100-601950-000ES - Dassault Falcon

advertisement

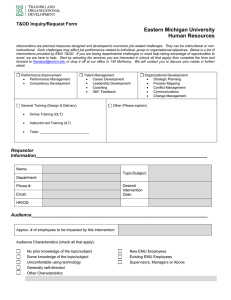

REVISION HISTORY REV NEXT ASSY DESCRIPTION DATE (YR-MO-DY) - Product Baseline Release. RA 05-0421 05-11-09 A Shts 18,19 & 25 revised. ECO 05-0544 05-12-12 D.C. B All sheets revised. ECO 06-0202 06-05-02 D.C FIRST USED ON APPLICATION (REF) ALL SHEETS ARE THE SAME REVISION STATUS CONTRACT NUMBER THIS DRAWING IS THE PROPERTY OF CMC ELECTRONICS INC. AND MAY BE NEITHER USED, COPIED, REPRODUCED OR OTHERWISE DEALT WITH OR ITS CONTENTS COMMUNICATED TO OTHERS EXCEPT IN ACCORDANCE WITH WRITTEN INSTRUCTIONS RECEIVED FROM CMC ELECTRONICS INC. Ref. MS Word APPROVED CMC Electronics Inc. Montreal, Quebec, Canada CONTRACTOR ORIGINATOR PILOTVIEW™ CLASS 2 EFB TECHNICAL DESCRIPTION DATE (YR-MO-DY) CHECKER ENGINEER SIZE APPROVAL A APPROVAL SCALE: CAGE CODE 90073 DWG NO. REV 100-601950-000ES SHEET 1 OF 18 B TABLE OF CONTENTS 1. OVERVIEW ........................................................................................................................................ 3 2. 2.1 2.2 PILOTVIEW™ ELECTRONIC FLIGHT BAG (EFB).......................................................................... 4 PilotView™ Electronic Display Unit (EDU)......................................................................................... 4 PilotView™ EFB Specifications.......................................................................................................... 5 2.2.1 EDU Characteristics ................................................................................................................ 5 2.2.2 EMU and Enhanced EMU (EEMU) Characteristics ................................................................ 8 2.2.3 EDU and EMU Installation..................................................................................................... 10 2.3 Aircraft Mounts ................................................................................................................................. 12 2.3.1 Side Mounts........................................................................................................................... 12 2.3.2 Yoke Mount ........................................................................................................................... 12 2.4 System Configuration ....................................................................................................................... 13 2.5 “CMC-Approved” Peripherals........................................................................................................... 14 3. 3.1 3.2 3.3 INSTALLATION ............................................................................................................................... 14 Qualification...................................................................................................................................... 14 PilotView™ MTBF / MTBUR ............................................................................................................ 14 PilotView™ Warranty ....................................................................................................................... 14 4. 4.1 4.2 4.3 4.4 4.5 4.6 APPLICATION ENVIRONMENT ..................................................................................................... 15 Standard Software Applications ....................................................................................................... 15 PilotView™ Master Menu Software.................................................................................................. 15 PilotView™ Note Taker .................................................................................................................... 16 PlotView™ Setup and Test Tools .................................................................................................... 16 Adobe® Reader® ............................................................................................................................... 16 Operator-Specific Applications......................................................................................................... 17 SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 2 B 1. OVERVIEW The PilotView™ EFB bridges the gap between low-end off-the-shelf PC tablets and high-end Class 3 EFBs, by offering an avionics-grade hardware package and certification to DO-160D. Many of the features found only in Class 3 EFBs, such as FMS-style line select keys, a very high- resolution, fully dimmable display, integrated communication capabilities and DO-160D certification make the PilotView™ EFB an ideal system to meet the varied requirements of the air transport and regional airline market. In addition to line select keys, the PilotView™ offers a “film-onglass” touch-sensitive screen providing pilots with a choice when accessing or navigating through EFB software applications. An optional feature unique to the PilotView™ also enables a pilot to immediately view what is on the other pilot’s display through the touch of a single key. Also unique to the PilotView™ is a one-touch video key (standard feature) that enables the pilot to toggle between the current application and video images from video surveillance systems. Multiple interfaces including integrated WLAN (802.11), PCMCIA, USB 2.0, 10/100BaseT Ethernet, RS232, RS422 (optional), and ARINC 429 (optional) provide the operator with a variety of methods for communications and updating of PilotView™ data such as electronic charts and documents. Optional discrete support is also provided to enhance applications. CMC, formerly known as Canadian Marconi Company, celebrated 100 years of innovation in 2003. As a world leader in high-technology products for the aerospace market, CMC has installed over 17,000 various avionics units with over 100 airlines in more than 50 countries around the world. