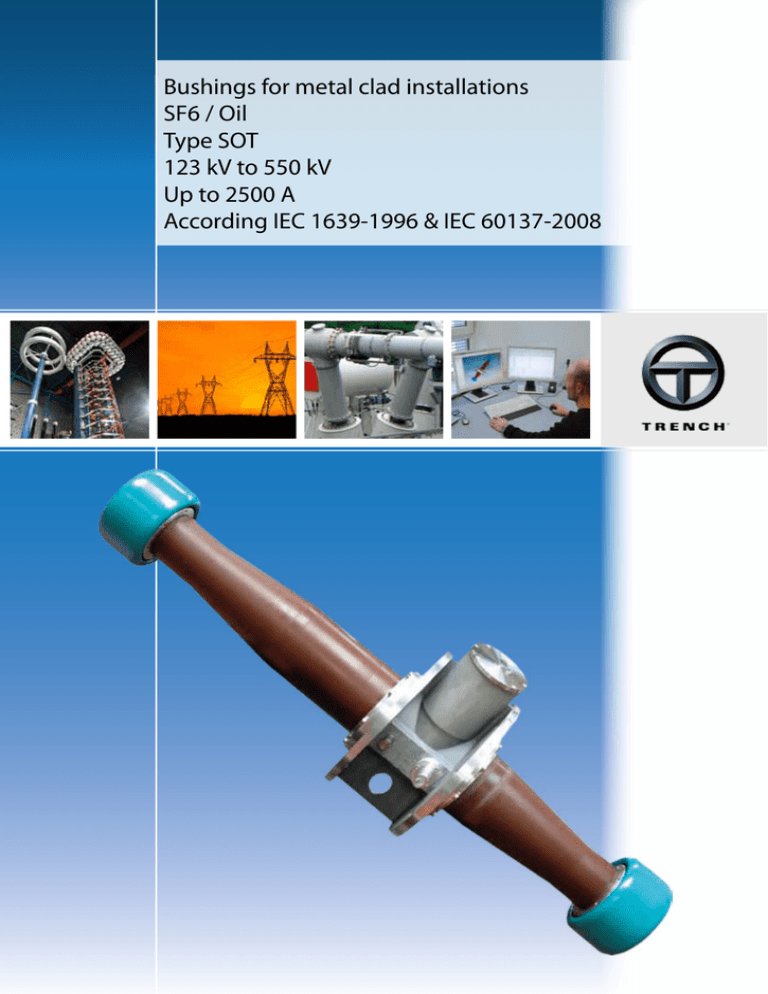

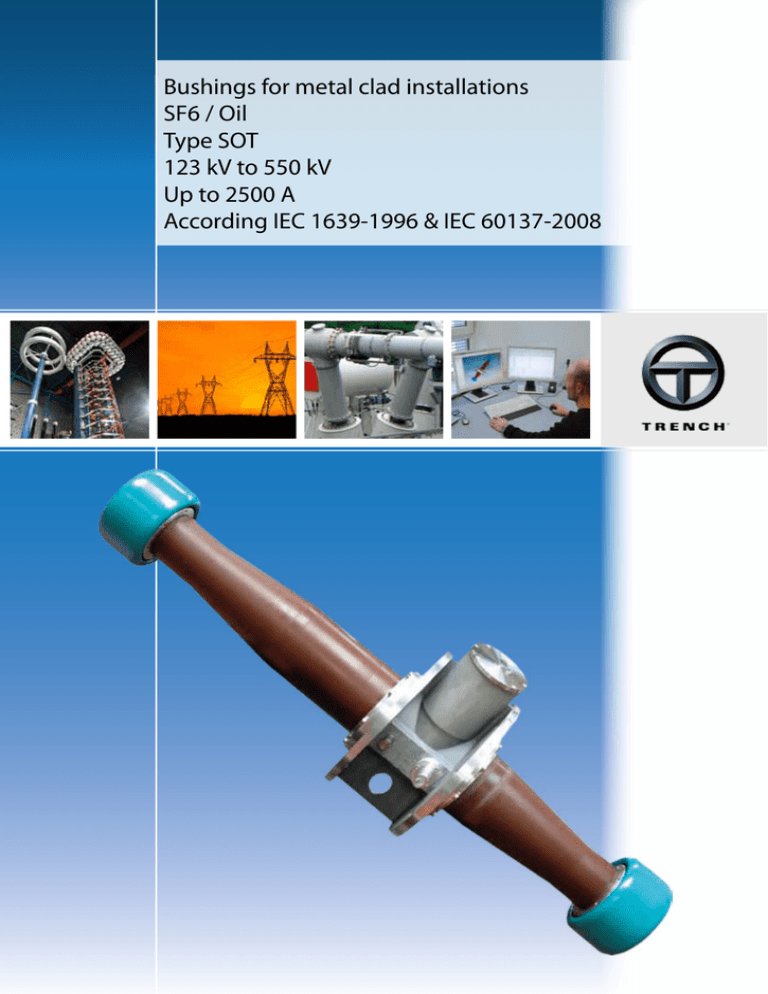

Bushings for metal clad installations

SF6 / Oil

Type SOT

123 kV to 550 kV

Up to 2500 A

According IEC 1639-1996 & IEC 60137-2008

Bushingsfor

for transformer

transformer to

Bushings

to gas

gas insulated

insulatedswitchgear

switchgearconnections

connections

Trench OIP technology for

Trench OIP technology for

Oil / SF6 bushings

Oil / SF6 bushings

Application:

Application:

Bushing Type SOT

Bushing Type SOT

SF6

SF6

This type of bushing, suitable for direct connection between metal

clad

switchgear

enables

the metal

This SF6-insulated

type of bushing,

suitableand

for transformers,

direct connection

between

integrating

of powerswitchgear

transformers

to transformers,

the grounded enclosure

clad SF6-insulated

and

enables the

system

of the

integrating

of switchgear.

power transformers to the grounded enclosure

system

of

the

switchgear.

It is no longer required

to join the transformers to the switchgear

by

of overhead

or cables,

thus savingtooutdoor

It ismeans

no longer

requiredlines

to join

the transformers

the switchgear

bushing

orof

cable

end boxes

switchgear

and transformer

by means

overhead

lineson

orboth

cables,

thus saving

outdoor

side.

bushing or cable end boxes on both switchgear and transformer

side.

Features:

Features:

Transformer

Transformer

Design is in line with latest requirements of IEC 1639 for gas

side connection.

Design is ininline

with latest

requirements

ofthan

IEC 1639

for gas

Experience

bushing

manufacture

for more

90 years.

side

connection.

Capacitance fine graded oil-paper insulation with long

Experience in bushing manufacture for more than 90 years.

experience.

Capacitance

