Standard Packages and Features for DIPIPM in Small

advertisement

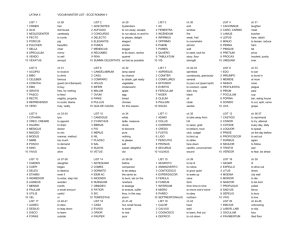

Standard Packages and Features for DIPIPM™ in Small Motor Drive Applications Eric R. Motto Powerex Inc., Youngwood, Pennsylvania, USA 1 ECCE 2013 Presentation Outline Applications & Requirements for small inverters: 0.2kW ~ 16kW (0.25HP ~ 21HP) The DIPIPM™ concept Development direction New Features The Complete DIPIPM™ Family Summary & Conclusions 2 ECCE 2013 Typical Applications –White Goods (Appliances) •Washing Machines, Refrigerators, Air Conditioners –Fitness Equipment •Treadmills, Stationary Bicycle – Commercial HVAC & Refrigeration • Package Air Conditioner – Pumps • Water & fuel in residential and commercial applications – Small Industrial Drives • General purpose & Servo 3 ECCE 2013 Requirements for Small Inverter Designs Reduced Total Cost Short Design Cycle Simplified Manufacturing Small Size High Efficiency Consistent High Reliability & Dependability 4 ECCE 2013 The DIPIPM™ Concept First introduced by Mitsubishi in 1998 ►Combine the discrete IGBTs, free wheel diodes and HVIC gate drivers for a small motor drive into a single component: Reduced component count – One part replaces more than ten Improved manufacturabily – No Need to Mount & Isolate multiple devices Small size – Increased integration yields compact finished equipment Increased reliability – IGBTs and HVICs designed and tested together 5 ECCE 2013 DIPIPM™ Key Technologies: Low cost packaging transfer molded lead Transfer-mold package frame (Original Mitsubishi concept introduced 1998) Bare HVIC die Isolated mounting to heatsink with UL recognized insulation and low thermal impedance. (TCIL technology with internal heat spreader) Low loss IGBT and soft recovery free wheel diode chips (Mitsubishi 5th 6th 7th SiC ) HVIC (High Voltage Integrated Circuit) for level- Leadframe IGBT chip Ultra fast recovery diode chip shift and gate drive (Mitsubishi original designs) New HVIC with 1200V level shift using divided RESURF structure 600V HVIC using conventional level shifting structure High Voltage Floating Circuits High Voltage Level Shifters 6 Al wire Molded resin FWDi, IGBT IC Insulated resin sheet Au wire Cu frame Al heat spreader ECCE 2013 New DIPIPM™ Development Directions Adopt 3 standard packages (1) Super Mini DIPIPM, (2) Mini DIPIPM, (3) Large DIPIPM Include Built-in Bootstrap Diode Less components to select, test, populate Relieves many critical spacing requirements on PCB Will not interfere with other power supply schemes Provide accurate analog temperature sensor Linear feedback, not logarithmic Make open emitters standard Easily connected together externally if not needed Update and Improve 1200V Line-Up. Adopt latest generation chip technology & add new smaller package 7 ECCE 2013 Standard Packages Covering: 3A-75A@600V, 5A-50A@1200V Super Mini DIPIPM™ Mini DIPIPM™ Large DIPPM™ 38mm X 24mm X 3.5mm 52.5mm X 31mm X 5.6mm 79mm X 31mm X 8mm 8 ECCE 2013 Super Mini DIPIPM™ Package Cross Section Cu Frame Al Wire Mold resin FWDi IGBT Au Wire IC Insulated thermal radiating sheet (Cu foil + insulated resin) 3A – 30A, 600V Optimized of lowest cost and compact size the Super Mini DIPIPM uses a high thermal conductivity insulating resin sheet (TCIL) between its lead frame and copper mounting surface to provide UL recognized 1500VRMS isolation. The heat of the transfer moulding process causes the resin sheet to cure simultaneously with the epoxy resin. The result is stable high reliability electrical insulation with low thermal impedance. 9 ECCE 2013 Direct wire bonding Simplified lead frame – Smaller Size Optimized HVIC and Power chip layouts along with direct wire bonding eliminates the need for intermediate lead frame islands. Previous DIPIPM™ 10 New DIPIPM™ ECCE 2013 New DIPIPM™ Internal View Highly optimized internal structure = Smallest Size & Lowest Cost 11 ECCE 2013 Technology Comparison POWEREX/Mitsubishi – DIPIPM™: Optimized HVICs + Optimized power chips + Direct wire bonding technology + Simple lead frame + Proprietary TCIL insulation = Efficient, Highly reliable, Low cost design A Competitor’s approach: Standard packaged ICs + Power chips designed for discrete packages + intricate IMS or FR4 patterned substrates = Complex assembly, difficult to control quality, long noise prone signal paths, reduced power cycling life 12 ECCE 2013 Mini DIPIPM™ Package Cross Section 20A, 30A, 50A 600V NEW: 5A, 10A 1200V The Mini DIPIPM™ has a thicker copper heat spreader to provide the improved thermal performance required for demanding industrial applications. The package also has a thicker profile with an undercut backside to provide the clearances needed for 2500VRMS isolation. 