Series 1000 Pressurization System Data Sheet

advertisement

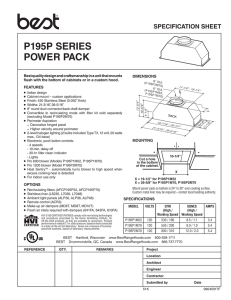

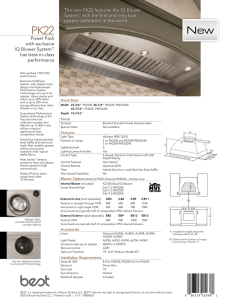

Series 1000 One Stage, Two Blower Automatic Pressurization Systems Application Operation Features The Series 1000 pressurization systems are designed to provide a reliable source of pressure for small air-supported radomes with automatic operation, even for unattended sites. The process of selecting a radome pressurization system is complex. Many factors such as design wind speed, radome diameter and truncation (height to diameter ratio) must be considered. In general, the Series 1000 systems are designed for use with small radomes up to 30 ft. (9.1m) in diameter, operating in winds up to 100 mph (44.7 m/sec.). Other systems are available for higher design wind speeds and for use with larger radomes. Normal Operation: Under normal operating conditions, one inflation blower operates continually to maintain radome pressure at approximately 5” H2O (127 mm H2O). • Low Pressure Operation: If radome pressure drops below 4.0” H2O (102 mm nd H2O), the 2 inflation blower will start after a five second time delay. The blower will operate for five minutes after normal pressure has been restored in the radome, then shuts off automatically. To enhance reliability, there are two pressure switches/circuits in parallel, either one is capable of activating the blower. The delay and overrun periods prevent the blower from starting as a result of momentary pressure variations. Audible and visual indicators are activated when a low pressure condition occurs, and will shut off automatically when normal pressure is restored. • Description Each Series 1000 pressurization system consists of a fully automatic control panel, two identical inflation blowers, motor starters and an air intake plenum, all mounted on an integral skid. The entire system is supplied as a modular, prewired unit. The blowers are of the centrifugal, non-overloading, backward inclined blade type, featuring constant pressure over a wide operating range. Each blower is equipped with a reverse flow check valve. The control panel and motor starters may be remotely located by simply extending the wiring. Dimensional Data • • • • • • • Blower motors start sequentially to minimize emergency power demands All blowers can be operated manually Control circuit operates on low voltage (24 VAC) supplied by selfcontained transformers All blower and control circuits are individually protected by circuit breakers All control circuit breakers activate visual and audible indicators when tripped Terminal boards provided for all external connections: power, blowers and remote status signals A panel-mounted pneumatic test valve simulates low pressure for testing control panel operation Panel mounted alarm horn with test switch Designed for high reliability in accordance with MIL-HDK-217, featuring: - Dual transformers - Dual low pressure switches and control circuits For Information Only Do not use for construction or fabrication Standard Model Specifications: 1st Blower Model Wind Speed Pressure Motor HP Pressure Motor HP Intake Duct 1000 100 mph 44.7 m/sec. 5.0” H2O 127 mm H2O 2 5.0” H2O 127 mm H2O 2 18” Ø 45.7 cm ENVIRONMENTAL: • Temperature Range, operating: -5ºF to +120ºF (-20ºC to +50ºC) • Temperature Range, non-operating: -40ºF to +130ºF (-40ºC to +55ºC) • Weather Protection: designed for indoor installations; control panel is NEMA 12 and also conforms to IEC 529, Class IP65 ELECTRICAL: • Blower Motors: 208 VAC, 3Ø, 60 Hz. • 2nd Blower Control Panel: 120 VAC, 1Ø, 60 Hz. Other voltages and frequencies available to meet specific site requirements (ex. 220/380, 230/400, 240/415, 3Ø, 50 Hz). REMOTE STATUS SIGNALS: • Signals are provided as 24 VAC (for optional remote status panel use) and Form C dry contacts rated at 3A @ 120 VAC/28 VDC: - Control Power On - Blower 1 On - Blower 2 On - Pressure Low - Tripped Circuit Breaker - Alarm Horn • OPTIONS: • Remote Status Panel: Provides pressure meter, duplication of all control panel indicators and alarm horn. Designed for standard 19” rack mounted installation. • Air Filtration System: Tri-stage intake air filter system for salt and particulate removal down to 1 micron in size. • Low Temperature Option: Extends minimum operating temperature to -40ºF (-40ºC). • Stainless Steel Blower Construction • Emergency Generator System: Diesel engine generator with dual-wall sub-base fuel tank, weather housing and automatic transfer switch. • Engineering Services: Engineering and drafting services are available for custom applications, design, installations, inspections and service. CONTROL PANEL DISPLAYS: • Pressure: 0-20” H2O (0-508 mm) • Indicators (press-to-test): - Control Power On - Blower 1 On - Blower 2 On - Pressure Low - Tripped Circuit Breaker • Alarm: panel mounted horn • Control Switches: - Blower 1 On/Off - Blower 2 Auto/Off/Man - Horn Auto/Off/Test • Test Valve: to simulate low pressure condition Pressure, 4-20 mA/0-20” H20 Specifications subject to change without notice. Saint-Gobain Performance Plastics Corporation 701 Daniel Webster Highway, Merrimack, New Hampshire 03054 U.S.A. Telephone: (603) 424-9000 Fax: (603) 424-9044 www.fabricatedsystems.saint-gobain.com Oct 2004