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 3 B 2. PILOTVIEW™ ELECTRONIC FLIGHT BAG (EFB) The PilotView™ EFB is an avionics grade Class 21 Commercial-Off-The-Shelf (COTS) EFB system specifically designed for flight deck environments to bring up-to-date Information Technology-related advantages to the pilot. The PilotView™ EFB consists of 2 LRUs: a lightweight, compact and self-contained Electronic Display Unit (EDU); and a companion Expansion Module Unit (EMU). Figure 1. EDU and EMU (Enhanced EMU-EEMU with ARINC429 and video options shown) 2.1 PilotView™ Electronic Display Unit (EDU) The EDU boasts an extremely high-quality, fully dimmable display that provides exceptional readability in all cockpit lighting conditions. A “film-on-glass” touch-sensitive screen complements the backlit “FMS-style” line select keys providing the user quick access to specific functions such as: Approach, airport or en-route electronic charts; Checklists; Electronic documents; Performance calculations; Surveillance and/or EVS video. 1 For a full description of Class 1, Class 2 and Class 3 Electronic Flight Bags and software applications, please refer to the FAA Advisory Circular: AC No. 120-76A. This document can be downloaded from the Internet at the following site: http://www.airweb.faa.gov/Regulatory_and_Guidance_Library/rgAdvisoryCircular.nsf/0/B5DE2A1CAC2E1F7B86256CED00786888? OpenDocument SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 4 B The PilotView™ EFB integrates several communication capabilities that provide flexibility for operators to introduce applications as their cockpit information management requirements evolve. It is truly a mobile cockpit information management tool offering the flexibility to be used as installed cockpit avionics or as a PC “tablet”. Please refer to Appendix 1 for an overview of communications capabilities. 2.2 PilotView™ EFB Specifications 2.2.1 EDU Characteristics The EDU integrates a high-end display, processing capabilities and the user interfaces of the PilotView™ EFB which include a touch screen as well as backlit bezel keys. Several bezel keys are pre-defined to facilitate user navigation across applications.’Main’ provides a shortcut to the Master Menu application (see para. 4.2), ‘Apps’ lists active applications. ‘Video’ launches CMC View if installed, a ‘Hot-Key’ button is also available and user configurable. In addition, and as shown in the photograph below, the display portion of the EDU slides up to reveal an “FMS-style” alphanumeric keyboard with backlit keys. Figure 2. PilotView™ EDU shown with keyboard extended SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 5 B Size Weight Casing Battery Display 8.5” H x 6.1” W x 1.5” D (216mm H x 155mm W x 40mm D); 3.5 lbs (1.6kg) including batteries Machined Aircraft grade aluminium alloy. Lithium Ion rechargeable (2 battery packs inside unit). Active Matrix Liquid Crystal Display (AMLCD) “Film-on-glass” touch-sensitive screen Custom, Cold Cathode Fluorescent Lamp (CCFL) backlight Low Voltage Differential Swing (LVDS) interface. 8.4”(214 mm) diagonal screen. Resolution 1024 x 768 (XGA); 262,144 colors; Fully dimmable from 800 nits to 1 nit; Viewing Characteristics: Vertical: +40°, -50° Horizontal: +60°, -60° The EDU display has very low reflectance and is readable in direct sunlight. An integrated ambient light sensor automatically adjusts brightness levels. In addition, at any time, the brightness level can also be easily adjusted using the controls in the upper right corner of the EDU. Memory The EDU provides 512 Mbytes of Error Correcting Code (ECC) RAM (standard configuration). ECC encoding protects the processing environment from electrical field interference, in particular, at high altitudes. As an option 1Gbytes of ECC RAM can be installed on the EDU. Storage The EDU has two internal interfaces that accommodate solid-state Compact Flash cards (providing a storage capacity of up to 8 Gbytes) that provide high performance and reliability particularly in high vibration environments. Processing Platform The EDU is designed around the latest Centrino Mobile family Pentium-M® and employs a 1.1GHz processor. It includes a 400MHz system bus and Enhanced SpeedStep® power management. The chipset integrates an Intel® Graphics and Memory Controller HUB (GMCH) as well a 3D graphics engine that supports Intel’s Extreme Graphics 2 suite of graphics drivers. EDU Power Interfaces EDU Communication Interfaces In the aircraft, during normal operation, the PilotView™ EFB is powered by the EMU-EDU interface. Battery backup in the EDU provides 40 minutes or more of independent power