KTF/RW-MF

(Constant Tension Feeder - ReWinder - MicroFeeder)

YARN CONTROL SYSTEM

Operating Manual

ENGLISH

Rev. 3.0 – December 2004

KTF/RW-MF – Rev. 3.0 – December 2004

Copyright - BTSR – All rights reserved.

This manual is intended for the users of KTF/RW-MF yarn feeding systems. You are kindly

recommended to carefully read the instructions reported in this manual before making the connections

and use the system.

BTSR reserves the right to change at any time the contents of this manual, without notice.

For any technical or commercial problem, please contact your local BTSR dealer or call directly BTSR

customer service center. We will be glad to meet your needs.

Thank you for your trust and good job.

The product described herein is compliant with the requirements of 89/336/EEC EMC Directive and

73/23/EEC Low Voltage Directive.

All BTSR products are covered by patents and adopt exclusive, profitable and high tech.

Solutions.

WindowsTM is a registered trademark of Microsoft Corporation

BTSR® is a registered trademark “Best Technology Study & Research” of BTSR International S.p.A.

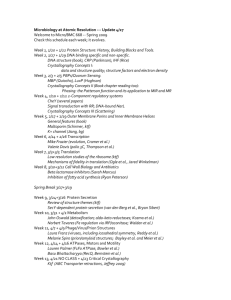

Table of Contents

TABLE OF CONTENTS

INTRODUCTION

The modular solution for yarn preparation machines ............................................................................................I.1

How to use this manual ..............................................................................................................................................I.2

Symbols used ...............................................................................................................................................................I.2

Reference Documentation ..........................................................................................................................................I.2

Chapter 1 - OVERVIEW

System Components................................................................................................................................................... 1.1

Modules and accessories of KTF/RW-MF system .................................................................................................. 1.2

Main Characteristics of KTF/RW-MF Systems...................................................................................................... 1.3

Advantages obtained by using the KTF/RW-MF systems ..................................................................................... 1.4

Further Advantages obtained by using the SMART KTF 2000 terminal combined with

KTF/RW-MF systems................................................................................................................................................ 1.4

Further Advantages obtained by using the PC-Link KTF Software on a Personal Computer connected to

KTF/RW-MF Systems ............................................................................................................................................... 1.5

Chapter 2 – TECHNICAL DATA AND INSTALLATION

Technical Features..................................................................................................................................................... 2.1

Electrical interface (Device Connection).................................................................................................................. 2.2

Electrical interface (Pin Assignment)....................................................................................................................... 2.3

SMART KTF 2000 – SM-DIN/RW-MF Connection .............................................................................................. 2.4

PC – SM-DIN/RW-MF Connection.......................................................................................................................... 2.5

Overall dimensions and fastening distances (in mm).............................................................................................. 2.6

SM-DIN/RW-MF module (Fastening on DIN rail or with screws) ......................................................................... 2.6

KTF/100RW yarn feeding unit ................................................................................................................................ 2.7

TS4/xxxyRW tension sensor ................................................................................................................................... 2.7

Optimum working positions

KTF/100RW yarn feeding unit, TS4/xxxyRW tension sensor and BYRW001 yarn braking device ...................... 2.8

The BTSR solution with accessories RWI.SP.005 – RWO.SP.010......................................................................... 2.9

Chapter 3 – KTF/RW-MF OPERATION

Operating Characteristics of KTF/RW-MF System............................................................................................... 3.1

Programming the KTF/RW-MF System ................................................................................................................. 3.3

General Diagram of Simple Programming Environment (PPS) .............................................................................. 3.3

Advanced Programming of KTF/RW-MF Systems................................................................................................ 3.4

General Diagram of P1÷P4 Advanced Programming Levels (PPA) ....................................................................... 3.5

Real-Time check of KTF/RW-MF internal temperature ....................................................................................... 3.6

Temporary lock of Yarn Feeding Motor ................................................................................................................. 3.6

P1 Programming Level.............................................................................................................................................. 3.7

P2 Programming Level............................................................................................................................................ 3.10

P3 Programming Level............................................................................................................................................ 3.14

Characteristics of the various working mode (Mode 00 ÷ 04)............................................................................... 3.15

KTF/RW-MF

-i-

Table of Contents

P4 Programming Level............................................................................................................................................ 3.17

INC/DEC Programmable Commands and Tension Alarm Activation ............................................................... 3.19

Mode 00................................................................................................................................................................. 3.19

Mode 01................................................................................................................................................................. 3.20

Mode 02................................................................................................................................................................. 3.21

Mode 03................................................................................................................................................................. 3.21

Increment/Decrement of Yarn Tension in Automatic Mode................................................................................ 3.22

Tension Profiler ....................................................................................................................................................... 3.23

Textile Machine Interfacing Modes when Tension Profiler and/or Target Functions are Enabled................. 3.24

Chapter 4 – KTF/RW-MF TROUBLESHOOTING AND MAINTENANCE

Indications Provided by the Red Leds on SM-DIN/RW-MF unit ......................................................................... 4.1

Troubleshooting on KTF/RW-MF System .............................................................................................................. 4.1

Ordinary Maintenance .............................................................................................................................................. 4.3

Repairs ........................................................................................................................................................................ 4.3

Updating the Software Version on SM-DIN/RW-MF System through the Microprocessor Replacement........ 4.4

APPENDIX A

- ii -

KTF/RW-MF

Introduction

INTRODUCTION

Congratulations for choosing a BTSR product.

With our KTF/RW-MF (Constant Tension Feeder - ReWinder - MicroFeeder)

yarn feeding systems, you got an innovative, unique solution able to offer you

multiple advantages concerning quality of your production.

The modular solution for yarn preparation machines

The KTF/RW-MF system comes from the experience built with KTF/100HP yarn

feeding device and it is mainly oriented to applications implemented on yarn

preparation machines: winding, doubling, copwinding machines, etc.

The main difference with respect to KTF/100HP device is due to the fact that while

KTF/100HP collects within a single physical device all the elements such as the

control electronics, the tension control sensor and the yarn feeding motor, the

KTF/RW-MF system has a modular structure consisting of separate elements, thus

allowing greatest installation and configuration freedom, etc. to meet the specific

machine requirements.

The KTF/RW-MF systems are in fact high precision measurement and control

instruments providing a real time display of the exact yarn tension and

guaranteeing, through an accurate adjustment, a constant yarn tension in every

working condition. This occurs regardless of the speed at which the textile machine

is running (either high or low speed) and the tension is kept constant even when the

yarn package tension is subject to change due to environment conditions such as

humidity, temperature, etc., or when the yarn packages are gradually emptying

during the normal working process.

The KTF/RW-MF systems are fully programmable and can easily be adapted to

any kind of yarn or tension adjustment. Furthermore, these systems are

manufactured using very high quality and precision electronic components which

guarantee an exact display of the yarn tension as well as an accurate real-time

control of the tension itself, all features which are unique to BTSR KTF systems.

Thanks to its modularity characteristics, the KTF/RW-MF system is capable of

managing not only the TS4.. tension sensor, but also the IS3.. image scanning

sensor, thus allowing the user to obtain a complete quality control for what

concerns both the yarn tension and the correct yarn running condition.

This is particularly important on doubling machines where multiple yarns are fed

using the same device, in order to stop the machine in case of breakage or lack of

one or more yarns.

KTF/RW-MF

- I.1 -

Introduction

How to use this manual

This Operation Manual consists of 4 Chapters + 1 Appendix.

Chapter 1 – Overview describes the main features, components and the operation

principle of KTF/RW-MF system.

Chapter 2 – Technical Data and Installation gives the instructions needed to

correctly install the system.

Chapter 3 – KTF/RW-MF Operation gives a detailed description of the operations

required to setup and program the KTF/RW-MF system according to the

application needs.

Chapter 4 – Troubleshooting and Maintenance provides a quick guide to solve

the main failures of KTF/RW-MF system.

