Turbine-Generator Blade and Shaft Torisonal Torques Due to Line

advertisement

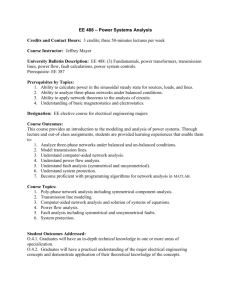

Turbine-Generator Blade and Shaft Torisonal Torques Due to Line Faults in Six-Phase Transmission Systems Evolved from Three-Phase Double-Circuit Line Systems Jong-Ian Tsai Rong-Ching Wu+ Tung-Sheng Zhan* Ting-Chia Ou** Wen-Yang Li Yong-Nong Chang# +*# ** Department of Electronic Engineering Department of Electrical Engineering Atomic Energy Council + * ** Kao Yuan University I-Shou University Kao Yuan University Institute of Nuclear Energy Research #National Formosa University Taiwan, R.O.C. jitsai@cc.kyu.edu.tw Abstract—Due to a restricted right-of-way and many factors, some of the local areas in Taiwan have become increasingly difficult to build new transmission lines. Since the majority of Taiwan power loads are located in the Norton, the demand of promoting transmission power could be of great urgency owing to the large amounts of power transferring from the South to the Norton. Aimed at overcoming this problem without changing the original conductors of the double-circuit transmission lines, the six-phase transmission scheme which could be one of the best schemes is presented and has several advantages such as transient stability enhancement, minimal corona, electric and magnetic fields, and radio interferences. As a result of the successful commercial operation of six-phase transmissions, the utility planner inevitably faces with the issue for the impact of turbine-generator torsional vibrations in the initial stage of the expansion into the a six-phase network. From the simulation comparisons between the three-phase double-circuit and evolved six-phase system, the latter offers better stability characteristic without deteriorating torsional vibrations from the viewpoint of the same line voltages. For the case of the same transmission capability, it significantly reduces the torsional vibrations. These conclusions provide a constructive suggestion for the department of generation and transmission. Under the assumption of the same line-to-line voltage, the six-phase transmission needs equal space of right-of-way and can carry up to 73% more power than a conventional double circuit three-phase line. In 1992, the high phase order transmission demonstration project converted NYSEG’s 115 kV double circuit short line between Goudey and Oakdale into a 93 kV six-phase line [1]. The power flow capability of such a system could be increased by 40%. Subsequently, numerous studies have been presented and attention has become focused on the system protection [2-3] and fault analysis [4-6]. Recently, there has been new interest in torsional interaction between this system and turbine-generator shafts [6]. However, it lacks for discussing the turbine blade torsional torques, stability, and comparison under the identical line voltage. Index Terms—Turbine, Torque vibration, Single-pole switching, Six-phase transmission, Transmission capability A. System Model The existing three-phase system used for investigation of this paper is shown in Figure 1(a). It consists of a turbinegenerator connected via step-up and -down transformers to an infinite bus network system through a three-phase, 345 kV double-circuit transmission line. The converted six-phase system, shown in Figure 1(b), consists of the same turbinegenerator connected via two pairs of phase conversion transformers to an infinite bus network system through a sixphase transmission line. One pair of phase converter transformers is connected wye/delta and the other pair is connected inverted wye/delta. Therefore, the 60-degree phase shift between adjacent phases is obtained. The phase diagrams for the studied three-phase double-circuit and six-phase systems are plotted in Figures 2(a) and 2(b) respectively. It is apparent that the line-to-line voltage magnitude of the sixphase system is the same as its phase voltage magnitude. I. INTRODUCTION There are three nuclear power plants in Taiwan, which serve as base-load units and began their operation in 1977. According to statistics for these plants, a total of 46, 68 and 62 incidents have occurred in 1997, 1998, and 1999, respectively. Among these, up to 10 incidents (induced from either typhoons or earthquakes) even caused tower collapse and serious disconnection between the northern and southern subsystem, incurring considerable financial expense to reconstruct the transmission system. Six-phase transmission technique allows the towers to be built smaller and more compactly than the three-phase one for the same power flow capability, effectively lessening the right-of-way problem without changing existing conductors. The cost saving could be recycled to strengthen the tower against collapse. 