AN95-005 How VCO Parameters Affect Each Other

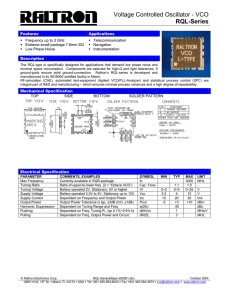

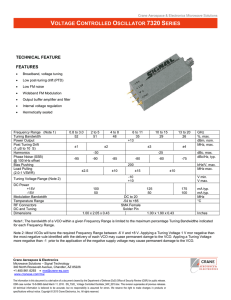

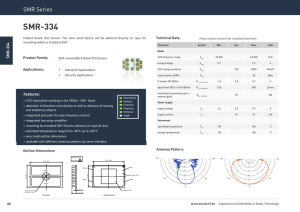

advertisement

How VCO Parameters Affect Each Other Relationships of VCO Performance Parameters Affecting Parameter Affected Parameter Frequency Range Power Output Frequency Range Tuning Sensitivity Pushing Pulling D.1. Power Output Tuning Sensitivity Supply Current C.1. A.2. I.1. Phase Noise J.2. C.3. A.3. Pulling A.4. J.3. G.2. B.1. Pushing J.4. J.7. B.2. E.2. Harmonics Suppression C.4. A.5. B.3. E.3. I.2. F. 1. Frequency Tuning Voltage Harmonics Modulation Suppression Bandwidth E.1. Supply Current Temperature Power Output Flatness A.1. G.1. D.2. J.6. H.1. C.2. J.1. J.5. F.2. Power Supply How To Use This Table In order to see an explanation on how the “Affecting Parameter” affects the “Affected Parameter”: 1. Go to the intersection on the table between the Affecting and Affected parameters ( for example, the intersection of how “Frequency Range” affects “Phase Noise” is J.2.”). 2. The figure appearing in the intersection ( “J.2.” in our example ) indicates where the explanation on the Effect appears in the text: the letter indicates the Article and the number indicates the Sub-Article ( for example, “J.2.” refers to Article “J”, Sub-Article “2”). 3. Empty cells indicate that the effect of the Affecting Parameter on the Affected Parameter is insignificant or does not exist at all. A. Parameters Affecting VCO Frequency Range B. Parameters Affecting VCO Power Output. The following parameters affect the VCO Frequency Range. The following parameters affect the VCO Power Output: A.1. TUNING VOLTAGE • An increase in tuning voltage range widens frequency range. B.1. SUPPLY CURRENT • Increasing supply current typically increases power output. A.2. TUNING SENSITIVITY • Lower sensitivity means a narrower frequency range for a given range of tuning voltage. B.2. PULLING • To improve pulling, output power should be reduced by connecting an attenuation circuit at the VCO output. • Improved pulling can also be achieved by connecting a buffer amplifier at the VCO output port. However, this buffer amplifier requires a higher supply current. A.3. PUSHING • Increased pushing causes decreased effective frequency range. B.3. TEMPERATURE. • From an ambient temp of +25ºC: a temp increase to +85ºC results in an output power decrease of 0.5dB to 1.0dB typically. A.4. PULLING • Increased pulling causes decreased effective frequency range. • From an ambient temp of +25ºC: a temp decrease to -55ºC results in an output power increase of 0.5dB to 1.0dB typically. A.5. TEMPERATURE • An increase in the range of the ambient operating temperature causes a decrease in the VCO’s frequency range and vice-versa. (NOTE: Definitions of VCO terms appear on Pages 40-41) ® P.O. Box 350166, Brooklyn, New York 11235-0003 (718) 934-4500 Fax (718) 332-4661 For quick access to product information see MINI-CIRCUITS CATALOG & WEB SITE TM The Design Engineers Search Engine Provides ACTUAL Data Instantly From MINI-CIRCUITS At: www.minicircuits.com ISO 9001 AN-95-005 Rev A (04/14/15) M150261 File: AN95005.pdf This document and its contents are the property of Mini-Circuits ®. CERTIFIED 1 OF 3 ® C. Parameters Affecting VCO’s Power Output Flatness H. Parameters Affecting VCO Modulation Bandwidth The following parameters affect the VCO Power Output Flatness: The following parameters affect the VCO Modulation Bandwidth: C.1. FREQUENCY BANDWIDTH • As the VCO frequency range is increased, the difficulty to achieve a flat output power is increased. H.1. FREQUENCY • Higher modulation bandwidth can easily be achieved at higher frequency. C.2. TUNING VOLTAGE • As the tuning voltage range is reduced and narrowed, a flatter output power can be achieved. I. Parameters Affecting VCO Harmonics Suppression C.3. TUNING SENSITIVITY • It is more difficult to achieve flat output power for high tuning sensitivity than for low tuning sensitivity. I.1. FREQUENCY BANDWIDTH • It is easier to achieve good harmonics suppression when frequency range is narrow. C.4. HARMONICS • Adding an output filter to suppress harmonics may in some cases degrade power output flatness. I.2. TEMPERATURE • With ambient temperature increase, the harmonic level gets lower. With ambient temperature decrease, the harmonic level gets higher. D. Parameters Affecting VCO Tuning Sensitivity J. Parameters Affecting VCO Phase Noise The following parameters affect the VCO Tuning Sensitivity: The following parameters affect VCO Phase Noise: D.1. FREQUENCY RANGE • For a given tuning voltage range, increasing the frequency range requires