Appendix A – shows the details concerning the possible configurations (including

the relevant accessories and corresponding codes) of the yarn feeding devices:

KTF/100MF and KTF/100RW.

Symbols used

! Highlights notes, warnings and subjects to which the attention of the reader

should be directed.

Indicates a particularly sensitive situation which could have an effect

on the safety or proper operation of the system.

2) TENSION ERROR

All the items concerning the device programming menus, within

this manual, are always show in CAPITAL LETTERS.

Reference Documentation

- I.2 -

Manual

SMART KTF 2000 – Rev. 2.0 – 05/2002

(KTF/RW-MF Programming/Monitoring using the SMART KTF 2000

Terminal).

Manual

PC LINK KTF – Rev. 1.0 – 01/2005

(Programming/Monitoring using a Personal Computer and PC-Link

KTF Software).

KTF/RW-MF

Overview

1 - OVERVIEW

System Components

The KTF/RW-MF system can be programmed and used either in individual and

autonomous way, or they can be connected to a monitoring/programming unit, thus

obtaining a complete system providing further levels of analysis, adjustment,

control and speeding-up of the production cycles, as well as providing statistical data

processing capabilities, particularly useful to reach the quality and saving goals

stated in the Introduction of this manual.

The programming/monitoring unit may be either a dedicated BTSR terminal

(SMART KTF 2000) or a Personal Computer operating under WindowsTM

environment with BTSR application software (PC-Link KTF).

The solution based on personal computer and PC-Link KTF software, besides a

greater operating flexibility, offers a set of additional functionalities which allow you

to customize the application according to your specific requirements (e.g. the

Tension Profiler) and to display/print in real time and in graphical form all the

significant data concerning the KTF/RW-MF system functionality.

As mentioned in the Introduction chapter, the KTF/RW-MF systems consist of

various independent modules and accessories, each one installable in the most

suitable position, depending on the type of textile machines.

The following page lists and shows all the modules and accessories which constitute

the system.

KTF/RW-MF

- 1.1 -

Overview

Modules and accessories of KTF/RW-MF system

Modules

Description

SM-DIN/RW-MF

Electronic unit containing the microprocessor, the

memory unit and the management logic of the whole

system. Besides the connectors used to interface all

the other I/O devices aimed at the control and

adjustment functions, it contains the alphanumeric

display, the operating push buttons and the signaling

LEDs. It can be fastened on DIN rails/screws within the

electrical cabinet or attached to the front panel by

means of suitable cover plates.

KTF/100/xx

Yarn feeding motor device. It is available in 2 versions:

See Appendix

!

KTF/100MF - up to 25 mN/m (Micro Feeder)

A

!

KTF100RW - up to 100 mN/m

TS4/xxxyRW

Yarn tension sensor. It is available in 2 versions:

!

TS4/100DRW – up to 100 g - Type D eyelet

!

TS4/1000ERW – up to 1000 g - Type E eyelet

IS3x/TS

Electronic sensor capable of detecting the image

variation provided by the yarn running.

It is available in 2 versions:

!

IS3W/TS = Wide version

!

IS3N/TS = Narrow version

RWI SP 004/005

Input bracket

RWO SP 003 ÷ 010

Output bracket

Type of eyelet

D

E

TS4/100DRW

TS4/1000ERW

(*) As an alternative

- 1.2 -

Note

KTF/RW-MF

Optional

Overview

Main Characteristics of KTF/RW-MF Systems

The KTF/RW-MF system is a high tech digital instrument that allows setting the

exact tension value at which you want to operate. The data setting is done through a

small three-button key-pad and a 3 digits display, located on the font side of

SM-DIN/RW-MF modules.

In normal operating conditions the alphanumeric display provides a real time

visualization of the exact yarn tension (in grams) during the manufacturing process.

In addition, the operator may read at any time the internal temperature of the device

(in °C) and the current absorption (in A), using the

Reset button.

An excessive increase of the temperature and/or current could in fact indicate a

wrong use of the device; for this reason, the software on board of the system

performs a continuous monitoring of both the internal temperature and the absorbed

current.

If such temperature exceeds 100°C or the absorbed current exceeds 3A (motors

KTF/100MF) or 6A (motors KTF/100RW), the NO1 STOP output is activated.

Thanks to a configurable safety code, all parameters can only be changed by

authorized personnel, knowing such safety code.

The KTF/RW-MF system may easily be programmed also using the SMART KTF

2000 terminal which, thanks to its flexibility allows programming of many devices at

a glance. Once you have chosen the desired working values on a given machine, you

will just transfer the selected setting data to the SMART KTF 2000 and then from

SMART KTF 2000 to other KTF/RW-MF systems installed on different machines;

all this in about 1 second (i.e. the time needed to complete the data transfer).

With a single SMART KTF 2000 monitoring/programming terminal, you will have

the possibility to control multiple SM-DIN/RW-MF units connected in daisy chain

configuration.

The flexibility of KTF/RW-MF system and the availability of standard communication

interfaces, also offer the possibility to program and monitor the system itself using a

Personal Computer or Notebook with BTSR software (PC-Link KTF).

The device has been designed bearing in mind not only the technological aspects, but

also the ergonomic ones. Thanks to these characteristics, the system can be perfectly

fitted within the machine structure, without compromising the machine spaces which

are usual to the operator.

The KTF/RW-MF system can work with a wide range of yarns, including very thin

yarns such as bare and covered elastomers, always guaranteeing a perfect control of

yarn tension values chosen by the user, which results in a high quality of the

manufactured product.

The KTF/RW-MF systems are controlled by an internal microprocessor ensuring

great versatility (parameters may be programmed depending on the various yarn

processing conditions).

The tension value displayed on SM-DIN/RW-MF’s display indicates the actual

tension with which the system is working. This guarantees a constant and accurate

monitoring of the working process.

KTF/RW-MF

- 1.3 -

Overview

Advantages obtained by using the KTF/RW-MF systems

# Constant yarn tension both when the machine speed changes and when the yarn

packages gradually get empty.

# Best efficiency by eliminating the yarn breakage (tears and extra tensions), and

possibility to work at the highest speed offered by the machine.

# Possibility to work with a wide range of yarn types including:

- Very thin yarns, such as bare elastomers 11/17 DTEX.

- Very difficult yarns; Elasticized yarns either bare or covered

- Nylon, cotton, viscose, wool, silk, etc.

# Yarn tension graduation capability, with 0.1 g. resolution (INC/DEC function BTSR Patent).

# Possibility to feed the strap elastic or wrist band, guaranteeing a constant

compression (hosiery machines).

# Possibility to perform gradual compression with no limits, and with a minimum

resolution of 0.1 grams (hosiery machines).

# Possibility to handle up to a maximum of 16 sensors of the IS3x/TS series, for

doubling machine applications where more than one yarn must be simultaneously

fed (by means of KTF/100xx) and controlled (by means of IS3x/TS).

Further Advantages obtained by using the SMART KTF 2000 terminal

combined with KTF/RW-MF systems

# Using the SMART KTF 2000 terminal connected to KTF/RW-MF systems you

have the possibility to develop a wide range of functions which facilitate the

practical use of the installed KTF/RW-MF units (immediate download and

upload of data), as well as to display fundamental data such as, yarn consumed

and yarn tension.

# Possibility to create up to 99 “articles”, saving them into a Data Base for an easy

subsequent recall. Without the need to setup new parameters, these will simply be

recalled from the Data Base and subsequently transferred to the KTF/RW-MF

systems installed on textile machines.

# Possibility to use the TARGET function (meter count) and the NO2 Stop output,

when reaching the amount of meters setup, with possible automatic bobbin

change enabling (autodoffing).

# Possibility to control and quickly correct the tension adjustments, thus eliminating

the defects due to irregular tensions, tears and wrong yarn unwinding.

# Possibility to identify the connected KTF/RW-MF units using an automatic

numbering procedure (BTSR Patent).

# Monitoring and control possibility of the stitch consumption related to the article

(during the production of manufactured articles such as knitted work,

stockings…), by means of the CONTROL function.

