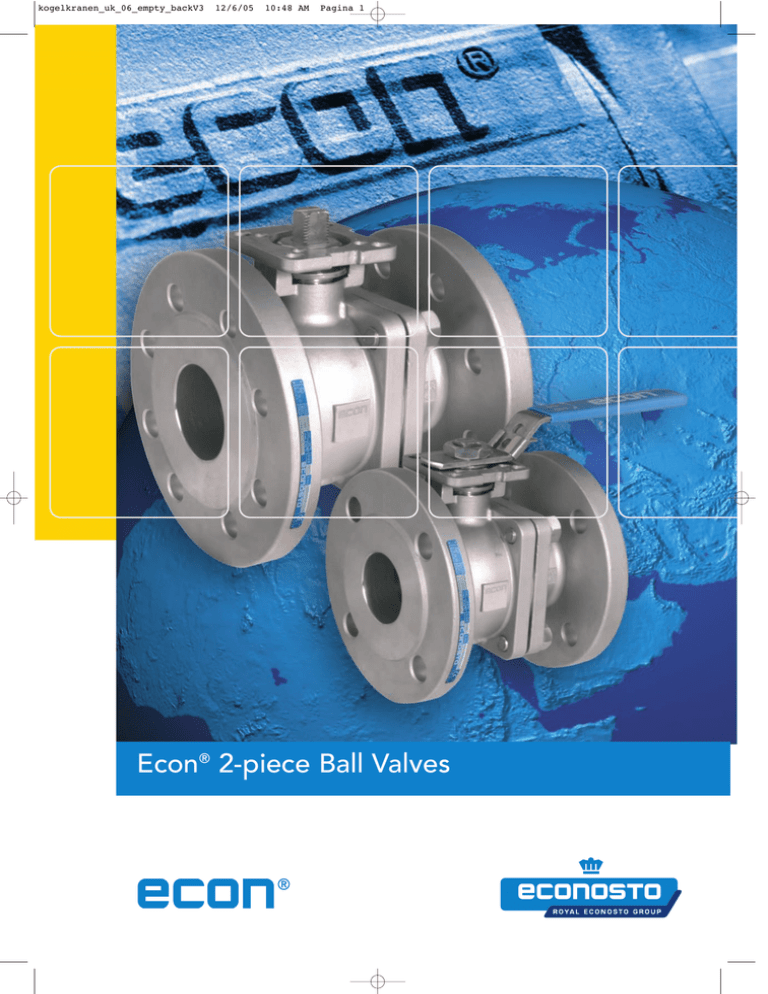

Econ® 2-piece Ball Valves

advertisement

kogelkranen_uk_06_empty_backV3 12/6/05 10:48 AM Pagina 1 Econ® 2-piece Ball Valves kogelkranen_uk_06_empty_backV3 12/6/05 10:48 AM Pagina 2 Econ® 2-piece Ball Valves Ball Valves take a leading role in the valve industry. The scope of applications is enormous, because of the quarter turn construction they are easy to operate and require almost no maintenance. Moreover full bore Ball Valves are ideal for conditions which require maximum flow capacity with minimum pressure drop. Besides these advantages, all Econ® two-piece flanged full bore Ball Valves are fire-safe and TA-Luft certified. The standard ISO Direct Mount feature enables an easy installation of any actuator, even after initial start-up in a manual configuration. Finally, the Econ® label ensures reliability and an excellent price quality ratio. Construction Direct Mount The Ball Valves are of a two piece construction and has a solid full bore ball. Relevant design standards are EN ISO 17292, EN 12516, ASME B16.34 and API 608. Carbon steel (1.0619/ASTM A 216 WCB) and stainless steel (1.4408/ASTM A351 CF8M) are the materials which form the standard supply. Other materials can be supplied upon request. A Direct Mount top-flange according to ISO 5211 is standard(1) for these Ball Valves. This feature makes it possible to mount an actuator without the need of a mounting bracket and drive adapter. This gives a considerable cost reduction, compact automated unit and a higher level of safety for operators. Fire-Safe Ball The Ball Valves are fire-safe certified according to API 607 4th Edition. In the event of fire, a secondary metallic seat prevents leakage through the valve port. A graphoil stem seal and a graphoil spiralwound body gasket ensures tightness through the stem packing and body joints. The highly polished solid ball has a pressure relief hole in the stem slot to equalize the pressure in the body cavity. This ensures a tight shutoff and long service life. TA-Luft Stem Because of the double stem seal construction utilising an O-ring and a spring loaded gland packing the Econ® flanged Ball Valves comply with very strict emission requirements. In this respect they are certified by TA-Luft (VDI 2440, Section 3.3.1.3). The valve stem assembly has a blow-out proof construction and a square(2) top connection. A PTFE thrust washer ensures a smooth operation between body and stem. Materials Anti-static & ATEX The ball-stem connection and the stem-body connection have an antistatic feature, which ensures electrical continuity between those parts. As result the Ball Valves comply with ATEX guidance 94/9/EC (Ex II 2 G-D Ec-c II) for potentially explosive environments. 