fine graded

oil-paper

insulation with long

Computer

optimized

electrical

field distribution.

experience.

Proven

high electrical withstand against transient or impulse

Computer optimized electrical field distribution.

test.

Proven high

withstand

transient

or impulse

Excellent

longelectrical

term stability

due toagainst

extremely

low partial

test.

discharge

and power loss factor.

Excellent

long

term

stability

due

to extremely

low

partial

Oil

immersed

part

and

SF6 part

covered

by epoxy

resin

tube

providing

high

impact

resistance.

discharge and power loss factor.

Tan

δ and PD-values

more

as good

as requested

by

Oil immersed

part and

SF6than

parttwice

covered

by epoxy

resin tube

IEC

60137.

providing high impact resistance.

Possibility

trace SF6more

gas by

means

doing

Tan δ and to

PD-values

than

twiceofas

goodDGA

as requested by

(dissolved

gas

analysis)

IEC 60137.

Long

term easy

storage:

Bushing

100% tight

towards

Possibility

to trace

SF6 gas

by means

of doing

DGAambient

humidity.

(dissolved gas analysis)

Long term easy storage: Bushing 100% tight towards ambient

humidity.

Certified ISO 9001

Certified ISO 9001

Certified ISO 14001

Certified ISO 14001

Page 2 / 12

Page 2 / 12

40497285_00

40497285_01

40497285_00

Oil/ SF6

/ SF6Bushing

Bushing

Oil

1

2

3

Design

Design

1

SF6 side Shield (on request)

SF6 side Shield (on request)

2

SF6 side Terminal

SF6 side Terminal

Terminal (Al or Cu) for connection is designed

according

1639.

Terminal

(Al standard

or Cu) forIEC

connection

is designed

according standard IEC 1639.

3

SF6 side end

SF6

side

end on the SF6 side is made of an epoxy

The

insulator

tube. on the SF6 side is made of an epoxy

Theresin

insulator

resin tube.

