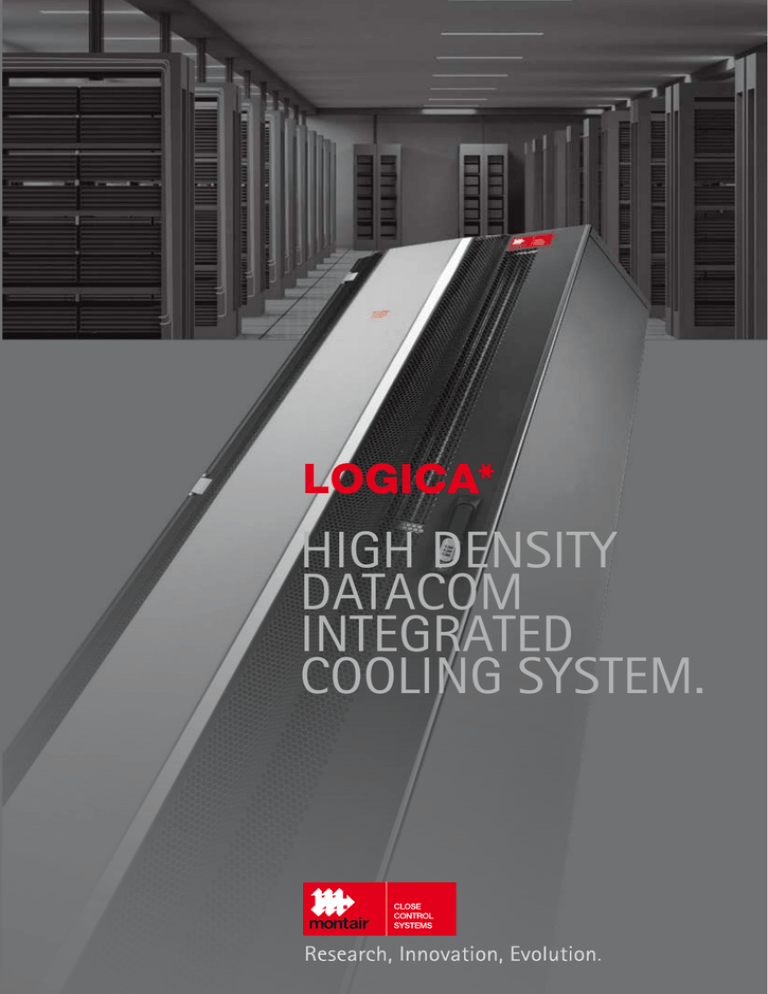

HIGH DENSITY DATACOM INTEGRATED COOLING SYSTEM.

