

/

hub

27

12

10

8

7

0

0

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

6

2

2

1

0

0

0

/

/

/

/

/

/

/

2

2

2

0

0

0

0

9

7

3

2

2

2

0

/

/

/

/

/

/

/

3

3

2

0

0

0

0

9

7

3

2

2

2

0

/

/

/

/

/

/

/

3

3

2

0

0

0

0

16

13

5

4

3

3

0

/

/

/

/

/

/

/

12

5

4

4

3

0

0

16

13

5

4

3

3

0

/

/

/

/

/

/

/

12

5

4

4

3

0

0

16

13

5

4

3

3

0

/

/

/

/

/

/

/

12

5

4

4

3

0

0

21

17

7

6

5

4

0

/

/

/

/

/

/

/

15

7

6

5

4

0

0

21

17

7

6

5

4

0

/

/

/

/

/

/

/

15

7

6

5

4

0

0

30

24

10

8

7

6

0

/

/

/

/

/

/

/

22

10

8

7

6

0

0

30

24

10

8

7

6

0

/

/

/

/

/

/

/

22

10

8

7

6

0

0

30

24

10

8

7

6

0

/

/

/

/

/

/

/

22

10

8

7

6

0

0

Hoffman Range Equivalent

"Concept" - CWS (Type 316L)

"Type 4X" - A4S (Type 316L)

FIXING CENTRES (inches)

Vertical

Horizontal

MATERIAL THICKNESS, swg

WEIGHT (empty)

TERMINAL MOUNTING RAIL

RAIL FIXING CENTRES (inches)

VERT

HORZ

VERT

HORZ

RAIL LENGTH (inches)

AVAILABLE GLANDING AREA (inches)

(with Gland Plates FITTED)

TOP & BOTTOM

LEFT & RIGHT

MAXIMUM ENTRY GUIDE

TOP & BOTTOM

LEFT / RIGHT

TERMINAL CONTENT

Terminal Size Orientation in Enclosure

2.5 mm2

VERT

1 x 36

2 x 36

2 x 56

3 x 56

4 x 56

3 x 77

4 x 77

3 x 97

4 x 97

6 x 97

4 mm2

VERT

1 x 17

1 x 30

2 x 30

2 x 47

3 x 47

4 x 47

3 x 64

4 x 64

3 x 81

4 x 81

6 x 81

6 mm2

VERT

1 x 13

1 x 23

2 x 23

2 x 35

3 x 35

4 x 35

3 x 48

4 x 48

3 x 61

4 x 61

6 x 61

10 mm2

VERT

1 x 10

1 x 18

2 x 18

2 x 28

3 x 28

4 x 28

3 x 38

4 x 38

3 x 49

4 x 49

6 x 49

1x9

1 x 15

2 x 15

2 x 23

3 x 23

4 x 23

3 x 32

4 x 32

3 x 40

4 x 40

6 x 40

16 mm2

NOTES : -

1 x 21

VERT

1. The information provided is based on the physical constraints of the enclosure.

2. This information is for guidance purposes only.

XLV - Imperial - 5" & 6"

Sheet 1 of 2

Please refer to the certificate for hazardous area applications.

Cooper Crouse-Hinds UK Ltd reserves the right to make any necessary changes without notice

Rev. 0205

TECHNICAL DATA SHEET

Ex-Cell Range Enclosures

CCH PART NUMBER

DIMENSIONS OVERALL (inches)

(HEIGHT X WIDTH X DEPTH)

Hoffman Range Equivalent

"Concept" - CWS (Type 316L)

"Type 4X" - A4S (Type 316L)

FIXING CENTRES (inches)

Vertical

Horizontal

MATERIAL THICKNESS, swg

BODY

DOOR

WEIGHT (empty)

lbs

TERMINAL MOUNTING RAIL

RAIL FIXING CENTRES (inches)

VERT

HORZ

VERT

HORZ

RAIL LENGTH (inches)

AVAILABLE GLANDING AREA (inches)

(with Gland Plates FITTED)

TOP & BOTTOM

LEFT & RIGHT

MAXIMUM ENTRY GUIDE

TOP & BOTTOM

LEFT / RIGHT

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

1/2 " NPT

3/4" NPT

1" NPT

1 1/4" NPT

1 1/2" NPT

2" NPT

2 1/2" NPT

IMPERIAL (DEEP)

XLV 121208

XLV 161208

XLV 161608

XLV 162008

XLV 201608

XLV 202008

XLV 202408

XLV 241608

XLV 242008

XLV 242408

XLV 243008

XLV 302008

XLV 302408

XLV 303008

12" x 12" x 8"

