Water Rockets

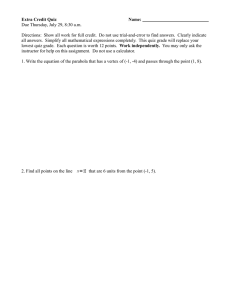

advertisement