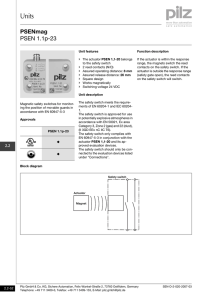

PSEN sensor technology for man and machine

advertisement