Power conversion mechanisms for wave energy

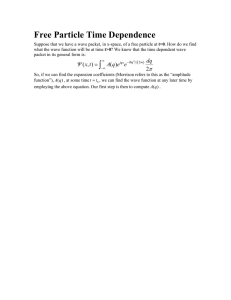

advertisement