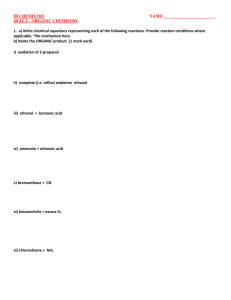

Nomex™ polyaramid

advertisement

Nomex™ polyaramid

O

O

N

H

N

H

n

Discovered: 1958, by P.W. Morgan (Du Pont).

Commercialised: 1967, in fibre form, by Du Pont.

Key properties: Very good thermal resistance

(Tm = 371 deg.C, c.f. nylon 66 which melts at 260

deg.C). Essentially flameproof in fabric form. Good

resistance to organic solvents (because of

crystallinity) but attacked and hydrolysed by strong

acids and bases, especially at high temperatures.

Excellent dimensional stability. Rated for

continuous use in electrical applications (several

thousand hours) at 200 deg.C. Very much higher

resistance to ! radiation than aliphatic polyamides.

61

Nomex™ polyaramid

O

O

N

H

N

H

n

Synthesis

H3C

O2

HOOC

CH3

Mn/Co

HNO3

COOH

O2N

NO2

H2

SOCl2

ClOC

H2SO4

COCl

H2N

Ni

NH2

DMAc

O

O

N

H

N

H

n

62

Nomex™ polyaramid

O

O

N

H

N

H

n

Fibre production: Fibre-spinning does not require

isolation of polymer from the reaction solution.

The solution is partially neutralised with ammonia,

the NH4Cl filtered off, and neutralisation is completed

with CaO (the so-formed CaCl2 helps retain the

polymer in solution).

This solution is dry-spun into hot air at 200 deg.C,

the fibre wound up at ca. 100 m/min, extracted

withwater to remove the CaCl2, and finally drawn in

steam to 5 or 6 times its original length.

63

Nomex™ polyaramid

O

O

N

H

N

H

n

Crystal and molecular structure

Aromatic rings are parallel but

not coplanar. Both acid- and

amine-derived rings are tilted

some 30 degrees from the

plane of the amide

group.Networks of H-bonds link

molecules in both the a and b

directions (perpendicular to the

chain axes).

64

Nomex™ polyaramid

O

O

N

H

N

H

n

Typical applications for Nomex fibre

Heat-resistance applications: Filter bags for hotgas filtration (e.g. from steel-making plants).

Insulating paper for electric motors and

transformers. Braided tubing for wire-insulation.

Sewing thread for high-speed machine sewing.

Fire-resistance applications: Protective clothing

for foundry workers, welders, pilots, racing drivers,

and fire-fighters. Carpets, upholstery, and tents.

Dimensional-stability applications: Conveyor

belts, fire-hoses.

Permselectivity applications: Hollow fibres of

Nomex are excellent semi-permeable membranes,

and are used commercially for desalination of

sewater and brackish water.

65

Tenax™ Polyphenylene ether

Ph

O

Ph

n

Discovered: 1968 by Hay (GE), using oxidative

polymerisation of 2,6-diphenylphenol.

Commercialised: 1970, by Akzo (Holland).

Key properties: Amorphous 'as made' (Tg = 230

deg.C), but crystallises rapidly above Tg.

Tm = 480 deg.C, so polymer unprocessable once

crystallised. Amorphous polymer soluble in

chloroform and benzene.

Applications: By far biggest application is as

very high temperature adsorbent in gas

chromatography. Otherwise, applications

remarkably underdeveloped.

66

Tenax™ Polyphenylene ether

Ph

O

Ph

n

Synthesis:

Ph

Ph

O2, TMED-CuCl2

HO

O

ODCB, 85oC

n

Ph

Ph

Mechanism:

Ph

OH

Ph

Ph

OH

Cu(II)

Ph

.

O

Ph

Ph

O

Ph

H

.

Ph

OH

Ph

Cu(I)

Cu(II)

Cu(I)

H+

Ph

etc.

