manual for packaged drinking water

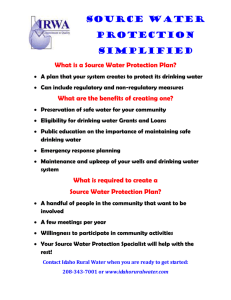

advertisement