978-1-4244-2800-7/09/$25.00 ©2009 IEEE 2961 To investigate these effects is the motivation behind the development of our article. From the simulation result, it is found that the six-phase system effectively lessens the torsional interaction under various transmission line faults. A transient computer program is developed by using Matlab-Power System Blockset [7]. II. SYSTEM DESCRIPTIONS ICIEA 2009 The steam turbine unit, including one high-pressure (HP) stage and two low-pressure (LP1, LP2) stage steam turbines, is a close-coupled and cross-compound reheat unit that operates at a rotational speed of 1800 rpm. The rated capacity of the generator set, installed in 1984, is 951MW and is the largest in Taiwan. Each of the two low-pressure steam turbines has A and B spindles and uses the shrunk-on rotor with 11 stages of each spindle, including rotary and stationary blade stages. sources to stress turbine mechanism, governing the turbine shaft and blade vibration behaviors. In this paper, the vibration modes of the turbine system have been analyzed by using the frequency-scanning method. Suppose that the terminal of the generator rotor is a shaker with E/M torque of one p.u., the frequency-scanning inspects the natural frequencies of steam turbines from 0.01 Hz to 140 Hz with an interval of 0.01 Hz. Figure 4 demonstrates the frequency scanning results for the B2F blade and LP2R-GEN shaft. Nine vibration modes are then presented as listed in Table 2. Clearly, these modes have been properly avoided from the forbidden frequency bands defined as 60Hz±5% and 120Hz±5%. Aimed at the excitations of the aforementioned three frequency component of E/M torque, it is clearly comparable that the most considerable blade torque response is excited by the double system- frequency component (-29.6db at 120Hz). This will impose supersynchronous oscillations in turbine blades. However, such an effect cannot be found in turbine shafts due to their low response (<-25dB at 120Hz). The shaft is more sensitive to the excitation of the unidirectional component while the blade is not. Both the blade and the shaft have the sensitivity of minor importance to the excitation of the system frequency component. Figure 1. System studied (a) three-phase double-circuit system (b) six-phase system Figure 2. Phase diagram (a) three-phase double-circuit system (b) six-phase system B. Simulation System Model For time-domain simulation investigations, the generator is represented by a six-order state-space d-q-0 model. The step-up transformer is represented by lumped model transformers. Each transmission line is modeled by its equivalent R-L lumped parameters. Each network source is treated as an infinite bus modeled by a fixed amplitude sinusoidal voltage source at nominal frequency. Each CB is represented as an ideal switch which is able to open at the current zero crossings. Dynamics of the excitation system modeled by IEEE type 1 exciter are included in the generator model. A mass-damping-spring model is adopted for turbine model representation, as Figure 3 illustrated. The simulation data are given in the Table 1. All of the parameters of this system are in the per-unit (p.u.) system, based on generator ratings. III. FREQUENCY DOMAIN ANALYSIS It is well-known that the electromagnetic (E/M) torque induced by power system fault consists of the following three components, a unidirectional component (<2 Hz), a systemfrequency component, and a double system-frequency component which correspond to the generator delivering power (or amplitude of armature current) swing, the generator DC armature current, and the negative-sequence armature current arising from the unbalanced operation respectively [8]. These three frequency types of E/M torques are the main excitation 2962 Figure 3. Turbine model. Figure 4. Results of frequency-scanning for LP2R-GEN shaft and B2R blade. Table 1. 