Standard Drawings 2006 Edition

advertisement

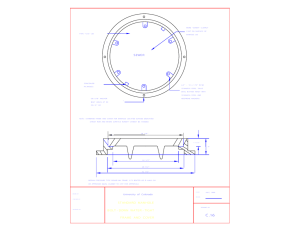

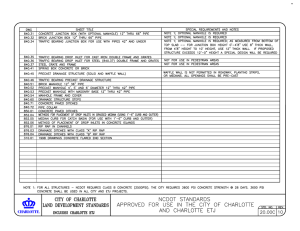

CHIEF ENGINEER 4" STANDARD METHOD OF INSTALLING SADDLES A 0 SECTION B-B 0 SHORT MORTAR CEMENT 420-C-2000 RADIUS BEND SEE NOTE EXISTING SEWER 6" STANDARD "Y" SADDLE B SADDLE 6" STD " T " 6" - 45 BY DISTRICT INSPECTOR IN FIRM SOIL WHEN APPROVED THIS PORTION MAY BE OMITTED SECTION A-A (SHALLOW LINE) SADDLE 6" STD " T " SEE NOTE EXISTING SEWER 6" STANDARD "T" SADDLE 420-C-2000 45 12" END VIEW 5" 5" C C 5" SEE NOTE SECTION A-A (DEEP LINE) SADDLE 6" STD " T " SEE NOTE SECTION C-C EXISTING SEWER STANDARD "T" SADDLE 4" ENCASEMENT 5" " Y " BRANCH CONNECTED CONCRETE 6" STD DOUBLE BRANCHES NOT PLUG ALL SURFACE GROUND 6" HOLES IN NRCP AND VCP 18" AND SMALLER MAY BE MADE BY CHIPPING THE PIPE. PER S-a-86. LARGER THAN 18" SHALL BE MADE BY CORE DRILLING HOLES IN RC PIPES AND IN NRCP AND VCP PIPES NOTE: THIS DRAWING DOES NOT APPLY TO CONNECTIONS TO LINED PIPE END VIEW B LE AB RI VA END VIEW LE AB RI VA 4" " Y " BRANCH 6" STD DOUBLE NOT CONNECTED 8" PLUG ALL BRANCHES MIN A 3" 4" STEPHEN R. MAGUIN VARIABLE 18" 3" COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING 2006 EDITION S-a-79 SHEET 1 OF 1 BLOCKOUT OR CORED HOLE SECURELY MORTAR STUB INTO 4" OR 6" DIA HC ONLY SECURELY MORTAR STUB INTO CORED HOLE " EL EV "A CORED HOLE DIA = OD + 1" MAX (TYP) CONNECTION TO REINFORCED CONNECTION TO RCP (ALL SIZES) CONCRETE STRUCTURE & NRCP & VCP 21" OR LARGER NOTES: 1. ELEVATION "A" FOR LATERAL SEWER CONNECTIONS SHALL BE AS SHOWN ON APPROVED LATERAL SEWER DRAWINGS. 2. HOUSE CONNECTION TO THE PIPE SHALL BE AS SHOWN ON S-a-79 EXCEPT AS SHOWN HEREON. THE CORED HOLE SHALL BE MADE WITH EQUIPMENT SPECIALLY DESIGNED TO CUT A SMOOTH HOLE WITHOUT SPALLING OR 3. DAMAGE TO THE REINFORCING STEEL, PIPE OR STRUCTURE. 4. THE CORING OF THE HOLE AND THE PLACING OF THE STUB SHALL BE DONE IN THE PRESENCE OF THE DISTRICT INSPECTOR. 5. NO CONNECTION SHALL BE MADE TO THE STUB UNTIL DISTRICT INSPECTOR HAS APPROVED THE STUB. THIS DRAWING DOES NOT APPLY TO CONNECTIONS TO LINED PIPES OR STRUCTURES COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER STANDARD METHOD FOR CONNECTION TO PIPES AND STRUCTURES 2006 EDITION S-a-86 SHEET 1 OF 1 STD MH F&C (SEE S-a-228) GROUND SURFACE 4" 8" BRICKWORK TO DEPTH OF 22’-0". 12" BRICKWORK BELOW DEPTH OF 22’-0" FORM CHANNELS WITH BRICK & MORTAR OR 420-C-2000 CONCRETE C VARIABLE C 4" MIN 660-B-4000 INLET 3/4 DIA 3’-9" MIN VARIABLE 1/2" OUTLET PLASTER BRICK ARCH FOR HEIGHT LESS THAN 6’-6" 5" 24" DIA USE TYPE "C" MANHOLE (S-a-203) 16" MAX 24" DIA (TYP) 1/2" P LAST ER 9" KEYS 2 x 4 x 3’-0" SECTION A-A SECTION B-B NOTES: B 1. FOR 15" SEWERS AND LARGER, TURN 8" ARCH OVER PIPE. OPTIONAL BASE 2. FOR 12" SEWERS AND SMALLER, TURN 4" ARCH OVER PIPE. MH STEP 3. (SEE NOTE 3 & 4) THE LOWEST MANHOLE STEP SHALL BE PLACED NOT LESS THAN 8" NOR MORE THAN 24" ABOVE SHELF. E A LF SHELF SH A 4. VARIABLE 48" DIA SEE NOTE THE UPPER MANHOLE STEP SHALL BE PLACED BETWEEN THE TOP OF MANHOLE AND MANHOLE FLOW COVER FRAME AND SHALL PROJECT NOT MORE THAN 4" INSIDE MANHOLE. ALL OTHERS SHALL PROJECT 5". 5. 6 FOR LAYING BRICK OR PLASTERING, THE MORTAR SHALL CONFORM WITH SECTION 201-5.1 (CLASS "D") OF THE STANDARD SPECIFICATIONS. SHELF 6. FOR 30" PIPE AND LARGER, THE TOP PORTION OF THE PIPES WITHIN THE MANHOLE SHALL BE CUT OUT TO PROVIDE A CIRCULAR OPENING BETWEEN THE PIPE ENDS OF NOT LESS THAN 42". THE CUT EDGES SHALL BE PLASTERED SMOOTH WITH CEMENT MORTAR FOR CONCRETE PIPE AND EPOXY FOR CLAY PIPE. THE CIRCULAR OPENING SHALL B BE CUT PRIOR TO INSTALLATION OF THE RISER SECTIONS. PLAN SECTION C-C FOR 8" TO 30" PIPE COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD MANHOLE, TYPE "A" S-a-201 SHEET 1 OF 1 GROUND STD 36" MH FRAME & 3" MAX CLASS COVER PER S-a-226 "B" MORTAR GROUND SURFACE SURFACE CONC RING ADJUSTING RING ( SEE NOTE 5 ) MH 9" MAX STEPS 6" MIN 36" DIA 36" DIA 36" PRECAST CONC SHAFT & PLASTIC LINER w/ LOCKING EXTENSIONS MH STEPS #5@12 FOR REINF PER S-a-209 SEE ROOF PLAN FOR REINF #5@12 C SEE ROOF PLAN 2" CLR " u " BARS (TYP) PULL RING PULL RING S-a-220 " w " BARS S-a-220 (TYP) #4@12 PLATE (TYP) INLET IAB VAR LE OD OF LOWER LIMIT OUTLET PIPE PLASTIC LINER OF PLASTIC LINER PLATE 3" " v " BARS 3" LOWER LIMIT OF PLASTIC D LINER PLATE " v " BARS #5@12 " w " BARS 30d MATCH EXIST ADJ PIPE, 90 O MAX LAP #5@12 LONGITUDINAL SECTION CROSS SECTION MH STEPS (SEE NOTE 2) PULL RING (SEE NOTE 1) #5 DIAGS T&B (TYP) ADD #5 T&B C L PIPE "r" "r" A B C L PIPE BARS 6" #5@12T "s" BARS IN N PE 36 O " D E IA G M H 6" BARS A EACH SIDE B " t " BARS #5@12T ROOF PLAN 0 O TO 15 O FOR 48" TO 96" PIPE COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD MANHOLE, TYPE "B" S-a-202 SHEET 1 OF 3 COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STEPHEN R. MAGUIN STANDARD DRAWING CHIEF ENGINEER STANDARD MANHOLE, TYPE "B" 2006 EDITION S-a-202 SHEET 2 OF 3 90" TO 96" 75" TO 84" 63" TO 72" 51" TO 60" 48" PIPE DIA DEPTH 12" 8" 8" 12" UP TO 30’ 31’ TO 50’ 7" 10" 7" 10" UP TO 30’ 31’ TO 50’ 7" 10" 7" 10" UP TO 30’ 31’ TO 50’ 6" 6" 6" B 8" 8" 8" A 31’ TO 50’ UP TO 30’ 31’ TO 50’ UP TO 30’ TO INV 20" 18" 18" 16" 18" 15" 18" 15" 15" 12" C 8" 8" 7" 7" 7" 7" 6" 6" 6" D DIMENSIONS 10” 5’-2" 4’-0" 15” 7” 15” 7” 5’-2" 4’-0" 8” 15” 4’-10" 4’-0" 15” 8” 4’-0" 4’-10" 15” 10” 15” 4’-8" 4’-0" 4’-8" 10” 4’-0" 10” 15” 4’-4" 4’-0" 15” 4’-0" 4’-4" 15” 15” (MAX) 4’-0" 4’-0" E "r" 5 - #9 4 - #9 5 - #8 4 - #8 5 - #9 4 - #9 5 - #7 4 - #7 4 - #8 4 - #7 3 - #8 3 - #7 3 - #7 3 - #6 TABLE OF DIMENSIONS AND REINFORCING BARS "s" #9@6 #8@6 #9@6 #7@6 #8@6 #7@6 #8@6 #7@6 #7@6 #6@6 #6@12 #5@12 #6@12 #5@12 #6@12 #5@12 #6@12 #5@12 #6@12 #5@12 "t" #6@6 #5@6 #6@6 #5@6 #5@6 #4@6 #5@6 #4@6 #4@6 #4@6 "u" "v" #8@6 #7@6 #8@6 #6@6 #7@6 #6@6 #5@6 #5@6 #5@6 #4@6 REINFORCING BARS "w" #8@6 #7@6 #7@6 #6@6 #7@6 #5@6 #6@6 #5@6 #5@6 #4@6 NOTES: 1. ALL MANHOLES SHALL BE PROVIDED WlTH A STANDARD PULL RlNG IN ACCORDANCE WlTH S-a-220. THE PULL RlNG SHALL BE LOCATED 6" ABOVE THE SOFFIT ON THE UPSTREAM SlDE OF THE MANHOLE AND ALONG THE AXIS OF THE DOWNSTREAM OUTLET. WHERE THE MANHOLE IS TO BE USED AS A DOWNSTREAM SIPHON MANHOLE, IT SHALL BE PROVIDED WlTH AN ADDITIONAL STANDARD PULL RING, BUT LOCATED 6" ABOVE THE SOFFIT ON THE DOWNSTREAM SlDE OF THE MANHOLE AND ON THE CENTERLINE OF THE UPSTREAM SIPHON PIPE. 2. MANHOLE STEPS SHALL BE IN ACCORDANCE WlTH S-a-209 AND SHALL BE UNIFORMLY SPACED NOT MORE THAN 16" APART. THE TOP STEP SHALL BE PLACED WITHIN 16" BELOW THE MANHOLE FRAME. THE BOTTOM MANHOLE STEP SHALL BE PLACED WITHIN 16" ABOVE THE TOP OF THE PIPE. THE MANHOLE STEP SHALL PROJECT 5". THE MANHOLE STEPS SHALL BE PLACED SUCH THAT THEY ARE ADJACENT TO BUT NOT INTERFERINGWlTH ACCESS TO THE PULL RING. 3. THE MANHOLE SHALL BE PROVIDED WlTH PLASTIC LlNER WlTH LOCKING EXTENSIONS. THE PLASTIC LlNER AND THE PLASTIC LlNER INSTALLATION SHALL BE IN ACCORDANCE WlTH THE STANDARD SPECIFICATIONS. THE LlNER SHALL EXTEND FROM THE BOTTOM OF THE ADJUSTING RINGS TO A POINT IN THE CHANNEL MATCHING THE BOTTOM OF THE LlNER IN THE LINED PIPE. LlNER RETURNS SHALL BE PROVIDED WHERE THE LlNER TERMINATES AT THE ADJUSTING RING. THE JOINT BETWEEN THE LlNER AND THE STAINLESS STEEL STEPS AND PULL RINGS SHALL BE THOROUGHLY SEALED WlTH MASTIC SEAM MATERIAL AS MANUFACTURED BY LINABOND INC., SYLMAR, CALIFORNIA (818) 362-7373, OR EQUAL. APPLICATION OF SEALANT AND PREPARATION OF SURFACES SHALL BE IN STRICT CONFORMANCE WlTH THE MANUFACTURER'S DIRECTIONS. 4. UNLESS OTHERWISE SPECIFIED, ALL CONCRETE SHALL BE 660-8-4000 AND ALL REINFORCING BARS SHALL BE DEFORMED BARS CONFORMING TO ASTM-A706 GRADE 60. 5. A 12" WIDE BY 12" HIGH CONCRETE RlNG SHALL BE PROVIDED AROUND THE MANHOLE FRAME. IN UNPAVED AREAS, THE CONCRETE RlNG SHALL BE PROVIDED WlTH #3 REBAR. 