HEATING COMPONENTS

1

Robertshaw® proprietary and confidential ©2014

Ignitors

Pilots / Thermocouples / Thermopiles

Air Pressure Sensing Switches

Heating Kits

Manufacturers Comparison

Literature

Website

Q&A

Universal Ignitor Kits

Product Advantages

Silicon Nitride Ignitors

Product Features

Manufacturer Analysis

Hot Surface Igniter Types

Robertshaw® 41-400 Series

Silicon Carbide

Robertshaw® 41-400N Series

Silicon Nitride (stronger)

Robertshaw ® Universal 41-800

Series

Kitted with brackets and screws

Kits include mounting brackets and hardware for contractor

convenience

Low cost and universal usage

Packaging is clam shell style for additional protection

Peg board ready

Replaces 130 competitor parts

See Sell Sheet 150-2185B for cross reference charts

41-803 is a GOOD offering

Silicon Carbide for good physical strength

Double helix spiral uses less current

1 Year Warranty

41-801N is a BETTER offering

Silicon Nitride technology for better durability

Rod shaped heating element

2 Year Warranty

41-802N is the BEST offering

Ultimate Silicon Nitride for best durability

Made by Kyocera™

Flat blade heating element

Best heat dissipation

3 Year Warranty

What is Silicon Nitride?

A light, hard material with low thermal expansion coefficient

Typical characteristics of Silicon Nitride (SiN) include:

High Mechanical Strength

Fracture resistance – stronger than Silicon Carbide

Good thermal shock resistance

Good chemical resistance

Resistant to deformation at room and elevated temperatures

Longer Usable Life

Unlike Silicon Carbide which has a porous construction, Silicon

Nitride is non porous and does not oxidize with age

Silicon Nitride ignitor elements can be cleaned with tough

cleaners and can withstand strong alkali’s and acids

Due to its outstanding performance, Silicon Nitride offers

peace of mind to the home owner when the temperatures dip

into the low teens during the winter months

2 Year Warranty

17 seconds or less to operating temperature – 1800°F

All ignitors are 120V AC

Ignitors are kitted with mounting hardware and OEM termination

or ceramic wire nuts

Durable, robust and resistant to dirt and oil

High temperature leads for wire protection

Flame sensor required for all Silicon Nitride ignitors

Less breakage during installation and servicing

12 SKUs available

Trusted Robertshaw® brand

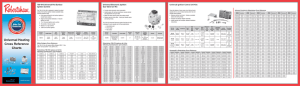

Feature

Robertshaw®

Crystal

Technica

MARS®

Series

41-400N

Glo-Stix 120- 67900

400

Supco

SSN2000

Replacement OEM

Hardware

OEM Termination

Passes 2 Meter Drop

Test

NA

Pros and Cons

Robertshaw®

Competition

Replacement OEM

Hardware

Easier installation ensuring

that

the igniters is placed in

position Correctly

Hardware with multiple

holes making it less durable

with variation in the

placement of the hot zone

OEM Termination

Quick tool free installation

Longer install time

Passes 2 Meter Drop Test

Durability for easier

installation

and handling

Fragility defeats one of the

purposes of SiN

What allows silicon nitride igniters to work in HVAC Heating

applications?

□ Low thermal expansion coefficient

□ High Mechanical Strength

□ Fracture resistance

□ All of the above

Silicon Carbide has a porous construction, Silicon Nitride is non

porous and does not oxidize with age?

□ True □ False

Pilot Basics

• Robertshaw® 1820 Series with Left or Right flame pattern type

• Pilot Uni-Kits® are with or without thermopile pre-mounted

•Used On

DC CURRENT

AC CURRENT

Flame Rod

(Smaller)

Flame Ground

(Larger)

PILOT / BURNER

– IPI Intermittent Pilot Ignition

– DSI Direct Spark Ignition

– HSI Hot Surface Ignition

How it Works

• Rectifies AC Current into DC

• Requires flame to ground

• Proves pilot or burner ignition

GND

“Hot” Junction

Copper-Nickel

Alloy

Copper-Iron

Alloy

“Cold” Junction

Insulated

Copper

Wire

Copper Sheath

Contact

Button

UUUUUUU

Load

(Safety Magnet)

Fitting

Nut

Contact Button

• The 1980 series offers easy installation into most pilot burners

• Uses Snap-Fit® technology

• End of part number refers to various lengths:

• 1980-012 is 12 inches

• 1980-072 is 72 inches

• The 1950 series thermopiles have two lead wire connections

and are primarily used in HVAC

• The 1951 coaxial series used on Commercial Cooking

Twin lead

wires

• Monitors Air Pressure

–

–

–

–

–

Conditioned Air Filters

Defrost Cycle in Refrigeration Coils

Gas-Fired Units with Draft from the Blower

Air-Supported Structures and Enclosures

Exhaust Fans and Fume Hoods

•

•

•

•

•

•

•

NEMA

NC

NO

PSI

SPST

SPDT

WC

=

=

=

=

=

=

=

National Electrical Manufacturers Association

Normally Closed (switch)