951MW turbine-generator system parameters Mechanical data Generator (1057MVA, 24kV) 60Hz Xd=1.574 Rs=0.00359 Mass Inertia, Damping, C 4 poles Xq=1.490 Rfd=0.00070 H P0=0.90 Xfdl=0.168 Rkd=0.02571 HP 0.1787 0.00180 Q0=0.07 Xl=0.190 Rkq=0.02571 LP1F 0.6546 0.00023 Vt=1.03 Xkd=0.110 Xkq=0.490 LP1R 0.6486 0.00021 Step-up/down TR. 1057MVA (each) LP2F 0.6575 0.00021 24/345kV, Xt1= 0.1430 Rt1=0.00192 LP2R 0.6676 0.00021 3P:Wye-Delta1,6P:Wye-Delta1/Delta11 GEN 1.1616 0.00012 PI transmission line (each) REC 0.00344 0 R=0.0366 XL=0.108 XC=340.55 EXC 0.00236 0 Torque distribution (%) Blade 0.0344 0.00004 HP 31 LP1F 14.45 LP2F 14.45 B1F 2.8 B2F LP1R 14.45 LP2R 14.45 B1R 2.8 B2R *units: H(MW-S/MVA), C(MW-s/MVA-rad), K(MW/MVA-rad) Stiffnes s, K 144.15 1595.0 206.0 1584.9 325.28 117.16 1.61 36.2 2.8 2.8 Table 2. Vibration modes (Hz) 1 2 3 4 5 6 7 8 9 19.40 37.40 40.25 47.02 101.80 104.11 127.05 133.25 134.25 Table 3. The 23 significant fault types of six-phase power systems and corresponding fault lines of three-phase systems Fault type 1-phase-G (1L-G) 2-phase-G (2L-G) 2-phase (2L) 3-phase-G (3L-G) 3-phase (3L) 4-phase-G (4L-G) 4-phase (4L) 5-phase-G (5L-G) 5-phase (5L) 6-phase-G (6L-G) 6-phase (6L) IV. Number of combinations 1 3 3 3 3 3 3 1 1 1 1 Six-phase fault phase a ac', ab, aa' ac', ab, aa' abc', aa'c',abc abc', aa'c',abc abc'a',abcc',aa'c abc'a',abcc',aa'c aa'bcc' aa'bcc' aa'bb'cc’ aa'bb'cc’ three-phase fault line a ac', ab, aa' ac', ab, aa' abc', aa'c',abc abc', aa'c',abc abc'a',abcc',aa'c abc'a',abcc',aa'c aa'bcc' aa'bcc' aa'bb'cc’ aa'bb'cc’ double circuit system, and in Figure 7(b) for the six-phase system with identical line-to-line voltage (345kV). Obviously, the six-phase system offers better transient stability characteristics than the conventional three-phase double-circuit system on account of the increment of 73% power flow capability. The damping on the rotor angle helps validate this assertion. TIME-DOMAIN SIMULATION RESULTS There are 11 and 120 possible fault combinations in a threephase and six-phase system respectively. Out of these large combinations, there are 5 and 23 combinations respectively, with distinct fault levels and phase interconnections [9]. To compare the impact on the turbine-generator set, the significant fault combinations are tabulated in the third column of Table 3 for a six-phase system, and in the fourth column for a threephase double circuit system, where the phase numbers are defined in Figure 3. Assume that the steady-state condition occurs at 0 second. Thus, the transient responses of six-phase phase voltage and phase current shown in Figure 5 agree with the phase relationship. In the following subsections, the fault is applied to the middle location (location P) of the transmission line at 0.1 second. Figure 5. Phase voltage and phase current for the six-phase system. A. Short-time Line Faults A.1 Transient Stability Comparison In the past, power accidents occurring as three-phase-toground faults were believed to induce the largest torsional stresses [10]. The peak-to-peak (deviation between maximum and minimum) shaft and blade torques are plotted in Figure 6 as functions of the three-phase-to-ground (abc-G) fault selfclearing time. It can be seen that the fault clearing time affects the peak-to-peak torsional torques due to the phase additive or subtractive effect at the instant of clearing time. There are similar sensitivity characteristics for the peak-to-peak torque curve between the three- and six-phase systems and their worst-case clearing time is 0.19 second (5.4 cycles). The transient behaviors subjected to a worst-case three-phase-toground fault are indicated in Figure 7(a) for the three-phase 2963 Figure 6. Peak-to-peak shaft and blade torsional torques as a function of the fault clearing time for a three-to-ground fault (a) three-phase double-circuit system (345kV) (b) six-phase system with the same line-to-line voltage (345kV) A.2 Torsional Torque Level Comparison Since the faulted armature current in the six-phase system has been restricted, the induced E/M torque can be alleviated. This contributes to the turbine shaft and blade torsional torque suppression as Figure 8(b) shows. If all the peak-to-peak torques from the curve in Figure 6 are averaged, the average peak-to-peak torque (Tpp) under the case of abc-G is derived and defined. It should be noted that between these two systems, symmetrical faults (such as abc, abc-G, 6L, and 6LG) bring the same torsional impact, and a 1L-G fault in the six-phase system can induce torsional torques higher than those induced due to a 2L fault. Besides, a 4L (aca’c’) fault in the three-phase system imposes the highest stresses on blades rather than shafts. This is because considerable negative-sequence current penetrates through the generator, which induces supersynchronous oscillations. Fortunately as can be seen from the double-system component of E/M