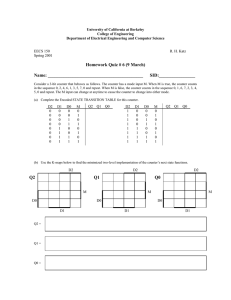

1769-UM006 - Rockwell Automation

advertisement