4

4

5

The active

Active

part part is made of oil-impregnated wide band

paper with layers of aluminum foil to control the

The active part is made of oil-impregnated wide band

electrical field radially and axially. Depending on the

paper

withrating,

layersthe

of paper

aluminum

foil are

to control

theon

current

and foil

wounded

electrical

field

radially

and

axially.

Depending

on the

either a central tube or conductor

current rating, the paper and foil are wounded on

either a central tube or conductor

Flange

6

Mounting flange with integrated test tap and oil

Flange

sampling device made of corrosion free aluminum

Mounting

flange with

integrated

test tap seal

and oil

alloy, machined

to ensure

an excellent

sampling

made and

of corrosion

free aluminum

betweendevice

the bushing

the transformer

or metal

cladmachined

SF6 insulated

switchgear.

alloy,

to ensure

an excellent seal

between the bushing and the transformer or metal

clad SF6 insulated switchgear.

Oil sampling device

5

6

Oil sampling device

7

7

8

8

9

9

Active part

10

10

Page 3 / 12

Page 3 / 12

Test tap

Test tap for through life capacitance and

Test tap

tan delta measurement.

Test tap for through life capacitance and

Oil side end

tan delta measurement.

The insulator on the SF6 side is made of an epoxy

Oilresin

sidetube.

end

Oilinsulator

side terminal

The

on the SF6 side is made of an epoxy

resin tube.

Terminal (Al or Cu) for connection

according customer request

OilDimensions

side terminal

Oil side

Terminal

(AlShield

or Cu)(on

forrequest)

connection

Dimensions according customer request

Oil side Shield (on request)

40497285_00

40497285_01

40497285_00

420 243 750

01

02

03

Type SOT

04

06

245 142 505

420 243 695

1250

2500

1250

140 5000

630 1425 1050 1600

265 4000

2500

280 5000

1250

240 4000

680 1550 1175 1600

265 4000

2500

280 5000

750

325

355

170 98

2586 1176 360 1050 ±2 25

650

240 4000

275

Page 4 / 12

130 4000 2012 860 382 770 ±2

-

23

23

25

25

280 5000

25

2586 1176 360 1050 ±2 25

24

23

25

26

99

110 139

40497285_00

24

mm

Page 4 / 12

20 365 640 700 365 640 690

22

2500

265 4000

240 4000

25

21

25 270 400 450 270 535 565

680 1550 1175 1600

1250

23

25 270 400 450 270 535 565

20

280 5000

265 4000

22

20 205 290 335 205 305 335 70

19

2500

20 205 290 335 205 305 335 70

240 4000

20

18

630 1425 1050 1600

1250

20

140 5000

23

23

25

17

2500

L5 L6 L7 L8 D1 D2 D3 D4 D5 D6 D7 D8 D9

130 4000 2012 860 382 770 ±2

25

1600

22

16

460 1050 850

22

120 4000

1325 575 230 520 ±1

15

1250

Mass Approx.

L3

90 4000

70 4000

90 3150

70 3150

90 3150

CT Space L4

14

1600

1250

1325 575 230 520 ±1

70 3150

Rated current (Ir)

L2

1600

1250

70 4000

mm kg

Maximum phase to earth voltage

13

14

16 17 18 19 20 21

Bushing

Dry 15

Power

frequency voltage

withstand (AC)

Transformer Power frequency voltage

withstand (AC)

Lightning Impulse withstand voltage

(BIL)

Switching Impulse withstand voltage

(SIL)

Highest voltage (Um)

27

28

29

30

90

70

115

90

16

12

24

22

16

L1 Cantilever

L2

L3 test

L5load

L6 (min)

L7 L8 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 n1 t1

mm

N

-

120 4000

L1

13

20 365 640 700 365 640 690

420 243 750

1600

90 4000

12

420 243 695

1600

305

90 3150

1600

1600

N

70 3150

L

1250

1250

1250

11

245 142 505

460 1050 850

90 3150

145 84

1600

-

750

70 3150

550

325

1250

230

650

L

255

275

10

123 71

-

mm kg

A

12

550

A

kV

11

230

09

kV

10

kV

08

kV

09

kV

Standard: 100, 300

08

kV

07

kV

07

355

06

kV kV

05

305

05

Highest voltage (Um)

255

Maximum phase to earth voltage

170 98

Bushing Dry Power frequency voltage

withstand (AC)

Transformer Power frequency voltage

withstand (AC)

Lightning Impulse withstand voltage

(BIL)

Switching Impulse withstand voltage

(SIL)

145 84

Rated current (Ir)

123 71

kV

04

CT Space L4

kV kV

03

Mass Approx.

