Section 400: Architectural Cabinets

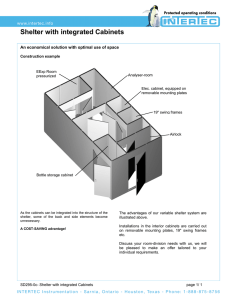

advertisement