13 ECCE 2013 Large DIPIPM™ Package Cross Section Al wire Molded resin FWDi, IGBT IC Insulated resin sheet Au wire Cu frame Al heat spreader 75A, 600V & 5A-50A 1200V The large DIPIPM™ combines TCIL (Thermally Conductive Insulating Layer) technology with a heavy aluminum heat spreader to provide low cost and excellent thermal performance. Heavier power pins and increased mechanical strength allows use of this package at ratings of up to 75A at 600V. The thicker body and undercut backside provides the spacing and clearance needed for 1200V devices up to 50A. 14 ECCE 2013 Typical DIPIPM™ Analog Temperature Feedback Signal Typical Temperature Sensor Characteristic 4.5 4 Output Voltage (V) The DIPIPM™ operating temperature is monitored by a circuit on the custom LVIC that provides gate drive for the IGBTs. Adding the sensor to the gate drive IC provides low cost implementation and accurate linear voltage feedback 3.5 3 2.5 2 1.5 1 20 40 60 80 100 120 140 Temperature (C) 15 ECCE 2013 DIPIPM™ Linear feedback versus NTC 16 Typical Output Voltage Characteristic 4.5 4 Output Voltage (V) The DIPIPM™ linear temperature feedback provides superior resolution in the critical range of 80C to 120C. In this range the DIPIPM™ provides an output change of 1V while the NTC provides a change of only about 0.2V. This makes implementation of over temperature protection easier and more reliable with the DIPIPM™. DIPIPM™ 3.5 NTC 3 2.5 2 1.5 1 20 40 60 80 100 120 140 Temperature (C) ECCE 2013 DIPIPM™ Integration of Bootstrap Circuit The new DIPIPM™ includes integrated bootstrap circuits. This eliminates the need for external components a relieves critical voltage spacing on the PCB. This leads to a more compact and simplified final design. PS21963-4 17 PSS10S92F6 ECCE 2013 Typical New Generation DIPIPM™ Application Circuit Built-In Boot strap diodes Fault Status feedback signal Analog linear temperature feedback signal Single Power Supply Operation 18 Open Low Side Emitters Short Circuit Protection ECCE 2013 Large DIPIPM™ Current Mirror CSTBT Technology for Reduced Power Loss Current Sensing CSTBT with current mirror This technique used in the large DIP-IPMs so that the current sensing resistor can be reduced from a several watt rating to a fraction of a watt. 19 ECCE 2013 DIP-IPM Product Line-Up (For new designs*) Product Series Super Mini‐DIP Mini‐DIP Large DIP Current 600V 5A 10A 15A 20A 30A 35A 5A 10A 20A 30A 50A 5A 10A 15A 25A 35A 50A 75A PSS05S92F6 PSS10S92F6 PSS15S92F6 PSS20S92F6 PSS30S92F6 PSS35S92F6 1200V PSS05S72FT** PSS10S72FT** PSS20S71F6 PSS30S71F6 PSS50S71F6 PS21A79 PS21A7A PSS05SA2FT PSS10SA2FT PSS15SA2FT PSS25SA2FT PSS35SA2FT PSS50SA2FT * This table does not include older types that are still in mass production. This does not imply impending obsolescence of these types. ** Does not meet UL840 or IEC60335-40 spacing. Use large DIP is this is required. 20 ECCE 2013 Sinusoidal Inverter Loss Simulation (Available from Powerex website: www.pwrx.com) 21 ECCE 2013 NEW: Hybrid/Full SiC DIPPFC (Featuring Super Mini DIPIPM package) Features: • • • • • Low loss, High frequency operation using SiC Over Current, Under Voltage and Over Temperature protection Fault feedback signal 1500VRMS Isolation RoHS Compliant Line-Up: 20ARMS, 600V Hybrid (SiC SBD) – PSH20L91A6 Full SiC – PSF20L91A6 Si IGBT or SiC MOSFET 22 ECCE 2013 SiC DIPPFC same height as Super Mini DIPIPM Simplified mechanical layout – height adjustment not needed 23 ECCE 2013 NEW: MOSFET DIPIPM™ (Featuring Super Mini DIPIPM™ package) Features: • • • • • • Improved losses at low currents compared to IGBT Pin compatible with Super Mini DIPIPM™ Over Current, Under Voltage and Over Temperature protection Fault feedback signal 1500VRMS Isolation RoHS Compliant Power Loss improvement compared to IGBT Super Mini DIPIPM™ Target Application: Consumer Refrigerator Conditions: 2-phase modulation, Io=0.25ARMS, Vcc=260V, fc=2.7KHz, PF=0.8 24 ECCE 2013 Conclusion: DIP-IPM Family Features and Benefits: Wide Line-Up: 3A-75A 600V, 5A-50A 1200V with common functionality for easy scaling of designs. Highest Reliability: fully tested module with HVIC gate drivers, six IGBTs and free wheeling diodes delivers consistent performance and improved reliability. Lowest cost: transfer molded package technology provides the advantages of an isolated module at a cost comparable to discrete components. Unsurpassed Efficiency: Low loss 6th generation IGBT and soft recovery free wheel diode chip technology provides 30% lower losses than competitive modules. Reduced Parts Count: one module replaces fifteen or more discrete components. Smallest size: Use of bare die and simplified lead frame cuts footprint to less than half of equivalent discrete components. Miniature 3KW Three-Phase Inverter Using 15A Super Mini-DIP Simplified Assembly: isolated base module eliminates the need for insulation materials and requires only two mounting bolts. 25 ECCE 2013 Questions? 26 ECCE 2013