16" x 12" x 8"

16" x 16" x 8"

16" x 20" x 8"

20" x 16" x 8"

20" x 20" x 8"

20" x 24" x 8"

24" x 16" x 8"

24" x 20" x 8"

24" x 24" x 8"

24" x 30" x 8"

30" x 20" x 8"

30" x 24" x 8"

30" x 30" x 8"

C-SD12126SS6

---

C-SD16128SS6

A-16H1208SS6LP

C-SD16168SS6

---

C-SD16208SS6

---

C-SD20168SS6

A-20H1608SS6LP

C-SD20208SS6

A-20H2008SS6LP

--A-20H2408SS6LP

C-SD24168SS6

A-24H1608SS6LP

C-SD24208SS6

A-24H2008SS6LP

C-SD24248SS6

A-16H2006SS6LP

--A-24H3008SS6LP

--A-30H2008SS6LP

C-SD30248SS6

A-30H2408SS6LP

C-SD30308SS6

A-30H3008SS6LP

13.24

9.50

17.24

9.50

17.24

10.00

17.24

14.00

21.24

10.00

21.24

14.00

21.24

18.00

25.24

10.00

25.24

14.00

25.24

18.00

25.24

24.00

31.24

14.00

31.24

18.00

31.24

24.00

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

18 swg

16 swg

12.76 lbs

14.54 lbs

17.87 lbs

21.24 lbs

21.24 lbs

25.17 lbs

29.1 lbs

24.61 lbs

29.1 lbs

33.6 lbs

40.3 lbs

34.96 lbs

40.3 lbs

48.25 lbs

8.11"

8.11"

8.90"

8.90"

12.05"

8.07"

12.83"

8.86"

12.05"

12.05"

12.83"

12.83"

12.05"

16.06"

12.83"

16.85"

16.06"

12.05"

16.85"

12.83"

16.06"

16.06"

16.85"

16.85"

16.06"

20.08"

16.85"

20.87"

20.08"

12.05"

20.87"

12.83"

20.08"

16.06"

20.87"

16.85"

20.08"

20.08"

20.87"

20.87"

20.08"

26.06"

20.87"

26.85"

26.06"

16.06"

26.85"

16.85"

26.06"

20.08"

26.85"

20.87"

26.06"

26.06"

26.85"

26.85"

10.27" x 4.88"

8.42" x 4.88" (L)

10.27" x 4.88" (R)

gland /

32 /

20 /

15 /

8 /

6 /

3 /

2 /

Left

26 / 14 15 / 8 12 / 6 6/5 5/2 2/2

2/2 -

hub

18

10

8

7

3

3

2

Right

32 / 18

20 / 10

15 / 8

8/7

6/3

3/3

2/2

10.27" x 4.88"

13.15" x 4.88"

18.11" x 4.88"

13.15" x 4.88"

18.11" x 4.88"

22.13" x 4.88"

13.15" x 4.88"

18.11" x 4.88"

22.13" x 4.88"

28.11" x 4.88"

18.11" x 4.88"

22.13" x 4.88"

28.11" x 4.88"

10.27" x 4.88"

10.27" x 4.88"

10.27" x 4.88"

13.15" x 4.88"

13.15" x 4.88"

13.15" x 4.88"

18.11" x 4.88"

18.11" x 4.88"

18.11" x 4.88"

18.11" x 4.88"

22.13" x 4.88"

22.13" x 4.88"

22.13" x 4.88"