In CONTROL environment, a yarn consumption self learning function (LEARN) is

available (BTSR Patent). With this function you can learn the amount of yarn fed

during a sample cycle and then check that such amount is kept constant during

the subsequent cycles, within the tolerance limits (+ and -); in case of deviation

from these limits the textile machine will be stopped.

# Possibility to obtain a progressive tension graduation (with 0.1 g resolution)

depending on the TARGET set (during the rewinding phases). E.g.: the user could

set the Target = 1000 m, the initial tension value = 10 g, and choose to increment

the tension by 1 g every 100 m. When reaching the TARGET, the system resumes

the initial tension value: 10 g.

! For more details, please refer to SMART KTF 2000 operating manual.

- 1.4 -

KTF/RW-MF

Overview

Further Advantages obtained by using the PC-Link KTF Software on a

Personal Computer connected to KTF/RW-MF Systems

# Using a Personal Computer connected to the KTF/RW-MF systems through

either a RS232 serial port or an USB port, with the aid of BTSR PC-Link KTF

software, you may program in quick and intuitive way, all the operating

parameters of KTF/RW-MF systems; in addition, you may display, through a

single synoptic screen, the operating status of all connected systems, thanks to an

easily interpretable color code.

# Possibility to associate each article with a “Tension Profiler” allowing you to

rapidly and effectively adapt the working parameters of KTF/RW-MF systems to

your specific application requirements.

# Possibility to display and/or print several graphics showing the real-time dynamic

variation of the significant operative items (such as yarn tension, current

absorbed by the motor, motor torque, etc.); this allows you to speed-up and

optimize the “tuning” of the whole system.

# Possibility to update the SM-DIN/RW-MF system’s software without having to

physically replace the microprocessor.

# The following screen shots have a merely indicative purpose, i.e. to show the

characteristics of the PC-Link KTF software graphical interface.

! For more detailed information, please refer to the PC-Link KTF operating

manual.

PC-Link KTF – Example of synoptic view with 20 KTF/RW-MF devices configured

over 10 machine sections (2 devices for section).

- Devices 1 - 12 =

Running

- Devices 13 - 14 =

Stopped (STOP)

- Devices 15 - 20 =

not connected (COMM ERROR)

KTF/RW-MF

- 1.5 -

Overview

PC-Link KTF – Example of graphic showing the dynamic progress of yarn tension

on devices 1 and 2, plus real-time display of speed, torque %, current and

temperature values.

PC-Link KTF – Example of graphic showing the dynamic progress of yarn tension,

motor torque and current absorbed by device 1.

- 1.6 -

KTF/RW-MF

Overview

PC-Link KTF – Examples of KTF/RW-MF device operation parameters

programming.

KTF/RW-MF

- 1.7 -

Overview

PC-Link KTF – Example of graphic screen showing the upload of working

parameters (style) to the KTF/RW-MF.

- 1.8 -

KTF/RW-MF

Technical Data and Installation

2 – TECHNICAL DATA AND INSTALLATION

Technical Features

SM-DIN/RW-MF control unit

Power supply voltage

Absorption

2 STOP Outputs (NO1 –Alarms – NO2 Target)

INC/DEC/EXC input voltage

Programmable yarn tension

Programmable alarms

Integrated keypad

Signaling

Dimensions

Operating Temperature range

Mounting type

Protection

24 Vdc ± 20% ; 24 Vac ± 10%

Typical: 0.2 A; Max: 6A

Relay contacts NO 120Vac/24Vdc – 1A

Min. 5 Vdc ; Max 30 Vdc

TS4/100DRW: 0.5 ÷ 100 gr. (resol. 0.1 gr.)

TS4/1000ERW: 5 – 1000 g (resol. 1 gr.)

0.1 ÷ 10 sec.

3 push buttons

3 digit display + 8 signaling LEDs

138 x 125 x 35 mm

10° ÷ 70 °C

Inside the cabinet: on DIN rail, or fastening

screws.

On panel: with cover plates

Self-restoring fuse, 5A

KTF/100xx yarn feeding device

Motor torque

KTF/100MF: up to 25 mN/m

KTF/100RW: up to 100 mN/m

TS4/xxxyRW Sensors

Power supply voltage

Absorption

12 .. 24 Vdc ± 20%

30 mA (max 50 mA)

0 - 10V

With integrated LEDs

50 x 25 x 12,5 mm

Analogue Output

Signaling

Dimensions

Temperature range

10° ÷ 60 °C

IS3x/TS Sensors

Power supply voltage

Absorption

STOP output

STOP output protection

Maximum Current of STOP output

Reaction Delay

Sensitivity

Signaling

Dimensions (mm)

Temperature range

12 .. 24 Vdc ± 20%

10 mA (max 15 mA)

NPN

Protection against over-voltages/short-circuits

200 mA continuous; 500 mA peack

Programmable from 5 to 1000 msec

Programmable (10 levels)

With integrated LEDs

15 x 15 x 36,5 (Narrow) - 25 x 15 x 36,5 (Wide)

10° ÷ 60 °C

SMART KTF 2000 Terminal

Power supply voltage

Maximum absorption

Dimensions

Operating Temperature range

LCD graphic display

Integrated Touch-pad

Protection

KTF/RW-MF

24 Vdc ± 20%

100 mA

135 x 95 x 40 mm

10° ÷ 60° C

80 x 40 mm

5 membrane buttons with integrated red LED

2 fuses 5 x 20 – 1A

- 2.1 -

Technical Data and Installation

Electrical interface (Device Connection)

As an alternative

Next SM-DIN/RW-MF units

Connector for Future Expansions

External interface

(INC+/-, DEC+/-, EXC+/-)

AC/DC power supply + Stop Output

Concerning all electrical systems, it is a suggested rule to ensure that the ground cable

(GND) is connected to the device support.

- 2.2 -

KTF/RW-MF

Technical Data and Installation

Electrical interface (Pin Assignment)

Concerning all electrical systems, it is a suggested rule to ensure that the ground cable

(GND) is connected to the device support.

KTF/RW-MF

- 2.3 -

Technical Data and Installation

SMART KTF 2000 – SM-DIN/RW-MF Connection

Concerning all electrical systems, it is a suggested rule to ensure that the ground cable

(GND) is connected to the device support.

- 2.4 -

KTF/RW-MF

Technical Data and Installation

PC – SM-DIN/RW-MF Connection

Concerning all electrical systems, it is a suggested rule to ensure that the ground cable

(GND) is connected to the device support.

KTF/RW-MF

- 2.5 -

Technical Data and Installation

Overall dimensions and fastening distances (in mm)

SM-DIN/RW-MF module (Fastening on DIN rail or with screws)

A

Space for DIN rail fastening

B

Holes for M4 x 20 fastening screws

- 2.6 -

KTF/RW-MF

Technical Data and Installation

KTF/100RW yarn feeding unit

A

Ceramic element for coil separations – ø 5

B

Adjustment screw for coil separation M4 x 12

C

Fastening holes with M4 x 20 screw

TS4/xxxyRW tension sensor

A

Fastening hole with M4 x 20 screw

B

Loading cell (tension sensor)

KTF/RW-MF

- 2.7 -

Technical Data and Installation

Optimum working positions

KTF/100RW yarn feeding unit, TS4/xxxyRW tension sensor and BYRW001 yarn braking

device

RECOMMENDED MOUNTING

BYRW001

D1

Suggested distance = 38 mm

D2

Suggested distance = 24 mm

D3

Suggested distance = 50 mm

D4

Suggested distance = 60 mm

P

- 2.8 -

TS4/xxxyRW

KTF/RW-MF

Yarn path

KTF/RW-MF

Technical Data and Installation

The BTSR solution with accessories RWI.SP.005 – RWO.SP.010

RECOMMENDED MOUNTING

RWI.SP.005

RWO.SP.010

KTF/RW-MF

- 2.9 -

Technical Data and Installation

Page intentionally left blank

- 2.10 -

KTF/RW-MF

KTF/RW-MF Operation

3 – KTF/RWKTF/RW-MF OPERATION

Operating Characteristics of KTF/RW-MF System

For programming and control of KTF/RW-MF system, 3 push buttons, 8 red

signalling LEDs and a 3 digit display are available to the operator.

