C25/C28 - BAUER Compressors

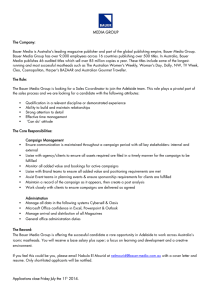

advertisement

C25/C28 ™ L - Series System Optional Features CNG System for Large Fleet Applications High Pressure Drying High pressure dryers save space and are more efficient than inlet dryers; an OEM product from BAUER, the experts in air and gas purification. Priority Filling For more efficient storage management, mechanical and electronic software-controlled priority fill system is an OEM product from BAUER, the experts in air and gas purification. Cell Phone Modem with Remote Notification Get real-time operational information sent from your C25/C28 L - Series to any webconnected browser including mobile devices. The automated notification feature sends out text messages to designated mobile devices when system is in error status. Integrated NEMA 7 Starter Panel For full “plug and play” functionality electrical panel for soft starter as well as disconnect can be provided in a NEMA 7 enclosure. Dispensing All L-Series models have the flexibility to interface with the industry leaders in dispensing. BAUER COMPRESSORS INC. sls@bauercomp.com www.bauercomp.com 757-855-6006 383.14.03.200SP subject to alteration without notice or obligation Performance: 38 - 75 GGE / hr (75 - 150 CFM) Integrated Storage: 46 - 92 GGE Usable Inlet Pressure: 1 - 5 PSIG Final Pressure: 5000 PSIG Power: 60 – 125 HP BENEFITS Powerful, completely integrated system in a compact footprint with on-board storage option of 46 - 92 usable GGE’s. Standard, pre-engineered system with customizable options. Integrated CNG system, both easy and economical to install. Just connect utilities, hook up to fuel dispenser and the system is ready to fuel. COMPRESSORS Featuring BAUER’s proven C250 & C280 Series, four stage air cooled compressors, at the heart of the system. Ideal for sites with low inlet pressure < 5 PSI Designed for continuous duty application Extremely durable workhorse CONTROL SYSTEM State-of-the-art control system and intuitive machine interface makes operating the unit simple. Real-time accurate diagnostics Remote interface via smartphone option Online Manual & Operating/Maintenance Instructions Attractive, state-of-the-art design means that the unit is suitable for placement within public view. Logo awning allows for customer branding. COST OF OWNERSHIP Like all BAUER compressors, the system is designed for long periods between maintenance intervals and very low cost of ownership. Easy to maintain with low cost of ownership makes the unit very economical to operate. BAUER’s legendary performance, quality and reliability are guaranteed and backed by the best warranty in the industry. Lifetime BAUER support. TEFC High Efficiency Motor Inlet Buffer Tank BAUER C250/C280 Compressor C25/C28 Touch Screen Operator Interface DIMENSIONS L x W x H inches (mm) 158” x 96” x 144” (4013 x 2438 x 3658) WEIGHT pounds (kg) 7800 - 12400 (3538 - 5625) depending upon model and options. Customizable Logo Awning Vapor Recovery Tank Enclosure Designed for Durability and Attractive Appearance NEMA 4 PLC Control Panel High Pressure Dryer (optional) Precision Formed Heavy-duty Steel Skid Weatherproof and Rustproof Powder-Coated Galvanneal Enclosure Optional subframe with integrated ASME 3-pack storage (C250/C280 only) 46 Usable GGE Single Stack 92 Usable GGE Double Stack SHOWN WITH OPTIONAL UNDER-SKID ASME STORAGE BAUER C25/C28 L-SERIES CNG SYSTEM PERFORMANCE TABLE TOTAL PERFORMANCE WARRANTY BAUER COMPRESSORS INC. reputation speaks for itself with over 70 years of market leadership. Superior performance and quality Innovative design Unmatched global support and 24/7 customer service Best Warranty in the Industry: 2 year system warranty 10 year enclosure warranty Inlet Pressure Model PSIG Final Pressure BAR PSIG BAR Capacity No. stages (min) (max) (min) (max) (max) (max) CFM M3/H DGE/H GGE/H C25.0 1 5 0.07 0.34 5000 345 75 127 33 38 C28.0 1 5 0.07 0.34 5000 345 150 255 67 75 Note: All referenced capacities are at maximum inlet pressure. For all models, lower minimum inlet pressures are possible but will reduce final discharge pressure and capacity. Motor Power Power Requirement at Max Final Pressure STORAGE VOLUME (SINGLE STACK) Storage equivalent water volume per cylinder CF 16 hp kW hp kW 4 60 45 57.2 42.7 Storage volume per cylinder at 4700 psig GGE 43 4 125 90 116.7 87.1 3 bottle storage volume (total at 4700 psig) GGE 130 3 bottle sequential usable storage volume at 4700 psig GGE 46