INS# 902-VGCE-___-___-___ 04

1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1196

Fax: 773-935-5613

www.purelighting.com

info@purelighting.com

Installation Instructions For

Verge Ceiling, 24VDC Plaster-In LED System

© 2016 Pure Lighting. All Rights Reserved.

IMPORTANT INFORMATION

- This product is ceiling mount only.

- This instruction shows a typical installation.

- This product is ETL listed for indoor use.

SAVE THESE INSTRUCTIONS!

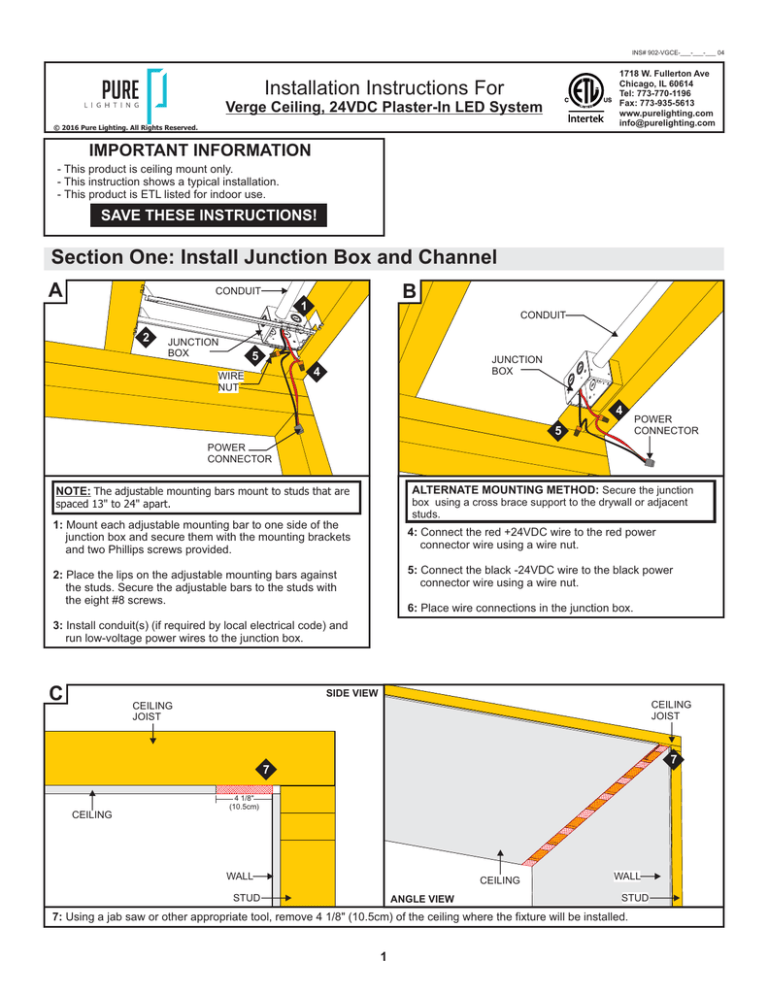

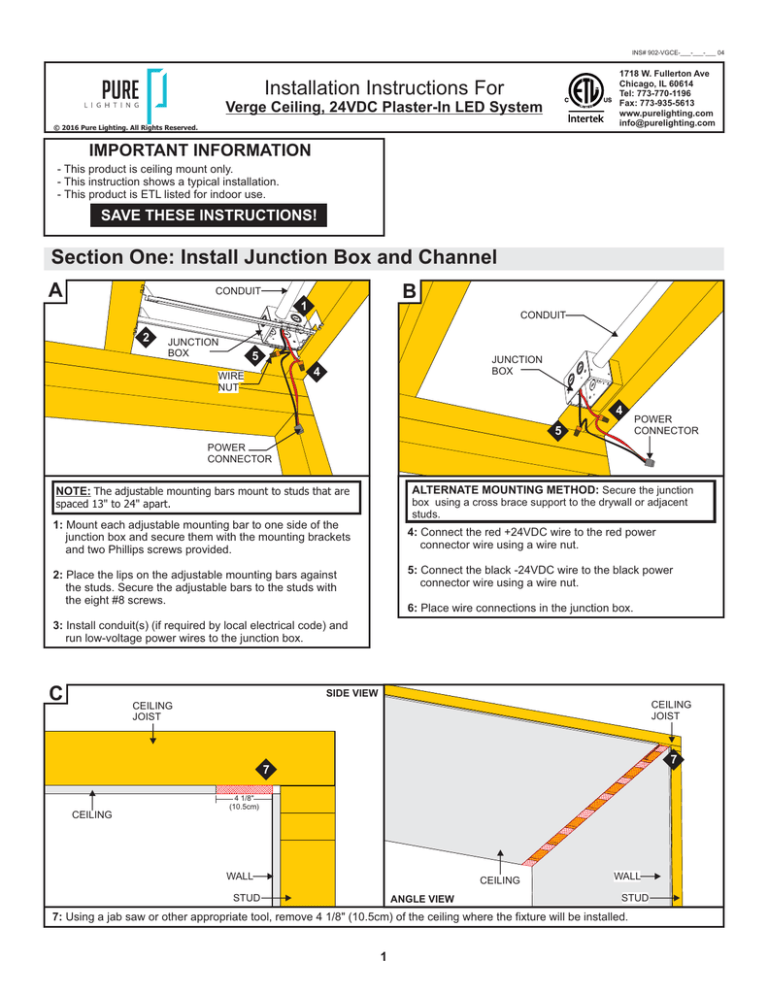

Section One: Install Junction Box and Channel

A

B

CONDUIT

1

2

JUNCTION

BOX

CONDUIT

5

JUNCTION

BOX

4

WIRE

NUT

4

5

POWER

CONNECTOR

POWER

CONNECTOR

ALTERNATE MOUNTING METHOD: Secure the junction

box using a cross brace support to the drywall or adjacent

studs.

NOTE: The adjustable mounting bars mount to studs that are

spaced 13" to 24" apart.

1: Mount each adjustable mounting bar to one side of the

junction box and secure them with the mounting brackets

and two Phillips screws provided.

4: Connect the red +24VDC wire to the red power

connector wire using a wire nut.

5: Connect the black -24VDC wire to the black power

connector wire using a wire nut.

2: Place the lips on the adjustable mounting bars against

the studs. Secure the adjustable bars to the studs with

the eight #8 screws.

6: Place wire connections in the junction box.

