Using high capacity MLCCs to provide DC power smoothing

advertisement

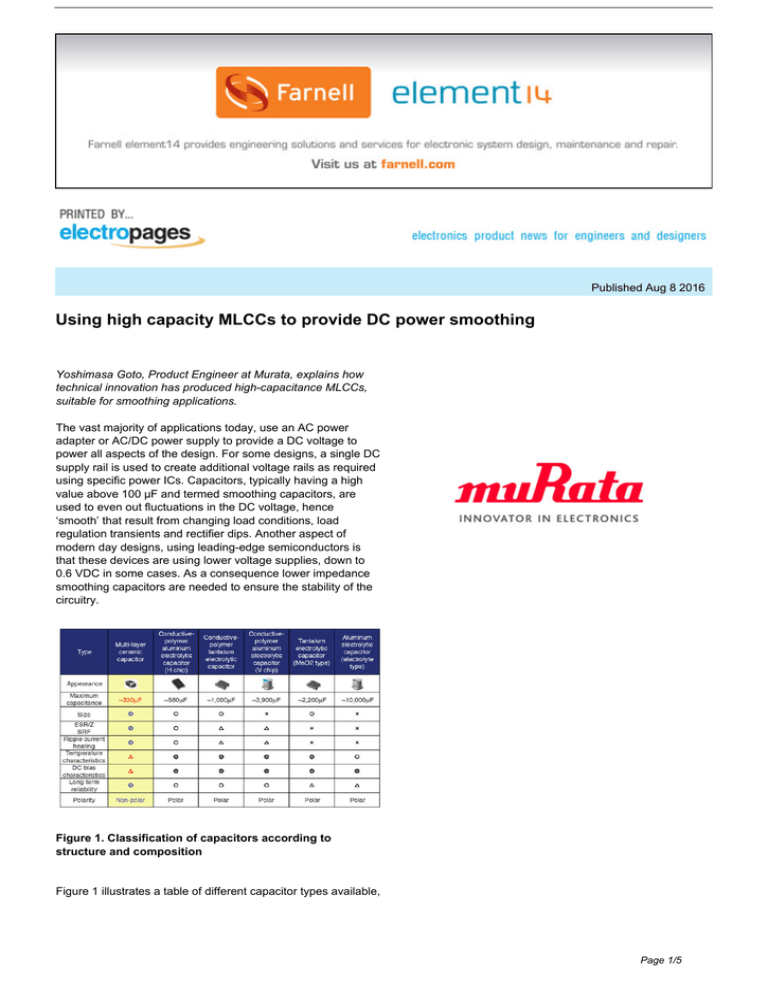

Published Aug 8 2016 Using high capacity MLCCs to provide DC power smoothing Yoshimasa Goto, Product Engineer at Murata, explains how technical innovation has produced high-capacitance MLCCs, suitable for smoothing applications. The vast majority of applications today, use an AC power adapter or AC/DC power supply to provide a DC voltage to power all aspects of the design. For some designs, a single DC supply rail is used to create additional voltage rails as required using specific power ICs. Capacitors, typically having a high value above 100 µF and termed smoothing capacitors, are used to even out fluctuations in the DC voltage, hence ‘smooth’ that result from changing load conditions, load regulation transients and rectifier dips. Another aspect of modern day designs, using leading-edge semiconductors is that these devices are using lower voltage supplies, down to 0.6 VDC in some cases. As a consequence lower impedance smoothing capacitors are needed to ensure the stability of the circuitry. Figure 1. Classification of capacitors according to structure and composition Figure 1 illustrates a table of different capacitor types available, Page 1/5 classified according to their basic structure and the materials used in the composition. The different advantages and disadvantages of each one is highlighted. There can be seen to be a number of advantages to using a multilayer ceramic capacitor, MLCC. These include their compact and small dimensions, their high reliability compared to other types of capacitors, and their low impedance or equivalent series resistance (ESR). In addition, they are very price competitive. However, some of the downsides to the MLCC is that they have a thermal dependence of capacitance and an effective capacitance value that decreases with voltage application. This last affect is more commonly termed its DC bias characteristic. As a consequence most small, high-capacitance capacitors are multilayer ceramic capacitors, while most of the smoothing capacitors in use today, which require over a 100µF capacitance value and low impedance characteristics, are conductive-polymer electrolytic capacitors. However, the disadvantages of the MLCC for use as a smoothing capacitor are being reduced thanks due to ongoing technical innovation aimed at increasing the capacitance values even higher. For example, Murata Manufacturing has already established technologies that allow stable, mass production of 1,000 or more, 1?m or less high-accuracy dielectric layers and reduction of their overall thickness. The result is the ability to reliably mass-produce MLCCs with capacitance values of 100 µF. An example of a 330 µF measuring just 3.2 x 2.5 mm is illustrated in Figure 2. Figure 2. A cross sectional diagram of a 3.2 × 2.5 mm, 330?F MLCC With the industry trend towards using lower voltage microcontroller and digital logic devices, the impact that the DC bias characteristic of an MLCC has on the reduction of the effective capacitance is diminished. As a result, higher value MLCCs are now increasingly being considered as a viable capacitor technology to use for smoothing DC supply voltages. An interesting perspective towards using MLCCs to replace the conductive-polymer electrolytic capacitors that have been traditionally used in smoothing applications is that the MLCC replacements can have a lower capacitance value. The reason for this is that multi layer ceramic capacitors have lower impedance and equivalent series resistance characteristics compared to the conductive-polymer devices. This is highlighted in Figure 2. Page 2/5 Figure 3. Impedance and ESR-frequency characteristics of conductive-polymer tantalum