E (ENTER) PUSH BUTTON

Press and hold down this push-button to gain access to the simple or advanced

device’s programmable functions.

During the programming phase, press it to confirm the displayed parameter.

Pressing and holding down this push-button for about 3 seconds on particular

parameters, you will have the possibility to enable/disable the corresponding function.

– (RESET) PUSH BUTTON

Press this push-button to cancel possible error signalling on SM-DIN/RW-MF

display (STOP RW LED on). During the Programming phase, press it to decrease

the value of displayed parameter. During the Control phase, without an alarm

condition in progress, it allows you to display the device’s internal temperature.

+ (CONTROL) PUSH BUTTON

Press this push-button to temporarily de-activate the motor (STOP RW LED on);

press it again to reactivate the motor. This button also allows de-activating (OFF)

the power unit. During the programming phase, press it to increase the value of

displayed parameter.

Press this push-button whenever you need to operate on the yarn

feeding motor (i.e. for yarn threading, coil separation device adjustment,

etc.) to avoid undesired start-up of the motor.

KTF/RW-MF

- 3.1 -

KTF/RW-MF Operation

LCD DISPLAY

It provides the real time display of measured and adjusted tension values, as well as

the parameters programmable within the various menus, the alarm signallings, etc.

Alarm/Warning Signallings

During the normal machine operation, the display shows, in real time the following

warning alarm or fault operating signallings.

Tension Alarm (see “characteristics of the various working mode” page 3.15)

(*)

Target reached

(*)

Motor locked; internal protection triggering.

TS4 sensor’s OFFSET out of calibration, TS4 sensor disconnected, dirty loading

cell, etc.

Temperature error.

Current error.

System error. External protection triggering due to over current.

INC/DEC overflow alarm.

INC/DEC underflow alarm.

(*) The signalling automatically disappears as soon as the generating condition is

removed.

!

- 3.2 -

As far as the failure signallings are concerned, please refer to chapter 4

“Troubleshooting”

KTF/RW-MF

KTF/RW-MF Operation

Signaling LEDs

Indicates with 1 flashing the increment of main tension.

Indicates with 1 flashing the decrement of main tension.

On = indicates the activation of Exclusion condition

On = P1 tension active – Off = P2 tension active

Flashing = Communication in progress between SM-DIN/RW-MF and SMART KTF

2000 or PC

On = Stop condition generated by an IS3x/TS sensor (if used)

On = Indicates the condition of feeding motor locked by means of

Flashing = indicates an alarm condition

button;

On = indicates the SM-DIN/RW-MF power on condition

Programming the KTF/RW-MF System

The KTF/RW-MF system offers two programming environments:

1) SIMPLE (allows programming exclusively the system’s main tension)

2) ADVANCED (allows programming all the system’s parameters)

To have access to the programming environment, press and hold down for 3 seconds the

ENTER button, while the systems is operating in Control environment.

To switch from SIMPLE to ADVANCED and vice versa, press and hold down for 3 seconds

the ENTER button.

! To avoid undesired changes of operating parameters, after the installation of

KTF/RW-MF systems and after having setup and checked all the working parameters

in ADVANCED programming environment, it is advisable to activate the SIMPLE

programming environment, so that when the operator will subsequently enter the

programming environment, he/she will only have the possibility to change the main

tension (1st variable of P1 menu).

General Diagram of Simple Programming Environment (PPS)

MAIN

TENSION

KTF/RW-MF

- 3.3 -

KTF/RW-MF Operation

Advanced Programming of KTF/RW-MF Systems

With the ADVANCED programming environment, each KTF/RW-MF can be programmed

with specific control parameters which depend on the type of yarn under processing, and

on the type of application:

•

•

•

•

•

•

MAIN TENSION

ERROR TENSION

TIME ALARM

INC-DEC TENSION

EXIT TENSION

MODE

Control Tension

Tolerance beyond which an Error is generated

Time for which the tension may stay out of tolerance

∆ Tension for INC/DEC graduation

Device Tension with machine stationary

Operating modes of INC/DEC command

The setting of these parameters is already done by BTSR during manufacturing (default

values), however it can be easily changed by the textile machine operator to meet specific

requirements, using the advanced programming features.

KTF/RW-MF systems offer 4 advanced programming levels: P1, P2, P3 and P4, clearly

indicated in the messages area of LCD during the programming sequences.

Within the P1 level the following parameters can be programmed:

P1.1

! MAIN TENSION

P1.2

! ERROR TENSION

P1.3

! TIME ALARM

P1.4

! INC-DEC TENSION

Within the P2 level the following parameters can be programmed:

P2.1

! EXIT TENSION

P2.2

! RAMP UP

P2.3

! RAMP DOWN

P2.4

! SYSTEM REACTIVITY CONSTANT

Within the P3 level the following parameters can be programmed:

P3.1

! OFFSET

P3.2

! MODE

P3.3

! ACCESS CODE

P3.4

! KTF IDENTIFICATION CODE

Within the P4 level the following parameters can be programmed::

P4.1

! MOTOR ROTATION DIRECTION

P4.2

! TENSION SENSOR SIZE IN GRAMS

P4.3

! COMMUNICATION BAUD RATE

! TYPE OF MOTOR/ADJUSTMENT

ALGORITHM USED

P4.4

To move from a programming level to the next level, press the + (Control) button, when

the display shows the label P1, P2, etc.

(Reset) button used to quit the programming environment

- 3.4 -

KTF/RW-MF

KTF/RW-MF Operation

General Diagram of P1÷P4 Advanced Programming Levels (PPA)

NOTE: The values shown indicate the default parameters (set by BTSR).

KTF/RW-MF

- 3.5 -

KTF/RW-MF Operation

Real-Time check of KTF/RW-MF internal temperature

At any time, you can check the internal temperature of a KTF/RW-MF system, by

simply pressing the

button.

button, for more than two seconds the system will

Holding down the

automatically show the value of absorbed current.

! The values shown in the example above indicate a temperature of 39°C and a current

absorption of 1.2 A.

Temporary lock of Yarn Feeding Motor

Prior to operate on yarn feeding device, you should temporarily lock the motor

pressing the

button.

In this condition the STOP RW LED turns On and the display shows the main

tension value (P1).

Press the

button whenever you need to operate on the yarn feeding

motor (i.e. for yarn threading, coil separation device adjustment, etc.) to

avoid undesired start-up of the motor.

- 3.6 -

KTF/RW-MF

KTF/RW-MF Operation

P1 Programming Level

ADVANCED

#

MENU P1

The P1 programming level allows you to setup 4 parameters:

1)

System’s main tension ;

2)

Tolerance with respect to the main tension;

3)

Max deviation time from tolerance band;

4)

Increment/Decrement resolution of graduated tension.

With the KTF/RW-MF in CONTROL status, press

seconds.

The display will show the label PPA (ADVANCED).

and hold it down for 3

to continue.

to start programming of parameters belonging to P1 menu.

1) MAIN TENSION

Tension value with which the systems must operate to create the desired article

(INC/DEC active). [Allowed values 0.5 ÷ 99.5 grams].

to continue

During programming phase you cannot set a tension value lower than the ERROR

TENSION value or greater than the difference between the full scale value (99.5 g.)

and the ERROR TENSION value.

Choose the desired value using:

(to increase the value) or

(to decrease the value).

to confirm.

2) ERROR TENSION

Tolerance band beyond which the machine will be stopped.

to continue

An error indication and a machine stop occur only if such tolerance is exceeded for

the time period set in the next parameter (TIME ALARM).

[Allowed values ± 0.1 ÷ 99.5 grams (with automatic limitation to 0.4 grams for

what concerns the negative tolerance)].