3: Install conduit(s) (if required by local electrical code) and

run low-voltage power wires to the junction box.

C

SIDE VIEW

CEILING

JOIST

CEILING

JOIST

7

7

4 1/8"

(10.5cm)

CEILING

WALL

CEILING

STUD

ANGLE VIEW

WALL

STUD

7: Using a jab saw or other appropriate tool, remove 4 1/8" (10.5cm) of the ceiling where the fixture will be installed.

1

D

INSTALLATION LENGTH

VERGE CHANNEL w/LENS

BACKER PLATE

8: Measure the installation length.

9: Cut the backer plate, Verge channel, and lens to length to match the installation area.

E

SIDE VIEW

ANGLE VIEW

CEILING

JOIST

10

CEILING

BACKER

PLATE

CEILING

10

BACKER

PLATE

WALL

WALL

STUD

STUD

10: Attach the Backer Plate to the ceiling joists using construction adhesive. Ensure that the short bent edge of the backer plate is

aligned with the wall.

F

SIDE VIEW

CEILING

JOIST

CEILING

JOIST

CEILING

11

CEILING

VERGE

CHANNEL

VERGE

CHANNEL

11

12

12

#8 DRYWALL

SCREW

WALL

STUD

ANGLE VIEW

11: Align the Verge channel with the installed backer plate.

12: Drill and countersink the channel. Attach the channel to the ceiling joists using #8 drywall screws.

2

#8 DRYWALL

SCREW

G

SIDE VIEW

CEILING

JOIST

ANGLE VIEW

BACKER

PLATE

BACKER

PLATE

13

PLASTER

PLASTER

13

CEILING

13

CEILING

13

PLASTER

WALL

WALL

STUD

STUD

13: Plaster, sand, and paint the Verge channel and backer plate (plaster highlighted in green above).