in the event of aircraft power failure. When used outside of the aircraft in a portable manner, the EDU is powered by an optional 110220Vac (50-60Hz) Power Adapter that is similar to a laptop computer power supply. The EDU communicates with aircraft systems via the EMU and the EDU-EMU cable. The EDU also provides an integrated IEEE 802.11 a/b/g wireless LAN communications capability. Dual antennas are integrated in the EDU case for optimum performance. This feature can be optionally removed. For additional i/o communications, the EDU incorporates a single channel PCMCIA/Card Bus interface on the motherboard through a TI PCI1510 Card Bus controller. Two (2) USB 2.0 ports are available externally, one on each side, of the EDU to interface to external devices such as USB memory stick or CD/DVD ROM. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 6 B Integrated IEEE 802.11 a/b/g Wireless LAN with dual antenna. Can be used for broadband content upload and download PCMCIA Type II Card Slot Can be used for GSM/GPRS card or Mass Storage Brightness Sensor Manual Dimming control Two USB 2.0 slots are onboard. Supporting CD/DVD reader updates or USB memory stick. Bezel keys provide efficient access to applications including zoom in/out, video button and configurable ‘hot’ button Locking mechanism for integrated keyboard open/close control. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 7 B 2.2.2 EMU and Enhanced EMU (EEMU) Characteristics The Expansion Module Unit (EMU) provides certified aircraft power to the EDU protecting applications from aircraft power spurious and short term interruptions. The Basic EMU provides, as standard, the following interfaces between aircraft systems and the EDU: RS232 (DB9). Used for Weather data inputs or GPS when required. 2 x USB 2.0 ports. High speed communication and USB power. Aircraft Power Interface 10Base T Ethernet EDU-EMU interface. Delivers power and high speed communications to EDU The Enhanced EMU provides the above interfaces as well as ARINC 429, RS422, discrete support and/or RS170 Video interface. Specific versions of the Enhanced EMU can be configured to satisfy specific aircraft installation requirements. ARINC429, RS422, Discrete Support (DB26) RS170/NTSC Video Input EVS head down display and secure camera RS232 (DB9). 2 x USB 2.0 ports. Aircraft Power Interface EDU-EMU interface. 10/100Base T Ethernet SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 8 B The EMU is easily installed in any convenient, accessible location within 15’ (4.5 m) of the EDU (2). Characteristics for the EMU and EEMU are listed below. Power Conditioning 22-30Vdc, nominal 28Vdc The EEMU provides power conditioning of the aircraft power and supplies 18Vdc to the EDU. Input power interruptions of up to 200 milliseconds will not affect power output of the EDU. Size Base EMU: 6.86” L x 5.22” W x 1.0” D (174mm H x 133mm W x 25mm D) Enhanced EMU : 6.88” L x 5.10” W x 1.87” D (175mm H x 130 mm W x 48mm D) Weight (Base and Enhanced EMU share mounting holes) Base EMU: 1.0 lbs (470g max) Enhanced EMU: 1.7 lbs (750g max) Power Consumption The EMU consumes 52W typical, 82W maximum (including EDU consumption) The EEMU consumes 60W typical, 95W maximum (including EDU consumption). The EDU consumes 45W typical, 75W maximum. Standard Interfaces Standard interfaces are provided by both the base EMU and Enhanced EMU: Two (2) USB 2.0 interfaces One (1) 10/100Base T RJ-45 interfaces One (1) RS232 (DB9) EDU-EMU interface Optional Interfaces Optional Interfaces available with the Enhanced EMU include: Video Interface. Analog signal inputs can be RS170, NTSC or PAL. Arinc429 which can be set for high or low speed with a choice of 1RX or 1RX +1 RX/TX configurations Up to two optional RS422 interfaces 4 discrete inputs and 2 discrete outputs The above optional interfaces can be configured based on customer requirements. CMC provides a set of APIs for these interfaces and for development of Windows XP applications on the EDU. 2 For installations requiring a longer distance between the EDU and EMU, an EECE unit can be used. Please refer to the relevant section of this document for additional information. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 9 B 2.2.3 EDU and EMU Installation As illustrated in the picture below, a typical installation of the PilotView™ EFB requires the following elements: Docking mount with latching device which holds the EDU to the mount and provides power and high speed interface to the unit EDU-EMU cable Mount to aircraft which can vary depending on aircraft configuration and operators’ preference including side mounting, yoke mounting, or knee mount. 