Choose the desired value using:

(to increase the value) or

(to decrease the value).

to confirm.

KTF/RW-MF

- 3.7 -

KTF/RW-MF Operation

- 3.8 -

Example 1:

Main Tension: 2.0 g

Error Tension: ± 0.5 g

Example 2:

Main Tension: 5.0 g

Error Tension: ± 2.0 g

Example 3:

Main Tension: 5.0 g

Error Tension: ± 6 g

KTF/RW-MF

KTF/RW-MF Operation

3) TIME ALARM

Time during which the tension value may exit from the tolerance band set by the

previous parameter (ERROR TENSION).

to continue

You may disable (OFF) this feature by holding the Enter button pressed for 3

seconds. [Allowed values 0.1 ÷ 10 seconds].

Choose the desired value using:

(to increase the value) or

(to decrease the value).

to confirm.

Example:

Main Tension: 2.0 g

Error Tension: ± 0.5 g

Time Alarm: 2.0 sec.

4) INC-DEC TENSION

Increment/decrement resolution of the tension graduated by INC/DEC external

pulses. [Allowed values 0.1 ÷ 25.0 grams].

to continue

(At every INC/DEC pulse, the main tension will be either increased or decreased

by the amount indicated by this parameter with respect to the value set in MAIN

TENSION

(1st variable of P1)). Chose the desired value using

or

to confirm and return to the beginning of P1 Menu.

to move to P2 Menu.

to return to CONTROL status without programming P2, P3 and P4 Menu.

KTF/RW-MF

- 3.9 -

KTF/RW-MF Operation

P2 Programming Level

ADVANCED

#

MENU P2

The P2 programming level allows you to setup 4 parameters:

1)

Device tension with machine stationary;

2)

Control of change-over speed from a given working tension to a higher

tension (RAMP UP);

3)

Control of change-over speed from a given working tension to a lower

tension (RAMP DOWN);

4)

System reactivity constant.

to select the P2 level.

to continue with programming of P2 menu parameters.

1) EXIT TENSION

Tension value of the device when the machine is stationary or out of yarn working

zone (INC/DEC pulses deactivated).

to continue.

Setting a value higher or lower than the value set with MAIN TENSION parameter of

P1 menu, you can control the deceleration phase of KTF/100xx device.

This function may be either enabled (with values ranging from 0.5 to 99.5 grams)

or disabled (OFF). To disable the function press and hold down for 3 seconds the

Enter button.

The OFF indication means that the function has been disabled. In this case the EXIT

TENSION parameter will assume the same value set on MAIN TENSION parameter

within the P1 programming level.

To re-enable this function press and hold down for 3 seconds the Enter button. The

OFF indication will disappear and it will be replaced by a modifiable numeric

value. Choose the desired value using:

(to increase the value) or

to confirm.

- 3.10 -

KTF/RW-MF

(to decrease the value).

KTF/RW-MF Operation

2) RAMP UP

This parameter allows you to control the change-over speed from a given working

tension to a higher tension, in such a way as to avoid undesired yarn breakages.

[Allowed values 1 ÷ 100]

The RAMP UP (t) is calculated using a reference table that determines an exponential

increase of the ramp time depending on the programmed value: [1 = very fast ramp

time (1ms) ... 100 = very slow ramp time (500 msec)]:

where

N = value programmed with parameter P2.2 (Ramp Up)

T1 = final tension value (high)

T2 = initial tension value (low)

Example 1:

Final tension = 10 g

Initial tension = 4 g

N=5

Example 2:

Final tension = 10 g

Initial tension = 4 g

N = 20

Example 3:

Final tension = 10 g

Initial tension = 4 g

N = 100

to continue.

Choose the desired value:

(to increase the value) or

(to decrease the value).

to confirm.

KTF/RW-MF

- 3.11 -

KTF/RW-MF Operation

3) RAMP DOWN

This parameter allows you to control the change-over speed from a given working

tension to a lower tension, in such a way as to avoid excessive yarn relaxations.

[Allowed values 1 ÷ 100]

The RAMP DOWN (t) is calculated using a reference table that determines an

exponential increase of the ramp time depending on the programmed value: [1 =

very fast ramp time (1ms) ... 100 = very slow ramp time (500 msec)]:

where

N = value programmed with parameter P2.3 (Ramp Down)

T1 = final tension value (low)

T2 = initial tension value (high)

Example 1:

Final tension = 4 g

Initial tension= 10 g

N=5

Example 2:

Final tension = 4 g

Initial tension= 10 g

N = 20

Example 3:

Final tension = 4 g

Initial tension = 10 g

N = 100

to continue.

Choose the desired value:

(to increase the value) or

to confirm.

- 3.12 -

KTF/RW-MF

(to decrease the value).

KTF/RW-MF Operation

3) SYSTEM REACTIVITY CONSTANT

This parameter represents a multiplier that affects the control algorithm depending

on the yarn elasticity characteristics.

[Allowed values 1 ÷ 5] (1 = Rigid Yarn…… 5 = Elastic Yarn)

to continue.

Choose the desired value according to the yarn characteristics, using:

(to increase the value) or

(to decrease the value).

to confirm and return the beginning of P2 Menu.

to move to P3 menu.

to return to CONTROL status without programming P3 and P4 menu.

KTF/RW-MF

- 3.13 -

KTF/RW-MF Operation

P3 Programming Level

ADVANCED

#

MENU P3

The P3 programming level allows you to setup 4 parameters:

1)

Offset;

2)

System operation mode;

3)

Access code to programmable functions;

4)

KTF/RW-MF identification code.

to select the P3 level.

to continue.

1) OFFSET

This function is used to adjust the mechanical clamping position of TS4 tension

sensor. It clears possible measurement errors due to the different clamping position

of the sensor on textile machine.

to continue.

The displayed indication is the actual OFFSET value resulting from the clamping

to

position of the sensor. While lifting the yarn above the load cell, press

check whether the stored OFFSET value corresponds to the actual OFFSET value. If

the two values are different, press

to align them.

to select the next parameter.

! If the actual tension value, detected with the OFFSET (P3.1) function is

lower than 1 gram, the offset operation is not performed and a E03

warning message appears (this prevents the offset procedure from being

executed in case of sensor temporarily disconnected or faulty.

2) MODE

Here you can select the different working modes of INC/DEC commands.

[Mode: 00, 01, 02, 03, 04].

to continue.

Choose the desired working mode using

to select the next parameter.

- 3.14 -

KTF/RW-MF

or

KTF/RW-MF Operation

Characteristics of the various working mode (Mode 00 ÷ 04)

Mode 00 - Standard INC/DEC commands selection

By selecting Mode 00, the KTF/RW-MF system will work as explained in

“INC/DEC programmable commands” paragraph (see the relevant example on

page 3.19);

in particular, whenever the INC/DEC commands are simultaneously disabled, the

related tension graduations performed, will be immediately reset (upon each

machine stop).

Mode 01 - INC/DEC commands selection for medical socks

By selecting Mode 01, it will be possible to “freeze” the graduated tension value

(upon each machine stop and each pause for “heel” processing). The graduation

performed will be cleared only when the INC/DEC commands will be

simultaneously deactivated/activated/deactivated within a time period of 1 second

(upon each exit from thread guide) (see example on page 3.20).

Mode 02 - Function selection without INC/DEC commands

By selecting Mode 02, the KTF/RW-MF system will be able to work without

INC/DEC commands. In such condition the system will use the parameters

programmed within P1 menu (MAIN TENSION – ERROR TENSION – TIME ALARM).

The KTF/RW-MF activates the ERROR TENSION alarm as soon as the programmed

tension goes out from limits set in ERROR TENSION. The alarm will automatically

be cleared as soon as the tension value will return within the programmed limits

(see example on page 3.21).

