If - Oerlikon

advertisement

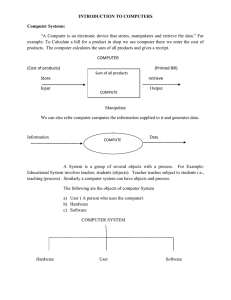

Special Edition JUNE 2005 USA Tel +1 949 863 1857 Fax +1 949 863 1866 Europe Tel +423 388 4870 Fax +423 388 5426 Taiwan Tel +886 3597 7771 Fax +886 3598 6161 Japan Tel +81 3 3225 9020 Fax +81 3 3225 9043 China Tel +86 21 50574646 Fax +86 21 50574647 Singapore Tel +65 6873 1188 Fax +65 6873 1133 Korea Tel +82 31 785 1300 Fax +82 31 785 1385 Emerging Markets Tel +423 388 5783 Fax +423 388 5426 info.datastorage@unaxis.com www.datastorage.unaxis.com Business and technical news from Unaxis Data Storage Project Managers / Editors Christophe Laurent Ursina Kesseli Unaxis Data Storage Marketing Communications Photography Michael Reinhard Photography (Herrliberg, Switzerland) Unaxis Photography unless stated otherwise Design / Layout Doubletake Design www.doubletakedesign.co.uk Printed in Switzerland Südostschweiz Print AG (Chur, Switzerland) Published by Unaxis Data Storage P.O. Box 1000 FL-9496 Balzers Liechtenstein If you have any comments, please contact us: tracks@unaxis.com or harddisk@unaxis.com For more information on Unaxis Data Storage please visit our website: www.datastorage.unaxis.com Tracks will return… 9th edition out early 2006 Dear Readers, Welcome to Tracks Special Hard Disk Dr. Stefan Seifried Dr. Ralph-Christian Ohr The very stimulating news in the Hard Disk market makes it especially timely that we publish this Tracks Special Edition. The transition to the new PMR technology together with the very positive changes in the use of Hard Disk technology for consumer electronic applications will require an increase in capacity in the next years. For us as a supplier of manufacturing solutions this means getting the right system platform and processes ready for our customers. During the last years when the Hard Disk business was running on a rather small level, Unaxis decided to relocate the Hard Disk activities from Unaxis Alzenau, Germany to the new Data Storage Center in Balzers, Liechtenstein. These activities, mainly in R&D and Supply Chain were consolidated with the strong Optical Storage business already established for many years in Balzers. A new Hard Disk Business Unit was formed and with support from Unaxis Germany the technology transfer has been completed. Jörg Frey In the last two years our efforts were mainly focussed on completing product developments mandatory for the PMR technology, like soft magnetic underlayer cathode solutions, a selfcleaning PECVD source for thin carbon overcoat and last but not least a full flexible software concept based on the WONDERWARE™. The strong in-house engineering force and our many years of experience in cathode development have already made us PMR process ready. Dr. Oliver Rattunde Following intensive discussions with our customers, we were able to identify the best future platform to support our well proven cathode and process technology. The result is our new linear concept “Racetrack” system, which we are launching today. Hartmut Rohrmann Dr. Jens Baumann I am convinced that RACETRACK, equipped with today’s and future technology, will revolutionize the Hard Disk industry. Beside the technology, the small footprint, ease of maintenance and use as well as low running costs are just a few of the features which will make RACETRACK the ideal production solution. The Unaxis philosophy is that software and hardware are of the same importance. The new RACETRACK will of course come with the proven WONDERWARE™ concept. Our Hard Disk business will be a vital part of our division’s future success and we have already started planning additional investments in hardware and manpower allowing us to be ready for the ramp-up in the years to come. Tony Sisca Andreas Meyer My special thanks go to our customers who supported us in the last years with whom we have made significant steps forward in our technology capabilities. We look forward to further developing and improving these partnerships. I wish you much success in 2005 and hope you will find this special edition of our yearly magazine an informative and enjoyable overview about the capabilities Unaxis Data Storage has to offer for the Hard Disk industry. Peter Tinner, Executive Vice President, Unaxis Data Storage Unaxis Data Storage Magazine RACETRACK ‘Revolution by Revolution’ Dr. Stefan Seifried BU Manager Hard Disk 3 Revolution by Revolution Introduction An introduction to Unaxis’ The transition to Perpendicular Magnetic Recording (PMR) will definitely come true in 2005. The first PMR Hard Disk Drive product is already announced and others will follow soon. However, the first PMR media products will most likely be produced on the existing equipment found in the manufacturing field. A shift to new hardware is not required at this point due to minimal demands by the current PMR layer stack design and manufacturers want to gain as much production experience as possible with this new process technology before making any major new purchases. Conversely, upcoming PMR developments will have to utilize new system hardware employing additional process steps to make any further areal density gains. new PMR machine RACETRACK - Revolution by Revolution 3 Unaxis concept for sputter processes 7 Deposition of Softmagnetic Under Layers (SUL) 9 New Carbon Gun 10 7 Sputter Processes Combining the best of Hard Disk and Optical Disc Substrate heating and temperature control Co 12 Cooling processes 13 Unaxis and the research for future hard disks 14 Nano-patterned perpendicular anisotropy magnetic 18 recording media fabricated on Unaxis CIRCULUS Miniature HDDs to Fuel Industry Growth in 2005 – technologies New systems are currently being tested and qualified. Unaxis, a world leader in thin film technology, first focused on getting the Jörg Frey Project Manager RACETRACK PMR technology component ready, by confirming all our capability for the necessary processes before considering a new platform. This has allowed Unaxis to gain much process experience that can be easily transferred to our customers – the media manufacturers. Equally, by starting first with the components Unaxis was able to benefit from huge insights in component integration and fast handling, creating an exceptional new dedicated system platform that will serve current and future Hard Disk media. The new RACETRACK, the name chosen because of its speed and high throughput, is a single disk system processing one disk at a time. In less than one and half years, the new revolutionary Unaxis RACETRACK system platform was realized. It addresses exactly the needs of a future Hard Disk Media Plant. Its introduction will change Hard Disk manufacturing, as we now know it. Let the revolution begin.... 12 Substrate Heating High uniform temperatures 19 in a cool environment Infrastructure to See Wave of Investment The race of RACETRACK started… 20 When only the best supply chain will do! 22 20 Unaxis Data Storage around the world 24 The Race is on... How it all started 24 Contacts Unaxis Data Storage around the world 2 | Tracks Unaxis 3 Unaxis Unaxis Tracks Tracks || A Unaxis Data Storage Magazine Process Chamber: Process environment with shield, Meissner trap and disk-carrier Customer oriented concept The RACETRACK system has a vertical layout addressing the double-sided simultaneous deposition required for all substrate form factors. After the previous Unaxis generations of circular operating systems, the RACETRACK process chambers are linearly aligned in two rows. Disks arriving from the clean room area are loaded into the system by means of a three vacuum stage loading module. In the third stage, the transfer-unit, the disk is then transferred into a carrier for process and transport. The process chambers are separated by enhanced gate valves for clean processing and independent venting. Generally, Unaxis Data Storage sputter systems are industry known for their high uptime and offering