advertisement

HIGH DENSITY DATACOM INTEGRATED COOLING SYSTEM. SYSTEM LOGICA is the most advanced alternative to the problem of cooling of server rooms MONTAIR is the trademark which represents excellence on the market for the production of special applications dedicated to high-tech environmental air conditioning. Its level of credibility is achieved thanks to a precise sustained mission of valuable know-how and human resources, engaged in the search for the best answers to the most specific requirement from the most demanding clientele. A success which pushes us to continuous improvement in order to maintain and consolidate the technological level accomplished. With over 25 years of experience in the construction of Chillers and Close Control units for air conditioning, today MONTAIR has achieved a position of leadership in Europe. MONTAIR has achieved a position of leadership by realizing products characterized by emphasized innovative content, accentuating energy saving, simplification and reduction of maintenance costs and through the particular attention paid to the matter of ecology and energy saving. MONTAIR today is present the world over with its realizations which are placed in highly specialized systems with excellent results; it is among the leading companies in the supply of units for the telecommunications and hospital sectors and that of high-tech applications and where quality and high reliability are fundamental requirements. MONTAIR pursues its objective of achieving continuous improvement in its offer through the search for new technological solutions and development of design and production standards to guarantee its clients the est performance over time: improvement in services, quality and training of professionals in assistance and attention to the ever more renewed and stringent demands of a market in continuous evolution. A system that offers unbeatable advantages. DIRECTLY COOLS THE SERVERS INSTEAD OF THEIR LOCATION YEARLY ENERGY SAVINGS UP TO 93% REDUCES SERVER SPACE BY 50% ALLOWING FOR THE ELIMINATION OF UNNECESSARY ELEMENTS FOR COOLING THE ROOM LOSS PREVENTION DUE TO A NEGATIVE WATER PRESSURE SYSTEM ALLOWS FOR THE REDUCTION OF 35% OF THE POWER REQUIRED FOR THE SERVICE CHILLER IT IS COMPLETELY FLEXIBLE ACCORDING TO REAL NEEDS AND FUTURE DEVELOPMENT NEEDS (POWER, USE, TIME) REDUCES INSTALLATION COSTS ELIMINATES DOUBLE FLOORING CAN BE ADAPTED TO ALREADY EXISTING RACK SYSTEMS EASY MAINTENANCE MAXIMUM SECURITY SYSTEM LOGICA SYSTEM consists of four main elements: 1 - LRD: LOGICA Rear Cooling Door. 2 - LPS: LOGICA Leak Prevention System. 3 - LRE: LOGICA High Energy Efficent Chiller. 4 - LMS: LOGICA Management System. HOW it works: 1. Chilled water is provided by a HIGH EFFICENCY LOGICA CHILLER (LRE). It can be also chiller with Free-cooling technology of both. 2. The resulting chilled water is drawn through the pipework by LOGICA Leak Prevention System (LPS). 3. Chilled water is then drawn through the LOGICA Cooling Rear Door (LRD). The waste heat from the active equipment housed within the cabinets is rejected to a heat exchanger. The net result is that the exhaust air returning back into the room is at ambient temperature and therefore has no impact upon the interior of the data centre. 4. The LOGICA MANAGEMENT SYSTEM (LMS) is the brain of the SYSTEM. Operating at rack and room level, the room’s temperature is locally controlled by the LOGICA Management System, which automatically adjusts the fan speeds, water flow rates and the circulating water temperature to achieve a consistent data centre temperature with no operator intervention. LRD: LOGICA COOLING REAR DOOR • It is the heart of the cooling system. • It operates with water temperature 18/23°C, so that no latent energy will be wasted. • It cools the air from 50°C to 24°C, instead than 24°C to 14°C (as the usual CRAC approach) al lowing high energy saving. • Twice ΔT across the coil, gives more than twice capacity with the same surface. • LRD are provide with Energy Efficient EC Plug-Fans. • It can be fitted to cabinets of any manufacturer using an Interface Frame. LRD LMS LMS: LOGICA MANAGEMENT SYSTEM • It’s the brain of the entire system. • The software was developed to keep the data exchange between the com ponents at highest possible rate and with the greatest fail-safe margin. • If any unit falls out of communica tion, it’s immediately reported to the BMS or any other means of communication to the supervisor. LPS LPS LPS: LOGICA LEAK PREVENTION SYSTEM • It ensures that in case of puncture or leaking joint, the conditioned space remains dry. • It monitors the presence of air and reports air entrainment to the BMS. • It ensures the water pressure is always below atmospheric. • Monitors the presence of doors and chiller to make sure no component falls out of network undetected. • The cooling doors software possess a sophisticated control algorythm to minimise the air flow and water flow. • The LPS software automatically manages the depression, the pressure lift and the water flow to minimize the pumping energy. • The software on chiller units receives the feedback from the cooling doors/racks that advise their own optimal working temperature. It calculates the best setpoint to minimise the energy consumption for the racks heat load. LRE LRE LRE: LOGICA HIGH ENERGY EFFICENT CHILLER • High energy efficient units with high EER and ESEER value. • Units suitable for any ambient condition from -20°C to +52°C. • Free-cooling solution available. • Unit with Scroll or Turbocor compressor • R410A and R134a Refrigerant. • Units are supplied with double pumps. • Units are provide with Energy Efficient EC axial Fans. • The chiller controls communicate directly, thanks to the LOGICA MANAGEMENT SYSTEM, to LPS and LRD and can vary dynamically the water temperature as required. SYSTEM A system that offers unbeatable advantages. Below is a comparison of traditional server room cooling systems with the LOGICA SYSTEM. Current server room cooling systems call for the installation of units for cooling the entire room. As a result, as reported in the picture below, they are extremely inefficient and costly. In particular, they require the installation of a floating floor through which the cold air is transferred to the rack units with obviously high installation costs. A traditional server room cooling system is generally made up of the following elements: 1. Close Control System for cooling the entire room; they draw in the hot air emitted by the rack units and release cooled air from under the floor. 2. The floating floor transfers the cold air, creating air columns directly on the rack units. 1 3 2 4 3. The cooler is sized to cool the entire room. This particular solution is extremely inefficient. Alternative solutions have currently been developed that improve the performance but involve an increased investment. 4. In traditional server rooms there are identifiable “hot aisles” and “cold aisles”. The image shows the technical solution that allows the two zones to be clearly separated, increasing the system’s efficiency. It is an improvement but: • Running costs remain high • No reduction on investments • Restrictions remain on electronic packaging densities The LOGICA SYSTEM allows for the elimination of negative effects that characterize traditional systems. 1. Eliminates the close control unit and the floating floor. The system calls for the installation of the REAR COOLING DOOR directly on the rack units. 2. Thanks to these innovations, the space dedicated to the server room (at the same installed power) is 50% less than with traditional solutions. 3. The system is guaranteed by the installation of the LPS which, by making the system work at negative pressure allows the Server to be saved in the case of Rear Cooling Door leaks. 4. The system works at high temperatures. Thanks to this technological system, cooling units can be sized with less power and with greater than average EER. 4 Summarizing: compared to same thermal load, LOGICA requires: • Fewer cabinets. • Less specialised real estate. • No raised floor. • Lower duty chiller. 3 2 1 It doesn’t cool the room. It just cools the warm spots rack-by-rack, where heat is produced. LOGICA replaces the traditional approach to data centre cooling, allowing loads of up to 45 kW per cabinet with the added benefit of removing real estate problems inherent with hot aisle cold aisle and aisle containment designs. The waste heat generated by equipment within the cabinets is removed at source by water cooling, without the risk of leakage in the data centre by our patent pending leak prevention system. LOGICA allows cooling water temperatures to rise from the traditional 6º C, reducing chiller size and energy costs and increasing the availability of energy efficient free-cooling. LOGICA SYSTEM: • Remove the traditional approach. • Remove unnecessary products. • Remove expansion restrictions. SAVING: Up to 93% energy saving year on year. Up to 27% saving on capital expenditure.