30 DIAMETER LAP. 6. EXCEPT AS NOTED HEREON, THE PRECAST UNITS SHALL BE MANUFACTURED AND TESTED IN ACCORDANCE WlTH ASTM C478. THE CURING OF THE PRECAST UNITS SHALL CONFORM TO SECTION 207-2.7 OF THE STANDARD SPECIFICATIONS. AS AN ALTERNATE, THE UNITS MAY BE CURED USING SATURATED STEAM FOR A MINIMUM OF 12 HOURS FOLLOWED BY 6 DAYS OF WATER CURING OR MEMBRANE CURING. IF THE UNITS ARE CURED BY THE ALTERNATE METHOD, THEY SHALL NOT BE SHIPPED PRIOR TO 8 DAYS AFTER CASTING NOR UNTIL THE CONCRETE HAS ATTAINED A MINIMUM STRENGTH OF 4,000 PSI. THE RISER SECTIONS MAY BE REINFORCED OR UNREINFORCED. REINFORCED SECTIONS SHALL HAVE A MINIMUM WALL THICKNESS OF 5" AND UNREINFORCED SECTIONS SHALL HAVE A MINIMUM WALL THICKNESS OF 6". JOINTS SHALL BE TONGUE AND GROOVE AND SHALL BE ASSEMBLED USING CLASS "B" MORTAR. THE MORTARED JOINTS SHALL BE FLUSH AND TROWELED SMOOTH. COUNTY STEPHEN R. MAGUIN CHIEF ENGINEER SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD MANHOLE, TYPE "B" STANDARD DRAWING 2006 EDITION S-a-202 SHEET 3 OF 3 PLASTIC LINER WITH LOCKING EXTENSIONS (SEE NOTE 3) CONCRETE RING 3" MAX CLASS FOR REINF "B" MORTAR SEE ROOF PLAN (SEE NOTE 6) 9" MAX STD MH FRAME & COVER 6" MIN (SEE NOTE 5) GROUND SURFACE SEE ROOF ADJUSTING RING(S) EDGE SEALING 10" DETAIL ON PRECAST CONC SHAFT & PLASTIC 2 1/2" S-a-206 (TYP) MH LINER w/ LOCKING EXTENSIONS C STEP 5" PULL RING C SHELF 3" (SEE NOTE 1) VARIABLE PULL RING (SEE NOTE 1) 9" SEE OUTLET INLET VARIABLE NOTE 8 VA RIA B LE 2" CL (TYP) 10" #5@12 #5@12 #5@12 6" #5@12 48" DIA 6" SECTION A-A SECTION B-B OPTIONAL BASE D B MH STEP #5 (SEE NOTE 2) HK @6 1 - #5 HKD 2" SHELF P) Y L 48" (T A FLOW C A 0" 2’- A DI DIA 1 - #5 HKD 4 - CL YP ) (T PULL RING HKD 2" SHELF 4 - #5@8 8 D K @ H #5 SEE NOTE 8 (SEE NOTE 1) #5 CONT 3 - LIFTING EYES @120 B 0 (SEE S-a-230) PLAN SECTION C-C ROOF PLAN FOR 8" TO 30" PIPE COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD MANHOLE, TYPE "C" S-a-203 SHEET 1 OF 3 NOTES: 1. ALL MANHOLES SHALL BE PROVIDED WlTH A STANDARD PULL RlNG IN ACCORDANCE WlTH S-a-220. THE PULL RlNG SHALL BE LOCATED 5" ABOVE THE TOP OF THE PlPE ON THE UPSTREAM SlDE OF THE MANHOLE AND ALONG THE AXIS OF THE DOWNSTREAM OUTLET. WHERE THE MANHOLE IS TO BE USED AS A DOWNSTREAM SIPHON MANHOLE, IT SHALL BE PROVIDED WlTH AN ADDITIONAL STANDARD PULL RING, BUT LOCATED 5" ABOVE THE TOP OF THE PIPE ON THE DOWNSTREAM SlDE OF THE MANHOLE AND ON THE CENTERLINE OF THE UPSTREAM SIPHON PIPE. 2. MANHOLE STEPS SHALL BE IN ACCORDANCE WlTH S-a-209 AND SHALL BE UNIFORMLY SPACED NOT MORE THAN 16" APART. THE TOP STEP SHALL BE PLACED WITHIN 16" BELOW THE MANHOLE FRAME. THE BOTTOM MANHOLE STEP SHALL BE PLACED WITHIN 16" ABOVE THE SHELF. THE MANHOLE STEP SHALL PROJECT 5". THE MANHOLE STEPS SHALL BE PLACED SUCH THAT THEY ARE ADJACENT TO BUT NOT INTERFERING WlTH ACCESS TO THE PULL RING. 3. THE MANHOLE SHALL BE PROVIDED WlTH PLASTIC LINER WlTH LOCKING EXTENSIONS. PLASTIC LINER WlTH LOCKING EXTENSIONS SHALL BE IN ACCORDANCE WlTH THE STANDARD SPECIFICATIONS. THE LINER SHALL EXTEND FROM THE BOTTOM OF THE ADJUSTING RINGS TO THE TOP OF THE SHELF. LINER RETURNS SHALL BE PROVIDED WHERE THE LINER TERMINATES AT THE ADJUSTING RlNG AND THE SHELF. THE JOINT BETWEEN THE LINER AND THE STAINLESS STEEL STEPS AND PULL RlNG SHALL BE THOROUGHLY SEALED WlTH MASTIC SEAM MATERIAL AS MANUFACTURED BY LINABOND INC., SYLMAR, CALIFORNIA (818) 3627373, OR EQUAL. APPLICATION OF SEALANT AND PREPARATION OF SURFACES SHALL BE IN STRICT CONFORMANCE WlTH THE MANUFACTURER'S DIRECTIONS. 4. UNLESS OTHERWISE SPECIFIED, ALL CONCRETE SHALL BE 660-8-4000 ALL REINFORCING BARS SHALL BE DEFORMED BARS CONFORMING TO ASTM-A706 GRADE 60. 5 . IN PAVED AREAS SUBJECT TO TRAFFIC, A 24" TRAFFIC MANHOLE FRAME AND COVER IN ACCORDANCE WlTH S-a-228 SHALL BE PROVIDED. IN ALL OTHER AREAS, A 24" LOCKING MANHOLE FRAME AND COVER IN ACCORDANCE WlTH S-a-207 SHALL BE PROVIDED. 6. A 12" WIDE BY 12" HIGH CONCRETE RlNG SHALL BE PROVIDED AROUND THE MANHOLE FRAME. IN UNPAVED AREAS, THE CONCRETE RlNG SHALL BE PROVIDED WlTH #3 REBAR, 30 DIAMETER LAP. COUNTY STEPHEN R. MAGUIN CHIEF ENGINEER I SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD MANHOLE, TYPE "C" STANDARD DRAWING 2004 EDITION S-a-203 NOTES: 7. EXCEPT AS NOTED HEREON, THE PRECAST UNITS SHALL BE MANUFACTURED AND TESTED IN ACCORDANCE WlTH ASTM C478. THE CURING OF THE PRECAST UNITS SHALL CONFORM TO SECTION 207-2.7 OF THE STANDARD SPECIFICATIONS. AS AN ALTERNATE, THE UNITS MAY BE CURED USING SATURATED STEAM FOR A MINIMUM OF 12 HOURS FOLLOWED BY 6 DAYS OF WATER CURING OR MEMBRANE CURING. IF THE UNITS ARE CURED BY THE ALTERNATE METHOD, THEY SHALL NOT BE SHIPPED PRIOR TO 8 DAYS AFTER CASTING NOR UNTIL THE CONCRETE HAS ATTAINED A MINIMUM STRENGTH OF 4,000 PSI. THE RISER SECTIONS MAY BE REINFORCED OR UNREINFORCED. REINFORCED SECTIONS, INCLUDING ECCENTRIC CONES, SHALL HAVE A MINIMUM WALL THICKNESS OF 5" AND UNREINFORCED SECTIONS, INCLUDING CONES, SHALL HAVE A MINIMUM WALL THICKNESS OF 6". JOINTS SHALL BE TONGUE AND GROOVE AND SHALL BE ASSEMBLED USING CLASS "B" MORTAR. THE MORTARED JOINTS SHALL BE FLUSH AND TROWELED SMOOTH. 8. THE TOP PORTION OF THE PIPES WITHIN THE MANHOLE SHALL BE CUT OUT AS NECESSARY TO PROVIDE A CIRCULAR OPENING BETWEEN THE PlPE ENDS OF AT LEAST 42". THE CUT ENDS SHALL BE PLASTERED SMOOTH WlTH CEMENT MORTAR FOR CONCRETE PlPE AND EPOXY FOR CLAY PIPE. THE CIRCULAR OPENING SHALL BE CUT PRIOR TO INSTALLATION OF THE RISER SECTIONS. COUNTY SANITATION DISTRICTS OF LOS OFFICE OF CHIEF ENGINEER ANGELES COUNTY I STEPHEN R. MAGUIN CHIEF ENGINEER I I STANDARD MANHOLE, TYPE "C" II STANDARD DRAWING 2006 EDITION S-a-203 SHEET 3 OF 3 3" MAX CLASS STD MH FRAME & COVER ADJUSTING RING "B" MORTAR (SEE NOTE 5) 9" MAX CONCRETE RING 6" MIN (SEE NOTE 6) GROUND SURFACE REDUCER MAX 21" 24" MAX - 12" MIN IF DEPTH OF MH CONE 24" MIN PLASTIC LINER WITH MIN 12" MH STEPS (SEE NOTE 2) LOCKING EXTENSIONS MH STEPS OR 16" (SEE NOTE 2) 15" ECCENTRIC PERMITS CONE 30" DIA 24" MIN RING ECCENTRIC 24" DIA 24" DIA 48" DIA 48" DIA ALTERNATE SECTION MAY BE USED IF SPECIFIED IN BID DOCUMENTS 3" PULL RING (SEE NOTE 1) B 9" SEE NOTE OUTLET 3/4 D INLET VARIABLE 8 "S" BARS (SEE NOTE 1) SH EL SHELF A #5@12 "R" BARS PULL RING F A SEE NOTE 10" 8 48" DIA #5@12 6" 48" DIA FLOW 6" SECTION A-A SHELF MH STEP (SEE NOTE 2) MH STEP PRECAST B CONC WALL PULL RING SHELF (SEE NOTE 1) VARIABLE PLAN "R" BARS TABLE OF REINFORCING BARS VA RIA BL E PIPE DIA 2" #5@12 CL DEPTH BARS "R" BARS "S" UP TO 15’ #5@12 #5@12 16’ TO 30’ #6@12 #6@12 UP TO 15’ #5@12 #5@12 16’ TO 30’ #7@12 #6@12 TO INV 8" TO 21" 24" TO 30" "S" BARS #5@12 SECTION B-B FOR 8" TO 30" PIPE COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD MANHOLE, TYPE "D" S-a-204 SHEET 1 OF 3 NOTES: 1. ALL MANHOLES SHALL BE PROVIDED WlTH A STANDARD PULL RlNG IN ACCORDANCE WlTH S-a-220. THE PULL RlNG SHALL BE LOCATED 5" ABOVE THE TOP OF PlPE ON THE UPSTREAM SlDE OF THE MANHOLE AND ALONG THE AXIS OF THE DOWNSTREAM OUTLET. WHERE THE MANHOLE IS TO BE USED AS A DOWNSTREAM SIPHON MANHOLE, IT SHALL BE PROVIDED WlTH AN ADDITIONAL STANDARD PULL RING, BUT LOCATED 5" ABOVE THE TOP OF PlPE ON THE DOWNSTREAM SlDE OF THE MANHOLE AND ON THE CENTERLINE OF THE UPSTREAM SIPHON PIPE. 2. MANHOLE STEPS SHALL BE IN ACCORDANCE WlTH S-a-209 AND SHALL BE UNIFORMLY SPACED NOT MORE THAN 16" APART. THE TOP STEP SHALL BE PLACED WITHIN 16" BELOW THE MANHOLE FRAME. THE BOTTOM MANHOLE STEP SHALL BE PLACED WITHIN 16" ABOVE THE SHELF. IN MANHOLE SHAFTS 36" IN DIAMETER AND LARGER, THE MANHOLE STEP SHALL PROJECT 5". IN MANHOLE SHAFTS SMALLER THAN 36" IN DIAMETER, THE MANHOLE STEP SHALL PROJECT 4". THE MANHOLE STEPS SHALL BE PLACED SUCH THAT THEY ARE ADJACENT TO BUT NOT INTERFERING WlTH ACCESS TO THE PULL RING. 3. THE MANHOLE SHALL BE PROVIDED WlTH PLASTIC LlNER WlTH LOCKING EXTENSIONS. PLASTIC LlNER WlTH LOCKING EXTENSIONS SHALL BE IN ACCORDANCE WlTH THE STANDARD SPECIFICATIONS. THE LlNER SHALL EXTEND FROM THE BOTTOM OF THE ADJUSTING RINGS TO THE TOP OF THE SHELF. LlNER RETURNS SHALL BE PROVIDED WHERE THE LlNER TERMINATES AT THE ADJUSTING RlNG AND THE SHELF. THE JOINT BETWEEN THE LlNER AND THE STAINLESS STEEL STEPS AND PULL RlNG SHALL BE THOROUGHLY SEALED WlTH MASTIC SEAM MATERIAL AS MANUFACTURED BY LlNABOND INC., SYLMAR, CALIFORNIA (818) 3627373, OR EQUAL. APPLICATION OF SEALANT AND PREPARATION OF SURFACES SHALL BE IN STRICT CONFORMANCE WlTH THE MANUFACTURER'S DIRECTIONS. 