Lab 3 : Annealing Height Measurement Hall Bar Geometry

advertisement

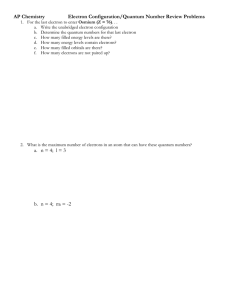

Lab 3 : Annealing Height Measurement Hall Bar Geometry Measurement TFE4180 - Semiconductor Manufacturing Technology Prepared by Andreas Liudi Mulyo andreas.liudi-mulyo@iet.ntnu.no Flow chart over the lab sessions 2 Our sample • Hall bar pattern: Complete 3D structure of channel connecting metal contact 3 What we want to achieve • Dopant activation (influencing electrical properties) on our sample. → Annealing process by rapid thermal processing • Height measurement of the etched profile → Profilometer • Hall bar geometry → Optical microscope +++ Cross-section and compositional analysis of our sample → Scanning electron microscope (SEM) + energy-dispersive X-ray spectroscopy 4 Annealing (I) Jipelec-JetFirst • Process of heating wafer to high temperature (1200°C or greater) in several seconds with the goal of activating doping, continued with cooling to room temperature in slower rate to avoid wafer breakage due to thermal shock. → Interface as well as metal can be altered (reducing unintentional barrier) → An alloy is formed between metal and semiconductor → possibility to repair damage from ion implantation • Annealing usually being done with rapid thermal processing, where the rapid heating is provided by Halogen lamps 5 Annealing (II) Reflector Halogen lamps Wafer Process chamber Susceptor Thermocouple Water cooling Vacuum inlet Pyrometer The cross-section of rapid thermal processing 6 Gases which are available for the annealing process, are N2, O2 and H2 diluted with Ar. N2 normally used for this kind of process as well as cooling. No mixing be happened between O2 and Ar diluted in H2, as they can trigger an explosion. Susceptor: absorb electromagnetic energy (radio frequency or microwave) efficiently → heat. Thermocouple: two different conductors are in contact → ΔV → ΔT (Seebeck effect), see here for more. Pyrometer: based on the blackbody radiation (cool object does not glow and hot object does-red), Thermal Oxidation During Annealing • Thermal oxidation is a process of producing a thin layer of oxide on the surface of a wafer. • The oxidizing component diffuses into the wafer at high temperature. • The thermal oxidation influences the distribution of impurities. It is important to control and minimize oxidation temperature in the minimal thermal budget which can be achieved using this method. 7 Metal • • • • • Pd Ge Ti Pt Au (200 Å) (400 Å) (400 Å) (300 Å) (2000 Å) Ohmic contact, with the advantages of: → No oxygen are observed → Diffusion barrier for the outdiffusion of As → Smooth morphological surface → Good thermal stability Contact resistance is the lowest (order of < 10-6): n-GaAs, with the annealing temperature of 400°C for ~17 sec p-GaAs, with the annealing temperature of 450°C for ~39 sec J. Appl. Phys. 74, 754 (1993) 8 Schottky to Ohmic Contact (I) Pd/Ge/Ti/Pt/Au GaAs • Metal -- semiconductor junction → barrier • Two possibility types forming junction: 1. Schottky contact has rectifying characteristics → One bias polarity (diode) type of contact is used 2. Ohmic contact is non-rectifying This to get signal (current) in and out (electrical measurement) from semiconductor device I-V → Two polarities Resistivity Hall bar • Ohmic contact can be achieved by: Solar cell 1. Lowering barrier height (by annealing) 2. Narrowing the barrier (by high doping) → Tunneling 9 Schottky to Ohmic Contact (II) • Example: metal-semiconductor (n-type), forward-bias Schottky contact qΦm > qΦs qΦs qΦm metal Ohmic contact qΦm < qΦs qΦm qΦs metal sc Forward-bias sc Evac - qV0 - ++ + EFm qV0 Evac Ec EFs qV EV EFm -- - qV + + + EV e- can flow much easier Note: in thermal equilibrium condition, EFs=EFm 10 Ec EFs Schottky to Ohmic Contact (III) Flash animation for better insight: • http://www.doitpoms.ac.uk/tlplib/semiconductors/p n.php • http://www.doitpoms.ac.uk/tlplib/semiconductors/ju nction_rectifying.php • http://www.doitpoms.ac.uk/tlplib/semiconductors/ju nction_ohmic.php • http://www.cleanroom.byu.edu/ohmicschottky.phtml 11 Schottky to Ohmic Contact (IV) • Current-voltage (I-V) characteristic of Schottky (green) and Ohmic contact (red) I Low R High R V Breakdown 12 Reverse bias Forward bias Geometry Measurement (I) • Profilometer - Tool to measure surface profiles (roughness) of surfaces. - This is a contact stylus-type (made from diamond) profilometer. Piezoelectric-based transducers Monitor 13 Geometry Measurement (II) • Optical microscope (differential interface contrast) - Principle: interferometry - It is able to enhance the contrast and gain optical path length of the sample 14 Geometry Measurement (+++) • SEM Electron gun source → electron beam Vacuum chamber - Anode - Condenser lens - Scanning coils - Objective lens Magnetic lens system Vacuum chamber* (during measurement) - 3-4 detectors, for different type of electron signals - Sample stage * Air can be introduced and vented 15 Scanning Electron Microscopy & Transmission Electron Microscopy (TEM) (I) • Electron interaction with specimen (SEM-left and TEM-right) Incident electrons (100-200 keV) Incident electrons (5-30 keV) Secondary Auger electrons electrons Backscattered electrons Characteristic X-rays Secondary Auger electrons electrons Backscattered electrons Characteristic X-rays Visible light Visible light 100 nm or less Thickness: order of mm or less Scattered electrons (elastically) at high angle 16 Bremsstrahlung X-rays Scattered Scattered electrons electrons Direct (elastically) (inelastically) transmitted at low angle electrons Scanning Electron Microscopy & Transmission Electron Microscopy (TEM) (I) • Signal information (SEM-left and TEM-right) Incident electrons (100-200 keV) Incident electrons (5-30 keV) Secondary Auger electrons electrons Topological Composition Backscattered electrons Characteristic X-rays Topological Composition Visible light Secondary Auger electrons electrons Topological Composition Backscattered electrons Characteristic X-rays Topological Composition Visible light 100 nm or less Thickness: order of mm or less Scattered electrons (elastically) at high angle HAADF 17 Scattered electrons Direct (elastically) transmitted at low angle electrons ADF, BF HRTEM Bremsstrahlung X-rays Composition Scattered electrons (inelastically) EELS EFTEM Scanning Electron Microscopy & Transmission Electron Microscopy (II) • The setup (SEM-left and TEM-right) Electron gun Condenser lens Scanning coil Electron gun Condenser lens Specimen Objective lens Objective lens Detector Intermediate + Projection lenses Specimen Detector 18