the lowest cost per disk. One reason for this is the high target utilization as result of intense cathode and process development. A target utilization up to 60%, a target exchange time of less than 60 sec. (after chamber venting), and the possibility of independent venting of each process chamber are key facts for achieving a minimum downtime in the manufacturing environment. In addition to this, customer oriented engineering allows consumables for both sides to be reached by accessing the tool just from one side. The linear transport works independently for each chamber without any feed-through, the driving force is only applied through the chamber walls. Both linear drive and gate valve are the fastest in the market and as integrated unit in the chamber already considered for other applications inside Unaxis. Transport from one row to the other is performed by two lift modules at each end of the rows. 4 | Tracks Unaxis Market trends show the small form factor disk to have the biggest growth in the next years. As in the past Unaxis offers with the new RACETRACK system also small form factor disk handling, loading and processing concepts. Focus of the work was on a particle free reliable concept with maximum throughput and minimum footprint. During transport and all process steps the disk is held in a carrier. The upper part of the carrier holds the disk with four notched springs based on an improved design from the CIRCULUS system. The lower part is optimized for fast transport and also avoids possible particle creation by a special wear protective coating. Processing takes places in up to 23 of the maximum 24 chambers with which the system can be configured. While the carrier with the disk is arriving and being positioned in the chamber the gate valve is closed simultaneously for a total separation of the process chambers from each other. Proven cathode concept Fast transport is not just one of the drivers to achieve a high throughput manufacturing environment, but also in combination with the excellent vacuum level (<5 x 10-8 mbar) the key to achieve a good magnetic performance by minimum contamination at the interfaces of the layers. Although some processes require a longer process time, clean interfaces allow the possibility to split up processes to gain throughput for manufacturing reasons. Fastest transport in the market With a throughput of up 1000 disks/hour (at a 2.9 sec. process time) the RACETRACK is the fastest system in the market transporting a single medium at a time. The keys to fast transport are: a minimized transport distance by a dimension optimized chamber design a specially developed linear magnetic drive with a transport time of less than 0.3 sec. from chamber to chamber, including positioning inside the chamber with an accuracy better than 0.2 mm a specially designed gate valve with an opening and closing time well below 0.2 sec. Small form factor solutions Without a doubt the most famous MP3 player, Apple's iPod led the move to new applications for the hard disk industry with up to 60 GB capacity As part of Unaxis Data Storage philosophy the manufacturing proven ARQ cathodes also formed the backbone for the RACETRACK system. The focus of development was on easy to handle and cost competitive solutions while keeping Unaxis known process performance. All PMR necessary processes are available: SUL Sputtering DC Sputtering RF Sputtering Heating Cooling Multilayer IBD Carbon Bias on glass disk In brief, for DC sputtering the proven compact layout with an internal asynchronous motor without belt will be used which will be adjusted for the soft-magnetic applications by a modified base plate and yoke. The RF cathode is based on the production solution of the DVD Sprinter cathode with dimensions adjusted for the smaller disk diameter. This RF cathode employs fully integrated software manageable tuning. As a carbon overcoat solution a self-biasing and self-cleaning PECVD source will be employed. Other carbon overcoat solutions are also under investigation for the future. Customers already using Unaxis equipment for Hard Disk production can benefit from their process know-how and very easily transfer existing processes to the RACETRACK system. Clever engineering allowed us to design a process geometry which is downwards compatible to the CIRCULUS by means of adapter kits. Currently, the handling, loading and processing of small formfactor disks is done by means of pallets where up to 5 disks can be handled and processed at a time. Our complete solution with less than 5 sqm footprint works with two independent robots where one is working for loading the SFF disks in the pallet and the other taken over to load the pallet into the machine’s conveyor system. The concept is independent of the regular system, can be easily integrated, and is already running in today’s LMR manufacturing areas. Easy modular and flexible setup Future media manufacturing requires flexibility with respect to hardware and software changes. The RACETRACK system allows addition and subtraction of process chambers in increments of four without any special alignment procedure up to a total of 24 chambers. This allows our customers to purchase only what is needed for their growth strategy. As the smallest unit, the so called process module (PM) comprises 4 process chambers and comes complete with all necessary hardware services and power supplies for an easy link up and efficient use of space. Overall, an impressively small footprint was realized which can be less than 25 sqm for a 20 chamber system including all supplies. Each process chamber can be addressed independently of the others for greater process flexibility and transport control. The RACETRACK system with its flexible proprietary software and hardware, will give our customers superior manufacturing flexibility, meeting today’s and future needs. Maintenance Every manufacturing system has to receive preventive maintenance to work according to the specification and manufacturing requirements. One of the main focus areas during the development of RACETRACK was on achieving excellent accessibility of all parts which might be maintained or exchanged from time to time. Parts involved in the sputter process like targets and shields can be accessed and exchanged for both sides by just opening the chamber from one side. Parts of the gate valves, e.g. the gate itself can be exchanged without taking out the entire body. Cabling and supplies are clearly arranged for fast error diagnostics. All fundamental maintenance can be carried out without the use of pulleys or similar tools. Unaxis Tracks | 5 Unaxis Data Storage Magazine UNAXIS CONCEPT FOR SPUTTER PROCESSES Software We placed great emphasis on getting the software right. The RACETRACK system runs on the WONDERWARE™ concept which has been a great success story on the DVD-SPRINTER systems and also successfully operating on the Unaxis CIRCULUS family worldwide, both under 24/7 manufacturing conditions. A PLC controller layout visualized by a logical, concise and real-time operating user interface based on WONDERWARE™ is at its heart. This concept allows a full flexible and easy configuration of the RACETRACK system. Adding, changing or subtracting components e.g. cathodes, pumps, mass flow controllers is very easy and self-explaining and could be done by any trained operator. Teaching of components involved in the handling and transport can be done without any other external controllers, just by the PC. Recent process parameters, like sputter pressure, gas-flows, sputtervoltage and current can be saved with their min., max. and average value in the disk logging file. 6 | Tracks Unaxis The desired process variance level which might be different for R&D in comparison to manufacturing can be easily adjusted. An easy transfer of recipes from system to system can be taken for granted. Of course options can also be