4. UNLESS OTHERWISE SPECIFIED, ALL CONCRETE SHALL BE 660-8-4000 ALL REINFORCING BARS SHALL BE DEFORMED BARS CONFORMING TO ASTM-A706 GRADE 60. 5. IN PAVED AREAS SUBJECT TO TRAFFIC, A 24" TRAFFIC MANHOLE FRAME AND COVER IN ACCORDANCE WlTH S-a-228 SHALL BE PROVIDED. IN ALL OTHER AREAS, A 24" LOCKING MANHOLE FRAME AND COVER IN ACCORDANCE WlTH S-a-207 SHALL BE PROVIDED. IF A 30" MANHOLE FRAME AND COVER IS REQUIRED, A FRAME AND COVER IN ACCORDANCE WlTH S-a-223 SHALL BE PROVIDED AND INSTALLED WHERE THE REDUCER RlNG IS SHOWN AND THE REDUCER RING, 24" ADJUSTING RINGS, AND 24" FRAME AND COVER SHALL BE OMITTED. 6. A 12" WIDE BY 12" HIGH CONCRETE RlNG SHALL BE PROVIDED AROUND THE MANHOLE FRAME. IN UNPAVED AREAS, THE CONCRETE RlNG SHALL BE PROVIDED WlTH #3 REBAR, 30 DIAMETER LAP. COUNTY STEPHEN R. MAGUIN CHIEF ENGINEER SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD MANHOLE, TYPE "D" STANDARD DRAWING 20- EDITION I S-a-204 SHEET 2 OF 3 NOTES: 7. EXCEPT AS NOTED HEREON, THE PRECAST UNITS SHALL BE MANUFACTURED AND TESTED IN ACCORDANCE WlTH ASTM C478. THE CURING OF THE PRECAST UNITS SHALL CONFORM TO SECTION 207-2.7 OF THE STANDARD SPECIFICATIONS. AS AN ALTERNATE, THE UNITS MAY BE CURED USING SATURATED STEAM FOR A MINIMUM OF 12 HOURS FOLLOWED BY 6 DAYS OF WATER CURING OR MEMBRANE CURING. IF THE UNITS ARE CURED BY THE ALTERNATE METHOD, THEY SHALL NOT BE SHIPPED PRIOR TO 8 DAYS AFTER CASTING NOR UNTIL THE CONCRETE HAS ATTAINED A MINIMUM STRENGTH OF 4,000 PSI. THE RISER SECTIONS MAY BE REINFORCED OR UNREINFORCED. REINFORCED SECTIONS, INCLUDING ECCENTRIC CONES, SHALL HAVE A MINIMUM WALL THICKNESS OF 5" AND UNREINFORCED SECTIONS, INCLUDING CONES, SHALL HAVE A MINIMUM WALL THICKNESS OF 6". JOINTS SHALL BE TONGUE AND GROOVE AND SHALL BE ASSEMBLED USING CLASS "B" MORTAR. THE MORTARED JOINTS SHALL BE FLUSH AND TROWELED SMOOTH. 8. THE TOP PORTION OF THE PIPES WITHIN THE MANHOLE SHALL BE CUT OUT AS NECESSARY TO PROVIDE A CIRCULAR OPENING BETWEEN THE PlPE ENDS OF AT LEAST 42". THE CUT ENDS SHALL BE PLASTERED SMOOTH WlTH CEMENT MORTAR FOR CONCRETE PlPE AND EPOXY FOR CLAY PIPE. THE CIRCULAR OPENING SHALL BE CUT PRIOR TO INSTALLATIONOF THE RISER SECTIONS. COUNTY STEPHEN R. MAGUIN CHIEF ENGINEER SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD MANHOLE, TYPE "D" STANDARD DRAWING ZOO6 EDITION S-a-204 SHEET 3 OF 3 3" MAX CLASS STD MH FRAME & COVER "B" MORTAR (SEE NOTE 5) ADJUSTING RING 9" MAX CONCRETE RING 6" MIN (SEE NOTE 6) GROUND SURFACE REDUCER RING 24" DIA 24" MAX - 12" MIN 30" DIA IF DEPTH OF MH CONE 24" MIN OR 16" ECCENTRIC (TYP) 15" PERMITS 4" MH STEPS (SEE NOTE 2) PLASTIC LINER WITH MH STEPS LOCKING EXTENSIONS 48" DIA 8" MIN PULL RING SHELF (SEE NOTE 1) 3" PULL RING (SEE NOTE 1) SEE NOTE 9 9" SEE NOTE 2" VARIABLE RIA BL E INLET 2/3 D VA VARIABLE 8 CL OUTLET #5@12 #5@12 (TYP) 6" 48" DIA 6" 3" #5@12 FOR REINF SEE CL 10" #5@12 S-a-204 (TYP) SECTION B-B SECTION A-A PULL RING B (SEE NOTE 1) SEE NOTE 8 MH STEP (SEE NOTE 2) A SHELF A DIA FLOW SHELF 48" SEE NOTE 8 MH OPTIONAL BASE COVER LOCATION B PLAN FOR 8" TO 30" PIPE COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD DROP MANHOLE S-a-205 SHEET 1 OF 4 C C ACCESS FRAME 14 1/2" 1/2" 11 3/4" 7/8" 1 1/2" 13 1/2" 1 1/4" 1/2" 2 3/4" 11 1/2" 2 3/4" 5/8" 1/2" 17" SECTION C-C 12" MIN 12" MIN THE LETTER "S" SHALL FINISHED SURFACE BE RAISED 3/8" D 11 3/4" D 12" MIN 18" MAX 3" s ACCESS CAP 11" DIA x 1/2" THICK WITH 3/4" DIA FINGER HOLE IN CENTER ACCESS COVER CONSTRUCTION JOINT 8" VCP RISER 7/8" 13" 3/8" 10" 3 7/8" 1 3/8" 3" 1" DETAIL 3/8" 10 3/4" SECTION D-D COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD DROP MANHOLE S-a-205 SHEET 2 OF 4 NOTES: 1. ALL MANHOLES SHALL BE PROVIDED WlTH A STANDARD PULL RlNG IN ACCORDANCE WlTH S-a-220. THE PULL RlNG SHALL BE LOCATED 5" ABOVE THE TOP OF PlPE ON THE UPSTREAM SlDE OF THE MANHOLE AND ALONG THE AXIS OF THE DOWNSTREAM OUTLET. WHERE THE MANHOLE IS TO BE USED AS A DOWNSTREAM SIPHON MANHOLE, IT SHALL BE PROVIDED WlTH AN ADDITIONAL STANDARD PULL RING, BUT LOCATED 5" ABOVE THE TOP OF PlPE ON THE DOWNSTREAM SlDE OF THE MANHOLE AND ON THE CENTERLINE OF THE UPSTREAM SIPHON PIPE. 2. MANHOLE STEPS SHALL BE IN ACCORDANCE WlTH S-a-209 AND SHALL BE UNIFORMLY SPACED NOT MORE THAN 16" APART. THE TOP STEP SHALL BE PLACED WITHIN 16" BELOW THE MANHOLE FRAME. THE BOTTOM MANHOLE STEP SHALL BE PLACED WITHIN 16" ABOVE THE SHELF. IN MANHOLE SHAFTS 36" IN DIAMETER AND LARGER, THE MANHOLE STEP SHALL PROJECT 5". IN MANHOLE SHAFTS SMALLER THAN 36" IN DIAMETER, THE MANHOLE STEP SHALL PROJECT 4". THE MANHOLE STEPS SHALL BE PLACED SUCH THAT THEY ARE ADJACENT TO BUT NOT INTERFERING WlTH ACCESS TO THE PULL RING. 3. THE MANHOLE SHALL BE PROVIDED WlTH PLASTIC LlNER WlTH LOCKING EXTENSIONS. PLASTIC LlNER WlTH LOCKING EXTENSIONS SHALL BE IN ACCORDANCE WlTH THE STANDARD SPECIFICATIONS. THE LlNER SHALL EXTEND FROM THE BOTTOM OF THE ADJUSTING RINGS TO THE TOP OF THE SHELF. LlNER RETURNS SHALL BE PROVIDED WHERE THE LlNER TERMINATES AT THE ADJUSTING RlNG AND THE SHELF. THE JOINT BETWEEN THE LlNER AND THE STAINLESS STEEL STEPS AND PULL RINGS SHALL BE THOROUGHLY SEALED WlTH MASTIC SEAM MATERIAL AS MANUFACTURED BY LINABOND INC., SYLMAR, CALIFORNIA (818) 362-7373, OR EQUAL. APPLICATION OF SEALANT AND PREPARATION OF SURFACES SHALL BE IN STRICT CONFORMANCE WlTH THE MANUFACTURER'S DIRECTIONS. 4. UNLESS OTHERWISE SPECIFIED, ALL CONCRETE SHALL BE 660-B-4000 AND ALL REINFORCING BARS SHALL BE DEFORMED BARS CONFORMING TO ASTM-A706 GRADE 60. 5 . IN PAVED AREAS SUBJECT TO TRAFFIC, A 24" TRAFFIC MANHOLE FRAME AND COVER IN ACCORDANCE WlTH S-a-228 SHALL BE PROVIDED. IN ALL OTHER AREAS, A 24" LOCKING MANHOLE FRAME AND COVER IN ACCORDANCE WlTH S-a-207 SHALL BE PROVIDED. IF A 30" MANHOLE FRAME AND COVER IS REQUIRED, A FRAME AND COVER IN ACCORDANCE WlTH S-a-223 SHALL BE PROVIDED AND INSTALLED WHERE THE REDUCER RlNG IS SHOWN AND THE REDUCER RING, 24" ADJUSTING RINGS, AND 24" FRAME AND COVER SHALL BE OMITTED. 6. A 12" WIDE BY 12" HIGH CONCRETE RlNG SHALL BE PROVIDED AROUND THE MANHOLE FRAME. IN UNPAVED AREAS, THE CONCRETE RlNG SHALL BE PROVIDED WlTH #3 REBAR, 30 DIAMETER LAP. - COUNTY STEPHEN R. MAGUIN CHIEF ENGINEER I I - - -- - - SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWlNG 2000 EDITION STANDARD DROP MANHOLE S-a-205 I SHEET 3 OF 4 NOTES: 7. EXCEPT AS NOTED HEREON, THE PRECAST UNITS SHALL BE MANUFACTURED AND TESTED IN ACCORDANCE WlTH ASTM C478. THE CURING OF THE PRECAST UNITS SHALL CONFORM TO SECTION 207-2.7 OF THE STANDARD SPECIFICATIONS. AS AN ALTERNATE, THE UNITS MAY BE CURED USING SATURATED STEAM FOR A MINIMUM OF 12 HOURS FOLLOWED BY 6 DAYS OF WATER CURING OR MEMBRANE CURING IF THE UNITS ARE CURED BY THE ALTERNATE METHOD, THEY SHALL NOT BE SHIPPED PRIOR TO 8 DAYS AFTER CASTING NOR UNTIL THE CONCRETE HAS ATTAINED A MINIMUM STRENGTH OF 4,000 PSI. THE RISER SECTIONS MAY BE REINFORCED OR UNREINFORCED. REINFORCED SECTIONS, INCLUDING ECCENTRIC CONES, SHALL HAVE A MINIMUM WALL THICKNESS OF 5" AND UNREINFORCED SECTIONS, INCLUDING CONES, SHALL HAVE A MINIMUM WALL THICKNESS OF 6". JOINTS SHALL BE TONGUE AND GROOVE AND SHALL BE ASSEMBLED USING CLASS "B" MORTAR. THE MORTARED JOINTS SHALL BE FLUSH AND TROWELED SMOOTH. 