2 ) ASME 300# 1/2” - 4” has a ISO 5211 top-flange, but not Direct Mount. 1 ) ASME 300# 1/2” - 4” has a double D spindle connection. 2 kogelkranen_uk_06_empty_backV3 12/6/05 10:48 AM Pagina 3 Gland Packing Flanges Two Belleville spring washers ensures optimal sealing performance, also compensating for changing process conditions. Advantages of this feature are an increased operational safety and less maintenance. In accordance with fire-safe requirements, packing material is made of graphoil. In order to comply with the very strict emission requirements for TA-Luft certification, a Viton TM O-ring has been placed under the gland packing. The flanges are in accordance with EN 1092-1 (DIN version) or ASME B16.5 RF (ASME version). Flange facings have a finish to Ra 3.2 - 6.3. Seats A flexible seat design provides tight shut-off at high and low pressures. Relief grooves at the outside of the seat protects the seat from being pushed against the ball by media pressure. This feature reduces wear to a minimum and gives favourable torque figures under various process conditions. Standard seat material is a high grade PTFE; TFM1600. Besides the proven mechanical and chemical properties of PTFE, this chemical reinforced version offers suitability for a wider range of applications in respect to pressure and temperature. Testing The Ball Valves are 100% tight shut-off and are tested in accordance with API598 (ASME) or EN 12266 (DIN). Face to face length The DIN Ball Valves are supplied with a face to face dimension in accordance with EN 558-1,27 (DIN 3202F18) and ASME Valves in accordance with B16.10 long pattern. NACE All stainless steel Econ® Ball Valves comply with NACE MR0175 as standard. On request we can also supply the steel version according to NACE specifications. Finish Castings have a high quality finish (minimum MSSSP112, level 2). Carbon steel Ball Valves have a primer and Blue top coat (RAL 5015). Operation The Ball Valves as standard are supplied with a SS304 handlever (DN15 - DN80) or a T-bar (DN100 - DN150). For DN 200 a gearbox can be supplied. All handlevers are lockable in open or closed position. Where Extra security is required a padlock should be fitted to lock the valve in the open or closed position. Options • Gearbox for all sizes • Manual override (emergency operator), in combination with a pneumatic actuator • Spring return lever • Extended Spindle to clear lagging • Extended bonnet for low temperature applications • Limit switches for remote open/close indication • Electric actuator • Pneumatic actuator • Hydraulic actuator Material and test certificates All Econ® flanged Ball Valves can be supplied with a EN 10204-3.1B test- and material certification. 