torque, six-phase system also mitigates the negative-sequence armature current and then reduces this phenomenon. Further Table 4 averages these torque levels from 23 types of faults. As compared from the table, the six-phase network faults impose minor torsional stresses especially on turbine blades based on the same peak-to-peak voltage (the same rightof-way). It is worth noting that as mentioned in [11], the most common type of fault in a three-phase system is the single lineto-ground (1L-G) fault, followed in frequency of occurrence by line-to-line (2L) fault, double line-to-ground (2L-G) faults, and three-phase (3L) faults. This means that in a six-phase system, the higher phase faults lead to having a much lower probability of occurrence. Consequently, aimed at the excitations of line faults below three phases (e.g. 1L-G, …, 3L, 3L-G), the torque reduction ratio for all shafts and blades in the six-phase system is about 20% on average. It is emphasized that a relatively modest reduction in the amplitudes of the torsional torques has a very significant impact on decreasing the induced fatigue loss in the material property of shafts or blades. A.3 The Case of the Same Power Flow Capability Based on the demand on restricted right-of-way, the line-toline voltage for the converted six-phase system can be reduced by 3 (namely 199kV) for the same power flow capability. Therefore, the rotor swing behavior keeps identical damping characteristics as shown in Figure 9. According to the line base voltage reduction, the per-unit impedance of the transmission line becomes higher. This adds the impedance value between the fault location and the generator, and diminishes the fault current. Therefore, all the turbine-generator torques has been considerably depressed. Figure 9 gives the average peak-topeak torques arising from various faults. It can be concluded that based on the same power capability, such a low voltage six-phase system is more prone to suppress turbine-generator torsional torques. On average the reduction ratios (depicted from the last rows of Table 4) in shafts and blades are about 36% and 43% respectively, as compared with a three-phase system. Figure 8. The average peak-to-peak torque (Tpp) following the fault types tabulated in Table 3 (a)three-phase double-circuit system (345kV) (b)sixphase system (345kV) Table 4. The average of the average peak-to-peak torque for the main shafts and blades subjected to 23 significant types of short-time line faults LP1RLP2RShaft/Blade section B2F B2R LP2F GEN 3-phase double-circuit 3.5315 5.0136 0.2140 0.2076 system(345kV) 6-phase system (345kV) 3.2281 4.3896 0.1583 0.1565 6-phase system (199kV) 2.3153 3.0755 0.1205 0.1192 Figure 9. As for Figs. 7 and 8, but for six-phase system (199kV). B. Fault Tripping and Auto-Reclosing B.1 Transient Stability Comparison In this section, the following six-phase protection scheme has been adopted in the Goudey-Okadal Project [2]. The main criterion is to perform a traditional single pole switching scheme from the respective transformer. As referred to Figure 3, one conventional three-phase step distance relay monitors phase a-b-c, and the other monitors phase a’-b’-c’. The following switching criteria are assigned [2, 3]: Figure 7. Generator armature current, E/M torque, torsional torque, and rotor angle responses due to a three-phase-to-ground (abc-G) fault from 0.1 sec to 0.19 sec (a) three-phase double-circuit system (345kV) (b)six-phase system (345kV) (1) For single line-to-ground faults, the faulted single pole trip and one shot high-speed autoreclose. When encountering unsuccessful reclosure, corresponding triple pole tripping with no further reclosure permitted. (2) For line-to-line or double line-to-ground fault on any adjacent (a-b’ or a-c’) or opposite (a-a’) phase conductors, the faulted pole trip and one shot high-speed autoreclose. (3) Three phase trip of all phases from one transformer (a-b-c or a’-b’-c’) for multi-phase faults from that transformer. No autoreclose would be attempted for fear of damaging turbinegenerator shaft or blades. Since a single line-to-ground fault has the largest occurrence probability among power line accidents, the 2964 transient responses involving with armature current during worst-case unsuccessful reclosing of a 5.4-60-5.4 cycle’s single line-to-ground fault occurred are indicated in Figure 10(a) for the three-phase system, in Figure 10(b) for the six-phase system with the same line-to-line voltage, and Figure 10(c) for the six-phase system