8. THE TOP PORTION OF THE PIPES WITHIN THE MANHOLE SHALL BE CUT OUT AS NECESSARY TO PROVIDE A CIRCULAR OPENING BETWEEN THE PlPE ENDS OF AT LEAST 42". THE CUT ENDS SHALL BE PLASTERED SMOOTH WlTH CEMENT MORTAR FOR CONCRETE PlPE AND EPOXY FOR CLAY PIPE. THE CIRCULAR OPENING SHALL BE CUT PRIOR TO INSTALLATION OF THE RISER SECTIONS. 9. THE DROP CONNECTION INTO THE MANHOLE SHALL BE VCP AND SHALL BE THE SAME SIZE AS THE LATERAL SEWER OR A MINIMUM OF 8" IN DIAMETER, WHICHEVER IS LARGER. THE RISER SHALL BE 8" VCP. COUNTY STEPHEN R. MAGUIN CHIEF ENGINEER I 1 SANITATION DISTRICTS OF LOS OFFICE OF CHIEF ENGINEER ANGELES COUNTY STANDARD DROP MANHOLE II STANDARD DRAWING 2006 EDITION S-a-205 SHEET 4 OF 4 & COVER SURFACE (SEE NOTE 5) 6" MIN (SEE NOTE 5) GROUND 9" MAX "B" MORTAR STD MH FRAME 6" MIN & COVER 9" MAX STD MH FRAME 3" MAX CLASS CONCRETE RING MH PLASTIC LINER WITH STEPS LOCKING EXTENSIONS VARIES MH STEP (SEE NOTE 2) A SEE ROOF EDGE VARIES DEPTH TO INVERT A SEALING DETAIL ON SHT 2 (TYP) 36" DIA PULL RING A (SEE NOTE 1) #5@12 " U " BARS (TYP) (TYP) OUTLET PRECAST CONC SHAFT w/ MIN 6’-6" DEPTH TO INVERT A ADJ RINGS REQ’D CONE AS 24" MIN ECCENTRIC (SEE NOTE 6) 3" PLASTIC LINER PLATE 3" (SEE NOTE 7) " V " BARS A 3" FLOW B t A INLET PULL RING (SEE NOTE 1) 9" (TYP) 2" CL SEE NOTE 10 " U " BARS (TYP) (TYP) t INLET 3" t (TYP) OUTLET #5@12 ID OF SHAFT CL 3" 2 - #5@12 #5@12 " V " BARS SECTION B-B 3" LOWER LIMIT (TYP) OF LINER PLATE (TYP) CASE II FLOW t ID + 2 t B SEE NOTE 7 " r " BARS HKD t A ID OF SHAFT 3" t CL " s " BARS HKD #5@12 SECTION B-B 2-#5@12 C PLASTIC LINER 2" PLASTIC LINER PLATE CL (TYP) CASE I " r " BARS HKD PLATE #5 CONT KD S H "s" BAR SHELF B B MH STEP (SEE NOTE 2) 36" OR 24" H M DIA G NIN OPE FLOW SHELF 9" BAR (SEE NOTE 1) "s" PULL RING (TYP) 96" MH SHAFT SEE NOTE 10 (SEE NOTE 9) (TYP) C PLAN - SECTION A-A 3 - LIFTING EYES @120 o 60", 72", 84" OR S H KD 2 - #4 (SEE S-a-230) DETAIL OF FLAT SLAB TOP 24" OR 36" x 60", 72", 84" OR 96" COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD MANHOLE, TYPE "E" S-a-206 SHEET 1 OF 4 PRECAST PIPE SHAFT MH STEP PLASTIC LINER WITH (SEE NOTE 2) LOCKING EXTENSIONS PULL RING (SEE NOTE 1) q PROVIDE PLASTIC LINER PLATE WHEN ADJ PIPE IS PVC T-LOCK LINED RGRCP, VARIES OTHERWISE LINE TO TOP OF SHELF ID OF #5@ TOP CA RR IER " U " BARS PIP _ 8" #5@12 TYPICAL EA SIDE, WHEN q > E 2" CL B+t " V " BARS PRECAST CONCRETE COVER #5@12 2 - #5@12 @ENDS MATCH EXIST 3/4" CHAMFER ALL ADJ PIPE, AROUND EXTERIOR 90 0 MAX TOP EDGES 4’ I.D. + 2 t + SECTION C-C BEARING PAD SHALL BE 1" THICK NEOPRENE PLASTIC LINER PLATE PAD TYPE 2, GRADE 2C1, PER ASTM D1056-00 AS PLASTIC LINER WITH MANUFACTURED BY LOCKING EXTENSIONS RUBATEX OR EQUAL PRECAST CONC WALL ROOF EDGE SEALING DETAIL TABLE OF REINFORCING BARS SHAFT DIA DEPTH REINFORCING BARS DIMENSIONS TO INV A B "r" "s" "u" "v" UP TO 15’ 10" 8" #6@6 #6@6 #5@12 #5@12 60" 16’ TO 30’ 12" 10" #7@6 #7@6 #6@10 #6@12 UP TO 15’ 10" 8" #6@6 #6@6 #5@12 #5@12 16’ TO 30’ 12" 10" #8@6 #8@6 #7@12 #7@12 UP TO 15’ 10" 10" #7@6 #7@6 #5@12 #5@12 16’ TO 30’ 14" 10" #8@6 #8@6 #7@12 #8@12 UP TO 15’ 12" 10" #7@6 #7@6 #6@12 #6@12 16’ TO 30’ 15" 12" #8@6 #8@6 #7@6 #8@12 72" 84" 96" COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD MANHOLE, TYPE "E" S-a-206 SHEET 2 OF 4 NOTES: 1. ALL MANHOLES SHALL BE PROVIDED WlTH A STANDARD PULL RlNG IN ACCORDANCE WlTH S-a-220. THE PULL RlNG SHALL BE LOCATED 5" ABOVE THE TOP OF PlPE ON THE UPSTREAM SlDE OF THE MANHOLE AND ALONG THE AXIS OF THE DOWNSTREAM OUTLET. WHERE THE MANHOLE IS TO BE USED AS A DOWNSTREAM SIPHON MANHOLE, IT SHALL BE PROVIDED WlTH AN ADDITIONAL STANDARD PULL RING, BUT LOCATED 5" ABOVE THE TOP OF PlPE ON THE DOWNSTREAM SlDE OF THE MANHOLE AND ON THE CENTERLINE OF THE UPSTREAM SIPHON PIPE. 2. MANHOLE STEPS SHALL BE IN ACCORDANCE WlTH S-a-209 AND SHALL BE UNIFORMLY SPACED NOT MORE THAN 16" APART. THE TOP STEP SHALL BE PLACED WITHIN 16" BELOW THE MANHOLE FRAME. THE BOTTOM MANHOLE STEP SHALL BE PLACED WITHIN 16" ABOVE THE SHELF. IN MANHOLE SHAFTS 36" IN DIAMETER AND LARGER, THE MANHOLE STEP SHALL PROJECT 5". IN MANHOLE SHAFTS SMALLER THAN 36" IN DIAMETER, THE MANHOLE STEP SHALL PROJECT 4". THE MANHOLE STEPS SHALL BE PLACED SUCH THAT THEY ARE ADJACENT TO BUT NOT INTERFERINGWlTH ACCESS TO THE PULL RING. 3. THE MANHOLE SHALL BE PROVIDED WlTH PLASTIC LlNER WlTH LOCKING EXTENSIONS. PLASTIC LlNER WlTH LOCKING EXTENSIONS SHALL BE IN ACCORDANCE WlTH THE STANDARD SPECIFICATIONS. THE LlNER SHALL EXTEND FROM THE BOTTOM OF THE ADJUSTING RINGS TO THE TOP OF THE SHELF UNLESS THE ADJACENT PlPE IS LINED. IF THE ADJACENT PlPE IS LINED, THE LlNER SHALL EXTEND TO A POINT IN THE CHANNEL MATCHING THE BOTTOM OF THE LlNER IN THE LINED PIPE. LlNER RETURNS SHALL BE PROVIDED WHERE THE LlNER TERMINATES AT THE ADJUSTING RlNG AND THE SHELF. THE JOINT BETWEEN THE LlNER AND THE STAINLESS STEEL STEPS AND PULL RINGS SHALL BE THOROUGHLY SEALED WlTH MASTIC SEAM MATERIAL AS MANUFACTURED BY LINABOND INC., SYLMAR, CALIFORNIA (818) 362-7373, OR EQUAL. APPLICATION OF SEALANT AND PREPARATION OF SURFACES SHALL BE IN STRICT CONFORMANCE WlTH THE MANUFACTURER'S DIRECTIONS. 4. UNLESS OTHERWISE SPECIFIED, ALL CONCRETE SHALL BE 660-B-4000 AND ALL REINFORCING BARS SHALL BE DEFORMED BARS CONFORMING TO ASTM-A706 GRADE 60. 5 . IN PAVED AREAS SUBJECT TO TRAFFIC, A 24" TRAFFIC MANHOLE FRAME AND COVER IN ACCORDANCE WlTH S-a-228 SHALL BE PROVIDED. IN ALL OTHER AREAS, A 24" LOCKING MANHOLE FRAME AND COVER IN ACCORDANCE WlTH S-a-207 SHALL BE PROVIDED. IF A 36" MANHOLE FRAME WlTH 30" COVER IS REQUIRED, A FRAME AND COVER IN ACCORDANCE WlTH S-a-226 SHALL BE PROVIDED. 6. A 12" WIDE BY 12" HIGH CONCRETE RlNG SHALL BE PROVIDED AROUND THE MANHOLE FRAME. IN UNPAVED AREAS, THE CONCRETE RlNG SHALL BE PROVIDED WlTH #3 REBAR, 30 DIAMETER LAP. COUNTY STEPHEN R. MAGUIN CHIEF ENGINEER SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD MANHOLE, TYPE "EM STANDARD DRAWING 2006 EDITION S-a-206 SHEET 3 OF 4 NOTES: EXCEPT AS NOTED HEREON, THE PRECAST UNITS SHALL BE MANUFACTURED AND TESTED IN ACCORDANCE WlTH ASTM C478. THE CURING OF THE PRECAST UNITS SHALL CONFORM TO SECTION 207-2.7 OF THE STANDARD SPECIFICATIONS. AS AN ALTERNATE, THE UNITS MAY BE CURED USING SATURATED STEAM FOR A MINIMUM OF 12 HOURS FOLLOWED BY 6 DAYS OF WATER CURING OR MEMBRANE CURING IF THE UNITS ARE CURED BY THE ALTERNATE METHOD, THEY SHALL NOT BE SHIPPED PRIOR TO 8 DAYS AFTER CASTING NOR UNTIL THE CONCRETE HAS ATTAINED A MINIMUM STRENGTH OF 4,000 PSI. THE RISER SECTIONS MAY BE REINFORCED OR UNREINFORCED. REINFORCED SECTIONS, INCLUDING ECCENTRIC CONES, SHALL HAVE A MINIMUM WALL THICKNESS OF 5" AND UNREINFORCED SECTIONS, INCLUDING CONES, SHALL HAVE A MINIMUM WALL THICKNESS OF 6". JOINTS SHALL BE TONGUE AND GROOVE AND SHALL BE ASSEMBLED USING CLASS "B" MORTAR. THE MORTARED JOINTS SHALL BE FLUSH AND TROWELED SMOOTH. UNLESS OTHERWISE INDICATED ON THE DRAWINGS, CASE I OR II MAY BE USED BY THE CONTRACTOR AT HIS OPTION CONSISTENT WlTH DIAMETER COVER LIMITATIONS INDICATED HEREON. CASE I SHALL NOT BE USED FOR COVER ON PlPE LESS THAN 12' CASE II SHALL NOT BE USED FOR COVER ON PlPE MORE THAN 12'. RISER SECTIONS 6 0 THROUGH 96" I.D. SHALL BE REINFORCED IN ACCORDANCE WlTH ASTM C 478 AND SHALL HAVE THE FOLLOWING MINIMUM WALL THICKNESS (t). 