Mode 03 - Function selection without INC/DEC commands

By selecting Mode 03, the KTF/RW-MF will be able to work without INC/DEC

commands. In such condition the system will use the tension value programmed in

EXIT TENSION (P2) as well as in ERROR TENSION and TIME ALARM (P1). The

KTF/RW-MF will activate the ERROR TENSION alarm as soon as the programmed

tension goes out from limits set in ERROR TENSION. The alarm will automatically

be cleared as soon as the tension value will return within the programmed limits

(see example on page 3.21).

Mode 04 (available from version 2.9) – Operating mode specific for machines

that work with elasticised yarns at a very high tension

In this type of machines, the system cannot easily manage the braking phase;

therefore it reverses the motor rotation direction to maintain the correct tension.

Warning! If you select Mode 04 without the presence of yarn, the motor

starts immediately a rotation, trying to recovery the yarn.

! For further information about modes 00-04 and the effects of INC/DEC

commands, please refer to the examples shown on pages 3.19 – 3.23.

KTF/RW-MF

- 3.15 -

KTF/RW-MF Operation

3) KEY CODE

This function allows you to define a secret numeric code to prevent non authorized

personnel from accessing the P1, P2, P3, P4 programmable functions.

to continue.

This function may be either enabled or disabled by holding down the

for 3 seconds

OFF indicates that the function is currently disabled.

button

If you enter an access code, this will be requested each time you attempt to activate

the programming environment.

When the Cod request appears, type the secret key-code using

buttons.

and

to increase the value of secret key code.

to decreases the value of secret key code.

to save the key-code and move to the next parameter.

4) KTF CODE

This function allows you to display the identification numeric code used as

identification address of the KTF/RW-MF in question. This function can be used

when the SM-DIN/RW-MF is connected to the SMART KTF 2000 terminal or to

the machine’s computer via the RS485 communication port.

to continue.

Enter the system’s code using the

and

buttons.

to confirm and return to the beginning of P3 menu

to move to P4 menu.

to return to CONTROL status without programming P4 menu.

- 3.16 -

KTF/RW-MF

KTF/RW-MF Operation

P4 Programming Level

ADVANCED

#

MENU P4

The P4 programming level allows you to setup 4 parameters:

1) Yarn feeding motor rotation direction;

2) Size in grams of TS4 tension sensor used (either 100 g. or 1000 g.);

3) Communication baud rate over the serial interface;

4) Type of motor used (25 mN/m or 100 mN/m).

to select the P4 level.

to continue.

1) MOTOR ROTATION DIRECTION

This function allows you to choose the rotation direction of yarn feeding motor

(C = Clockwise, CC = Counter-Clockwise).

to continue

To move from C value (Clockwise) to CC value (Counter-Clockwise) or vice versa,

press and hold down for 3 seconds the

button.

to move to next parameter.

2) TENSION SENSOR SIZE IN GRAMS

[Allowed values 101 or 102]

to continue

Choose the size in grams of the TS4 tension sensor used:

(101 if you use the TS4/100DRW sensor or 102 if you use the TS4/1000ERW

sensor)

to confirm.

KTF/RW-MF

- 3.17 -

KTF/RW-MF Operation

3) COMMUNICATION BAUD RATE

This parameter allows you to setup the communication speed on the

SM-DIN/RW-MF serial interface.

[Allowed values: 09.6 (9600 baud) – 19.2 (19200 baud) – 38.4 (38400 baud) –

57.6 (57600 baud) – 115 (115000 baud)]

to continue.

Choose the desired speed using

and

.

to confirm.

4) TYPE OF MOTOR AND YARN USED

This parameter allows you to choose the type of motor used in the KTF/100xx yarn

feeding device as well as the type of algorithm used for motor handling, depending

on the type of yarn to be feed.

[Allowed values]:

1

2

3

Elastic yarns

Non-elastic yarns with discontinuous absorption (*)

Non-elastic yarns with continuous absorption (**)

1

2

Small motor (KTF/100MF)

Large motor (KTF/100RW)

(*) Machines with stroke effect

(**) Beam warpers

to continue.

Choose the desired speed using

and

.

to confirm and return to the beginning of P4 menu.

to return the CONTROL status.

- 3.18 -

KTF/RW-MF

KTF/RW-MF Operation

INC/DEC Programmable Commands and Tension Alarm Activation

Using the INC-DEC commands it is possible to either Increment or Decrement the

tension set in P1 (MAIN TENSION).

The reset of INC/DEC graduation, as well as the management of “Error Tension”

Alarm depend on the selected working mode.

MODE 00

The typical characteristics of Mode 00 are the following:

! Immediate graduation reset, as soon as the INC/DEC signals are simultaneously

de-activated;

! “Error Tension” Alarm active only when KTF/RW-MF operates with P1

Tension (MAIN TENSION).

Immediate

Graduations

Reset

P1 = MAIN TENSION = 2.0 gr.

EXIT TENSION = 4.0 gr.

INC-DEC TENSION = 0.1 gr.

! The time between two INC/DEC commands must be at least 60 msec.

KTF/RW-MF

- 3.19 -

KTF/RW-MF Operation

MODE 01

The typical characteristics of Mode 01 are the following:

!

!

Reset of graduated tension synchronized through a defined sequence of INC/DEC

(deactivation/activation/deactivation);

“Error Tension” Alarm active only when KTF/RW-MF operates with P1 tension.

Graduations

Reset

! The A and B pulses, must not necessarily have the same duration, however it is

important that their duration is not less than 60 msec.

If the two pulses A and B occur in a time less than 1 second, the programmed tension

will be restored to the original value, always 1 second after the time S.

- 3.20 -

KTF/RW-MF

KTF/RW-MF Operation

MODE 02

The typical characteristics of Mode 02 are the following:

!

!

!

INC/DEC commands usable like for Mode 00;

The KTF/RW-MF generates the “Error Tension” Alarm when the tension

goes out of the programmed tolerance band and automatically resets the

alarm as soon as the tension returns within the programmed tolerance band.

“Error Tension” Alarm active only when KTF/RW-MF operates with P1

tension (MAIN TENSION)

Main Tension:

Error Tension:

Time Alarm:

2.0 g.

± 0.5 g.

2.0 sec.

MODE 03

The typical characteristics of Mode 03 are the following:

!

!

!

INC/DEC commands usable like for Mode 00;

The KTF/RW-MF system generates the “Error Tension” Alarm when the

tension goes out of the programmed tolerance band and automatically

resets the alarm as soon as the tension returns within the programmed

tolerance band.

“Error Tension” Alarm active only when KTF/RW-MF operates with P2

Tension (EXIT TENSION)

Exit Tension:

Error Tension:

Time Alarm:

4.0 g

±1g

3 sec.

MODE 04

The typical characteristics of Mode 04 are the following:

! INC/DEC commands usable like for Mode 00;

! “Error Tension” alarm active only in P1 (MAIN TENSION);

! Motor rotation direction reverse after a stop, to recovery the yarn.

KTF/RW-MF

- 3.21 -

KTF/RW-MF Operation

Increment/Decrement of Yarn Tension in Automatic Mode

(Function available only when using the SMART KTF 2000 Programming Terminal)

In the KTF/RW-MF System, the yarn winding tension can be controlled either at

hardware level (using the INC/DEC inputs, according to the modes described on

page 3.15) on at software level through the automatic graduation parameters setup

on SMART KTF 2000 terminal (NEW/MODIFY functions) or via machine

computer.

In this case, the KTF/RW-MF System will increment or decrement by a fixed

amount, at regular intervals, the main working tension, until the target value is

reached; then the tension will be restored to its initial value (MAIN TENSION).

Example:

- 3.22 -

-Initial Main Tension =

-Target =

-Automatic Increment (resolution) =

-Increment Interval =

KTF/RW-MF

10g

10000m

0,1g

100m

KTF/RW-MF Operation

Tension Profiler (Function available only when using the PC-Link KTF

Programming/Monitoring Software on Personal Computer)

The “Tension Profiler” function allows you to adjust in dynamic way the yarn

tension during the textile machine operation, setting some control parameters during

the article programming phase through the Style menu of PC-Link KTF software.