limited to certain user levels by means of password security. Finally, software updates based on customer or Unaxis input can be done during regular system maintenance. Glass Bias solution Although maybe not considered in the first stage of PMR, Unaxis can offer already a solution for applying a bias to glass substrates. The concept is both simple and clever using standard parts already used in other areas of the system. The glass bias station can be integrated and moved very easily to any chamber of the system. Parts of the transfer-unit, the spring-opening devices are used to release the disk from the carrier while a gripper (hub) takes over. The gripper unit lifts backwards and turns the disk by a certain angle before lifting towards the carrier for further processing. A solution for up to four SFF disks processed in a pallet is already engineered but will be disclosed later for patent reasons. COMBINING THE BEST OF HARD DISK AND OPTICAL DISC TECHNOLOGIES Revolutions in summary: world’s highest single-disk throughput: 1000 disks per hour at 2.9 sec. process world’s fastest transport time of 0.3 sec. resulting in 0.7 sec. plasma to plasma (process to process) time excellent base pressure of less than 5x10-8 mbar for clean processing maximum 23 process chambers separated by enhanced gate valves easy modular setup - allowing for full flexible configuration serves all form factors from 0.8 to 3.5 inch proven handling, loading and processing concepts for small form factor disks fast target exchange time < 1 minute (after chamber venting), ensuring a quick return to production and profit easy access to all maintenance relevant parts and consumables from one side of the system without any special lifts or pulleys Hartmut Rohrmann Senior Scientist R&D Dr. Oliver Rattunde R&D Manager Hard Disk Components As part of the Unaxis philosophy the manufacturing proven cathodes are at the heart of the RACETRACK sputter processes. The new cathode designs combine the best features of the Unaxis hard disk and optical disc deposition sources. This results in easy to handle and cost competitive solutions while keeping Unaxis known process performance. Highlights All cathodes are compact and lightweight. The rotating magnet arrays are directly driven by asynchronous motors. They are easily accessible from the rear without breaking the vacuum. The cathodes take form factor optimized target sizes of up to 160 mm diameter and the target substrate distance TSD can be adjusted to 25 mm or to 32 mm, depending on the process requirements. A newly developed geometry for sputter gas management provides homogenous plasma conditions on the targets and symmetry for the process on both sides of the disk substrate. Unaxis Tracks | 7 Unaxis Data Storage Magazine DEPOSITION OF SOFTMAGNETIC UNDERLAYERS Process compatibility The process conditions in RACETRACK are downwards compatible to existing Unaxis equipment. Production process know-how can be easily transferred. The layout of the cathodes offers the freedom to take targets and magnet arrays of CIRCULUS M12 and CIRCULUS M14 systems at an identical process geometry (target - shield - substrate holder geometry, target substrate distance, target magnet distance). Thus established magnet array - target combinations can be run on the new system with guaranteed performance. DC & DC-SUL sputter cathode The key technology for PMR media production The sputter workhorse to serve most applications By reducing the demands on the new sputter source onto the essentials for thin film deposition we designed a compact, easily to handle cathode for all DC and pulsed DC sputter applications. The design is UHV compatible with only two sealings (O-rings for mounting the target base plate to the chamber). For critical applications these Viton rings can be replaced by metal seals. RACETRACK DC & DC-SUL sputter cathode A spacious compartment for easily accessible magnet arrays (max. diameter 172 mm, height up to 50 mm) allows flexibility in the magnetron design. High magnetic fields for strongly magnetic targets can be provided by long permanent magnets. For the demands of different magnetic and nonmagnetic target alloys a variety of dedicated magnet arrays are available. Increased storage density of PMR relies on SUL Performance data The upcoming generation of PMR media promises a further increase in storage density. The main advantage for reducing the bit size by going perpendicular comes from the soft magnetic underlayer (SUL). It draws the magnetic flux from the writing pole through the storage layer generating far higher writing fields than made possible with longitudinal recording. This allows the introduction of storage alloys of increased magnetic anisotropy giving long term magnetic stability for smaller grains/bits. Target thickness Deposition rate Thickness uniformity Target inventory Magn. anisotropy of SUL Hartmut Rohrmann Senior Scientist R&D Marcel Neusch Project Manager R&D more than 6 mm Fe, more than 10 mm CoTaZr up to 25nm/sec better than ± 4% for whole target life 2.2 mm for 6 mm Fe target radial easy axis (CoTaZr, NiFe) Pre-magnetisation of the target, a Unaxis solution for SUL sputtering The deposition of soft magnetic layers is a challenge. Targets of only a few millimeter thickness already shorten the magnetron sputter field of standard magnet arrays. A Unaxis solution is to introduce pre-magnetisation of the targets by static magnets and flux guides surrounding the target. Then the rotating magnet array has to provide less extra field to saturate and penetrate the target locally. This cathode layout also supports a further demand on the SUL sputter source: During film deposition it provides a radial magnetic field at the substrate resulting in a radially oriented easy axis of the soft magnetic layer. The sputter deposition of softmagnetic underlayers is provided by a special version of the DC cathode, using a modified target base plate with multimagnet option. RF Sputtering Expertise from an installed base of over 600 cathodes The SUL cathode in RACETRACK follows this design principle already well proven in CIRCULUS. It is based on the standard DC cathode with a specially designed target base plate and target environment. Complex computer modeling and simulation was performed to optimize the magnet layout for maximized target thickness, target inventory and film uniformity without losing the radial easy axis. Since RF processes may become more important for future Hard Disk technologies the new RACETRACK system features a new, dedicated RF cathode with fully integrated RF matching. This planar magnetron cathode has been adapted from the well proven Unaxis SPRINTER ARQ 21 RF cathode with an installed base of over 600 cathodes worldwide. Efficiency of SUL source (6mm Fe target) RF sputter source with integrated, software-manageable RF matching The new RACETRACK version features: Compact size for targets of up to 160 mm diameter, 32 mm target substrate distance Fully integrated, software manageable RF matching RF plasma ignition with well defined, very short (~100ms) pressure pulse through small aperture diaphragm independent of preset sputter pressure Synchronized RF power supplies with accurate phase control for A-/B-side uniformity 8 | Tracks Unaxis For tests with extremely high Bs material pure Fe (target thickness up to 7mm) was chosen. The measured erosion profile matches the results of the simulation closely. Towards the end of the target life the magnetron effect is enhanced at the outer diameter by the residual target material. This effect is obvious for high Bs targets. To minimize this the magnet array design has to be matched to the individual magnetic properties of the chosen target material. Tests with CoTaZr targets showed a well defined radial easy axis in the softmagnetic underlayers. Erossion profile of 6mm Fe target on SUL cathode Numerical simulation & experimental data Unaxis Tracks | 9 Unaxis Data Storage Magazine NEW CARBON GUN Proven manufacturing solution for ultrathin carbon overcoats Dr. Oliver Rattunde R&D Manager Hard Disk Components Dr. Ralph-Christian Ohr Product Manager Hard Disk Systems PMR layer architecture requires sophisticated solutions for ultrathin carbon overcoats down to 2 nm with maximum wear and corrosion protection. Taking the best from the proven Unaxis CIRCULUS solution, the new RACETRACK Carbon Gun comes with the same plasma beam source and Acetylene based PECVD process with in-situ oxygen cleaning. Furthermore, the new RACETRACK machine layout and exceptional carrier transport system result in a number of process advantages related to higher throughput and less particle generation. In addition, the self-biasing characteristic of the plasma beam source offers major advantages with respect to processing small form factor (SFF) glass disks. Advantages of the new RACETRACK layout Process Information Carbon Gun in-situ oxygen plasma cleaning (ashing) has been proven to be very effective in preventing particle generation, but oxygen gas must not come in contact with the sensitive layer stack on the disk. In CIRCULUS systems with their central spider wheel an elaborate shutter mechanism has been put in place to isolate the Carbon Gun chamber from the rest of the machine during oxygen cleaning. The carbon deposition process is based on a capacitively coupled and magnetically enhanced RF discharge at 27 MHz with Acetylene (C2H2) as the process gas. The specific design of the patented plasma beam source with a transparent extraction grid on ground potential results in an inherent homogeneous neutralization of the beam. The positive ions are accelerated onto the grid by means of the RF self bias (up to 100 eV per C-atom) and are then directed towards the substrate which is not part of the RF circuit. The new RACETRACK system however, with its innovative carrier transport system and gate valves between each process station, enables carriers to be moved out of a process station individually and independently of the overall handling cycle. Thus, cleaning will take place after the processed disk has been moved out of the Carbon Gun chamber to an empty position e.g. in the lift module. Additional shutter mechanisms can be eliminated which offers a number of process advantages: No more moving parts, especially those which can get carbon covered, and the same geometry for deposition and cleaning process – assuring even lower particle counts. Reduced chamber size resulting in less gas volume to be pumped out (approx. 10 liter total chamber volume in the RACETRACK compared to two times 23 liters for CIRCULUS M12) which enables faster evacuation of process gases, especially in between cleaning and deposition process. Smaller distance between plasma beam source and substrate are possible which results in higher deposition rate (see page 11) and less carbon stray coverage in the chamber (less amount of carbon to be cleaned). The last two points contribute to a significantly increased throughput of 750 disks/hour with one Carbon Gun station and 1000 disks/hour for two consecutive Carbon Gun stations. 10 | Tracks Unaxis Manufacturing solution for SFF glass disks As ion energy results from RF self bias and not from a DC bias which has to be applied to the substrate carrier, the Carbon Gun is also ideally suited for the manufacturing of SFF glass disks. In conventional systems, a bias voltage can only be applied to glass disks after the metal coated disks have been re-gripped, usually by means of a rotation station, which turns out to be very difficult to realize for several small disks being located in a FF95 carrier. The Unaxis Carbon Gun offers the big advantage of high quality IBD carbon coating without having to apply substrate bias. Deposition rate at 1E-3mbar C2H2 pressure as a function of distance between plasma beam source and substrate Film Properties Thickness uniformity C-C sp3 content Hydrogen content Density Roughness (on Si wafer) AFM scratch resistance ± 5% (FF95 disk) 55 - 60 % 25 - 30 % 2.4 g/cm3 Room Temperature (RT) # 0.12 nm 2.7 times higher than sputtered CNx films Unaxis Tracks | 11 Unaxis Data Storage Magazine COOLING PROCESS High Rate Cooling with optional applied magnetic field Dr. Jens Baumann R&D Manager Key Components Hartmut Rohrmann Senior Scientist R&D SUBSTRATE HEATING AND TEMPERATURE CONTROL High uniform temperatures in a cool environment For the heating process the RACETRACK can rely on the excellent performance of the Circulus heating stations. It was possible to introduce a more compact simplified design by containing the process relevant geometries and properties. The infrared radiation is generated by resistive carbon elements at temperatures of about 1000°C. The emitted wavelength spectrum is of high efficiency for metal and glass substrate heating. Water cooled reflectors form a highly reflecting cavity around substrate and heater elements providing three benefits: High energy transfer even for low absorbing substrate surfaces Low heat load for the disk carrier and the process chamber Fast response without long term drifts. The thermal equilibrium is reached 30 sec. after power has been switched on In 0.6 mm glass substrates a rate of temperature raise of up to 45°C/sec was achieved without breaking the disks.The station itself would be able to deliver doubled power if required in future. The heating element geometries were optimized for 12 | Tracks Unaxis homogenous circumferential temperature on the disks and distinctive radial temperature ramps. By combining a hot ID heater with a hot OD heater in the opposing positions of a station the radial temperature ramp can be set by the power ratio of the heaters. A set of two heating stations with identical heaters showed the following performance for a mean temperature of ~240°C on 65 mm disks: Heater type Radial ramp Circumferential Flat +1.3°C < ±1.7°C Hot ID +12.0°C < ±1.6°C Uniformity of the radially oriented magnetic field for two different disk form factors. Efficient and reliable cooling stations - made by UNAXIS - are already successfully integrated in CIRCULUS hard disk machines as well as in DVD SPRINTER systems for optical storage media. The existing knowhow was integrated into a new, compact and user-friendly design for the cooling station of the RACETRACK system. All disk form factors can be addressed by simply changing the front cooling plate. The cooling rate is increased by decreasing the temperature of the cooling plate and by increasing the pressure of the cooling gas in the station. Current and future HD technologies ask for cooling steps adjusted to different applications: Substrate cooling is one way to improve the properties of the protective carbon overcoat or to influence the microstructure of the storage layer. On the other hand, PMR technology may require a cooling step after deposition of the soft magnetic underlayer in the presence of a radially oriented magnetic field. For the new RACETRACK cooling station, permanent magnet arrays are available as an option for all disk dimensions. Hot OD -7.0°C < ±1.7°C The substrate temperature is controlled by fast pyrometers ‘on the fly’. On half way during the disk transport to the next station a sensor with a raise time less than 5 msec looks on the speeding disk. The read temperature is displayed on the screen and stored in the data logging for enhanced process control. Unaxis Tracks | 13 Unaxis Data Storage Magazine UNAXIS AND THE RESEARCH FOR FUTURE HARD DISKS HIDEMAR (High Density Magnetic Recording) is a research project supported by the European Hartmut Rohrmann Community. A consortium of 8 Senior Scientist R&D partners (CNR Rome, NCSR’D’ Athens, UPMC Paris, CSIC Madrid, CNRS Paris, TU Vienna, STM Milano and Unaxis Balzers) investigates different approaches for future hard disks. A main focus is on Co/Pd and Co/Pt multilayers and on fct phases of FePt and CoPt as storage layers. Broad interest is given to patterning, especially to techniques that may fit for mass production, and to the magnetic behaviour and the read/write properties of patterned media. These experiments are supported by computer modeling and read/write simulations. In parallel the approach of self assembled media is pursued to get comparative evaluations. All Co/Pd multilayers were prepared on Unaxis Hard Disk systems in Balzers using the TRIATRON, and magnetic characterisation was done in the Unaxis lab. The reports from TU Vienna and CSIC Madrid show a small part of the experiments and results on the Unaxis multilayers investigated in the HIDEMAR project. 