Normally Open (switch)

Pounds per Square Inch

Single Pole Single Throw

Single Pole Double Throw

Water Column in Inches

• Reliable devices to remotely sense operation of

– Fans

– Blowers

• Senses positive, negative or differential air pressure

– Maximum pressure 10.0“ Water Column

• Adjustable air sensing actuates internal switch

• Types of switches

– SPST = Single Pole Single Throw

– SPDT = Single Pole Double Throw

• Robertshaw line up of air pressure switches is Simply the Right Choice™ for

flexibility, reliability, accuracy and ease-of-use

• With a wide array of applications, the 2374-510 kit replaces hundreds of other

manufacturers’ air pressure switch models

• HVAC contractors now have a one-stop option to meet all their air pressure

switch needs

• This latest addition to the Robertshaw product line includes:

•

•

•

•

•

High impact polycarbonate housing

Works in a variety of harsh conditions

Snap-acting switch with three male 90º quick-connect terminals

Field adjustable set points ranging from 0.10” to 10” WC

Installers use 10-650 sensing probe kit for hard-to-reach air streams

• Sensing switch 2374-510 is field adjustable

• Relatively insensitive to temperature

• Range includes -40°F to 190°F

• Operates at 120 or 277 VAC

• Detection of static pressure drop across filters and coils

• Air switches can turn ON or OFF the following

•

•

•

•

•

•

•

Blowers

Exhaust Fans

Electronic air cleaners

Remote status indicators

Alarms

Control circuits

And more

•Sensing Switch 2374-510 contractor kit includes the

following:

–

–

–

–

Calibration Springs (5 options within 0.05” to 10.0” WC)

Orifice Restrictors (4 options)

Mounting Brackets (2 options)

Calibration adjustment tool (hex wrench)

• Easy installation and calibration

• 2 Year Warranty

• Housing is made of plastic to compete on price

•When extended tube is needed for hard-to-reach air

streams use Robertshaw® Sensing Probe Kit 10-650

•Probes are used in conjunction with the air switch as a

means to sense air pressure in the appliance

• Probes are mounted in:

•

•

•

•

•

Ducts

Intakes

Vents

Pressure Control Rooms

All HVAC Applications

Typical Applications For

Sensing Switch and Sensing Probe

Kit

1

Positive static pressure increases as the

filter gets dirty.

2*

Differential across filter changes as filter

gets dirty.

3

Flow is reduced as filter gets dirty.

4

Fan operation or air flow with little or

no static pressure.

5

Negative pressure increases as the filter

gets dirty.

6*

Fan operation and true air flow with

varying amounts of static pressure.

Probes must be perpendicular to the air

flow.

* Applications uses two Sensing Probe Kits

Fan

Filter

Fan

Filter

Fan

SPDT switch stands for what?

1.

2.

3.

4.

Single Pole Differential Terminal

Single Polarity Dip Termination

Single Pole Double Throw

Single Pole Single Throw

•

•

•

•

•

•

Robertshaw® 2374 series

Honeywell® IS2 series

Micro Pneumatics Logic® MPL 9370 series

Endura® ES2000 series

White-Rodgers®

Siemens®

Features

Robertshaw®

Honeywell®

MPL®

Endura®

2374-510

IS2

MPL9370

ES2000

Complete

Installation Kit

Full Line of

Replacement

Switches

Self Cleaning

Contacts

Series

Wider

Operating

Range

(up to 10.0 “ W.C.)

(3” W.C.)

(2” W.C.)

Product cross references at www.uni-line.com

(5” W.C.)

Robertshaw®

Competition

Complete

Installation Kit

Easier Installation with all Necessary

Hardware and Tools Included

Incomplete Kit Complicates

Installation

Full Line of

Replacement Switches

One Source for All Major

Replacements with Cross Reference

Charts

Multiple Suppliers Needed

and Possible Obsolescence

Self Cleaning Contacts

Helps Resist Welding from Arcing

Switch May Stick and Need

Service Calls

Rated for More

Applications

Rated for Fewer Applications

Made in the USA

Majority Imported

Pros and Cons

Wider Operating

Range

US Jobs

Value

Proposition

Wholesaler /

Distributor

Contractor

End-User

Complete

Installation Kit

“One Stop Shop”

Offering Includes

Hardware & Tool

“Grab and Go”

No Need to Wonder

About Right

Installation Tools

“Hi and Bye”