gland

32

20

15

8

6

3

2

/

/

/

/

/

/

/

/

hub

18

10

8

7

3

3

2

gland

42

26

21

11

9

4

3

/

/

/

/

/

/

/

/

hub

23

13

11

9

4

3

3

gland

58

36

30

15

13

5

4

/

/

/

/

/

/

/

/

hub

33

18

16

13

6

5

4

gland

42

26

21

11

9

4

3

/

/

/

/

/

/

/

/

hub

23

13

11

9

4

3

3

gland

58

36

30

15

13

5

4

/

/

/

/

/

/

/

/

hub

33

18

16

13

6

5

4

gland

72

44

36

19

16

7

5

/

/

/

/

/

/

/

/

hub

41

23

19

16

7

6

5

gland

42

26

21

11

9

4

3

/

/

/

/

/

/

/

/

hub

23

13

11

9

4

3

3

gland

58

36

30

15

13

5

4

/

/

/

/

/

/

/

/

hub

33

18

16

13

6

5

4

gland

72

44

36

19

16

7

5

/

/

/

/

/

/

/

/

hub

41

23

19

16

7

6

5

gland

94

57

47

24

20

9

7

/

/

/

/

/

/

/

/

hub

51

30

25

21

9

8

7

gland

58

36

30

15

13

5

4

/

/

/

/

/

/

/

/

hub

33

18

16

13

6

5

4

gland

72

44

36

19

16

7

5

/

/

/

/

/

/

/

/

hub

41

23

19

16

7

6

5

gland

94

57

47

24

20

9

7

/

/

/

/

/

/

/

/

hub

51

30

25

21

9

8

7

32

20

15

8

6

3

2

/

/

/

/

/

/

/

18

10

8

7

3

3

2

32

20

15

8

6

3

2

/

/

/

/

/

/

/

18

10

8

7

3

3

2

32

20

15

8

6

3

2

/

/

/

/

/

/

/

18

10

8

7

3

3

2

42

26

21

11

9

4

3

/

/

/

/

/

/

/

23

13

11

9

4

3

3

42

26

21

11

9

4

3

/

/

/

/

/

/

/

23

13

11

9

4

3

3

42

26

21

11

9

4

3

/

/

/

/

/

/

/

23

13

11

9

4

3

3

58

36

30

15

13

5

4

/

/

/

/

/

/

/

33

18

16

13

6

5

4

58

36

30

15

13

5

4

/

/

/

/

/

/

/

33

18

16

13

6

5

4

58

36

30

15

13

5

4

/

/

/

/

/

/

/

33

18

16

13

6

5

4

58

36

30

15

13

5

4

/

/

/

/

/

/

/

33

18

16

13

6

5

4

72

44

36

19

16

7

5

/

/

/

/

/

/

/

41

23

19

16

7

6

5

72

44

36

19

16

7

5

/

/

/

/

/

/

/

41

23

19

16

7

6

5

72

44

36

19

16

7

5

/

/

/

/

/

/

/

41

23

19

16

7

6

5

TERMINAL CONTENT

Terminal Size Orientation in Enclosure

2.5 mm2

VERT

4 mm2

2 x 36

2 x 56

3 x 56

4 x 56

3 x 77

4 x 77

6 x 77

3 x 97

4 x 97

6 x 97

7 x 97

4 x 128

6 x 128

7 x 128

2 x 30

2 x 47

3 x 47

4 x 47

3 x 64

4 x 64

6 x 64

3 x 81

4 x 81

6 x 81

7 x 81

4 x 106

6 x 106

7 x 106

6 mm2

VERT

2 x 23

2 x 35

3 x 35

4 x 35

3 x 48

4 x 48

6 x 48

3 x 61

4 x 61

6 x 61

7 x 61

4 x 80

6 x 80

7 x 80

10 mm2

VERT

2 x 18

2 x 28

3 x 28

4 x 28

3 x 38

4 x 38

6 x 38

3 x 49

4 x 49

6 x 49

7 x 49

4 x 64

6 x 64

7 x 64

2 x 15

2 x 23

3 x 23

4 x 23

3 x 32

4 x 32

6 x 32

3 x 40

4 x 40

6 x 40

7 x 40

4 x 53

6 x 53

7 x 53

16 mm2

NOTES : -

VERT

VERT

1. The information provided is based on the physical constraints of the enclosure.

2. This information is for guidance purposes only.

XLV - Imperial

Sheet 2 of 2

Please refer to the certificate for hazardous area applications.

Cooper Crouse-Hinds UK Ltd reserves the right to make any necessary changes without notice

Rev. 0305

Cooper Crouse-Hinds are premier manufactures of high quality and robust enclosure solutions and

assemblies configured to meet the requirements of the most demanding hazardous area and industrial

environmental applications. With over 30 years of experience in the design, engineering and

manufacture of enclosure solutions, Cooper Crouse-Hinds provides, tried and tested solutions to meet

the toughest project and installation needs.

The STB range is an “ATEX certified” heavy-duty junction box solution fully compliant with the impact,

thermal and ingress protection requirements of EN50014. These are available in a wide range of sizes

to meet a diverse range of applications.

With our customizing service fittings such as cable glands, breather drains and blanking plugs can be

provided and fitted as specified. Additionally appropriately certified components such instrument

transmitters and field-bus modules maybe fitted to provide fully certified OEM solutions.

Using the highest quality materials and design benefits the STB junction box range is the industry

benchmark for quality and performance enclosure solutions for both electrical and instrumentation

applications.

The retained stainless steel slotted

hex bolt fastenings provide a rapid

means of achieving high integrity

ingress protection (IP) of 66 for