02

Cantilever test load (min)

01

Standard: 100, 300

Type SOT

25

40497285_01

40497285_00

26

27

99

70

110 139

90

32

16

8

20

16

n2 t2

31

34

35

36

4

M12

4

M10

M12

n3 m3 n4 m4

33

08: Other extension current transformer on request

03

04

05

06

Page 5 / 12

21

22

23

24

25

26

27

28

29

30

2586 1176 360 1050 ±2 25

25

20

mm

365 640 700 365 640 690 110 139

16

25

17

25

18

20

19

20

21

L5 L6 L7 L8 D1 D2 D3 D4 D5 D6 D7 D8 D9

365 640 700 365 640 690 110 139

11,12: L1 depends on L4. The values in the table are valid for L4= 100mm. If L4>100mm add L4 to L1 and L.

25

Cantilever test load (min)

22

23

mm

24

40497285_00

90

115

16

24

L5 L6 L7 L8 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 n1 t1

Mass Approx.

L3

CT Space L4

L3

15

Page 5 / 12

20

14

08: Other extension current transformer on request

280 5000

265 4000

240 4000

265 4000

280 5000

265 4000

240 4000

L2

2500

280 5000

2586 1176 360 1050 ±2 25

240 4000

19

Rated current (Ir)

L2

N

1675 1175 1600

240 4000

N

280 5000

L1

13

Comments related to columns :

03: Bushings test voltage at 50Hz 60 sec.

680

550 318 750

265 4000

mm kg

L1

18

Transformer Power frequency voltage

withstand (AC)

Lightning Impulse withstand voltage

(BIL)

Switching Impulse withstand voltage

(SIL)

17

Bushing Dry Power frequency voltage

13withstand

14

15 16

(AC)

L

12

1250

2500

11

2500

1675 1175 1600

Standard: 100, 300

1250

10

1550 1175 1600

2500

L

12

1250

1250

11

1550 1175 1600

A

10

mm kg

kV

09

A

680

Highest voltage (Um)

Maximum phase to earth voltage

09

550 318 750

Maximum phase to earth voltage

Highest voltage (Um)

08

kV

08

680

kV

07

kV

07

680

06

kV kV

02

11,12: L1 depends on L4. The values in the table are valid for L4= 100mm. If L4>100mm add L4 to L1 and L.

01

Comments related to columns :

03: Bushings test voltage at 50Hz 60 sec.

Bushing Dry Power frequency voltage

withstand (AC)

Transformer Power frequency voltage

withstand (AC)

Lightning Impulse withstand voltage

(BIL)

Switching Impulse withstand voltage

(SIL)

550 318 750

Rated current (Ir)

550 318 750

kV

05

CT Space L4

kV

04

Standard: 100, 300

kV kV

03

Mass Approx.

02

Cantilever test load (min)

01

25

26

40497285_01

40497285_00

27

90

32

16

20

n2 t2

31

34

35

36

4

M12

4

M10

n3 m3 n4 m4

33

Dimensional Drawing

Dimensional

Drawing

L3

L3

SF6-Side

SF6-Side

øD4

L

L1

L1

øD1

L4

øD1

L4

L5

L5

L

L2

L2

L6 L6

øD4

Oil-Side

Oil-Side

Page 6 / 12

Page 6 / 12

40497285_00

40497285_01

40497285_00

Dimensional

Drawing

Dimensional

Drawing

SF6 side

SF6 side

Ø D6

Ø D6

Ø D5

Ø D5

0

n3 x M 3

n3 x M 3

Ø D8 0-0.5

Ø D8 -0.5

Ø D7 ± 0.3

Ø D7 ± 0.3

L7

L7

n2 x ø t2

n2 x ø t2

Oil side

Oil side

Ø D3

Ø D2

Ø D3

Ø D2

L8

n1 x ø t1

n1 x ø t1

n4 x M 4

n4 x M 4

Ø D9

Ø D10

Ø D9

L8

Ø D10

Page 7 / 12

Page 7 / 12

40497285_00

40497285_00

40497285_01

Standard

G1/4 Air Outlet

Standard

G1/4 Air Outlet

Flat gasket

Flat gasket

6

6

Test tap (2kV)