3 kogelkranen_uk_06_empty_backV3 12/6/05 10:48 AM Pagina 4 Econ® 2-piece Ball Valves Econ® 2-pce full bore Ball Valves Fig. 7249 Fig. 7289 Carbon steel (fig. 7249) and Stainless steel (fig. 7289) Flange connections EN 1092-1 Pressure rating DIN PN16/40 DN 15-200 DIN PN16/40 DN 15-200 Design EN ISO 17292, EN 12516 Face to face length EN 558-1, 27 (short) ISO 5211 Direct Mount API 607 4th Edition Fire-Safe certified TA-Luft (VDI 2440, Sec. 3.3.1.3) certified Anti-static / ATEX 94/9/EC (Ex II 2 G-D EX-c II) 18 17 15 16 13 14 11 12 19 25 20 9 26 22 10 8 6 24 4 2 7 28 1 3 21 5 27 Remarks: - DN 15 - 80 with handlever - DN 100 - 150 with T-bar - Standard spare part kit consists of pos. Nr.: 4, 8, 9 ,10, 11 and 21 - DN 200 is without operator. On request a gearbox can be supplied POS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 4 NAME MATERIAL (Carbon steel) Body 1.0619 Body end 1.0619 Ball 1.4308 4) Seat ring PTFE (TFM1600) Stud 1.7225 (A193-B7) Stem 1.4301 4) Anti-static device 1.4301 Thrust washer PTFE O-ring VITON (FKM) Glandpacking GRAFOIL Bush 1.4301 Gland 1.4401 Belleville washer 1.4310 Nut 1.4301 (A194-8) 2) Spiralwound 1) DN100 - 150 MATERIAL (Stainless steel) 1.4408 1.4408 1.4408 PTFE (TFM1600) 1.4301 (A193-B8) 1.4401 1.4401 PTFE VITON (FKM) GRAFOIL 1.4301 1.4401 1.4310 1.4301 (A194-8) 3) Zinc plated MATERIAL MATERIAL (Carbon steel) (Stainless steel) 1.4301 1.4301 15 Lock plate 1.4301 1.4301 16 Ring 1.4301 (A194-8) 1.4301 (A194-8) 17 Nut Plastic Plastic 18 Sleeve 1.4301 1.4301 19 Handlever 1.4301 1.4301 20 Locking device 1.4401 2) 1.4401 2) 21 Body gasket 1.4301 (A193-B8) 1.4301 (A193-B8) 22 Cap screw 1.4301 (A194-8) 23 Nut 1.4301 (A194-8) 1.4301 24 Stop plate 1.4301 1.4308 25 T-bar support 1.4308 St. A53 3) 26 T-bar 1) St. A53 3) 27 Nut 1.0503 (A194-2H) 1.4301 (A194-8) 28 Name plate 1.4301 1.4301 4) Upon request also available with 1.4408 ball and 1.4401 stem POS NAME kogelkranen_uk_06_empty_backV3 12/6/05 10:48 AM Pagina 5 Seat rating Carbon steel DN 15 - 50 50 Pressure in bar Pressure in bar Pressure/temperature rating 60 DN 65 - 100 DN 125 - 200 60 Seat rating 50 40 30 30 Body rating PN 40 DN 65 - 100 DN 125 - 200 40 20 Body rating PN 40 20 10 Stainless steel DN 15 - 50 10 Body rating PN 16 Body rating PN 16 0 0 -30 0 50 100 150 200 230 250 -30 0 50 100 150 Temperature ºC 200 230 250 Temperature ºC M ØN2 F ØN1 H1 E H Ød 4 x ØO2 4 x ØO1 ØA DN 100 - 150 with T-bar T L1 L DN Ød 15 20 25 32 40 50 65 80 100 125 150 200 15 20 25 32 38 50 63 76 100 125 150 200 ØA PN16 95 105 115 140 150 165 185 200 220 250 285 340 ØA PN40 95 105 115 140 150 165 185 200 235 270 300 375 #E F 9 9 11 11 14 14 17 17 22 27 27 27 9 9 11 11 14 14 17 17 22 27 27 27 H 48,0 53,0 58,5 71,0 76,0 85,0 101,5 111,5 140,0 183,0 202,0 252,5 H1 79,0 84,0 90,5 103,0 111,0 120,0 150,0 160,0 182,0 260,0 280,0 279,5 L 115 120 125 130 