6 0 I.D. - 5";72" I.D. - 6"; 84" I.D. - 7"; 96" I.D. - 8" THE TOP PORTION OF THE PIPES WITHIN THE MANHOLE SHALL BE CUT OUT AS NECESSARY TO PROVIDE A CIRCULAR OPENING BETWEEN THE PlPE ENDS OF AT LEAST 54" IN THE 60" DIAMETER MANHOLE AND 66" IN THE 72" DIAMETER MANHOLE, 78" IN THE 84" DIAMETER MANHOLE AND 90" IN THE 96" DIAMETER MANHOLE. THE CUT ENDS SHALL BE PLASTERED SMOOTH WlTH CEMENT MORTAR FOR CONCRETE PlPE AND EPOXY FOR CLAY PIPE. THE CIRCULAR OPENING SHALL BE CUT PRIOR TO INSTALLATION OF THE RISER SECTIONS. COUNTY STEPHEN R. MAGUIN CHIEF ENGINEER SANITATION I I DISTRICTS OF LOS OF CHIEF ENGINEER A N G E L E S COUNTYOFFICE STANDARD MANHOLE, TYPE "E" I 1 STANDARD DRAWING 2006 EDITKIN S-a-206 SHEET 4 OF 4 1/ 4" P) 2" Y (T (TYP) 6 - 1/2" RIBS 1/ SEE DETAIL OF NOTCHES 3/ 4" 2" 1/ P) Y (T 1/8" 1 "A" C L SLOT 3/4" 1 3/8" A 31 A B 9/1 6 B C " 3" 6" 3" 7 1/2 28 15 C 71 /2 LOCKING GUIDE (TYP) 60 3" 25 1/4" DIA "A" C L SLOT SLOT "A" 1 1/4" 22 1/2" DIA 1 1/2" PLAN OF COVER TOP VIEW R=1/8" (TYP) PLAN OF FRAME 7/8" 25 1/4" DIA 3/4" 25 1/2" DIA 2 5/8" 3/4" DIA 1 1/2" 9/16" 1/8" 1/8" 1 3/4" 7/32" 29/32" 2 3/16" 3 5/16" 1 1/8" 1 1/2" 3/4" R=1/8" 4 1/8" HOLE 4" 3 PLCS VARIABLE SECTION A-A 3 7/8" 24" 31 3/4" SECTION B-B END VIEW 60 3 7/8" 3/4" 23 3/4" 1 11/32" 1 9/32" 1 5/16" 1 3/16" (TYP) 1 5/32" 6" 8" " 4 1/8" 1" 2 1/2" 5/8" 1" 5/8" SIDE VIEW C-C 1 1/2" LOCKING GUIDE 3/4" 7/ 2" 3/16" 16 1/ 30 3/ 5" 3/4" 1 3/4" 1/8" " /8 63 9" (TY P) 1/2" 30 73 /8 " 60 1 1/2" COVER LUG DETAIL OF NOTCHES 1" HOLE 20 3/4" (TYP) NOTES: 21 1/8" 1. CAST IRON USED SHALL CONFORM WITH ASTM A-48 CLASS 35B. 22 1/8" 2. FRAME AND COVER SHALL BE COATED WITH ASPHALTUM OR BITUMINOUS PAINT AFTER TESTING AND INSPECTION. 22 1/2" 25 1/4" DIA PLAN OF COVER 3. FRAME AND COVER SHALL BE TESTED FOR ACCURATE FIT PRIOR TO DELIVERY AND SHALL BE MARKED IN SETS. 4. ALL CASTINGS SHALL COMPLY WITH SECTION 206-3 OF THE STANDARD SPECIFICATIONS. BOTTOM VIEW COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN STANDARD 24" LOCKING MANHOLE CHIEF ENGINEER FRAME AND COVER 2006 EDITION S-a-207 SHEET 1 OF 1 28 15/16" 27 3/16" 27 1/16" 1 13/32" 1 3/4" 1 3/4" 3 1/4" NOTE: COVER SHALL BE SNUG FIT, NOT TIGHT 5/8" DIA x 10" LG SS ANCHOR BOLT " 7" OR CONC) ON 5 /16" x 24 1/2" FLAT SLAB TYPE 316 SS PLATE 2 1/ 6" MH WALL (BRICK 1" 7/8" w/ HH NUT TYPE 316 SS TYPE 316 (2 REQUIRED) TOP 22 1/2" 24" 31 3/4" APPLY ANTI-FREEZE CASTING TO BE SET SECTION AGENT (TYP) IN WET MORTAR 2 3/32" MANHOLE FRAME AND COVER 1 7/32" 1 1/2" 3/8" 1/16" 1 3/4" 3 3/8" 1/8" 1/4" 5/32" 1 5/8" 1" 11/16" 3/16" 1 1/2" 15 R R = 1/4" DIA " R 3/8" x 1" TYPE 316 1 3/4" =1 24 3/4’’ " 1/2 11/16" SS CAP SCREW (12 REQUIRED) 3 1/8" 6" 15 /2 =1 7/8" USS STD THD 7/8" 1/2’’ DIA HOLE (TYP) 3/4" 24 1/2" 1" IA 1/ SECTION B-B 1 1/8" SS PLATE " /2 3 1 2 IA 3 1/2" 5/16’’ TYPE 316 NEOPRENE GASKET 10" D 1 1/4" 1 1/8’’ WIDE BY 1/8" 1/2" 3/4" 2" D 4 5/8" 27 1/16" SECTION A-A PRESSURE PLATE 1’’ DIA HOLE 2 PLCS 3/4’’ DIA HOLE (TYP) 7" A DI 9 C S D E W E " 3/4 R A 23 11 /2" IA D 4" 1/ IA B B S 1 /2 71 4" 1/ D 29 R 2" 1/ A 1 2" 1/ DRILL & TAP 3/8’’ 7 1/ 2 1 30 5 PRY NOTCH PLAN OF COVER PLAN OF COVER PLAN OF FRAME BOTTOM VIEW TOP VIEW NOTE: FOR NOTES SEE S-a-207. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN STANDARD 24" PRESSURE MANHOLE CHIEF ENGINEER FRAME AND COVER 2006 EDITION S-a-208 SHEET 1 OF 1 CONC WALL CONC WALL OR MH RISER OR MH RISER 3/4" DIA SS BAR TYPE 316 CAST-IN-PLACE PLASTIC LINER WITH LOCKING EXTENSIONS A 1 1/2" C L A C L C L 2 1/2" 1’-2" C L 4" OR 5" AS REQ’D C L 4" OR 5" AS REQ’D 8" FOR PRECAST SECTIONS 13" FOR CAST-IN-PLACE C L PLAN SECTION A-A TYPE I MANHOLE STEP CONC WALL CONC WALL 3/4" DIA SS BAR TYPE 316 PLASTIC LINER WITH LOCKING EXTENSIONS C L B B C L 2 1/2" 1’-2" C L THREADED BARS IN DRILLED HOLES AND EPOXY GROUT (TYP) 4" OR 5" AS REQ’D C L 4" OR 5" AS REQ’D 13" C L PLAN SECTION B-B TYPE I I MANHOLE STEP COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD MANHOLE STEP S-a-209 SHEET 1 OF 1 TRAP CASTING SHELF C 1/2" MORTAR B SEWAGE LEVEL IN TRAP BASE WHEN NO SEWAGE INLET C / 2 WATER SEAL TRAP AND /2 MANHOLE C CHANNEL BASE 9" INCREASER BASE B VARIABLE A A D SECTION A-A OUTLET C INCREASER VARIABLE 9" CAULK WITH CEMENT MORTAR TRAP TRAP CASTING SHELF LEVEL 1" CASTING POINT WITH MORTAR OUTLET A 2" MIN IS FLOWING VARIABLE NORMAL CHANNEL BASE B PLAN - SINGLE TRAP BASE A 660-B-4000 INLET VARIABLE 9" CHANNEL BASE T 1 1: TRAP AND OUTLET 1: 1 VARIABLE THE ENGINEER 1/2" AS APPROVED BY C / 2 OR OFFSET OUTLET C / 2 B 420-C-2000 SECTION B-B TABLE OF DIMENSIONS DIA OF MANHOLE BASE (D) INLET INLET TRAP TRAP DIA INCREASER SIZE PER VARIABLE OUTLET DIAMETER 8" 10" 12" 4’ 4’ 4’ 4’ 4’ INLET INCREASER 8" x 10" 10" S-a-211 10" 10" x 12" 12" S-a-211 C /2 MANHOLE 8" ( FOR 12" INLETS AND LARGER SEE CONSTRUCTION DRAWINGS ) INCREASER TRAP BASE DIMENSIONS 9" A A A TRAP CASTING OUTLET /2 VARIABLE C INLET VARIABLE D A B C 10" 7 1/2" 14 1/2" 13" 28 1/2" 9" 12" 8 1/2" 16 1/2" 15" 32 1/2" 10" A+B+ /2 T MIN NOTES: 1. WHERE A TRAP IS NECESSARY IN AN EXISTING STRUCTURE, BREAK OUT CONCRETE AND CONSTRUCT NEW BASE. 2. PLAN - DOUBLE TRAP BASE C TRAP DIA FOR GENERAL NOTES AND CONSTRUCTION DETAILS OF BRICKWORK, SEE S-a-201. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD TRAP MANHOLE BASE S-a-210 SHEET 1 OF 1 DIMENSIONS OF CASTINGS 1 3/8" INLET DIA A B R L 10" 6" 9" 11" 14 3/4" 12" 7" 11" 13" 17 3/4" 7/16" x 3/4" 7/8" MACHINED SLOT 7/8" R 1" R 1/ 60 3/4" 1. CAST IRON USED SHALL CONFORM WITH ASTM A-48 CLASS 35B. 2. FLANGES OF CASTING SHALL BE MACHINED FACED. 3. CASTINGS SHALL BE DIPPED TWICE IN HOT ASPHALT PAINT. 4. RUBBER GASKET SHALL BE NEOPRENE 35-50 SHORE. 2 3/4" 1 7/8" 7/16" HOLE NOTES: 3/4" o R 1 7/8" 4" 1" 1/2" 1 1/2" 2" DETAIL "A" SEE DETAIL "A" DETAIL "B" SEE DETAIL "B" 1/4 " 1/8" 1/4" 3/4" A 2" 2" " 2" 1 4 1/ R B 1/8" 2" 1" BRASS FACING 1 1/2" DIA BRAZED & MACHINE FINISHED o 85 o 2" 65 R 1" R 1/4" x 1/2" RUBBER GASKET 1" SEE DETAIL "C" 1/2" L SECTIONAL VIEW 3/8 " 1/4" x 1/4" GROOVE 1/4" x 1/2" IN FLANGE FACE RUBBER OF ELBOW BRASS COTTER PIN GASKET 3/4" 4 3/8" DETAIL "C" 1’ BRASS WASHER 3/4" 3/4" BRASS ROD 2 5/8" 3/8" x 6 3/4" 3/4" 1’ BRASS WASHER 3/4" 3/8" BRASS COTTER PIN PLAN VIEW COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD TRAP CASTING S-a-211 SHEET 1 OF 1 O D IN O 6" IN M PERMISSIBLE EXCAVATION LINE M PERMISSIBLE EXCAVATION LINE CRADLE TYPE 1 6" MIN D O 6" 6" 6" MIN 1/4 OD M D 1/4 OD 6" 6" MIN MIN 6" MIN IN PERMISSIBLE EXCAVATION LINE CRADLE TYPE 2 ENCASEMENT TYPE 1 6" MIN 6" MIN 6" MIN 6" MIN 6" MIN D D 6" OPTIONAL CONST JOINT 6" MIN 6" MIN 2" 6" MIN 1/4 OD 2" 6" O 3/4 OD O 1/4 OD D 1/4 OD O OPTIONAL CONST JOINT CRADLE TYPE 1A CRADLE TYPE 2A ENCASEMENT TYPE 1A NOTES: 1. ALL CONCRETE FOR CRADLES TYPE 1 AND 2 AND ENCASEMENT TYPE 1 SHALL BE 420-C-2000. ALL CONCRETE FOR CRADLES TYPE 1A AND 2A AND ENCASEMENT TYPE 1A SHALL BE 660-B-4000. USE IS LIMITED TO BEDDING CONCRETE OVER WHICH BACKFILL WILL BE PLACED NOT LESS THAN 40 HOURS AFTER PLACEMENT. FOR BACKFILL AFTER 24 HOURS, ADD A NON-CHLORIDE ACCELERATING ADMIXTURE APPROVED BY THE ENGINEER AT DOSEAGES AS REQUIRED BY THE MANUFACTURER OF THE ADMIXTURE. FOR BACKFILL AFTER 16 HOURS AND REMOVAL OF SHEETING AFTER 18 HOURS, USE 660-C-4000 WITH A NON-CHLORIDE ACCELERATING ADMIXTURE APPROVED BY THE ENGINEER AT DOSAGES AS REQUIRED BY THE MANUFACTURER OF THE ADMIXTURE. 2. THE CONCRETE FOR CRADLES TYPE 1 AND 2 AND ENCASEMENT TYPE 1 SHALL NOT BE POURED AGAINST TRENCH SHEETING, FORMS, OR ON LOOSE MATERIAL IN THE TRENCH BOTTOM, BUT SHALL BE POURED AGAINST AND ON THE UNDISTURBED TRENCH WALLS AND BOTTOM. 3. THE CONCRETE FOR CRADLES TYPE 1A AND 2A AND ENCASEMENT TYPE 1A MAY BE POURED AGAINST TRENCH SHEETING, FORMS, OR AGAINST THE TRENCH WALLS, BUT SHALL NOT BE POURED ON LOOSE MATERIAL IN THE TRENCH BOTTOM. 4. UNLESS OTHERWISE PROVIDED IN THE SPECIFICATIONS OR AUTHORIZED BY THE ENGINEER, WHEN THE MAXIMUM ALLOWABLE TRENCH WIDTH HAS BEEN EXCEEDED. THE PIPE SHALL BE CRADLED WITH TYPE 1 OR TYPE 2 IF THE TRENCH IS IN UNDISTURBED SOIL OR TYPE 1A OR TYPE 2A IF THE TRENCH IS IN UNSTABLE SOIL. IF THE TRENCH WIDTH IS LESS THAN ONE AND ONE HALF TIMES THE MAXIMUM ALLOWED BY THE SPECIFICATIONS WITHOUT SPECIAL BEDDING, OR IF THE COVER ON THE PIPE IS LESS THAN TEN FEET. CRADLE TYPE 1 OR 1A SHALL BE USED. IF THE TRENCH WIDTH IS MORE THAN ONE AND ONE HALF TIMES THE MAXIMUM ALLOWED BY THE SPECIFICATIONS WITHOUT SPECIAL BEDDING AND THE COVER IS TEN FEET OR MORE, CRADLE TYPE 2 OR 2A SHALL BE USED. 5. UNLESS OTHERWISE AUTHORIZED BY THE ENGINEER, ALL CRADLES AND ENCASEMENTS SHALL BE PLACED SUCH THAT BOTH ENDS TERMINATE WITHIN 18 INCHES OF A FLEXIBLE JOINT. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER STANDARD CONCRETE CRADLES AND ENCASEMENTS 2006 EDITION S-a-212 SHEET 1 OF 1 A 2" 6" 1’-4" 4" 3" V A R IA B LE 4" 4" 420-C-2000 MAIN SEWER PIPE A PLAN SECTION A-A 3" 1’-4" MAIN SEWER PIPE ELEVATION COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD "T" FOUNDATION S-a-213 SHEET 1 OF 1 NOTES: 6" 1. A THE UPPER END OF THE CHIMNEY PIPE SHALL BE 8 FEET BELOW THE GRADE OF THE LOWER 6" 12" CURB, UNLESS OTHERWISE SPECIFIED. 2. WHERE ONE OR TWO HOUSE CONNECTIONS ARE TO BE JOINED TO THE CHIMNEY PIPE, USE A SINGLE "Y" BRANCH. WHERE THREE HOUSE CONNECTIONS ARE TO BE JOINED USE A DOUBLE CEMENT "Y" BRANCH. MORTAR 3. WHERE THE CHIMNEY PIPE IS TO BE USED FOR A SINGLE HOUSE CONNECTION, FACE THE "Y" TOWARDS THE PROPERTY TO BE SERVED; WHERE USED FOR HOUSE CONNECTIONS ON BOTH SIDES OF THE SEWER, THE "Y" SHALL FACE TOWARD THE RIGHT (LOOKING UP GRADE) AND THE HOUSE ON THAT SIDE SHALL BE CONNECTED TO THE "Y" BRANCH BY A 6 INCH ONE-EIGHTH BEND AND THE HOUSE CONNECTION ON THE LEFT SIDE SHALL BE 1’-4" 1’-4" CONNECTED TO THE UPPER END OF THE CHIMNEY BY A 6 INCH ONE-QUARTER BEND UNLESS OTHERWISE SPECIFIED. 4. THE MAIN SEWER PIPE SHALL BE OF THE MATERIAL SHOWN ON THE PLANS. 6" VCP B 2" B 420-C-2000 3" 3" V A R IA B LE 4" MAIN SEWER PIPE SECTION A-A A ELEVATION 4" 4" 1’-4" MAIN SEWER PIPE PLAN-SECTION B-B COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD CHIMNEY PIPE S-a-214 SHEET 1 OF 1 LIFTING EAR & RIB 8 PLCS 1 1/4" DIA SEE DETAIL HOLE 8 PLCS A A B 45 0 B IB R S C 8" L 7/ P 8 30 0 PRY NOTCH PLAN OF COVER TOP VIEW 8 40 1/2" PLAN OF FRAME 5/16" 20 PRY 1" 3 1/8" (TYP) DIA 1 1/4" GROOVE (TYP) 42 1/4" 1" 39" 1" 3/4" 4" 3/4" 3/4" 37" 1 1/2" 6" 20" 1 1/4" 5" 1/2" 8 2 1/2" 3 1/4" 5/8" 3" 1 1/4" 2 1/2" 40 3/4" NOTCH 36" CLEAR SECTION A-A 4" 44" SECTION B-B 1 1/4" 30 1 1/2" 1" DIA HOLE 2 PLCS 1 1/4" HOLE 8 PLCS " /2 11 R = PRY 2 1/2" 1" (TYP) 5/8" (TYP) NOTCH DETAIL 13 1/4 " LIFTING EAR & RIB R 45 NOTES: 1. CAST IRON USED SHALL CONFORM WITH ASTM A-48 CLASS 35B. 2. FRAME AND COVER SHALL BE COATED WITH ASPHALTUM OR BITUMINOUS PAINT AFTER TESTING AND INSPECTION. 2 22 1/ 3. PRIOR TO DELIVERY AND SHALL BE MARKED IN SETS. 4. PLAN OF COVER FRAME AND COVER SHALL BE TESTED FOR ACCURATE FIT ALL CASTINGS SHALL COMPLY WITH SECTION 206-3 OF THE STANDARD SPECIFICATIONS. BOTTOM VIEW COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN STANDARD 36" MANHOLE FRAME CHIEF ENGINEER AND COVER 2006 EDITION S-a-215 SHEET 1 OF 1 PLUG SEWER LATERAL FROM HOUSE 4" MIN FLOW 1" 5" MIN MIN FLOW STD 4" SPIGOT END HAND-HOLE TRAP NOTES: 1. GAS TRAP SHALL BE INSERTED AT THE POINT OR POINTS OF CONNECTION TO THE HOUSE PLUMBING TWO (2) FEET OUTSIDE THE BUILDING AT PROPERTY OWNER’S EXPENSE. 2. SPIGOT END HAND-HOLE TRAPS OF CAST IRON SOIL PIPE MAY BE USED IN LIEU OF VITRIFIED CLAY PIPE FITTINGS. 3. GAS TRAP MADE OF OTHER MATERIALS MAY BE SUBMITTED FOR APPROVAL. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD HOUSE CONNECTION GAS TRAP S-a-216 SHEET 1 OF 1 PIPE OD 6 OD MIN A APPLY 1 COAT ASPHALT CONCRETE CONCRETE SUPPORT SUPPORT PROPOSED PROPOSED SEWER SEWER EMULSION OR APPROVED EQUAL TO PREVENT BONDING. 6" DIA HOLES OD MIN A ELEVATION SECTION A-A NOTES: 1. CONCRETE SUPPORT SHALL BE POURED AGAINST UNDISTURBED SOIL ON THE BOTTOM AND SHALL EXTEND THE FULL WIDTH OF EXCAVATION. 2. CONCRETE SHALL BE 420-C-2000. WHEN APPROVED BY THE ENGINEER, THE CONTRACTOR MAY SUBSTITUTE CONCRETE WITH 2-SACK CEMENT SAND SLURRY. 3. CONTRACTOR SHALL OBTAIN APPROVAL FROM THE ENGINEER OF HIS PROPOSED METHOD OF SUPPORTING THE EXISTING PIPE LINES DURING CONSTRUCTION. 4. CONTRACTOR SHALL PROVIDE CONCRETE PIPE SUPPORT UNDER ALL EXISTING CONCRETE, ASBESTOS CEMENT, CLAY, TELEPHONE AND POWER CONDUITS AND UNDER ALL OTHER CONDUITS WHERE REQUIRED ON THE PLANS OR REQUESTED BY 5. OWNER. CONCRETE PIPE SUPPORT TO BE PAID UNDER THE APPROPRIATE PIPE BID ITEM. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD CONCRETE PIPE SUPPORT S-a-217 SHEET 1 OF 1 GROUND SURFACE GROUND SURFACE EXIST BRICK OR 24" DIA CONCRETE WALLS STEP (SAND FILL) (SAND FILL) BREAK OUT 2 DRAIN HOLES 100-C-100 24" MIN 100-C-100 HALF SEGMENT OF PIPE TIGHTLY SEATED ER ER W ET SE AM K DI N U FLOW TR TIGHTLY SEATED DIAMETER HALF SEGMENT OF PIPE 6" TRUNK SEWER 6" CUT AWAY EXISTING MASONRY OR CONCRETE TO FORM SEAT FOR SEGMENT AND MORTAR LONGITUDINAL SECTION CROSS SECTION NOTES: 1. FORTY-EIGHT HOURS PRIOR TO COMMENCING THE ABANDONMENT OF THE MANHOLE. THE CONTRACTOR SHALL CONTACT THE DISTRICTS’ SUPERINTENDENT OF MAINTENANCE AT (323) 774-7272. 2. NO WORK SHALL BE DONE ON MANHOLE EXCEPT IN THE PRESENCE OF COUNTY SANITATION DISTRICT REPRESENTATIVE. 3. MANHOLE FRAME AND COVER OF THE MANHOLE TO BE ABANDONED SHALL BE SALVAGED, CLEANED AND DELIVERED TO THE DISTRICTS’ COMPTON FIELD OFFICE, 920 SOUTH ALAMEDA STREET, COMPTON, CALIFORNIA. 4. THE CONTRACTOR SHALL REMOVE A MINIMUM OF THREE FEET OF THE MANHOLE SHAFT BELOW STREET SUBGRADE. 5. IF THE LOWER PORTION OF THE EXISTING CHANNEL THROUGH THE MANHOLE IS NOT AS SHOWN. THE CHANNEL SHALL BE REFORMED AS DIRECTED BY THE COUNTY SANITATION DISTRICT REPRESENTATIVE. 6. HALF SEGMENT OF PIPE SHALL BE OF THE TYPE USED IN THE SEWER. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER STANDARD ABANDONMENT OF EXISTING MANHOLES TYPE "A" OR "D" 2006 EDITION S-a-218 SHEET 1 OF 1 RESET MANHOLE FRAME AND COVER 5" PROPOSED GROUND SURFACE 48" MAX EXISTING GROUND SURFACE (DIM " A ") 10" REMOVE EXISTING 24" DIA 30" DIA FRAME & COVER EXISTING EXISTING GROUND SURFACE GROUND SURFACE 1/2" PROPOSED PLASTER CONC CURB & GUTTER EXISTING PORTION NEW PLASTER TO REMAIN ALLOWABLE NEW BRICK- PLASTER NEW BRICK5 WORK CASE I WORK 2 ALLOWABLE VERTICAL WALL TO REMAIN MAXIMUM 1/2" 24" DIA MAXIMUM EXISTING PORTION 2 TO REMAIN 5 5 EXISTING PORTION 30" MIN 24" DIA TO BE REMOVED 1/2" WORK TO BE REMOVED SURFACE 2 EXISTING PORTION EXIST. PORTION GROUND EXISTING PORTION BRICKPROPOSED CASE II CASE III NOTES: 1. PRIOR TO THE REMOVAL OF THE FRAME OF ANY MANHOLE, THE CHANNEL OF THE MANHOLE SHALL BE COMPLETELY COVERED WITH PLANKING OR OTHER SUITABLE MATERIAL SO AS TO PREVENT DEBRIS FROM ENTERING THE CHANNEL. AFTER THE MANHOLE RECONSTRUCTION HAS BEEN COMPLETED ALL DEBRIS SHALL BE REMOVED FROM WITHIN THE MANHOLE AND THE COVER OVER THE CHANNEL SHALL BE REMOVED. 2. WHEN THE MANHOLE IS TO BE RECONSTRUCTED TO A STRAIGHT SIDED MANHOLE, THE BRICK WORK SHALL BE REMOVED TO THE HIGHEST POINT OF THE VERTICAL WALL. THE SLOPE OF THE CORBELED SIDE SHALL NOT EXCEED 2 INCHES IN 5 INCHES. THE MANHOLE STEPS SHALL BE PLACED ON THE VERTICAL SIDE. SEE CASE III. 3. WHEN THE MANHOLE IS TO BE RAISED AN AMOUNT SUCH THAT DIMENSION "A" (CASE II) IS LESS THAN 4’, THE BRICKWORK SHALL BE REMOVED TO A POINT WHERE THE INSIDE DIAMETER IS A MINIMUM OF 30 INCHES. THE MANHOLE WALL SHALL THEN BE CONSTRUCTED VERTICALLY TO A POINT 15 INCHES BELOW THE TOP OF THE MANHOLE. SEE CASE II. 4. WHERE THE MANHOLE IS TO BE RAISED SUCH THAT DIMENSION "A" (CASE II) WOULD EXCEED 4’, THE BRICKWORK SHALL BE REMOVED TO THE HIGHEST POINT OF THE VERTICAL WALL AND THE MANHOLE RECONSTRUCTED PER S-a-201 OR S-a-204. 5. WHEN THE DEPTH OF THE MANHOLE TO BE LOWERED IS SUCH THAT THE MAXIMUM ALLOWABLE SLOPES FOR THE BRICKWORK SHOWN FOR CASE I WOULD BE EXCEEDED. THE MANHOLE SHALL BE RECONSTRUCTED AS 6. A TYPE "C" MANHOLE PER S-a-203. MANHOLE STEPS, PER S-a-209, SHALL BE PLACED UNIFORMLY SO AS NOT TO BE MORE THAN 16 INCHES APART WITH THE TOP STEP BEING 16 INCHES BELOW THE MANHOLE FRAME. 7. PRIOR TO COMMENCING WORK OF RECONSTRUCTION, THE CONTRACTOR SHALL CONTACT DISTRICTS’ SUPERINTENDENT OF MAINTENANCE AT (323) 774-7272. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER STANDARD RECONSTRUCTION OF BRICK MANHOLES 2006 EDITION S-a-219 SHEET 1 OF 1 3/4" DIA SS TYPE 316, R=3" ASTM A-276 PLASTIC LINER WITH INSIDE FACE OF VARIES 6" CONCRETE 9" R =1" BRICK OR STRUCTURE WALL 3" LOCKING EXTENSIONS FOR CONCRETE STRUCTURE OR TYPE "A" MANHOLE WALL DRYPACK WITH 5000 psi 3/4" DIA SS TYPE 316, R=3" ASTM A-276 NON-SHRINK GROUT PLASTIC LINER WITH PRECAST MANHOLE LOCKING EXTENSIONS VARIE S 3" SECTION WASHER (TYP) MIN 2" 2" x 2" x 3/8" SS 1" x 9" BACKFILL IN 2-SACK BLOCKOUT SAND SLURRY FOR PRECAST MANHOLE SECTION OR CONCRETE WALL LESS THAN 8" 3/4" DIA SS THREADED BAR IN EPOXY ADHESIVE 3/4" DIA SS TYPE 316, R=3" ASTM A-276 CONCRETE ANCHORS PLASTIC LINER WITH 3" WALL EMBEDMENT CL 2" 8" MIN LOCKING EXTENSIONS 3 3/8" 3 3/8" ALTERNATE PULL RING FOR CONCRETE STRUCTURE COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD PULL RING S-a-220 SHEET 1 OF 1 4’-0" 3" SEWER CONSTRUCTION PROJECT 2 1/2" 3" CONTRACTOR 2" 6" CONTRACTOR’S NAME 3" PHONE 2" DISTRICT NUMBER FOR 6’-0" 4’-0" 5" INSERT 3 1/2" 2" 2" SANITATION DISTRICT No. OF LOS ANGELES COUNTY STEPHEN R. MAGUIN 2 1/2" 1 1 1 1 1/2" 1/2" 3/4" 3/4" 1" CHIEF ENGINEER & GENERAL MANAGER 6" 1’-11" 2’-0" 3" 6" 5’-0" FRONT VIEW SIDE VIEW NOTES: 1. ALL FRAMING LUMBER SHALL BE 2" x 6" S4S D.F. 2. ENTIRE SIGN, INCLUDING FRAMING, SHALL BE PAINTED WITH TWO COATS OF EXTERIOR OIL BASE WHITE PAINT. 3. LETTERING SHALL BE DONE IN BLACK BY QUALIFIED SIGN PAINTER AND TO THE SATISFACTION OF THE ENGINEER. 4. SIGNS SHALL BE MAINTAINED IN A CONDITION SATISFACTORY TO THE ENGINEER. 5. SIGNS SHALL BE FURNISHED BY CONTRACTOR AND INSTALLED AND MOVED BY CONTRACTOR AS DIRECTED BY THE ENGINEER. NO CONSTRUCTION SHALL COMMENCE UNTIL SIGNS ARE IN PLACE. TWO REQUIRED. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD PROJECT SIGN S-a-221 SHEET 1 OF 1 C L BEARING BLOCKS C L BEARING BLOCKS SPAN 2" THICK A TIMBER PADS STEEL BEAM (SEE TABLE) DETAIL "1" STEEL SUPPORT BEAMS (SEE TABLE) 2x OR 4x 2’ 4’ MAX MAX 2x12 OR 4x12 Gr 2 S4S BEARING TIMBER BLOCKS (TYP) BLOCKS (SEE TABLE) (SEE TABLE) DETAIL "2" TURNBUCKLE (SEE TABLE) TURNBUCKLE WIRE CLIPS VERTICAL 3 WIRE ROPE SHORING AS CLIPS EACH SIDE REQUIRED @ 3" O.C. WIRE WIRE ROPE ROPE EXISTING PIPE EXISTING PIPE 4x4 TIMBER BLOCKS 8" LONG (TYP) NOTE: 4x4 TIMBER BLOCK 8" A LONG (TYP) A MINIMUM OF 2 HANGER ASSEMBLIES PER JOINT OF PIPE ELEVATION SECTION A-A WIRE ROPE THIMBLE (TYP) 2" THICK TIMBER PADS STEEL BEAM STANDARD TURNBUCKLE (SEE TABLE) WIRE ROPE 3 WIRE ROPE CLIPS EACH SIDE @ 3" O.C. DETAIL "1" DETAIL "2" COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD TEMPORARY PIPE SUPPORT S-a-222 SHEET 1 OF 2 TABLE OF MEMBER SIZES (PART I) STEEL BEAMS PIPE WIRE SPAN SIZE 0’ - 10’ 11’ - 15’ 16’ - 20’ TURNBUCKLE ROPE 21’ - 30’ 31’ - 40’ 8" - 10" w6x9 w6x9 w6x9 w 8 x 18 w 10 x 22 3/8" 1/2" 12" - 15" w6x9 w 6 x 15 w 6 x 20 w 10 x 22 w 12 x 30 3/8" 1/2" 18" - 21" w6x9 w 8 x 18 w 8 x 24 w 10 x 33 w 12 x 53 3/8" 1/2" 24" - 27" w 6 x 15 w 8 x 18 w 8 x 28 w 12 x 40 w 12 x 72 3/8" 1/2" 30" w 6 x 15 w 8 x 18 w 8 x 31 w 12 x 53 2 - w 12 x 53 1/2" 5/8" 33" w 8 x 18 w 8 x 24 w 10 x 33 w 12 x 65 2 - w 12 x 65 1/2" 5/8" 36" w 8 x 18 w 10 x 22 w 10 x 33 w 12 x 72 2 - w 12 x 65 1/2" 5/8" 39" w 8 x 18 w 10 x 22 w 10 x 39 w 12 x 72 2 - w 12 x 72 1/2" 5/8" 42" w 8 x 18 w 10 x 22 w 10 x 49 w 12 x 79 2 - w 14 x 61 1/2" 5/8" 48" w 8 x 18 w 12 x 30 w 12 x 53 1/2" 5/8" 54" w 10 x 22 w 12 x 30 w 12 x 53 5/8" 3/4" 60" w 10 x 22 w 12 x 40 w 12 x 65 5/8" 3/4" 66" w 10 x 33 w 12 x 53 2 - w 12 x 53 5/8" 3/4" 72" w 12 x 30 w 12 x 53 2 - w 12 x 65 5/8" 7/8" TABLE OF MEMBER SIZES (PART II) BEARING BLOCKS PIPE SPAN SIZE 0’ - 10’ 11’ - 15’ 16’ - 20’ 21’ - 30’ 31’ - 40’ 8" - 10" 1 - 2 x 12 x 2’ 1 - 2 x 12 x 2’ 2 - 2 x 12 x 2’ 2 - 2 x 12 x 2’ 2 - 2 x 12 x 2’ 12" - 15" 1 - 2 x 12 x 2’ 1 - 2 x 12 x 2’ 2 - 2 x 12 x 2’ 2 - 2 x 12 x 2’ 2 - 4 x 12 x 3’ 18" - 21" 1 - 2 x 12 x 2’ 1 - 2 x 12 x 3’ 2 - 2 x 12 x 3’ 2 - 4 x 12 x 3’ 2 - 4 x 12 x 4’ 24" - 27" 1 - 2 x 12 x 3’ 2 - 2 x 12 x 2’ 2 - 2 x 12 x 3’ 2 - 4 x 12 x 5’ 3 - 4 x 12 x 4’ 30" 1 - 2 x 12 x 3’ 2 - 2 x 12 x 3’ 2 - 4 x 12 x 4’ 3 - 4 x 12 x 4’ 3 - 4 x 12 x 5’ 2 - 4 x 12 x 4’ 3 - 4 x 12 x 5’ 2 - 2 x 12 x 2’ 33" 2 - 2 x 12 x 3’ 36" 2 - 2 x 12 x 2’ 2 - 2 x 12 x 3’ 2 - 4 x 12 x 4’ 39" 2 - 2 x 12 x 3’ 2 - 4 x 12 x 4’ 2 - 4 x 12 x 5’ 42" 2 - 2 x 12 x 3’ 2 - 4 x 12 x 4’ 2 - 4 x 12 x 5’ 48" 2 - 4 x 12 x 4’ 2 - 4 x 12 x 5’ 3 - 4 x 12 x 5’ 54" 2 - 4 x 12 x 4’ 2 - 4 x 12 x 5’ 3 - 4 x 12 x 5’ 60" 2 - 4 x 12 x 4’ 3 - 4 x 12 x 5’ 3 - 4 x 12 x 5’ 66" 2 - 4 x 12 x 5’ 3 - 4 x 12 x 5’ 3 - 4 x 12 x 6’ 72" 2 - 4 x 12 x 5’ 3 - 4 x 12 x 5’ 4 - 4 x 12 x 5’ 3 - 4 x 12 x 5’-6" 4 - 4 x 12 x 5’ 4 - 4 x 12 x 5’-6" 3 - 4 x 12 x 6’ 4 - 4 x 12 x 5’-6" 4 - 4 x 12 x 6’ 4 - 4 x 12 x 6’-6" NOTES: 1. FORTY-EIGHT HOURS PRIOR TO COMMENCING CONSTRUCTION OF THE TEMPORARY SUPPORT, THE CONTRACTOR SHALL CONTACT THE DISTRICT SUPERINTENDENT OF MAINTENANCE AT (323) 774-7272. 2. APPROVAL SHALL BE OBTAINED FROM THE COUNTY SANITATION DISTRICT REPRESENTATIVE OF THE SPAN TO BE USED IN DETERMINING THE SIZE OF THE STEEL BEAM. 3. ALL WORK ON THE TEMPORARY SUPPORT SHALL BE DONE ONLY IN THE PRESENCE OF THE COUNTY SANITATION DISTRICT REPRESENTATIVE. 4. THE CONTRACTOR SHALL BE COMPLETELY RESPONSIBLE FOR THE ADEQUACY OF THE TEMPORARY SUPPORT AND FOR THE MANNER IN WHICH IT IS INSTALLED. 5. FOR PIPES AND MEMBER SIZES NOT SHOWN IN THE ABOVE TABLES, THE CONTRACTOR SHALL SUBMIT DETAILS OF THE PROPOSED SUPPORT AND CALCULATIONS PREPARED BY CIVIL / STRUCTURAL ENGINEER REGISTERED IN THE STATE OF CALIFORNIA TO THE COUNTY SANITATION DISTRICT REPRESENTATIVE FOR WRITTEN APPROVAL PRIOR TO COMMENCING CONSTRUCTION. 6. APPROVAL SHALL BE OBTAINED FROM THE COUNTY SANITATION DISTRICT REPRESENTATIVE PRIOR TO USING MEMBERS OR PARTS OF THE TEMPORARY SUPPORT DIFFERENT THAN DETAILED. 7. LARGER STEEL BEAMS WITH CORRESPONDINGLY LARGER SECTION MODULI MAY BE SUBSTITUTED. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD TEMPORARY PIPE SUPPORT S-a-222 SHEET 2 OF 2 3 1/2" HIGH LETTERS A A TYP 7 1/2 4" R B LE B A C 3 0" PRY NOTCH 4" PLAN OF COVER TOP VIEW 32" 3 1/8" DIA 1 1/4" 1 1/8" 5/16" 1" (TYP) GROOVE 20 PLAN OF FRAME (TYP) 5 1/2" DIA 2 3/4" 2" 1 1/4" 1" (TYP) 5/8" (TYP) 33 3/4" PRY 32 1/4" NOTCH 26 1/2" 1 1/4" 5 2 MIN (TYP) 29 1/4" 5" SECTION A-A 5 1" DIA HOLE 30" CLEAR 4" 5/8" 4" 1 1/4" 1 1/2" 7/8" 30 2 PLACES 38" 1" (TYP) 5/8" (TYP) SECTION B-B PRY NOTCH 12 " R (TY P) NOTES: 45 1. CAST IRON USED SHALL CONFORM WITH ASTM A-48 CLASS 35B. 2. FRAME AND COVER SHALL BE COATED WITH ASPHALTUM OR BITUMINOUS PAINT AFTER TESTING AND INSPECTION. 3. FRAME AND COVER SHALL BE TESTED FOR ACCURATE FIT PRIOR TO DELIVERY AND SHALL BE MARKED IN SETS. 2 22 1/ 4. ALL CASTINGS SHALL COMPLY WITH SECTION 206-3 OF THE STANDARD SPECIFICATIONS. PLAN OF COVER BOTTOM VIEW COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN STANDARD 30" MANHOLE FRAME CHIEF ENGINEER AND COVER 2006 EDITION S-a-223 SHEET 1 OF 1 B VARIES B 3" TO 4’-0" " t " BARS " r " BARS (TYP) (TYP) " r " BARS (TYP) (TYP) A " s " BARS C PLASTIC LINER PLATE PLASTIC LINER LAP D (TYP) MIN 1’ - 6" PIPE SIZE E BL A RI VA A C 3" (SEE TABLE) PLATE " t " BARS (SEE TABLE) " s " BARS MATCH EXIST. ADJACENT (TYP) PIPE, 90 LONGITUDINAL SECTION 0 MAX CROSS SECTION TABLE OF REINFORCING BARS PIPE DEPTH TO SIZE INVERT 24" TO 0’ TO 15’ 33" 16’ TO 30’ 36" 48" 54" 16’ TO 30’ 16’ TO 30’ 8" 3" 16" #4 @ 10" 8" 3" 6" 8" 3" 7" 8" 3" 7" 8" 4" 7" 8" 4" 8" 8" 4" 8" 10" 5" 8" 10" 5" 0’ TO 15’ 0’ TO 15’ 15’ TO 30’ #4 @ 12 2 - #4 16" #4 @ 12 2 - #4 #4 @ 8 #4 @ 10 9" 12" 5" 9" 12" 6" 0’ TO 15’ 96" "t" NOTES: 6" 0’ TO 15’ 15’ TO 30’ "s" #4 @ 10 0’ TO 15’ 16’ TO 30’ 84" 6" 0’ TO 15’ 16’ TO 30’ 72" "r" 0’ TO 15’ 16’ TO 30’ 66" D 0’ TO 15’ 16’ TO 30’ 60" C 0’ TO 15’ 16’ TO 30’ 42" REINFORCING BARS B 0’ TO 15’ 16’ TO 30’ 39" DIMENSIONS A 16" #4 @ 6 16" #4 @ 10 20" #5 @ 10 16" #4 @ 10 20" #5 @ 8 16" #4 @ 8 20" #5 @ 8 16" #4 @ 6 24" #6 @ 8 20" #5 @ 8 28" #7 @ 8 20" #5 @ 8 28" #7 @ 6 20" #5 @ 8 28" #7 @ 6 20" #5 @ 6 28" #7 @ 6 #4 @ 12 2 - #4 #5 @ 12 2 - #5 #5 @ 12 2 - #5 #5 @ 12 2 - #5 1. CONCRETE SHALL BE 660-B-4000. 