5’’ Mount Design Latching Device EDU-EMU Cable Latching Device The EDU accepts a docking mount that provides mounting, with a physical latch of the system to the articulating mounting arm and hard-wired connections. The associated I/O connections include power and USB 2.0. The pins in the connector are hooded and the sockets protrude (similar to ARINC 600 connectors). Hot-docking The EDU is hot-pluggable and can be docked and undocked while active. There are no impacts on applications provided appropriate actions are taken by the user to disable any USB devices active across the USB ports. Interconnect Cable The interface cable between the EDU Docking Mount and (E) EMU is installation dependent. The Interconnect Cable is a shielded, high flex (high strand count), impedance controlled cable suitable for power and USB 2.0 transmission. The cable can be up to 15” in length SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 10 B EECE When the installation requires, the EDU to EMU Cable Extension (EECE) enables longer distances between the EDU and EMU. Up to two EECE and associated cables can be used to install the EDU up to 45” away from the (E)EMU. The EECE is self powered and has the following characteristics: Dimensions: 08’’ x 3.08’’ x 1.71’’ Weight : 0.2 lbs (90g) SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 11 B 2.3 Aircraft Mounts PilotView™ EFB is a Class 2 system. Associated installation requirements are as per AC12076a which mandate the use of a suitable mount. CMC has experience in yoke mounted, side mounted EFB configurations as well as knee mounts where cockpit constraints or operators preference mandate this option. A physical survey of the aircraft is required to enable CMC to recommend the most costeffective, certified mounting solution. Such physical survey may cover the following considerations: Re-use of existing clip board location where applicable Does not obstruct cockpit instrument panel viewing Placed where pilot and co-pilot usually look for similar data No obstruction to pilot entering seat 2.3.1 Side Mounts CMC offers Side Mount in both 5” and 3” design. Each mount is tested for cockpit environment and crashworthiness. CMC side mounts provide the following benefits: Single handed operation and adjustment. Pilot selectable positioning and viewing angles Hot-pluggable latching mount releases EDU for mobile use Fully tested for use during all phases of flight Simple design and operation Robust hardware When attached to the articulating arm, the EDU can be readily positioned, with one hand, for optimal viewing by the pilot. In addition, since the EDU is “hot-pluggable”, it can be easily removed for use in a portable fashion. 2.3.2 Yoke Mount For some aircraft, yoke mounting will be a preferred choice. CMC offers a yoke mount which provides the same level of compliance to cockpit environment as the Side Mounts. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 12 B 2.4 System Configuration Depending on the choice of applications to be used, the PilotView™ EFB system can be configured to operate with aircraft or third party systems including FMS, GPS units, Weather transceiver data sources, communication systems such as Iridium or Satcom units, and printers. The EMU can interface with a GPS receiver to enable geo-centered moving maps (or “own ship” position on moving maps when permitted). A cockpit printer, if so desired, can be connected to one of the EMU’s USB ports. Optionally, the EMU can provide connectivity to an on-board file server or video surveillance camera interface unit via the integrated 10/100BaseT interface. Appendix –1- provides an overview of possible communication options. In a standard dual configuration, each EDU is installed with its own EMU. Additional EDUs can be installed in the cabin or galley if desired (bulk head configuration). The EDU/EMUs can be linked together via a cross talk cable providing easy updating of documents for a specific aircraft type or aircraft fleet. CMC can provide reference installation documentation for interfacing of the PilotView™ EFB with external systems such as Arinc429 FMS or GPS unit, RS232 GPS and weather units, RS-422 weather units. EDU - EMU cable EMU to EMU cable (10/100BaseT) GPS Printer Weather SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 13 B 2.5 “CMC-Approved” Peripherals CMC has tested a variety of “cockpit-ready” printers, CD-ROM drives, File Servers, “memory sticks” and other peripheral devices to ensure complete compatibility with the PilotView™ EFB. Please contact us for a list of approved devices. 3. INSTALLATION The PilotView™ EFB Installation Manual (available upon request: P/N 929-600040-000) contains information regarding installation in the aircraft. 3.1 Qualification The PilotView™ EFB meets the FAA AC 120-76A requirements for Electronic Flight Bags (class 2), and is qualified to RTCA DO160-D. Please contact CMC for a copy of CMC’s DO160D qualification report. 3.2 PilotView™ MTBF / MTBUR The predicted Mean Time Between Failure (MTBF) and Mean Time Between Un-scheduled Repair (MTBUR) expressed in aircraft operating hours are defined as follows: Table 1 Description MTBF (1) MTBUR (2) PilotView™ EFB System(*) 6,000 hrs 5,100 hrs (1) System comprised of EDU, EMU and associated EDU-EMU cable. (2) MTBUR estimated at 85% of projected MTBF. May vary depending on operators’ definition for MTBUR. 3.3 PilotView™ Warranty The PilotView™ EFB system is offered with a standard 24 months warranty. Longer term warranty provisions can be offered depending on operators’ requirements. Full details of the PilotView™ warranty are contained in the CMC’s “General Terms & Conditions of Sale and Product Support Provisions” document, which also details after warranty support and warranty available for repaired items. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 14 B 4. APPLICATION ENVIRONMENT 4.1 Standard Software Applications The PilotView™ EFB comes with a software application environment that includes the following as standard: PilotView™ Master Menu Software (user-configurable) PilotView™ Note Taker PilotView™ Setup and Test Tools Adobe® Acrobat Reader® for .pdf documents Microsoft® Windows® XP Professional Operating System (OS) 4.2 PilotView™ Master Menu Software CMC offers a suite of industry leading applications to satisfy the operational requirements for a wide range of business jet and air-transport aircraft types. The PilotView™ EFB application environment is supported by a CMC-controlled Windows XP Operating System and BIOS. Depending on Operator’s requirements, CMC’s Master Menu software provides a configurable environment for rapid and consistent access to applications during Flight Preparation, In-Flight and after the flight is complete. It provides the following key benefits: Automatic launch at power. Operates as a shell from the Windows XP environment simplifying user navigation from application to application; The Human Machine Interface is designed specifically to satisfy cockpit operations with the use of large buttons, suitable colour-coding, and reduced steps to get to each application rapidly at any time; Applications operate in their native Windows environment without any requirement for change or the need for software integration on the platform. Some application enhancements may be required to fully leverage the Bezel and Line-Select key capabilities provided with the PilotView™ EFB. Configuration tools allow for changes to the Main Menu configurations while ensuring the overall integrity of the EFB system. A password protected access to native functions of the Windows XP environment is possible at all times, should this be required. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 15 B 4.3 PilotView™ Note Taker Included with the PilotView™ EFB is a “Note Taker” application that provides up to ten (10) full pages of free text. These pages can be saved and retrieved at any time during flight. Each page allows entry of notes via the touch screen with either a finger or “PDA-type” stylus to keep important data such as clearances, waypoints, or other information close at hand. 4.4 PlotView™ Setup and Test Tools The EFB setup and test tools application provides the means to control the configuration of applications by providing the capability for the customer to: Specify user preferences including appearance and behavior of the EFB applications; Set preferred security options via the SETUP application; Choose which software application links are displayed on the Master Menu Screen as well as the physical positioning of the links; Set passwords to restrict access to protected areas, such as the Operating System Customize the links to the e-Docs as well as modify the physical position of the links on the main menu; Specify the application that is launched when the “Hot-Key” button is pressed; 4.5 Adobe® Reader® The PilotView™ EFB is shipped with an integrated document browser (Adobe® Acrobat Reader®) that provides access to user-defined documents that are stored safely on its solidstate mass storage devices. Document links are gathered by topic, into three distinct Categories: OPS (operational), MAINT (maintenance), REGS (regulatory). Each Category allows up to 12 user configurable e-Docs links. Amongst a range of optional applications which can be installed on the PilotView™ EFB, CMC offers an enhanced version of a Document Viewer integrated with the EFB Content Manager (ECM) software suite. This optional package offers enhanced browsing and presentation support for PDF,XML, HTML based documents and an automatic means of maintaining and updating the e-Docs configured on the PilotView™ EFB. Please refer to the PilotView® Website for additional information on these CMC EFB applications at www.cmcelectronics.ca. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 16 B 4.6 Operator-Specific Applications The PilotView™ EFB will support any operator-specific applications that are compatible with the Microsoft® Windows® XP environment. The standard “EFB Setup and Test Tools” application (see paragraph 4.4) enables the user to modify the Main Menu to include operator-specific applications. CMC also provides installation recommendations for a large number of third party applications including installation pre-requisites, recommended system configurations, and suggested setup options. This information is provided as part of the Question and Answer (Q&A) reference material. SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 17 B Appendix –1- Communications Capabilities GPRS IEEE 802.11a/bg IEEE 802.11a/b/g CWLU (ARINC 763) - access to file server - wireless printing - cabin wireless PilotView™ EDU PilotView™ EMU FMS GPS Units Ethernet Network File Server (ARINC 763) Ethernet VHF or VDL ACARS* CMU ARINC 724B/758 TWLU GATELINK (ARINC 763) VPN Access IP-Intranet Video Converter or Video Surveillance System SATCOM VPN access IP-Intranet VPN Access IP-Intranet SATCOM ARINC 740 Printer* Cameras *Requires ACARS s/w application in the PilotView™ EFB Figure 3 SIZE CAGE CODE A 90073 SCALE: DWG NO. REV 100-601950-000ES SHEET 18 B