electrolytic capacitors and multilayer ceramic capacitors. The ?gure indicates that in the frequency range above 100 kHz, which is a switching frequency for power ICs used in digital devices, multilayer ceramic capacitors have a lower impedance and ESR values than conductive-polymer tantalum electrolytic capacitors, even if the former have a lower capacitance than the latter. Also, multilayer ceramic capacitors are more effective in suppressing high-frequency noise because at frequencies higher than the resonance frequency, they have much lower impedance than conductive-polymer tantalum electrolytic capacitors. Figure 4. Test results and diagram of the evaluation circuit In order to validate the capacitor differences an investigation was carried out on capacitor replacement using an evaluation board for double data rate (DDR) power ICs for PCs. Figure 4 shows the evaluation circuit and the examination results. In this evaluation board, DC 1.4 V voltage was used, and two conductive-polymer tantalum electrolytic capacitors (7.3 × 4.3 mm, 2.0V, 330 µF, M tolerance) were initially used as smoothing capacitors. Then, these capacitors were replaced with 150 µF and 220 µF multi-layer ceramic capacitors (3.2 × 1.6 mm, 6.3 V, M tolerance) to examine voltage ?uctuation associated with changes in ripple voltage, spike volt-age, and Page 3/5 load. Before this examination, phase adjustments were made to ensure the stability of the evaluation board. The results showed that multi-layer ceramic capacitors tend to have a lower ripple voltage even though they have a lower nominal capacitance than conductive-polymer tantalum electrolytic capacitors. This is probably because at the switching frequency, multi-layer ceramic capacitors have low impedance and ESR, and so cause the voltage ?uctuation to decrease. The results also showed that multi-layer ceramic capacitors tend to have a lower spike voltage in a similar manner. This is probably because they have low ESL, and as a result, suppress high-frequency noise. However, in a load change test where current was changed signi?cantly, there was a large voltage ?uctuation when 150 µF multi-layer ceramic capacitors were used. This is probably because the load change test has a correlation with the effective capacitance of capacitors obtained when voltage is applied. The multi-layer ceramic capacitors used in this test have a lower nominal capacitance than the conductive-polymer tantalum electrolytic capacitors, and their effective capacitance is decreased by DC bias characteristics; this is the reason for the large voltage ?uctuation in this test. However, the voltage ?uctuation was reduced by using 220 µF high-capacitance capacitors. As the use of low-voltage semiconductor devices has been rapidly increasing, conductive-polymer electrolytic capacitors featuring high capacitance and low ESR have been widely used as smoothing capacitors for power ICs that supply DC power to the semiconductor devices. Size reduction and long-term reliability, however, are considered more important for other devices that use these semiconductor devices, such as server computers, and they are also important for smoothing capacitors. There is, therefore, a demand for expansion of > 100 µF multi-layer ceramic capacitors that can be more easily miniaturized, are more reliable, and feature low impedance, ESR, and ESL. Murata www.murata.com/en-eu By Yoshimasa Goto Yoshimasa Goto is a Product Manager at Murata Electronics Singapore. He has been working at Murata for 17 years, starting as a product engineer for noise suppression products. He later moved on to MLCCs. Currently, as product manager, Goto is responsible for the Capacitor, Inductor and Noise suppression products in the India and ASEAN markets. Page 4/5 Page 5/5