Bachelor`s Thesis

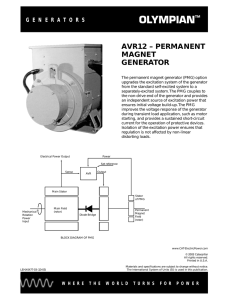

advertisement