140 150 170 180 190 325 350 400 L1 PN16 49,5 54,0 56,0 57,4 58,0 63,0 69,0 74,5 83,0 153,0 162,0 191,0 L1 PN40 49,5 54,0 56,0 57,4 58,0 63,0 64,0 69,5 78,0 160,0 176,0 221,0 M Ø N1 Ø N2 Ø O1 Ø O2 145 145 175 175 194 194 265 265 400 600 800 - 36 36 42 42 50 50 70 70 - 42 42 50 50 70 70 102 102 102 125 125 125 6 6 6 6 7 7 9 9 - 6 6 7 7 9 9 11 11 11 14 14 14 T PN16 16 18 18 18 18 20 18 20 20 22 22 24 T PN40 16 18 18 18 18 20 22 24 24 26 28 34 m[kg] PN16 13,8 17,7 25,2 60,0 71,8 127,0 m[kg] PN40 2,4 3,2 4,2 5,5 6,9 9,5 13,8 17,8 30,5 62,5 73,8 152,0 5 kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 6 Econ® 2-piece Ball Valves Econ® 2-pce full bore Ball Valves Fig. 7245 Fig. 7285 Carbon steel (fig. 7245) and Stainless steel (fig. 7285) Flange connections ASME B16.5 RF Pressure rating ASME 150# DN 1/2" - 8" ASME 150# 1/2” - 8” Design ASME B16.34, API 608 Face to face length ASME B16.10 long pattern ISO 5211 Direct Mount API 607 4th Edition Fire-Safe certified TA-Luft (VDI 2440, Sec. 3.3.1.3) certified Anti-static / ATEX 94/9/EC (Ex II 2 G-D EX-c II) 18 17 15 16 13 14 11 12 19 25 20 9 26 22 10 8 6 24 4 2 7 28 1 3 21 5 27 Remarks: - Sizes 1/2" - 3" with handlever - Sizes 4" - 6" with T-bar - Standard spare part kit consists of pos. Nr.: 4, 8, 9 ,10, 11 and 21 - Size 8" is without operator. On request a gearbox can be supplied POS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 6 NAME Body Body end Ball Seat ring Stud Stem Anti-static device Thrust washer O-ring Glandpacking Bush Gland Belleville washer Nut 1) 4" - 6" MATERIAL (Carbon steel) A216-WCB A216-WCB A351-CF8 4) PTFE (TFM1600) A193-B7 A276-304 4) AISI 304 PTFE VITON(FKM) GRAFOIL AISI 304 AISI 316 AISI 301 A194-8 2) Spiralwound MATERIAL (Stainless steel) A351-CF8M A351-CF8M A351-CF8M PTFE (TFM1600) A193-B8 A276-316 AISI 316 PTFE VITON(FKM) GRAFOIL AISI 304 AISI 316 AISI 301 A194-8 3) Zinc plated MATERIAL MATERIAL (Carbon steel) (Stainless steel) AISI 304 AISI 304 15 Lock plate AISI 304 AISI 304 16 Ring A194-8 A194-8 17 Nut Plastic Plastic 18 Sleeve AISI 304 AISI 304 19 Handlever AISI 304 AISI 304 20 Locking device AISI 316 2) AISI 316 2) 21 Body gasket 22 Cap screw A193-B8 A193-B8 23 Nut A194-8 A194-8 24 Stop plate AISI 304 AISI 304 25 T-bar support A351-CF8 A351-CF8 26 T-bar 1) St. A53 3) St. A53 3) 27 Nut A194-2H A194-8 28 Name plate AISI 304 AISI 304 4) Upon request also available with A351-CF8M ball and A276-316 stem POS NAME kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 7 25 Seat rating Carbon steel ½ " - 2" 2½" - 4" 20 Pressure in bar Pressure in bar Pressure/temperature rating 5" - 8" 25 Seat rating Stainless steel ½" - 2" 2½" - 4" 20 5" - 8" 15 15 10 10 5 5 Body rating 150# Body rating 150# 0 0 -29 0 38 93 149 200 230 260 -29 0 38 93 149 200 