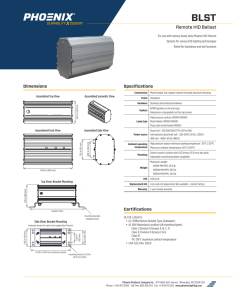

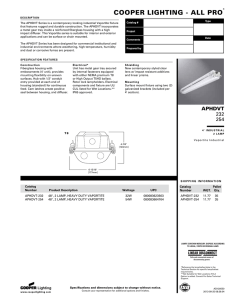

HID Lighting: Enclosed and Gasketed

advertisement