Ph

Ph

O

Ph

Ph

OH

O

H

Ph

+

Ph

Ph

OH

Ph

67

Tenax™ Polyphenylene ether

Ph

O

Ph

n

Crystal structure: Polymer is helical, with four monomer

residues per turn. Unit cell contains two chains, running in

opposite directions (the chain has directionality).

X-ray fibre diagram of Tenax

68

Part 3

Liquid Crystalline Polymers

69

Basic Concepts

Liquid Crystals: Crystals are fully ordered in three

dimensions over a long range. Liquids may have shortrange correlations of molecular position, but are essentially

disordered. What about long-range order in only one or two

dimensions?

Many organic compounds display phases ('liquid crystal-'

or 'meso-' phases) which have just such degrees of order.

Key feature is shape of molecule. It must be highly

anisotropic, so that the cumulative intermolecular forces

operate strongly in one or two directions, but not three.

Strong interaction

Weak interaction

Mesophases can occur lyotropically (by increasing the

concentration of a material in solution), or thermotropically

(by raising the temperature of a crystalline solid).

70

Basic Concepts

Liquid crystal polymers: Two main classes,

side-chain LC polymers and main-chain LC

polymers. Only concerned here with main-chain

types. Require an essentially rigid-rod structure.

Existence predicted by Flory in 1956. At about

the same time, Robinson and Ballard (Courtaulds)

discovered liquid crystalline solutions of synthetic

polypeptides, e.g. poly(g-benzyl-L-glutamate).

Rigid, linear, helical structure of such polymers

gives rise to lyotropic LC behaviour.

71

Basic Concepts

Rigid-rod polymers: Wide range of chemical

structures give rise to this type of polymer. Total rigidity

not necessary, though can be achieved, e.g. in

poly(p-phenylenebenzobisthiazole):-

N

S

S

N

n

Forms liquid-crystalline solutions in polyphosphoric acid

Low-energy molecular conformations should be

linear (i.e. restricted rotations needed), but significant

flexibility allowed:O

O

O

X

X

X

(X = NH or O)

O

X

72

Basic Concepts

Fibres: Characterised by anisotropy, both in dimensions

and properties. Ratio of l/d for natural fibres (cotton, flax,

wool) typically 1000 -2000. Anisotropic properties of

many fibres (strength, stiffness etc.) caused by molecular

orientation in the long-dimension of the fibre. For

conventional synthetic fibres, orientation is achieved

mechanically , by drawing:

draw direction

Perfect alignment very difficult to obtain with flexible

polymers, since cannot avoid knots and entanglements.

Consequently theoretical fibre performance not even

approached. Theoretical tensile strength depends only

on strength of covalent bond, since, when perfect

alignment achieved, intra-molecular bonds are weaker

than sum of inter-molecular forces (!)

73

Kevlar™ polyaramid

O

O

N

H

H

N

n

Discovered: 1965, by Stephanie Kwolek of

Du Pont.

Commercialised: 1971, by Du Pont.

Key Properties: Forms liquid-crystalline solutions

in organic solvents, and a liquid-crystalline

complex with sulphuric acid. Such solutions

self-orient under shear, so polymer can be spun to

give highly ordered fibres without subsequent

drawing. Kevlar fibres have extremely high

tensile strength (2.64 GPa) and modulus (127.5

GPa) when compared with aliphatic polyamides

such as Nylon 66 (0.90 and 5 GPa respectively).

Because of low density, Kevlar has highest

specific modulus of any known material. Very good

thermal stability (to 450 deg.C), and 60% of

strength is retained at 300 deg.C.

74

Kevlar™ polyaramid

O

H

N

N

H

O

n

Typical applications: The extreme tensile strength and

lightness of Kevlar® leads to applications including

knife-and bullet-proof clothing, boat hulls, racing cars,

cut-resistant gloves, fiber-optic cable-sheathing, firefighters! suits, fuel hoses, helmets, aircraft

components, radial tyres, spacecraft, bicycles, tennis

and squash racquets, golf clubs and skis.