an increase in the tuning sensitivity, and vice-versa. J.1. FREQUENCY • As carrier frequency increases, it’s more difficult to achieve good phase noise. D.2. TUNING VOLTAGE • For a given frequency range, increasing the tuning voltage range decreases the tuning sensitivity, and vice-versa. J.2. FREQUENCY RANGE • It’s easy to achieve good phase noise when frequency range is narrow. E. Parameters Affecting VCO Supply Current The following parameters affect the VCO Supply Current: E.1. POWER OUTPUT • Increasing power output requires higher supply current. E.2. PULLING Same As B.2. E.3. TEMPERATURE • From an ambient temp of +25ºC: a temp increase to +85ºC typically results in a supply current increase of approximately 10%. • From an ambient temp of +25ºC: a temp decrease to -55ºC typically results in a supply current decrease of approximately 10%. The following parameters affect VCO Harmonics Suppression: J.3. TUNING SENSITIVITY • Increasing the tuning sensitivity degrades phase noise and vice-versa. J.4. SUPPLY CURRENT • It is typically easy to achieve good phase noise at higher offset frequencies (> 1kHz) in designs with a high supply current. J.5. TUNING VOLTAGE • For a given frequency range it is typically easy to achieve good phase noise in designs with a wide tuning voltage range. J.6. TEMPERATURE • Phase noise varies typically by 3dB in the –55ºC to +85ºC range. J.7. PUSHING • High pushing can cause phase noise degradation due to increased sensitivity to the power supply noise. F. Parameters Affecting VCO Pushing The following parameters affect the VCO Pushing: F.1. FREQUENCY • As the VCO frequency increases, difficulty in achieving good pushing is increased. F.2. POWER SUPPLY • Good pushing is easier to achieve in designs with high current. G. Parameters Affecting VCO Pulling The following parameters affect the VCO Pulling: G.1. FREQUENCY • As the VCO frequency increases, difficulty in achieving good pulling is increased. • See B.2. G.2. SUPPLY CURRENT • It is difficult to achieve good pulling when there is a limit on supply current consumption, due to the fact that (connecting a buffer amplifier at the VCO output port) improving pulling increases current consumption. Typical values of narrow band VCOs are shown in the table below: PHASE NOISE (-dBc/HZ) FREQUENCY (GHz) 115÷120 <0.5 110÷115 0.5÷1 102÷110 1÷2 95÷102 2÷3 see us on the web www.minicircuits.com AN-95-005 Rev A (04/14/15) M150261 File: AN95005.pdf This document and its contents are the property of Mini-Circuits ®. 2 OF 3 IMPORTANT NOTICE © 2015 Mini-Circuits This document is provided as an accommodation to Mini-Circuits customers in connection with Mini-Circuits parts only. In that regard, this document is for informational and guideline purposes only. Mini-Circuits assumes no responsibility for errors or omissions in this document or for any information contained herein. Mini-Circuits may change this document or the Mini-Circuits parts referenced herein (collectively, the “Materials”) from time to time, without notice. Mini-Circuits makes no commitment to update or correct any of the Materials, and Mini-Circuits shall have no responsibility whatsoever on account of any updates or corrections to the Materials or Mini-Circuits’ failure to do so. Mini-Circuits customers are solely responsible for the products, systems, and applications in which Mini-Circuits parts are incorporated or used. In that regard, customers are responsible for consulting with their own engineers and other appropriate professionals who are familiar with the specific products and systems into which Mini-Circuits’ parts are to be incorporated or used so that the proper selection, installation/integration, use and safeguards are made. Accordingly, Mini-Circuits assumes no liability therefor. In addition, your use of this document and the information contained herein is subject to Mini-Circuits’ standard terms of use, which are available at Mini-Circuits’ website at www.minicircuits.com/homepage/terms_of_use.html. Mini-Circuits and the Mini-Circuits logo are registered trademarks of Scientific Components Corporation d/b/a Mini-Circuits. All other third-party trademarks are the property of their respective owners. A reference to any third-party trademark does not constitute or imply any endorsement, affiliation, sponsorship, or recommendation: (i) by Mini-Circuits of such third-party’s products, services, processes, or other information; or (ii) by any such third-party of Mini-Circuits or its products, services, processes, or other information. AN-95-005 Rev A (04/14/15) M150261 File: AN95005.pdf This document and its contents are the property of Mini-Circuits ®. 3 OF 3