2. ALL REINFORCING BARS SHALL BE ASTM A-706, CLASS 60. 3. THE CONCRETE SHALL BE CONSOLIDATED BY MEANS OF HIGH FREQUENCY INTERNAL VIBRATORS. 4. DETAIL APPLIES FOR PIPES WITH COVER FROM 3’-0" TO 30’-0" FOR TRENCH CONDITION AND FOR PIPES WITH COVER #5 @ 12 2 - #5 #5 @ 12 3 - #5 #5 @ 12 3 - #5 3’-0" TO 10’-0" FOR EMBANKMENT CONDITION. 5. PIPE BARRELLING SHALL BE DONE AT LOCATIONS AND LENGTHS SHOWN ON THE DRAWINGS OR AUTHORIZED BY THE ENGINEER. #5 @ 12 3 - #6 #5 @ 9 3 - #6 COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD PIPE BARREL S-a-224 SHEET 1 OF 1 ANGLE VARIES 0 o TO 10 o A (TYP) B B A (TYP) A " r " BARS (TYP) (TYP) " s " BARS " s " BARS A/2 (TYP) 2 1/2" CL 2" CL VARIABLE V E BL " r " BARS (TYP) (TYP) 24d LAP (TYP) IA AR INSTALL " r " BARS WATERSTOP MATCH EXIST. ADJACENT PIPE, 90 0 PER NOTE 6 MAX CROSS SECTION LONGITUDINAL SECTION TABLE OF REINFORCING BARS DIMENSIONS REINFORCING BARS PIPE DIAMETER A B 24" TO 36" 8" 8" #4 @ 8 #4 @ 12 39" TO 57" 8" 10" #6 @ 8 #5 @ 12 60" TO 78" 10" 12" #7 @ 6 #5 @ 12 84" TO 96" 12" 16" #7 @ 6 #5 @ 9" "r" "s" NOTES: 1. CONSTRUCT CONCRETE COLLAR WHERE REQUIRED ON THE DRAWINGS AND AT ALL PIPE JOINTS WHERE THERE IS A CHANGE IN THE TYPE OF JOINT OR A CHANGE IN THE THICKNESS OF THE WALLS OF ADJACENT PIPES. 2. UNLESS OTHERWISE SPECIFIED, CONCRETE SHALL BE 660-B-4000 AND ALL REINFORCING BARS SHALL BE DEFORMED BARS CONFORMING TO ASTM-A706 GRADE 60. 3. EXTERIOR SURFACES OF CONCRETE PIPE SHALL BE CLEANED BY SANDBLASTING PRIOR TO PLACING CONCRETE. 4. THE CONTRACTOR SHALL SUBMIT WORKING DRAWINGS THAT SHOW DETAILS FOR JOINING ANY PLASTIC LINERS IN ADJACENT PIECES OF PIPE. 5. FOR VITRIFIED CLAY PIPE HAVING NO ANGULAR DEFLECTION, THE CONTRACTOR MAY USE A REPAIR COUPLING AND OMIT THE REINFORCING STEEL FROM THE CONCRETE COLLAR. SHEAR BAND. 6. THE REPAIR COUPLING SHALL INCLUDE AN INTEGRAL DETAILS OF THE REPAIR COUPLING SHALL BE SUBMITTED TO THE DISTRICTS FOR APPROVAL. HYDROTITE CJ - 2010 - 2 / 6 HYDROPHILIC WATERSTOP OR ADEKA MC 2010M OR EQUIVALENT. INSTALL ALL AROUND. EACH PIPE. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD CONCRETE COLLAR S-a-225 SHEET 1 OF 1 1" DIA HOLE 2 PLACES A 45 7 1/2 (TY P) A B B R C A LE 30 3/4" 3 1/2" HIGH LETTERS PRY NOTCH PLAN OF COVER TOP VIEW 31 3/4" 3 1/8" DIA 3 5/16" 1" (TYP) 1 3/8" GROOVE (TYP) 1" (TYP) PRY 1/8" 3 3/8" PLAN OF FRAME NOTCH 2" 1 1/2" 20 8 3/4" DIA 1/2" (TYP) 1 1/4" 1 1/2" DIA HOLE (4 REQ’D) ON 34 1/4" 27" DIA 43 1/2" DIA 32" DIA RING ID SECTION A-A 5 + - 30 3/4" 2 PLACES 2 7/8" 1" DIA HOLE 1 1/4" 1 1/4" 1 1/2" 5 5/8" 30 3" 1 1/2" 3 3" 30" DIA CLEAR 36" DIA MIN 5" MIN 47" DIA MIN 1" (TYP) 5/8" (TYP) 5" MIN PRY NOTCH SECTION B-B 12 " R (TY P) 45 NOTES: 1. CAST IRON USED SHALL CONFORM WITH ASTM A-48 CLASS 35B. 2. FRAME AND COVER SHALL BE COATED WITH ASPHALTUM OR BITUMINOUS PAINT AFTER TESTING AND INSPECTION. 3. FRAME AND COVER SHALL BE TESTED FOR ACCURATE FIT PRIOR 2 22 1/ TO DELIVERY AND SHALL BE MARKED IN SETS. 4. ALL CASTINGS SHALL COMPLY WITH SECTION 206-3 OF THE STANDARD SPECIFICATIONS. PLAN OF COVER BOTTOM VIEW COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN STANDARD 36" MANHOLE FRAME CHIEF ENGINEER WITH 30" COVER 2006 EDITION S-a-226 SHEET 1 OF 1 4" OR 6" VC S OR CI PIPE MINIMUM BEDDING 1/2 OD OF PIPE CLASS "C" MORTAR DEPTH A OF COVER 1-#5 BAR IF BEAM SEWER IS PRECAST 2" CL (TYP) t CONNECTION 2" CL HOUSE SEE TABLE FOR BAR No. A "X" 1 "V" BOTTOM 1 BLE VARIA 10" ELEVATION SECTION A-A DIMENSIONS OF NOTE: REINFORCED CONCRETE BEAM BEAM CONCRETE SHALL BE 660-B-4000. ALL REINFORCING BARS SHALL BE DEFORMED BARS CONFORMING TO ASTM-A706 GRADE 60. DEPTH OF COVER A "V" BOTTOMED BEAM AS DETAILED ABOVE SHALL BE POURED S 0 TO 8’-0" (FEET) 8’-1" TO 16’-0" IN PLACE OR, IF APPROVED BY THE ENGINEER. A RECTANGULAR PRECAST BEAM SHALL BE PLACED ON t BAR No t BAR No. 4 8" 4 10" 5 5 9" 5 12" 5 6 10" 5 13" 6 BACKFILL WHICH HAS BEEN PREVIOUSLY CONSOLIDATED TO THE INVERT OF THE HOUSE CONNECTION AND REEXCAVATED TO ACCOMMODATE THE BEAM. IN EITHER CASE, THE BEAM SHALL BEAR ON UNDISTURBED OR CONSOLIDATED SOIL. 7 11" 6 15" 6 8 12" 6 16" 6 9 13" 6 17" 7 10 14" 7 19" 7 MINIMUM LENGTH OF BEARING 11 15" 7 20" 7 OF ENDS OF REINFORCED CONCRETE BEAMS 12 16" 7 22" 7 13 17" 7 23" 8 14 18" 8 25" 8 15 19" 8 26" 8 16 20" 8 17 21" 8 18 22" 8 DEPTH OF COVER 0 TO 8’-0" 8’-1" TO 16’-0" S MIN BEARING - "X" 0 TO 12’-0" 18" 12’-1" TO 18’-0" 24" 0 TO 7’-0" 18" 7’-1" TO 11’-0" 24" 11’-1" TO 15’-0" 30" COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN STANDARD CONCRETE BEAM FOR CHIEF ENGINEER HOUSE CONNECTIONS 2006 EDITION S-a-227 SHEET 1 OF 1 28 11/16" MIN 27 3/16" 27 1/16" 1 3/4" 1 3/4" 3 1/4" 1 13/32" DIA NOTE: COVER SHALL BE SNUG SEE DETAIL 1 4" FIT, NOT TIGHT 7" DIA CASTING TO BE SET IN WET MORTAR 24" 34" SECTION MANHOLE FRAME AND COVER 2 11/32" 1 7/32" 3/4" 1 5/8" 1 5/8" 1/16" 3 3/8" 15 R = 1/4" 1/2" DIA HOLE IN 1/2" THK PLATE4" 11/16" 1/4" 1 3/4" 1 1/2" 11/16" 3/16" 15 3/8" 1 31/32" 1 1/2" 3 REQ’D AT 120 1/8" 3/8" 0 3/4" 1" SECTION A-A 5/32" 27 1/16" 5" 1’’ DIA HOLE 2 PLCS DETAIL 1 R E W E 1" 15 4" A 71 /2 2" 1/ S 1 A R 1/ S D 7 1/2 /4" 93 1 C 30 PRY NOTCH NOTE: PLAN OF COVER PLAN OF COVER BOTTOM VIEW TOP VIEW FOR NOTES SEE S-a-207. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN STANDARD 24" TRAFFIC MANHOLE CHIEF ENGINEER FRAME AND COVER 2006 EDITION S-a-228 SHEET 1 OF 1 48" 40" 38 1/4" 38" 3 1/4" 1" 1" (TYP 8 PLCS) 2 1/4" SS ANCHOR BOLT w/ H H NUT 1 1/4" 5/8’’ DIA x 10’’ LG TYPE 316 1 3/8" 5/16" 3 1/8" DIA 1" 7 1/4" 7" 1" 6" 1/2" PAINT WITH 5/8" ASPHALTUM PAINT CASTING TO BE SET 33" IN WET MORTAR 5/8’’ DIA x 1 1/4’’ LG TYPE 316 1 1/8’’ WIDE (MIN) X 1/8’’ THICK SS CAP SCREWS, (TYP OF 24) NEOPRENE GASKET REINFORCED 36" CONCRETE SECTION APPLY ANTI-FREEZE 1/2" 1 1/2" MANHOLE FRAME AND COVER AGENT (TYP) 7/8" 1 7/8" + 32" 1 7/8" 0 10 1 1/4" LIFTING EYE, (TYP 2 PLCS) SEE DETAIL 3/4’’ x 1 1/2 ’’ x 32’’ LG 1/4 1/8" 6 1/16" 4 REQ’D AT 90 0 5/8" (TYP 2 PLCS) TYP 3/4" 1/2" DIA HOLE TYPE 316 L SS FLAT BAR 4 13/16" TYPE 316 L SS FLAT BAR R = 17 8" 7/ 3/4’’ DIA HOLE 5/ (TYP 24 PLCS) 8" 3/4" THREAD FOR 3/4" 3/4" 1/2" TYPE 316 L SS PLATE 35 3/4" DIA 3/4’’ x 1 1/2’’ x 15 5/8’’ LG 3" 0 2" 15 7 1/2 45 - 5/8" CAP SCREW 1 1/2" R =1" 1/4 TYP 1 1/2 - 6 PRESSURE PLATE 7 1/2" TYPE 316 L BAR TYP 3/16 3 1/2" 1/2’’ DIA SS DETAIL- LIFTING EYE SECTION A-A BOTTOM VIEW 45 1’’ DIA HOLE DRILL 3/4’’ 22.5 2 PLACES C S D E W E A NOTCH 34 1 /2" 43 " D IA PRY A R /4" 13 1 P) (TY DIA DRILL & TAP 1 S 4" 1/ R ) Y FOR 5/8’’ SCREW 8" P (T ) P 5/ Y 1 1" (T PRY NOTCH " 2 1/ FLANGE RIBS 30 PLAN OF COVER 0 3/4’’ THICK TOP VIEW (TYP 8 PLCS) PLAN OF FRAME PLAN OF COVER BOTTOM VIEW NOTE: FOR NOTES SEE S-a-207. COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN STANDARD 36" PRESSURE MANHOLE CHIEF ENGINEER FRAME AND COVER 2006 EDITION S-a-229 SHEET 1 OF 1 7/8" DIA SS 3" R TYPE 316 ROD (TYP) PRECAST CONCRETE 2" CL SEE PLAN 3" SLAB 6" PLASTIC LINER w/ LOCKING EXTENSIONS TYPE I LIFTING EYE DETAIL B A 3" 3" A 5" 5" B PLAN 10" CONCRETE SLAB 8" TYPE 316 ROD 6" PRECAST 7/8" DIA SS 4" 2" CL 3" R 6" PLASTIC LINER w/ FILL RECESS w/ "HENRYS" ROOF FILL RECESS w/ "HENRYS" ROOF PLASTIC LINER w/ LOCKING MASTIC OR APPROVED EQUAL EXTENSIONS MASTIC OR APPROVED EQUAL SECTION A-A LOCKING EXTENSIONS 7/8" DIA SS TYPE 316 ROD SECTION B-B TYPE II LIFTING EYE DETAIL (FOR COVER LESS THAN 12" THICK) COUNTY SANITATION DISTRICTS OF LOS ANGELES COUNTY OFFICE OF CHIEF ENGINEER STANDARD DRAWING STEPHEN R. MAGUIN CHIEF ENGINEER 2006 EDITION STANDARD LIFTING EYE S-a-230 SHEET 1 OF 1