Characteristics of fibre dominate composite-materials

properties – excellent in tension but poor in compression.

1.5

tension

1.0

COMPOSITE

STRESS (GPA)

0.5

compression

0.5

1.0

1.5

COMPOSITE STRAIN (%)

75

Kevlar™ polyaramid

O

O

N

H

H

N

n

Applications

76

Kevlar™ polyaramid

O

O

H

N

N

H

n

Synthesis: Original Du Pont process involved:COCl

NH2

+

RT

COCl

O

HMPA

O

H

N

N

H

n

NH2

Toxicity of HMPA required an alternative solvent

before commercialisation possible: NMP/CaCl2

found to be usable though less than ideal (low MW

oligomers tend to precipitate; problem overcome by

use of high-shear reactor-design).

Alternative synthesis (Higashi et al.):

COOH

NH2

+

P(OPh)3

NMP/LiCl

Py/CaCl2

100oC

COOH

NH2

O

O

N

H

H

N

n

77

Kevlar™ polyaramid

O

N

H

O

H

N

n

Mechanism of phosphorylative synthesis

COOH NH2

P(OPh)3

NMP/LiCl

Py/CaCl2

+

COOH NH2

O

O

100oC

H

N

N

N

H

n

PhOH

P

ArCOO

ArCOOH + P(OPh)3

OPh

OPh

Ar'NH2

ArCONHAr'

O

O

P

H

OPh

OPh

O

H P

Ar

NHAr'

OPh

OPh

78

Kevlar™ polyaramid

O

O

H

N

N

H

n

Fabrication: Polymer forms solid complex with

100% H2SO4 in mole ratio 1:10. Complex melts

at 70 deg.C to give a liquid crystalline phase which

can be spun into water, via an air-gap. Liquidcrystal domains become oriented during spinning:-

domain structure

spinneret

orientation

partial deorientation

air-gap

water

reorientation

precipitation

79

Kevlar™ polyaramid

O

O

N

H

H

N

n

Structure: As well as showing liquid-crystalline

behaviour in solution, Kevlar has a high degree

of 3-dimensional crystallinity in the solid state.

X-ray fibre pattern

N.B. C=O- - - H-N hydrogen bonds

80

Kevlar™ polyaramid

O

O

N

H

H

N

n

Crystal Structure:

N.B. C=O- - - H-N hydrogen bonds

81

Kevlar™ polyaramid

O

N

H

O

H

N

n

Supramolecular structure: Molecules form hydrogenbonded sheets which stack radially in the fibre. Nice

example of molecular self-organisation. Not previously

observed in synthetic fibres, and can even lead to

spontaneous growth of Kevlar fibres under gel-type

polymerisation conditions.

O

O

O

H

H

H

N

N

O

fibre

axis

O

O

O

O

O

N

N H

N H

N H

O

O

O

82

Kevlar™ polyaramid

O

N

H

O

H

N

n

Contrast between (high) tensile- and (low) compressive

modulus:

Chains are fully extended (all-trans)

so very high tensile modulus

Compressive stress

however leads to

buckling of the supramolecular sheet

structure

O

O

O

H

H

H

N

N

O

O

O

O

O

O

N

N H

N H

N H

O

O

O

83

Vectra™ thermotropic polyester

O

O

O

0.7n

O

0.3n

Discovered: 1974, by Calundann of Celanese.

Commercialised: 1985, by Hoechst-Celanese.

Key Properties: Melts at ca. 275 deg.C, to form

a liquid crystal phase which can be processed in

similar fashion to conventional thermoplastic, i.e.

by injection moulding, extrusion, or fibre-spinning.

Major differences however are 1) the mesophase

has very much lower viscosity than a conventional

polymer melt, and 2) molecular orientation occurs

under shear, so that anisotropic mouldings and

extrusions are abtained. Have very high modulus

in shear direction, but can be much weaker in other

diections. Orientation leads to fibrillar wood-like

texture. Materials are tough, with good impactresistance, and retain useful strength up to

200 deg.C. Thermochemically stable, with

continuous service temperatures up to 220 deg.C.

