Control - Carrier

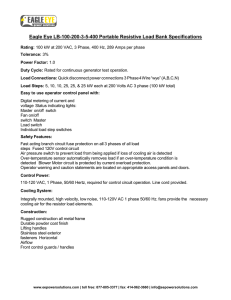

advertisement