Installer

Minimizes

Disruption

Full Line of

Replacement Switches

Limits Need for

Carrying Several

Suppliers

Full Selection From

One Source

Installer has

Right Part

Regardless of

Application

Upsell Reliability

Opportunity

Limits Call Backs

Reliable

Operation to

Minimize Future

Service Calls

Additional

Feature to Sell

Wider Range of

Applications

Quality Product

Self Cleaning

Contact

Wider Operating

Range

Cross Reference available online at:

www.robertshaw.com/Products/Cross-Reference

• Sell Sheets with Cross Reference Charts

– Part Number in English: 150-2314

Literature available online at www.Uni-Line.com

UNI-KIT 360

MILLIVOLT KIT

Millivolt Heating Kit

Uni-Kit 360 Heating Repair Kit

Applications

Sales Support Tools

Millivolt Kit is updated

New pricing

New packaging

New mercury-free thermostat

Universal Kit 360

All universal parts

Replaces 1600 parts in field

Reduces inventory with easy-to-order SKU

Reduces installation time with right parts

Gas Valve 710-502

Thermostat 986-1R

Pilot 1820-009

Plus Free

Pocket Guide

Low capacity gas valve 710-502 used in space heaters

Designed for natural gas applications

Natural gas max 70,000 BTU, ½” inlet and outlet

Nat to LP conversion kit 1751-013 included

Economy mechanical Robertshaw® thermostat 986-1R

Simply reliable with easy installation

24V AC with UL Listing

Robertshaw® 1820-009 with 90° right flame pattern

Pilot Uni-Kits® with thermopile 1950-532 pre-mounted

Replaces ITT-General part number PG9A42JTL02

Wall Thermostat

Gas Cock

Safety

Pilot Line

Operator

Pilot and

Thermopile

Safety

Magnet

OPERATOR

TH/TP

R

TP

W

Safety

Magnet

OPERATOR

TH/TP

TP

TP

R

W

TH

1950 Series

Two-Lead

Thermopile

TH

1951 Series

Coaxial

Thermopile

Gas Valve

Ignition Control Module

Nitride Ignitor

Flame Sensor

Air Pressure Sensing Switch

Plus free tools

Robertshaw® Toolbag

Robertshaw® Screwdriver

Pocket Guide

Cross Reference Guide

Reorder form

Gas Valve 720-079

Universal model

Intermittent Pilot

Direct Spark

Hot Surface

150,000 BTU, ½” inlet and ¾” outlet

Factory set at 3.5” W.C. for natural gas

Can be converted to LP with conversion kit included

Universal hot surface ignition module kit 780-910

Designed for gas fired systems

Diagnostic green LED for quick troubleshooting

Kit includes all necessary hardware

Replaces most hot surface modules manufactured

by Robertshaw®, Honeywell® and White-Rodgers®

Local or remote sensing

120V AC units

Hot Surface Igniter Types

Silicon Nitride

Silicon Carbide (fragile)

Robertshaw® 41-802N

Silicon Nitride

Brackets included

Flame Sensor 10-760

Rod can withstand 1800 °F

Rod is 4” and can be cut and bent

Replaces White-Rodgers 760-401

56

Universal Air Pressure Sensing Switch 2374-510

Senses air flow from 0.10” to 10.0” W.C.

Switch controls wide variety of HVAC applications

Kit includes springs, orifices, mounting bracket

Calibration hex tool included

Robertshaw® replaces 1,600 solutions

Not all kits have the same parts

Uni-Kit 360 equivalents:

50M56U-843 White-Rodgers ®

Y8427U9045 Honeywell®

Natural Gas or Liquid Propane

Inlet and Outlet Size

BTU Requirement

Ignition Method being Used

Outlet Pressure Setting Requirement

Ambient Temperature

Orientation of Gas Valve

Valves should not to be mounted upside down

Actuator Type: Manual, Millivolt, Voltage, Hydraulic

Opening and Closing Speed of Gas Valve

Condition

Flame Too Large

Noisy Flame

Yellow Tip Flame

Floating Flame

Possible Cause

Possible Cure

1. Outlet pressure too high

1. Adjust regulator

2. Defective regulator

2. Replace regulator

3. Orifice too large

3. Replace Orifice

1. Excessive primary air

1. Adjust air shutter

2. Noisy Pilot

2. See Pilot Troubleshooting slide

3. Burr in orifice

3. Remove burr or replace orifice

1. Too little primary air

1. Adjust air shutter

2. Clogged burner ports

2. Clean burner ports

3. Misaligned orifice

3. Realign orifice and burner

1. Blocked venting

1. Inspect vent and clean

2. Insufficient primary air

2. Adjust air shutter

Condition

Delayed Ignition

Failure to Ignite

Burner won’t turn “Off”

Rapid Burn Cycles

Possible Cause

Possible Cure

1.

2.

3.

4.

Improper ignition location

Pilot flame too small

Burner ports clogged

Low outlet pressure

1.

2.

3.

4.