84

Vectra™ thermotropic polyester

O

O

O

0.7n

O

0.3n

Typical applications: Low mesophase viscosity

allows very complex and finely detailed mouldings

to be obtained (e.g. for microelectronic applications).

Transparency to microwaves, coupled with thermal

stability, means material suitable for microwave

cookware. Orientation under shear allows meltspinning of high-modulus fibre, c.f. Kevlar.

85

Vectra™ thermotropic polyester

O

O

O

O

0.7n

0.3n

Synthesis:

COOH

O

H3C

+

O

COOH

O

H3C

O

200oC, N2 purge

Clear melt

250 - 280oC

CH3COOH

Turbid dispersion

280 - 340oC

O

O

O

0.7n

O

0.3n

Opalescent polymer "melt"

86

Vectra™ thermotropic polyester

O

O

O

0.7n

O

0.3n

Q. Why a co-polymer?

A. Because the homopolymers are intractable.

The homopolymer of 4-hydroxybenzoic acid is in

fact manufactured, as 'Ekonol', but it can only be

fabricated via powder-metallurgy techniques such

as high-energy-rate forging and plasma-spraying.

O

O

PhOH

Ph

O

HO

n

O

Ekonol

'Ekonol' undergoes a thermal transition at 350

deg.C, to give an as yet incompletely characterised

phase which may or may not be liquid crystalline.

Copolymerisation with 2,6-HNA however

produces materials with a crystal-to-mesophase

transition as low as 250 deg.C (60:40, HBA:HNA)

87

Vectra™ thermotropic polyester

O

O

O

0.7n

O

0.3n

Sructure: The detailed structure of liquid crystal

polyesters is still a matter of debate. 13C NMR of

Vectra indicates the polymer-sequence is fully random,

and yet it shows a relatively high degree of crystallinity.

One possible explanation is based on formation of

non-periodic layer crystallites :-

ababbababbababaababababbbabaab

ababbaababbabaababbababaababba

aababbaababababababaabaaabbaba

abbbbabbabbabababbbaaabaabbaba

aababbabbabababaabbababbabbaab

Essentially involves matching of sequences in adjacent

chains. Limited length of matches results in low melting

point, but overall can still achieve significant crystallinity.

88

Vectra™ thermotropic polyester

O

O

O

0.7n

O

0.3n

Non-periodic layer crystallites: Very remarkable

theory, and increasing evidence appearing in the

literature, but still controversial idea. Best seen

via computational simulation:-

89

Chain Rigidity and Polymer Crystal Melting

We have seen that crystalline polymers with rather rigid and inflexible

chains (e.g. aromatic polyamides and aromatic polyesters) have

extremely high crystal melting points, generally above their

decomposition temperatures. Unless a thermotropic liquid-crystalline

phase can be obtained, e.g. by copolymerisation, such polymers

cannot be processed in the melt, and must be fabricated from solution

or by using solid-state techniques such as powder-sintering.

The close relationship between chain rigidity and polymer crystal

melting point can be explained as follows:

"Gm = "Hm - Tm"Sm,

but for a phase transition "G = 0, so that:

0 = "Hm - Tm"Sm

and therefore:

Tm = "Hm / "Sm

For a flexible chain, the entropy of melting "Sm, will be large as the

chain can take up only one conformation in the crystal but very many

in the melt state.Thus Tm will be low. For a rigid chain however, "Sm

will be small, as the number of different chain conformations available

in the melt is very small, and Tm will be very much higher. (This

assumes that "Hm, which depends mainly on intermolecular attractive

forces, is not greatly different in the two cases).

As an example, the aliphatic polyamide Nylon 6,6 melts at 280 °C,

whereas the much more rigid aromatic polyamide, Kevlar, does not

melt below its decomposition temperature of ca. 450 °C.

90