14 | Tracks Unaxis MICROSTRUCTURE AND MAGNETIZATION REVERSAL IN CoPd PERPENDICULAR RECORDING MEDIA Prof. Josef Fidler Dr. Sabine Höfinger Prof. Thomas Schrefl Vienna University of Technology, Institute of Solid State Physics TEM investigation of microstructure Transmission electron microscopic (TEM) investigations of the microstructure of novel magnetic multilayer materials in combination with micromagnetic simulations of the magnetization reversal processes reveal guidelines for the influence of the real microstructure on the switching processes of newly developed magnetic media with superior recording densities. The main objectives of these investigations are to obtain upper limits for the bit writing of the highest density recording media based on realistic microstructural features. In high areal density recording media the microstructure, especially the grain size has to be in the order of 5-10 nm and the magnetic layer thickness in the range between 10 und 15 nm, respectively. Since the important length scales of thin film media are in the nanometer range, transmission electron microscopy (TEM) with the capability of high resolution imaging is an important tool for the study of thin film media. In commercial hard disks which have been used so far, the easy axis of magnetization lies in the plane of the recording layer and hence the media is called longitudinal recording media. In order to show the rapid development of the microstructure and recording density the micrograph of Fig. 1 depicts a cross-sectional view of a commercial hard disk of ~1 Gbit/in2 areal density which was state of art about 10 years ago. An underlayer (UL) of about 80 nm is employed to control the crystallographic texture and the grain size of the magnetic layer (ML). The magnetic layer is in the order of ~50 nm, the particle size ~30-40 nm, respectively. Due to the large bit size of about 3100x150 nm2 for the low recording density the grain size was in the right order to give a low signal to noise ratio of the bit signal to the recording heads. To achieve a high areal recording density beyond 100 Gbit/in2 with a bit size of about 130 x 45 nm2 a reduction of the grain size to the order of 6-8 nm has been necessary and a shift from longitudinal recording to perpendicular recording technology will be necessary. Since the magnetization direction during reading and writing process is perpendicular to the thin magnetic layer, the soft magnetic underlayer (SUL) forms a flux closure and therefore acts as a part of the head. The intermediate layer is used to decouple the SUL from the recording layer and also to control the grain and texture growth of the recording layer. All the layers in perpendicular recording media except the SUL are required to be as thin as possible to decrease the distance between the head and the media and SUL [1]. A schematic configuration of a perpendicular recording media is given in Fig. 2. Promising materials for novel perpendicular recording media are Co-Pd multilayer structures, which have a preferred orientation perpendicular to the magnetic layer with Co-layer thickness (0,2 – 0,3 nm) [2]. The samples which have been investigated in this study constisted of a magnetic multilyer system (12 nm Pd layer, followed by alternating Co-Pd layers) and were directly sputtered on a soft magnetic underlayer. Differences in the microstructure were found in dependence on different sputter-gases and gas pressure. The structure of sputtered thin films is responsible for their properties. The context between layer growth, morphology and mechanical properties can be described by Thornton´s structure zone model [3]. The magnetic properties (especially the Hc-value) of samples sputtered with high pressure are increased compared with samples sputtered with low gas pressure. That fact can be explained by the magnetic decoupling of the grains. The decoupling of the grains is a result of the columnar growth and shadowing effect. A columnar growth is clearly seen in samples sputtered with higher gas pressure (see Fig. 3 plane view, and Fig. 4 cross sectional view). Fig.1: TEM bright field image of a conventional hard disk of ~1Gbit/in2 areal density (state of the art in the year 1995) Lubricant Intermediate Layer Overlayer Soft Underlayer Magnetic Layer Substrate Fig.2: Schematic configuration of the layer system of perpendicular recording media The crystallographic parameters and orientations of the investigated hard disk specimen can be easily obtained and associated with any specific region by means of selected area electron diffraction (SAD). SAD is therefore often used to determine the identity of phases and grain textures in recording media. The comparison between the experimental SAD pattern, and theoretical calculated diffraction rings of a CoPd disordered fcc and ordered fct phase is given in Fig. 5. The experimental pattern fits very well with the calculated fcc phase pattern. Distinctive differences between fcc and fct phase can be seen by the splitting of the second and fourth diffraction ring. Fig.3: Plane view of decoupled magnetic grains of a CoPd hard disk specimen for perpendicular recording Unaxis Tracks | 15 Unaxis Data Storage Magazine Modelling and numerical micromagnetic simulations of bit writing in CoPd mulilayer We have used a three dimensional micromagnetic model describing the granular microstructure of magnetic thin film recording media and taking into account long range magnetic stray field interactions and short range direct exchange interactions in order to show and calculate the switching of the magnetization during the application of a local external head field [4]. The size of the model allows us to simulate two written bits and study their interactions and stability. Recording data densities larger than 100 Gbit/in2 are possible when the media have thermally stable, magnetically decoupled grains with grains sizes less than 10 nm. Fig.4: Cross sectional view of a CoPd hard disk specimen for perpendicular recording with soft magnetic NiFe underlayer Fig.5: Selected area diffraction pattern (SAD) of CoPd multilayer structure (top) and calculated pattern of CoPd fcc (bottom left) and CoPd fct (bottom right) 16 | Tracks Unaxis Micromagnetics is a continuum theory to describe magnetization processes on a length scale which is large enough to replace the atomic spins by a continuous magnetization vector and small enough to resolve the magnetization transition inside a domain wall. Depending on the magnetocrystalline anisotropy the characteristic length scale, the domain wall width or the minimum discretisation size, is in the order of several nanometers to micrometers. Computational micromagnetism leads to a deeper understanding of hysteresis effects at an intermediate length scale between magnetic domains and atomic distances by visualization of the magnetization reversal process. Switching of small particles, thin film elements and nano-wires becomes increasingly important in magnetic storage and magnetoelectronic devices. The magnetization reversal processes are studied using a 3D hybrid finite element/ boundary element micromagnetic