Temperature ˚C 230 260 Temperature ºC M ØN2 F ØN1 H1 E H Ød ØA 4 x ØO2 4 x ØO1 4" - 6" with T-bar T L1 L DN ½" ¾" 1" 1¼" 1½" 2" 2½" 3" 4" 5" 6" 8" Ød 15,0 20,0 25,0 32,0 38,0 50,0 63,5 76,0 100,0 125,0 150,0 200,0 ØA 89,0 98,6 108,0 117,0 127,0 152,5 177,8 190,5 228,6 254,0 279,4 342,9 #E 9 9 11 11 14 14 17 17 22 27 27 27 F 9 11 11 14 14 17 17 22 27 27 27 H 48,0 53,0 58,5 71,0 76,0 81,0 101,5 111,5 140,0 183,0 202,0 252,5 H1 79,0 84,0 90,5 103,0 111,0 116,0 150,0 160,0 182,0 260,0 280,0 279,5 L 108 117 127 140 165 178 190 203 229 356 394 457 L1 45,5 50,0 54,0 62,4 64,0 78,0 85,0 91,5 108,0 153,0 162,0 191,0 M 145 145 175 175 194 194 265 265 400 600 800 - Ø N1 Ø N2 Ø O1 Ø O2 36 36 42 42 50 50 70 70 - 42 50 50 70 70 70 102 102 102 125 125 125 6 6 6 6 7 7 9 9 - 6 7 7 9 9 9 11 11 11 14 14 14 T 9,7 10,5 11,2 12,7 14,2 15,9 17,5 19,1 23,9 24,0 25,4 28,5 m[kg] 1,7 2,2 2,9 3,9 5,9 8,4 13,4 17,8 30,5 53,5 72,0 131,4 7 kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 8 Econ® 2-piece Ball Valves Econ® 2-pce full bore Ball Valves Fig. 7257 Fig. 7297 Carbon steel (fig. 7257) and Stainless steel (fig. 7297) Flange connections ASME B16.5 RF Pressure rating ASME 300# DN 1/2" - 4" ASME 300# 1/2” - 4” Design ASME B16.34, API 608 Face to face length ASME B16.10 long pattern ISO 5211 top-flange API 607 4th Edition Fire-Safe certified TA-Luft (VDI 2440, Sec. 3.3.1.3) certified Anti-static / ATEX 94/9/EC (Ex II 2 G-D EX-c II) 18 17 15 19 13 14 11 12 25 20 9 26 22 10 8 6 24 4 2 7 28 1 3 21 5 27 Remarks: - Sizes 1/2" - 3" with handlever - Size 4" with T-bar - Standard spare part kit consists of pos. Nr.: 4, 8, 9 ,10, 11 and 21 POS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 8 NAME Body Body end Ball Seat ring Stud Stem Anti-static device Thrust washer O-ring Glandpacking Bush Gland Belleville washer Nut 1) 4" MATERIAL (Carbon steel) A216-WCB A216-WCB A351-CF8 4) PTFE (TFM1600) A193-B7 A276-304 4) AISI 304 PTFE VITON(FKM) GRAFOIL AISI 304 AISI 316 AISI 301 A194-8 2) Spiralwound MATERIAL (Stainless steel) A351-CF8M A351-CF8M A351-CF8M PTFE (TFM1600) A193-B8 A276-316 AISI 316 PTFE VITON(FKM) GRAFOIL AISI 304 AISI 316 AISI 301 A194-8 3) Zinc plated POS 15 17 18 19 20 21 22 23 24 25 26 27 28 4) Upon NAME Lock plate Nut Sleeve Handlever Locking device Body gasket Cap screw Nut Stop plate T-bar support T-bar 1) Nut Name plate MATERIAL (Carbon steel) AISI 304 A194-8 Plastic AISI 304 AISI 304 AISI 316 2) A193-B8 A194-8 AISI 304 A351-CF8 St. A53 3) A194-2H AISI 304 MATERIAL (Stainless steel) AISI 304 A194-8 Plastic AISI 304 AISI 304 AISI 316 2) A193-B8 A194-8 AISI 304 A351-CF8 St. A53 3) A194-8 AISI 304 request also available with A351-CF8M ball and A276-316 stem kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 9 60 Seat rating ½" - 2" 50 