Thanks to the possibility to either enable or disable specific parameters and to use in

appropriate way the available input/output signals (EXC, NO1, NO2), you may obtain

different operating conditions to meet any application need. The programmable

parameters are the following:

START TENSION

Yarn tension at the position startup.

START METER

Number of meters for which the START TENSION is applied.

WORK TENSION

Yarn tension after the number of meters set in START METER.

INC/DEC TENSION

Increment/decrement amount of the WORK TENSION

(resolution) with the interval set in INC/DEC METER.

INC/DEC METER

Interval with which the WORK TENSION is incremented/

decremented by the amount set in INC/DEC TENSION.

TARGET TENSION

Yarn tension when reaching the target set in TARGET METER.

TARGET METER

Total amount of yarn to wind.

The above example refers to an application with a WORK TENSION of 14 grams and a

START TENSION of 20 grams to facilitate the yarn crimp. The start tension is applied for

50 meters (START METER), then the system switches to the work tension that will be

decremented by 0.1 grams (INC/DEC TENSION) every 1000 meter (INC/DEC METER) until

reaching the target (10000 meters, set in TARGET METER). After the target reset, the

system will start again with the START TENSION.

! For further details and application examples, please refer to the PC-Link KTF

manual (Menu Style → New)

KTF/RW-MF

- 3.23 -

KTF/RW-MF Operation

Textile Machine Interfacing Modes when Tension Profiler and/or Target

Functions are Enabled

The use of Tension Profiler and/or Target function allows you to implement some

functionalities that may result particularly useful in special applications.

Such functionalities may be obtained using in appropriate mode the hardware

input/output signals provided by SM-DIN/RW-MF system and the capability of Pc –

Link KTF software.

The usable input/output signals are typically the following:

- INC/DEC input – (EXT connector on SM-DIN/RW-MF)

- EXC input – (EXT connector on SM-DIN/RW-MF)

- Target output – NO2 – (POWER connector on SM-DIN/RW-MF)

- Error output – NO1 – (POWER connector on SM-DIN/RW-MF)

The functionalities that can be implemented are the following:

1 – Use of INC/DEC Input and Target Output (NO2) to Reset the Target Signalling

and Manage the Automatic Restart of Machine with Autodoffing Feature, after

the Target Reaching

The example shown below is based on the following assumptions:

- 3 different tension values have been programmed in Tension Profiler:

-

Start Tension

-

Work Tension

Target Tension

- The INC/DEC input is connected to the automatic Start/Stop signal of textile

machine.

- 3.24 -

KTF/RW-MF

KTF/RW-MF Operation

Event Sequence

1) The machine starts working (cycle 1) with the Start Tension.

The Inc/Dec input and NO2 output are both active.

2) After the number of meters set in Start Meter, the Work Tension is activated.

3) When reaching the target: the textile machine is temporally stopped l, the Target

Tension is activated, the NO2 output is activated and the

message appears

on the display of SM-DIN/RW-MF device.

The machine stop causes the de-activation of Inc/Dec input and the start of

Autodoffing operation.

4) The activation of Inc/Dec input causes the re-activation of NO2 output (with 1

second of delay), but the

message is maintained on display.

5) At the end of Autodoffing operation, the Inc/Dec input is re-activated, the

message disappears, the textile machine starts a new cycle (cycle 2) reactivating

the Start Tension ..... and so on!

2 – Use of INC/DEC Input and Target Output (NO2) to Reset the Target Signalling and

Manage the Restart of Machine with Manual Bobbin Replacement, after the Target

Reaching

This case is identical to the previous one, with only two differences:

1) The Inc/Dec input is connected to the machine Start/Stop button.

2) The time elapsing between the Inc/Dec signal de-activation and its re-activation is

not automatically managed by the textile machine, but is subordinate to the

operator intervention i.e. when the operator presses the start button after the

manual bobbin replacement.

KTF/RW-MF

- 3.25 -

KTF/RW-MF Operation

3 – Use of EXC Input to Reset the Target Signal and Manage the Machine Restart

In cases 1 and 2 described above, each machine position works in autonomous mode

controlled by its own SM-DIN/RW-MF system and the tension application (Start

Tension, Work Tension and Target Tension) is managed by the INC/DEC and Target

(NO2) interface signals for each individual position.

However, there are cases in which the bobbin collection must be carried out

simultaneously on all the machine position as soon as any of such positions reaches

the Target, even if the other positions have not yet reached it.

To implement this functionality it is possible to use the EXC input connecting it to

the Stop output (NO2) of all the SM-DIN/RW-MF devices.

In this way, the first device that reaches the Target activates its NO2 Stop output

which, in turn, activates the EXC input (3) and resets all the Target counters,

including those of the other positions.

As soon as the EXC input is de-activated (4), the machine will start a new cycle

(Cycle 2), re-activating the Start Tension ..... and so on!

- 3.26 -

KTF/RW-MF

Troubleshooting and Maintenance

4 – KTF/RWKTF/RW-MF TROUBLESHOOTING AND MAINTENANCE

Indications Provided by the Red Leds on SM-DIN/RW-MF unit

For the correct interpretation of signaling provided by red leds on front panel of SM-DIN/RW-MF unit,

please refer to Operating Characteristics of KTF/RW-MF System paragraph on page 3.3.

Troubleshooting on KTF/RW-MF System

Faults

Causes

Solutions

The display of

System power off

SM-DIN/RW-MF is blank

E02 displayed on the

SM-DIN/RW-MF display

! Check that the POWER connector is correctly

plugged in and that there is a 24 Vac/Vdc power

voltage on pins 1-2.

1) Motor locked

1) Check if the motor of KTF/100RW or KTF/100MF

module is correctly turning; remove possible yarn

residuals preventing the motor from turning

correctly.

Correctly thread the KTF/100RW or KTF/100MF

device as shown on page 2.8 and/or 2.9

2) Temporary triggering of internal

protections

2) Turn the electrical supply of device OFF and then

ON again

! If you cannot locate the cause of failure,

please contact your BTSR reseller (it could be

necessary to send the device to the BTSR

repair center).

E03 displayed on the

SM-DIN/RW-MF display

1) Presence of yarn residuals

under the loading cell of TS4

sensor.

1) Clean the loading cell of the sensor (see page 2.7),

using a light air blow (max 1 bar).

2) OFFSET value of TS4 sensor

device out of adjustment

2) Perform a correct adjustment of the OFFSET value

on TS4 device as described on page 3.14.

3) You are trying to perform the

offset procedure using the P3.1

menu function, but the tension

detected is lower than 1 gram.

3) Ensure that the KTF system on which you are trying

to perform the offset procedure does not have the

TS4 device disconnected or that the device itself is

not defective.

1) Parameter P1.3 is de-activated

The machine is not

(OFF)

stopped by SM-DIN/RWMF unit in case of yarn

2) The Increment and Decrement

breakage

controls are not correctly

managed within the machine

program

1) Check the correct programming of parameters on

SM-DIN/RW-MF unit.

2) Check the machine program handling the INC-DEC

controls. The INC-DEC and P1 leds must be ON.

3) The Stop function managed by

3) Check the machine program handling the STOP

the machine and associated with

input and confirm that it is enabled when the yarn

the KTF/RW-MF systems has

fed by KTF/100RW-MF is in working condition.

not been correctly enabled

within the machine program.

4) Wiring problem

4) If the STOP RW led turn on when the yarn breakage

occurs, check the machine connecting cables.

! To check the correct operation of the

SM-DIN/RW-MF STOP output press the

button and confirm that the STOP RW led turns

ON; if this does not occur please contact your

BTSR reseller (it could be necessary to send

the device to the BTSR repair center).

KTF/RW-MF

- 4.1 -

Troubleshooting and Maintenance

Faults

Causes

Solutions

A – o or A – u

displayed on

SM-DIN/RW-MF display

1) Incompatibility between the

SM-DIN/RW-MF programming

and the number of Increments/

Decrements generated by the

machine program

1) Check the SM-DIN/RW-MF programming, in

particular the INC-DEC tension parameters in P1,

and the machine program (check the number of

Increments/Decrements required).