model. Transient magnetization states during switching are investigated numerically in thin nanoelements and multilayers of various shapes and dimensions. Switching dynamics are calculated for different external field profiles and frequencies. The numerical solution of Brown’s equations can be effectively performed using finite-element and related methods that easily handle complex microstructures and take into account the long-range magnetostatic interactions and short-range exchange coupling between the grains in granular thin films. Dynamic finite-element simulations successfully predict the influence of microstructural features like grain size, particle shape, intergranular phases, and surface irregularities on the magnetic properties. Theoretical limits for remanence, coercive field, switching behaviour at a short time scale of less than 1 ns, and other properties have successfully been calculated for a large number of materials. The numerical finite element micromagnetic technique is based on the standard Galerkin discretisation on tetrahedral meshes with linear basis functions. A static energy minimization, dynamic time integration and the nudged elastic band method have been implemented. In the light of the importance of the granular microstructure of magnetic materials the finite element method has been chosen. For the calculation of the demagnetising field a hybrid finite element/ boundary element method is used. The total energy of a micromagnetic system is given by the Gibbs free energy, which depends on the magnetic polarization, the external field and some temperature dependent material parameters. It includes macroscopic contributions such as the Zeeman energy and the magnetostatic energy as well as microscopic contributions like the magnetocrystalline anisotropy energy and the exchange energy. The minimization of the total energy yields an equilibrium magnetization distribution. To increase data storage density, i.e. to decrease the bit size and to increase the signal to noise ratio, higher symmetry textures and narrow grain size distributions are necessary. In order to separate individual data bits arrays of patterned thin film elements are fabricated by lithographic and/or imprint techniques. As an example, the magnetisation reversal dynamics has been simulated for the granular microstructure of the magnetic layer in combination with the soft underlayer as described in Fig.6 consisting of abut 1000 textured grains with about 10 nm grain size and 15 nm film thickness. In order to simulate the write process in a 100 Gbit/in2 medium a bit size of 50 x 130 nm2 was assumed with a head speed of 20/ms corresponding to a trapezoidal external field profile with 2.5 ns bit writing time including 0.1 ns rise and 0.1 ns decay time. The micromagnetic simulations start form the state of randomly magnetized grains and clearly show in Fig.7 the switching of individual fully decoupled grains in a thin film medium with perpendicular magnetocrystalline anisotropy after writing two individual bits (after 5 ns). The material parameters used for the simulations are Js=0.30 T, K1=0.1 MJ/m3, A=10 pJ/m, α=0.02. A random misorientation of the grains up to ±10° is taken into account. Partially switched grains produce a large contribution to the media noise. It is obvious from the domain images obtained during the writing of two bits that the individual bit structure cannot be stabilized in a granular film consisting of completely coupled grains. The assumption of fully decoupled grains reveals a clear bit pattern after writing two bits as shown in Fig. 7 (after 5 ns). The jagged bit shape obviously results in a contribution to the media noise. In summary it has been shown that finite element micromagnetics in combination of microstructural investigations is the ideal tool for the simulation of nanostructures and granular microstructures. In novel thin film recording media, the coercive field, remanence and switching properties can be tailored by controlling the grain size, texture, shape, defects and intergranular coupling. Numerical micromagnetic simulations are used to fully understand new magnetic switching phenomena observed in granular thin films and structures and for the design of future magnetic recording devices with areal storaging densities larger than 200 Gb/in2. Fig.6: Micromagnetic model of 420 in plane randomly oriented grains used for the simulation of the switching of two bits a medium for perpendicular recording. The intergranular exchange coupling between the grains is variable. Fig.7: Simulation of the bit writing in a perpendicular CoPd thin film with fully decoupled grains after 5 ns. Blue means magnetization points outwards of plane and red means magnetization points inwards. [1] Peng, Y., T. Ohkubo, (2003), “The investigation of nanostructures of magnetic recording media by TEM”, Scripta Materialia 48, 937-942. [2] Carcia, P. F., A. D. Meinhaldt, (1985), “Perpendicular magnetic anisotropy in Pd/Co thin film layered structures”, Appl. Phys. Lett. 47, 178-180. [3] Thornton, J. A. (1977), “High Rate Thick Film Growth”, Annual Review of Materials Science, 239-260. [4] J. Fidler, J., Schrefl, T., Scholz, W., Suess, D., Dittrich, R., Kirschner, M., (2004), ”Micromagnetic modelling and magnetization processes”, J. Magn. Magn. Mater. 272-276, 641-646 Unaxis Tracks | 17 Unaxis Data Storage Magazine MINIATURE HDDs TO FUEL INDUSTRY GROWTH IN 2005 – INFRASTRUCTURE TO SEE WAVE OF INVESTMENT NANO-PATTERNED PERPENDICULAR ANISOTROPY MAGNETIC RECORDING MEDIA FABRICATED ON UNAXIS SPUTTER SYSTEMS 1 Prof. Dr. Fernando Briones Dra. Marisol Martín-González Instituto de Microelectrónica de Madrid (CSIC), Spain J. M. García-Martín L. Vila & G. Faini J. Montserrat Hartmut Rohrmann Senior Scientist R&D, Unaxis Data Storage Instituto de Microelectrónica de Madrid (CSIC), Spain Laboratoire de Photonique et de Nanostructures, LPN-CNRS, France Institut de Microelectrònica de Barcelona (CSIC), Spain But that is now changing. The HDD industry, after shipping 305 million units in 2004, will expand to 378 million units in 2005, a growth rate of 24%. Looking out through 2010, unit and revenue growth expectations, if met, will polish the image of HDDs and provide competitive returns for investors. Over 600 million HDDs will be sold in 2010, an impressive growth rate fueled by the vast expansion of HDD usage throughout the consumer electronics realm. Present day magnetic hard disk recording density on longitudinal magnetic media is practically reaching the superparamagnetic limit. For that reason, perpendicular and nanopatterned magnetic storage media, able to overcome that limit, are widely investigated [1]. In this work, carried out within HIDEMAR, an EC funded collaboration program between European Industrial and Academic Research Institutions, the possibility of defining a magnetic nano-patterning process compatible with the current Unaxis vacuum based hard disk fabrication technology, has been explored. The proposed approach is based on a local modification of the medium magnetic properties by localized, in-situ, low energy ion implantation. A similar concept has been described previously by Chappert et al. [2]. HDD manufacturer market shares, in unit terms, changed in 2004. Seagate Technology remains the leader, but several smaller manufacturers gained additional share in 2004 with focused product lines and strategies. A summary is as follows: 2 Seagate Technology Western Digital Maxtor Hitachi GST Samsung Toshiba Fujitsu Others Co/Pd multilayered films ~175 Å thick with a strong perpendicular anisotropy have been prepared by means of a Circulus sputtering deposition system equipped with Triatron cathodes. 