with the same phase voltage. As can be anticipated, the 345kV six-phase system possesses the best stability performance and stability margin. Even after a threepole tripping during unsuccessful reclosing (>1.29 sec), the 345 kV six-phase system becomes the original three-phase singlecircuit system. However, at this instant, the 199 kV six-phase system becomes a 199kV three-phase single-circuit system and leads to a rapid rotor acceleration because of the effect of double transmission impedance. Converting a system with less right-of-way consideration is against system stability margin. B.2 Torsional Torque Level Comparison As a result of the effective reduction for the single line-toground fault current as evidenced by armature current in Figures 10(b) and 10(c), there are smaller induced abovementioned three components of E/M torque. Thereby, the shafts and blades suffer inconsiderable vibrations especially for the 199kV six-phase system. Besides, during the dead time between single-pole tripping and line reclosing, the negative sequence current gives rise to the E/M torque with the double system frequency component which may stimulate turbine blades [8]. In the figures, they reveal that, during the dead time, the six-phase system injects more negative sequence currents to the generators as the voltages decreases. But fortunately, the onerous supersynchronous oscillation in turbine blades is not induced since the vibration modes stay away from the forbidden band of double system frequency. The effectiveness of restricting blade vibrations is still guaranteed. V. [4] L. J. Oppel and E. Krizauskas, “Evaluation and testing of a single terminal step distance scheme for use on a six phase transmission system,” IEEE Trans. Power Delivery, vol. 13, No. 4, pp. 1527-1529, October 1998. [5] A. K. Mishra, A. Chandrasekaran, S. S. Venkata, “Estimation of errors in the fault analysis of six phase transmission lines using transposed models,” IEEE Trans. Power Delivery, vol. 10, pp. 1401-1407, 1995. [6] S. O. Faried and T. S. Sidhu, ”A new method for fault analysis of sixphase transmission systems,” Electric Power Systems Research, vol. 53, pp. 157–163, 2000. [7] The Mathworks Inc., "Power System Blockset for Use with Simulink User's Guide", June 2001. [8] C. H. Lin and T. P. Tsao, “Suppress vibrations on turbine blades by high temperature super-conductive fault current limiter,” IEE Proc. Generation, Transmission and Distribution, Vol. 148, No. 2, pp. 97-103, March 2001. [9] E. H. Badawy , M. K. El-sherbiny, A. A. Ibrahim, “A method of analyzing unsymmetrical faults on six-phase power systems,” IEEE Trans. Power Delivery, vol. 6, no. 3, July 1991. [10] T. J. Hammons, "Stressing of large turbine-generators at shaft couplings and LP turbine final-stage blade roots following clearance of grid system faults and faulty synchronization," IEEE Trans. Power Apparatus and Systems, vol. 99, no. 4, pp. 1652-1662, 1980. [11] Arthur R. Bergen, Vijay Vittal, Power System Analysis, USA, PrenticeHill, 2000. CONCLUSIONS 1. Under the assumption of identical line-to-line voltage, there are a 25% torque reduction for the turbine blades on average following various line faults and considerable stability improvement in the six-phase system. Under the assumption of identical transmission capability, there is up to 40% torque decrement on turbine shafts and blades. 2. For the most frequent fault of the single line-to-ground fault, the six-phase system induces more significant negativesequence current during the dead time and stability margin reduction problem under single-circuit line tripping. However, the torsional torque suppression on either blades or shafts is still effective and satisfying. REFERENCES [1] [2] [3] T. L. Landers, R. J. Richeda, E. Krizauskas, J. R. Stewart, and R. A. Brown, “High phase order economics: Constructing a new transmission line,” IEEE Trans. Power Delivery, vol. 13, pp. 1521–1526, 1998. A. P. Apostolov and R. G. Raffensperger, “Relay protection for faults on NYSEG’s six-phase transmission line,” IEEE Trans. Power Delivery, vol. 11, pp. 191–196, 1996. L. J. Oppel and E. Krizauskas, ”Evaluation of the performance of Line Protection Schemes on the NYSEG Six Phase Transmission System,” IEEE Trans. Power Delivery, vol. 14, No. 1, pp. 110-115, January 1999. 2965 Figure 10. Transient responses during unsuccessful reclosing of a 5.4-60-5.4 cycles single line-to-ground fault (a) three-phase double-circuit system (345kV) (b)six-phase system (345kV) (c)six-phase system (199kV).