Reposition ignition source

Check orifice and clean

Clean burner ports

Adjust pressure regulator

1.

2.

3.

4.

Main gas “Off”

Poor electrical connections

Defective gas valve

Defective thermostat

1.

2.

3.

4.

Open manual valve

Check, clean, & tighten

Replace with new

Replace with new

1. Poor thermostat location

2. Defective gas valve

3. Defective thermostat

1. Relocate thermostat

2. Replace with new

3. Replace with new

1. Clogged furnace filters

2. Excess t-stat anticipation

3. Poor thermostat location

1. Clean or replace

2. Adjust t-stat anticipator

3. Relocate thermostat

When all else fails…check gas supply is in the “ON” position

Condition

Solution

Correct Flame

Tip of thermocouple or thermopile is

3/8” to 1/2” into pilot flame

Noisy, Lifting, Blowing Flame

High gas pressure

Wrong Pilot Orifice

Lazy Yellow Flame

Clogged primary air opening

Low gas pressure

Clogged pilot orifice

Wavy Blue Flame

Draft condition as pilot

Hard Sharp Flame

High gas pressure

Pilot orifice too small

Small Blue Flame

Wrong pilot orifice size

Low gas pressure

Clogged pilot tube

Open circuit 25 to 30 Millivolts

HOT

JUNCTION

30 MV

COLD

JUNCTION

CONTACT

BUTTON

MILLIVOLT

METER

Hot

Junctions

Cold

Junctions

UUUUUU

Load

(Safety Magnet)

UUUUUU

Load

(Gas Valve)

1950

Twin Lead

Connector

•

•

•

Problem # 1: Hot Surface Igniter Does Not Glow Red

Possible Causes

– No main power

– Faulty Transformer

– Faulty Thermostat- check call for heat

– Faulty Limit Switch

– Faulty blower interlock switch

– Faulty hot surface igniter

– Faulty ignition control

– Remember to wait for purge time, 17 or 34 seconds

Troubleshooting

– With power on and thermostat at its highest position, check voltage between “TH” and

“TR” on HS780 module.

•

•

–

If 24 Volts not present, check transformer output

If no 24 Volts present on secondary side, change transformer

Check for 120 Volts at the igniter across “IGN” and “GND”

•

•

If voltage present, change igniter

If no voltage present, change module

•

•

•

Problem # 2: Igniter Glows Red but Main Burner Will Not Light

Possible Causes

– Improper Igniter or Sensor Alignment

– Faulty Ignition Control

– Faulty Gas Valve

– High Inlet Gas Pressures

– Polarity Reversed

– No Earth Ground

Troubleshooting

– Check availability of gas at gas valve. Make sure valve upstream is in the Full On position. Check

pressure ok.

– Check “GRD” and “PV/MV” by reversing wires

• If reversed the gas valve will not open.

– Check proper ignition position and properly grounded

– Check for 24 Volts at gas valve terminals

– “1” and “2” on a 7200 series, “TH” and “TR” on a 7000 series

• If Yes, check wire resistance or change gas valve

• If no, change the 780 series module

•

•

•

Problem # 3: Main Burner Shuts Off before the Thermostat is Satisfied

Possible Causes

– Improper Igniter or Sensor Alignment

– Faulty Ignition Control

– Contaminated Igniter and/or sensor

– Bad burner ground

Troubleshooting

– Check polarity

– Check for proper igniter position

– Check for proper ignition control grounding

– Visually inspect igniter and remote sensor for any contamination.

• Clean and replace

– Check main burner ground

– If above steps are ok, replace igniter

•

•

•

Problem # 4: Main Burner Does Not Shut Off When Thermostat is Satisfied

Possible Causes

– Faulty Gas Valve

– Faulty Ignition Control

Troubleshooting

– Check thermostat to make sure contacts are open

– Check for 24 Volts between “TH” and “TR”

• Should be Zero, if gas valve is stuck open, replace valve

– Check for 24 Volts between “PV/MV” and “GND”

• If 24 Volts present, replace ignition control

• If 24 Volts not present, replace gas valve

Telephones:

Technical Service

1-800-445-8299

Technical Service Fax

1-630-260-7294

Customer Service

1-800-304-6563

Customer Service Fax

1-800-426-0804

Websites:

Uni-Line® Catalog: www.robertshaw.com/Uni-Line

Cross Reference: www.robertshaw.com/Products/Cross-Reference

Toolbox: www.robertshaw.com/toolbox/Toolbox-Main

General Information for:

Robertshaw®, Paragon®, Ranco®, Uni-Line® and Publication Zone®

Robertshaw®, Paragon®, Ranco®, Uni-Line®, and Make the Connection™ are propriety marks of Robertshaw or its subsidiaries.

All third party trademarks and service marks are the proprietary marks of their respective owners.

© 2016 Robertshaw. All rights reserved.