95mm hard disk samples have been irradiated through an e-beam patterned mask with different ions (N, P and As) at different energies (20-30 KeV). According to simulations, this ion energy range is appropriate to cause interface disorder at the precise depth of the Co/Pd multilayers, locally reducing magnetization and perpendicular anisotropy and contributing to isolate nanosize bit domains at predefined track positions. After implantation, no changes have been detected by X-ray Reflectrometry (XRR) and Atomic Force Microscopy (AFM) on the ultra-smooth diamond-like carbon coated disk surface. Implantation effects on magnetic characteristics have been analyzed by means of Extraordinary Hall effect, Magneto-optical Kerr effect (MOKE) microscopy and Magnetic Force Microscopy (MFM). The MFM images in fig.1 & 3 show the magnetic domains before and after irradiation, respectively. Fig.2 gives an AFM image of a thin film with a lithographic mask aimed to study the effect of localized implantation on both shape and location of magnetic domains This work has been supported by the EC contract G5RD-CT-2002-00731. M.S.M.G. and J.M.G.M. would like to thank the Ramon y Cajal program. [1] M. Albrecht et. Applied Physics Letters, 81,15,2875 (2002) [2] C. Chappert et al., Science 280 1919 (1998) MFM Image of magnetic domains of the virgin sample in a demagnetized state 1 AFM image of photo resist mask with bits pattern prepared by SEM photolithography 2 MFM image from the edge of the nanopatterned area after 14N+ implantation 3 18 | Tracks Unaxis For years, mention of the words “data storage” is evoked both wonderment and winces from investors. This is particularly true when talking about the HDD industry. It would be hard to find an industry that has enjoyed so much growth, generated such a high level of innovation, and provided more value to end-users. At the same time, any traditional measurement of return on investment, return on assets, and stock price appreciation makes the HDD industry look like a black hole in space. 2004 26.9% 17.9% 17.6% 15.3% 7.6% 7.2% 5.8% 1.8% 2003 28.9% 17.2% 21.2% 16.5% 5.7% 5.8% 4.4% 0.5% Change -2.0% +0.7% -3.6% -1.2% +1.9% +1.4% +1.4% +1.3% Looking ahead, there three key factors that will positively influence the HDD market and its infrastructure: 1. Consumer electronics 3 Devices are rapidly incorporating HDDs, complementing core demand from PC and server markets. It’s not just digital video recorders (DVRs) and gaming consoles, it’s the iPod and its legion of clones that are stimulating innovation and investment. Sales of HDDs to PCs and servers were exceptional in 2004, and will continue to be the backbone of storage demand for years. But HDD sales to CE applications will account for approximately 20% of unit output in 2005, and are on a trajectory to surpass 40% by 2008. Developed countries will go from about 2-3 HDDs per household to nearly 10 HDDs within five years. Hard disks can now be found in all sorts of devices such as Samsung's YEPP video jukebox or in the world's first mobile phone fitted with a 1.5 GB hard disk which it recently launched. 2. HDD industry dynamics are rapidly evolving Growth momentum will be fueled by miniature HDDs, 1.8”, 1”, and sub-1” devices used in a variety of CE products. However, storage requirements for MP3 players, personal video players, and mobile phones, many of which will employ HDDs the size of postage stamps, are skyrocketing. TRENDFOCUS sees demand for miniature drives doubling in 2005 and growing more than 50% yearly through 2009. Mark Geenen President, TrendFOCUS 3. Investment is badly needed in the HDD infrastructure Shortages abound through the HDD value chain, thanks to a financial hangover brought on by overspending in the 1990s on plant and equipment. Disk drive makers are now facing manufacturing capacity limitations, an issue they haven’t experienced in years. While all have expanded manufacturing capabilities in small increments, demand from PC and CE markets are already outstripping the industry’s ability to produce. This will cause more expansion, and more spending on equipment. At the components level, there are shortages of glass substrates and finished media. Ironically, after the HDD industry (over)spent more than $1 billion on media capacity in the 1995-1998 timeframe, a glut of capacity forced consolidation and saw disk prices fall by more than 60%. The last three years have seen only modest capacity expansions, and near-term demand is far exceeding the media/substrate industry’s ability to supply. Watch for a sustained capital investment expansion through at least 2006 – but, hopefully, the industry won’t overextend itself like it did 10 years ago. Data storage is perhaps the most important element in IT and CE markets. The digitization of content and information will create never before anticipated opportunities for storage. High-definition TV will quadruple the number of gigabytes consumed in a DVR. High-speed, broadband communications will allow quick, inexpensive transfer of huge video and audio files – all of which need to be stored. Equipment companies such as Unaxis, with its RACETRACK system for PMR, are likely to see increased spending on their products - a welcome change from the last several years of restricted capital investment. While we must carefully watch capital spending and manage our companies more effectively than ever, the future has never been brighter for the HDD industry! Unaxis Tracks | 19 Unaxis Data Storage Magazine THE RACE OF RACETRACK STARTED …in the Swiss mountains at a point where customers told us they needed a modular concept for the future. So Unaxis Data Storage took up the challenge. Dr. Stefan Seifried BU Manager Hard Disk Tony Sisca Sales Manager Hard Disk North America The team went for a two-day workshop to discuss possibilities for a future hard disk platform addressing future needs. More than 20 members from all parts of the organization, such as R&D, Business Unit, Supply Chain, Assembly, Sales & Service gathered in a small village in October 2003. They concluded that the most critical parameters in future media manufacturing were: small footprint ease of maintenance good vacuum level and fast transport for a clean processing particle-free handling concepts and these became the basis for all considerations and discussions. 20 | Tracks Unaxis More than 50 ideas for various concepts were generated, drafted, summarized and categorized into four groups. Two concept groups were selected for further considerations and developed. Although the last generations of Unaxis Data Storage systems were circular ones, the company already has a lot of experience in linear systems. As part of various customer visits, these approaches were presented and discussed in detail during Q1 2004. We are very happy to offer this new platform to our customers with a development time of less than one and a half years. Starting last and overtaking the competition is a difficult task, but the RACE is not over yet, it has just begun – on track with RACETRACK! After the decision for the linear concept was made, RACETRACK was brought to life. Engineering started, leveraging synergies with existing Unaxis Data Storage systems. Suppliers were newly chosen or taken from the CIRCULUS base. And finally a name was selected out of 50 ideas. It closely associates the system with Formula 1 racing in so far as the system offers the following: focussed driving within a closed loop track fastest speed in the league, with optimized design and weight maintenance and parts exchange as quick as a flash Focussing on our core competencies such as process module design, cathode development and software engineering, the development took place together with selected partners. Our revolutionary fast transport system, a key element, went through many iterations which involved changes in the chamber design, the gate valve layout, the linear drive dimensioning and of course, the software, until we were finally 100% satisfied. Unaxis Tracks | 21 Unaxis Data Storage Magazine HARD DISK - WHEN ONLY THE BEST SUPPLY CHAIN WILL DO! Andreas