Test tap (2kV)

Multiple spring contact

22

Multiple spring contact

O-ring gasket

O-ring gasket

22

Oil sampling device

Oil sampling device

Valve

Valve

Page 8 / 12

Page 8 / 12

40497285_00

40497285_01

40497285_00

On

On request

request

Pressure control

Pressure control

This system

This system

permit to control

permit to control

the pressure

the pressure

inside of the

inside of the

bushing

bushing

Stress shield

Stress shield

Stress shields are also available

Stress shields are also available

with bayonet fixing system and

with bayonet fixing system and

screwed fixing system

screwed fixing system

If you need any Oil / SF6 bushing proven

If you need any Oil / SF6 bushing proven

in operation conditions around the world,

in operation conditions around the world,

Trench has it!

Trench has it!

Page 9 / 12

Page 9 / 12

40497285_00

40497285_01

40497285_00

Technical

Technicaldata

datarequest

request

Mark the requested value…

Mark the requested value…

Um

Um

123kV

123kV

145kV

145kV

170kV

170kV

245kV

245kV

420kV

420kV

550kV

550kV

Other

Other

………………………………………………………………………………………………………………………………………………...

………………………………………………………………………………………………………………………………………………...

Up Transformer

230kV

Up Transformer

230kV

275kV

275kV

325kV

325kV

460kV

460kV

630kV

630kV

680kV

680kV

Other

Other

………………………………………………………………………………………………………………………………………………...

………………………………………………………………………………………………………………………………………………...

BIL

550kV

BIL

550kV

650kV

650kV

750kV

750kV

1050kV

1050kV

1425kV

1425kV

1550kV

1550kV

1675kV

1675kV

Other

Other

………………………………………………………………………………………………………………………………………………...

………………………………………………………………………………………………………………………………………………...

Rated Current

1250A

Rated Current

1250A

1600A

1600A

2500A

2500A

Other

Other

………………………………………………………………………………………………………………………………………………...

………………………………………………………………………………………………………………………………………………...

CT Space

100mm

CT Space

100mm

300mm

300mm

Other

Other

………………………………………………………………………………………………………………………………………………...

………………………………………………………………………………………………………………………………………………...

Terminals Material

Aluminum

Terminals Material

Aluminum

Copper

Copper

Other

Other

………………………………………………………………………………………………………………………………………………...

………………………………………………………………………………………………………………………………………………...

Maximum Oil Temperature

70°

Maximum Oil Temperature

70°

80°

80°

90°

90°

100°

100°

Other

Other

………………………………………………………………………………………………………………………………………………...

………………………………………………………………………………………………………………………………………………...

Bus Duct Temperature

60°

Bus Duct Temperature

60°

70°

70°

80°

80°

Other

Other

Page 10 / 12

40497285_00

40497285_01

Page 10 / 12

40497285_00

Notes:

…………………………………………………………………………………………………………………………………

Notes:

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………

Page 11 / 12

Page 11 / 12

40497285_00

40497285_01

40497285_00

Product Range

Quality

Bushings for

At Trench quality is a way of life.

Trench quality assurance

complies with the most stringent

standards of ISO 9001 and ISO 14001.

• Power Transformers

up to 550 kV, 5000A

• High Current Application

up to 52 kV, 40kA

Certified by AFAQ since 1994

• Transformer to SF6

connection up to 550kV

• Gas-insulated Switchgear

(GIS) up to 800 kV, 6000A

• Generators

up to 36 kV, 50kA

• Railways

• Buildings , Wall

up to 245 kV, 5000A

• Bushings according

Standard IEC 60137

• Bushings according to

customer’s special specification

Trench® France SAS

16, rue du Général Cassagnou

B.P. 80070

F-68302 Saint-Louis Cedex France

Phone : +33 3 89 70 23 23

Fax :

+33 3 89 70 23 59

imprimerie de saint-louis troendlé bieler

40497285_01

www.trenchgroup.com

Sales-bushing.fr@trench-group.com

All rights reserved.

Brands and trademarks used in this document

are the property of Trench®

Subject to change without prior notice.

The information in this document contains general

descriptions of the technical options which are not

necessarily available in every single case. The required

features must therefore be defined in each individual case

when concluding the contract.