Catalog of cables LEONI (pdf.en)

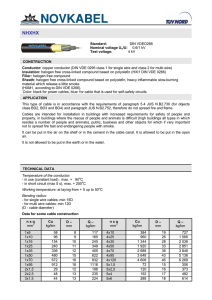

advertisement