Meyer Head of Supply Chain Management The Supply Chain for RACETRACK is designed to meet the exact technology, quality and delivery requirements of Hard Disk customers. Unaxis Data Storage has designed its global Supply Chain Management to ensure optimal support for the life cycle of each product line starting with the concept of a new product, continuing through its production life and ending with its phase out. Standardized job profiles and structures enable the organization to optimally respond to changes in demand and manage fluctuations. Additionally, it also allows the back-up of local Hard Disk supply chain management resources from our regional supply chain organisation, in so far as back-up resources can easily step in. This gives us maximum flexibility to cover peaks in demand and to act globally. The Hard Disk team receives support throughout the whole life cycle of its products from dedicated Supplier Managers, responsible for setting up an optimized supply base and for the strategic supplier relationship, Supplier Quality Engineers, responsible for best in class supplier quality, and buyer/planners, making sure that all deliveries are on time and potential delays are resolved immediately. development tasks, our partners contribute with specific solutions for optimal manufacturability, serviceability and ensure modularity of the machine. From the very first idea for the development of a new Hard Disk sputtering machine, it has been essential to have a strong network of development partners. While Data Storage leads the whole Racetrack concept and all technology and process related Besides the development partner network, strong and reliable suppliers for serial deliveries are also essential. A thorough, multi step supplier qualification process has been put in place to ensure that only strong, capable partners are selected. The selection process starts with an evaluation of the supply risk situation for each module and core component of the Racetrack. Quality demands, technical expertise and ease of manufacturing are just some of the areas which get evaluated to assess the complexity of supplier requirements. Soft factors are also taken into account: environmental and occupational health and safety risks also get evaluated to give a complete picture. The result of this whole process is a recommendation, if in depth audit of a supplier is required for a specific module or component. Supply Chain, Manufacturing and Assembly, Business Continuity Management, Information Systems and Sustainability. All new and existing suppliers for module and components, which are assigned to be critical, get audited on multiple capabilities: Management, Finance, Quality Management, Product Development, Customer Relationship, During serial production the buyer/planners take over the main responsibility for coordinating all supplier deliveries. An integrated SAP system facilitates the planning of the customer deliveries and ensures total In order to ensure the leadtime and quality standards we have promised to our customers, we built a reliable, flexible supply chain with multiple capable suppliers who can ramp up rapidly. Supplier Quality Engineers with a strong background in assembly are available to support and coach the suppliers in such ramp-up phases. A first prototype gets thoroughly qualified and serial production gets verified by an initial pre-series. transparency about all key deliveries. The planning activities out of one hand ensure that corrective measures can immediately be taken as soon as necessary whenever a customer delivery is at risk or even needs to be brought forward. Quality is always our first priority and our Supplier Quality Engineers work hand in hand with the internal Quality Assurance to proactively identify potential weaknesses and to take counter measures. A dedicated Supply Chain organization for the hard disk business, backed up by a global Supply Chain Management network, using state of the art methodologies and an global integrated SAP system, all designed for one simple goal, to ensure that our customers will receive the best technology, manufactured to the highest quality standards and right on time. 1 2 3 1 Key Sourcing and Supplier Quality activities during the development phase 2 Example for the result of a supply risk assessment 3 Example for the result of an On-Site Supplier Audit 22 | Tracks Unaxis Unaxis Tracks | 23 Unaxis Data Storage around the world Wherever and whenever you may need us – anywhere in the world. Headquarters & Technology Center, Unaxis Balzers Liechtenstein/Switzerland Unaxis Balzers Aktiengesellschaft P.O. Box 1000 FL-9496 Balzers Liechtenstein/Europe Tel +423 388 4870 Fax +423 388 5426 North America Unaxis USA Inc. Data Storage Division 18881 Von Karman Avenue Suite 200 Irvine, CA 92612 USA Tel +1 949 863 1857 Fax +1 949 863 1866 Peter Tinner Executive Vice President Unaxis Data Storage peter.tinner@unaxis.com Helfried Weinzerl Director Sales and Service, North America Unaxis Data Storage USA helfried.weinzerl@unaxis.com David Bernegger Genereal Manager CD/DVD Unaxis Data Storage david.bernegger@unaxis.com Mike McBride Eastern Regional Sales Manager Unaxis Data Storage USA mike.mcbride@unaxis.com Allan Jaunzens International Sales and Market Manager, Europe Unaxis Data Storage allan.jaunzens@unaxis.com Tony Sisca Western Regional Sales Manager Unaxis Data Storage USA tony.sisca@unaxis.com Christophe Laurent Marketing Manager Unaxis Data Storage christophe.laurent@unaxis.com Russel O'Brien Business Development Manager Unaxis Data Storage USA russel.obrien@unaxis.com Hans Ebinger General Manager Line Business hans.ebinger@unaxis.com Japan harddisk@unaxis.com info.datastorage@unaxis.com www.datastorage.unaxis.com 24 | Tracks Unaxis Unaxis Japan Co. Ltd. 3-2-1 Shinjuku, Shinjuku-ku 160-0022 Tokyo Japan Tel +81 3 3225 9020 Fax +81 3 3225 9043 Unaxis Europe and Emerging Markets Fiorenzo Slaviero Sales Manager, Unaxis Italy dorenzo.slaviero@unaxis.com Unaxis Shanghai Co. Ltd. #33 Building No. 76, Fu Te Dong San Rd. Waigaoqiao Free Trade Zone Pudong, Shanghai 200131 P.R. China Tel +86 21 5057 4646 Fax +86 21 5057 4647 Jim Bingen Sales Manager North Europe Unaxis Data Storage jim.bingen@unaxis.com Morning Zhao Sales Representative Unaxis Shanghai morning.zhao@unaxis.com Peter Henning Sales Manager Europe and Emerging Markets peter.henning@unaxis.com Stanley So Sales Representative stanley.so@unaxis.com Egon Längle Marketing & Sales Manager South Europe and Emerging Markets egon.laengle@unaxis Korea Doroteo Gonzalez Sales Manager, Unaxis Spain doroteo.gonzalez@unaxis.com Taiwan Unaxis Taiwan Ltd. No. 32 Fushing Road Hsinchu Industrial Park Hukou Hsiang, Hsinchu Hsien Taiwan Tel +886 3597 7771 Fax +886 3598 6161 Hong-Ji Chen Local Division Manager Asia Pacific hong-ji.chen@unaxis.com Yasuyoshi Tamura Local Division Manager, Unaxis Data Storage Japan yasuyoshi.tamura@unaxis.com Yung Tang Sales Manager Asia Pacific Unaxis Data Storage Taiwan yung.tang@unaxis.com Nobuo Mizuno Deputy General Sales Manager Unaxis Data Storage Japan nobuo.mizuno@unaxis.com Christy Liu Sales Taiwan Unaxis Data Storage Taiwan christy.liu@unaxis.com Yoshitaka Tokuhara Sales Manager Unaxis Data Storage Japan yoshitaka.tokuhara@unaxis.com Henfy Su Sales Taiwan Unaxis Data Storage Taiwan henfy.su@unaxis.com Hirofumi Iwanabe Sales Manager Unaxis Data Storage Japan hirofumi.iwanabe@unaxis.com China Unaxis Korea Inc. 3rd Fl. Jellzone 2 Tower, 159-4, Jungja-dong Pundang-Ku, Sungnam, Kyungki-Do Korea Tel +82 31 785 1300 Fax +82 31 785 1385 Jung-Ki Jun Local Division Manager Unaxis Data Storage Korea jung-ki.jun@unaxis.com Singapore Unaxis Singapore Pte Ltd 1 Science Park Road #03-10 Capricorn Building Singapore 117528 Tel +65 6873 1188 Fax +65 6873 1133 Han Chih-Heng Local Division Manager chihheng.han@unaxis.com Andrew Loh Sales Engineer Data Storage Division andrew.loh@unaxis.com