E – t displayed on the

SM-DIN/RW-MF display

The internal temperature exceeded Check the usage conditions of the systems.

100°C

! If you cannot locate the cause of failure,

please contact your BTSR reseller (it could be

necessary to send the device to the BTSR

repair center).

E – c displayed on the

SM-DIN/RW-MF display

The current absorption of the

system exceed 3A in case of

KTF/100MF motor or 6A in case of

KTF/100RW motor.

Check the usage conditions of the systems.

E – S displayed on the

SM-DIN/RW-MF display

Internal protection triggered due to

over current.

Check the usage conditions of the systems.

The SM-DIN/RW-MF

unit does not

communicate with

SMART KTF 2000

terminal or with the PCLink KTF software on

Personal Computer

1) The identification code of

SM-DIN/RW-MF unit is not

correct

1) Check that the parameter corresponding to the

identification number (parameter P3.4) is correct; if

necessary carry out the numbering procedure using

the SMART KTF 2000 terminal.

2) Failure on SMART KTF 2000

terminal

2) Check the correct operation of SMART KTF 2000

terminal using the numbering procedure described

in the SMART KTF 2000 manual.

3) Wiring problem

3) Check the wiring on SM/IN and SM/OUT connectors

of SM-DIN/RW-MF units and on SMART KTF 2000

terminal.

! If you cannot locate the cause of failure,

please contact your BTSR reseller (it could be

necessary to send the device to the BTSR

repair center).

! If you cannot locate the cause of failure,

please contact your BTSR reseller (it could be

necessary to send the device to the BTSR

repair center).

4) Wrong communication baud rate 4) Check the configured baud rate (parameter P4.3)

(*) If you are using the PC-Link KTF software, run the

diagnostic functions provided by the software itself,

using the reference manual as a reference.

Even if the torque of KTF/100RW or KTF/100MF motor is very low and does not involve

hazards for the operator safety, it’s always advisable to lock the motor prior to operate on

the device (yarn threading, tilt adjustment of coil separation device, etc.) in order to avoid

undesired motor start-up events.

To lock the motor, just press the CONTROL

button on SM-DIN/RW-MF unit and check

that the STOP RW red LED turns-on.

At the end of the manual operation press again CONTROL

button and check that the

STOP RW red LED turn-off.

!

If the fault is not included in this table, please contact your local BTSR reseller, giving a detailed

description of the kind of fault and the conditions in which it occurred. In the case where the BTSR

Technical Service intervention would be required, before calling it is suggested to take note of the

code printed on the faulty device, as this information will make diagnoses for the BTSR technicians

easier.

Example:

Device code:

SM-DIN/RW-MF ……………………

- 4.2 -

KTF/RW-MF

Troubleshooting and Maintenance

Ordinary Maintenance

The KTF/RW-MF systems do not require special maintenance interventions,

except a periodical cleaning, depending on the environment condition in which

they operate.

For cleaning purposes, do not use solvent, but rather a soft cloth

dampened with neutral detergent or alcohol.

Repairs

Any repair intervention on KTF/RW-MF systems must be carried out

by specialized personnel from BTSR.

Any intervention attempt by non authorized personnel, voids the

warranty terms.

KTF/RW-MF

- 4.3 -

Troubleshooting and Maintenance

Updating the Software Version on SM-DIN/RW-MF System through the

Microprocessor Replacement

The software updating on SM-DIN/RW-MF system is a relatively easy operation.

However it must be carried out following scrupulously the instructions given in this

manual and using the indicated tools to avoid damaging the equipment and/or

microprocessor contacts.

Tools Needed:

1.5 mm Allen key

IC extractor

Operating Procedure:

1. Take note of the currently set parameters on the 4 menu

levels (P1 – P4).

Fig. 1

Fig. 2

2.

Disconnect the electrical supply of SM-DIN/RW-MF system

and check that all the leds as well as the display are off.

3.

Remove the SM-DIN/RW-MF system from its support bracket.

4.

Disconnect all the system connectors, tacking note of their

respective positions.

5.

Unscrew the 2 locking screws and remove the side cover

(Fig. 1).

6.

Using the IC extractor, remove with care the Integrated Circuit

from the socket located on the right top corner of PCB (Fig. 2).

7.

Place the Integrated Circuit, containing the new software

version, over the socket paying attention to its correct

orientation (Fig. 3).

8.

Applying a moderate and progressing pressure with both

thumbs, push the integrated circuit down into the socket

(Fig. 4).

9.

Reassembly the side cover and lock it using the 2 locking

screws.

10. Reconnect all connectors to their respective position.

11. Fasten the SM-DIN/RW-MF system on support bracket.

Fig. 3

12. Power on the system and check that:

-

All the leds turns on

The display shows

followed by the identification

code of the new software version.

13. Restore the parameters detected at step 1.

During this operation, avoid the conditions that

could cause static discharges!

Fig. 4

- 4.4 -

! If you are using the PC-Link KTF software, then the software

updating can be carried out directly through the serial line of

computer, without having to physically replace the

microprocessor. See the PC-Link KTF Manual.

KTF/RW-MF

Appendix A

APPENDIX A

The KTF/100MF and KTF/100RW yarn feeding devices may be equipped with

several accessories properly designed to optimize the operation of the devices

themselves depending on the application needs.

The following pages show the characteristics and order codes of such accessories.

! For further details please contact your BTSR dealer.

KTF/RW-MF

- A.1 -

Appendix A

- A.2 -

KTF/RW-MF

Appendix A

(-)

(30)

(33)

(AA)

KTF.SP.015

KTF.SP.030

KTF.SP.033

Other

(Orientable yarn brake with antiball. Ø65)

(Orientable yarn brake with antiball. Ø80)

(Orientable yarn brake with antiball. Ø65)

(-)

(HG)

(HH)

(XX)

MF.SP.001

(KTF/MF wheel carbon made)

MF.SP.001/HG (KTF/MF wheel rubber coated)

MF.SP.001/HH (KTF/MF wheel chrome coated)

Other

Micro-Feeder

(100) TS6/100A/MF (Tension Sensor gr. 100)

(-)

Without TS6/100A/MF

Product code

No.

Code

Description

REV.

Q.ty

1

KTF/MFB

Microfeeder device base

1

1

2

KTF.SP.015

Orientable yarn brake

3

1

3

MF.SP.001

KTF/MF wheel

1

1

4

TS6/100A/MF

Tension Sensor gr. 100 - Base

2

1

5

MM.2.091

Allen screw BRUN – UNI 5931 – M 2 X 5

--

--

KTF/RW-MF

- A.3 -

Appendix A

- A.4 -

KTF/RW-MF

Appendix A

(-)

(04)

(05)

(06)

(AA)

KTF.SP.003

KTF.SP.004

KTF.SP.005

KTF.SP.006

Other

(coil separator with diamond finishing)

(coil separator with chrome finishing)

(rotating coil separator)

(low friction coil separator)

(-)

(HG)

(HH)

(XX)

RW.SP.001

(KTF/RW wheel carbon made)

MF.SP.001/HG (KTF/RW wheel rubber coated)

MF.SP.001/HH (KTF/RW wheel nickel coated)

Other

ReWinder

(100) Torque 100 mN/m

Product code

No.

Code

Description

REV.

Q.ty

1

KTF/100RWB

Torque actuator 100 mN/m - Base -

1

1

2

RW.SP.001

KTF/RW wheel, carbon made

2

1

3

RW.SP.003

Standard coil separator

1

1

4

MM.2.085

3x6 Allen screw counter clockwise

--

--

KTF/RW-MF

- A.5 -

Appendix A

Page intentionally left blank

- A.6 -

KTF/RW-MF

DISTRIBUTOR

BTSR International S.p.A.

Via S. Rita

21057 OLGIATE OLONA (VA)

Tel. 0331-323202

Fax 0331-323282

Internet: www/btsr.com

REV. 3.0 – 12/04