H

I

VIEW FROM

WALL

VIEW FROM

WALL

BACKER

PLATE

BACKER

PLATE

VERGE

CHANNEL

16

15

17

VERGE

LENS

VERGE

CHANNEL

PAPER

BACKING

NOTE: It may be necessary to remove material from ceiling

joists, backer plate, Verge channel, or lens to route power to the

installation. Consult installation design when considering routing

power.

17: Snap the cut lens sections into the channel. Ensure all

sections of channel are fully seated, especially where the

lens sections meet in the corner of the installation.

NOTE: If installation requires RGB, RGB+W, or Tunable White,

refer to wiring diagrams on pages 4 and 5.

14: Clean the inner channel surface with alcohol to remove

any dust or debris before continuing.

15: Carefully remove the backing from the LED soft strip,

making sure not to remove the adhesive.

16: Align the red wire side of the power connector with the

"+24VDC" marking on the soft strip. Push the male

connector of the soft strip into the female power connector.

Test the soft strip prior to installing in channel.

Section Two: Wiring Diagrams

General 24VDC Configuration

INPUT

120VAC

120VAC (HOT)

WHITE (NEUTRAL)

24V LED SOFT STRIP

NEU

GND

POWER SUPPLY

BLACK (HOT)

ELV DIMMER

3

Standard RGB Configuration

Using LED Power Supply with RGB Soft Strip & CDP or CTP Control

VDC-

VDC+

EXT in-

24VDC

LEDSync

outLEDSync

out shield

DMX in

shield

DMX in -

LEDSync

out+

DMX in +

EXT in+

CDP

CONTROLLER

N L

+-

LINE

CONTROLLER

POWER SUPPLY

POWER SUPPLY

L

N

GND

VDC+

VDCLED supply +

Ext in-

Group 1 -

Ext in+

Group 2 -

DMX in +

Group 3 -

DMX in DMX in shield

LedSync thru+

DMX CABLE

LedSync thru-

Group 4 -

M

LedSync shield

RGB LED

SOFT STRIP

DVR-RGB

RGB+W Configuration

Using LED Power Supply with RGB+W Soft Strip & CDP or CTP Control

VDC-

VDC+

EXT in-

24VDC

LEDSync

outLEDSync

out shield

DMX in

shield

DMX in -

LEDSync

out+

DMX in +

EXT in+

CDP

CONTROLLER

N L

+-

LINE

CONTROLLER

POWER SUPPLY

POWER SUPPLY

L

N

GND

VDC+

VDCLED supply +

Ext in-

Group 1 -

Ext in+

Group 2 -

DMX in +

Group 3 -

DMX in -

DMX CABLE

DMX in shield

LedSync thru+

LedSync thru-

Group 4 -

M

LedSync shield

DVR-RGB

4

RGB+W LED

SOFT STRIP

Tunable White Configuration

Dual Power Supplies Controlled Via Individual ELV Dimmers

ELV DIMMER

WHITE (NEUTRAL)

INPUT

120VAC

+24VDC

RED

NEU

Power Supply

120VAC (HOT)

GND

-24VDC

BLACK

HOT

BLACK (HOT)

WHITE (NEUTRAL)

INPUT

120VAC

+24VDC

RED

NEU

Power Supply

GND

120VAC (HOT)

-24VDC

BLACK

HOT

BLACK (HOT)

ELV DIMMER

RGB Power Supply with DMX Controller

LED SYUNC OUT SHIELD

L N

120VAC

O

N

1

2

3

4

5

6

7

24VDC

Power Supply

+ RED

LED SYNC OUT -

If using a CDP Color Dial, configure your CDP

to Warm White mode using DIP switches and

follow CDP operating instructions:

- BLACK

LED SYNC OUT +

CDP/CTP or other

DMX Signal From Any

Compatible Controller

VDC+

VDCLED supply +

Ext in-

Group 1 -

Ext in+

Group 2 -

Driver

DMX in +

DMX in -

DMX Cable

(belden #9841 or CATS)

DMX in shield

LedSync thru+

LedSync thru-

Group 3 Group 4 -

M

LedSync shield

5

+24VDC

+

+

-