2½" - 4" Pressure in bar Pressure in bar Pressure/temperature rating Carbon steel 60 Stainless steel ½" - 2" 50 40 40 30 30 20 20 10 Seat rating 2½" - 4" 10 Body rating 300# Body rating 300# 0 0 -29 0 38 93 149 200 230 -29 260 0 38 93 149 Temperature ºC 200 230 260 Temperature ºC M ØN F E H1 H 4 x ØO Ød ØA G L1 F 4" with T-bar T L DN ½" ¾" 1" 1¼" 1½" 2" 2½" 3" 4" Ød 15,0 20,0 25,0 32,0 38,0 50,0 63,5 76,0 100,0 ØA 95,3 117,4 124,0 133,4 155,5 165,1 190,5 209,5 254,0 #E 6,3 6,3 9,0 9,0 9,6 9,6 16,0 16,0 18,0 F 20,0 20,0 24,0 24,0 27,0 27,0 42,5 42,5 47,5 G 10,0 10,0 11,0 11,0 16,0 16,0 21,0 21,0 25,0 H 37,0 40,5 45,5 50,0 62,0 71,0 89,0 100,0 120,0 H1 86 90 96 102 114 127 177 183 209 L 140 152 165 178 190 216 241 282 305 L1 61,5 67,5 73,0 77,4 77,0 97,0 111,0 132,0 146,0 M 135 135 170 170 200 200 250 250 400 ØN ØO 42 50 50 70 70 70 102 102 102 6 7 7 9 9 9 11 11 11 T 14,3 15,9 17,5 19,1 20,7 22,3 25,4 28,6 31,8 m[kg] 2,4 3,2 4,2 5,5 6,9 9,5 13,8 17,7 25,2 9 kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 10 Econ® 2-piece Ball Valves Econ® 2-pce full bore Ball Valves Fig. 7257 Fig. 7297 Carbon steel (fig. 7257) and Stainless steel (fig. 7297) Flange connections ASME B16.5 RF Pressure rating ASME 300# DN 5" - 8" ASME 300# 5” - 8” Design ASME B16.34, API 608 Face to face length ASME B16.10 long pattern ISO 5211 Direct Mount API 607 4th Edition Fire-Safe certified TA-Luft (VDI 2440, Sec. 3.3.1.3) certified Anti-static / ATEX 94/9/EC (Ex II 2 G-D EX-c II) 15 16 13 14 11 12 25 9 26 22 10 8 24 6 4 2 7 28 1 3 21 5 27 Remarks: - Sizes 5" - 6" with T-bar - Standard spare part kit consists of pos. Nr.: 4, 8, 9 ,10, 11 and 21 - Size 8" is without operator. On request a gearbox can be supplied POS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 10 NAME Body Body end Ball Seat ring Stud Stem Anti-static device Thrust washer O-ring Glandpacking Bush Gland Belleville washer Nut 1) 5" - 6" MATERIAL (Carbon steel) A216-WCB A216-WCB A351-CF8 4) PTFE (TFM1600) A193-B7 A276-304 4) AISI 304 PTFE VITON (FKM) GRAFOIL AISI 304 AISI 316 AISI 301 A194-8 2) Spiralwound MATERIAL (Stainless steel) A351-CF8M A351-CF8M A351-CF8M PTFE (TFM1600) A193-B8 A276-316 AISI 316 PTFE VITON (FKM) GRAFOIL AISI 304 AISI 316 AISI 301 A194-8 3) Zinc plated POS 15 16 21 22 23 24 25 26 27 28 4) Upon NAME Lock plate Ring Body gasket Cap screw Nut Stop plate T-bar support T-bar 1) Nut Name plate MATERIAL (Carbon steel) AISI 304 AISI 304 AISI 316 2) A193-B8 A194-8 AISI 304 A351-CF8 St. A53 3) A194-2H AISI 304 MATERIAL (Stainless steel) AISI 304 AISI 304 AISI 316 2) A193-B8 A194-8 AISI 304 A351-CF8 St. A53 3) A194-8 AISI 304 request also available with A351-CF8M ball and A276-316 stem kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 11 Seat rating Pressure in bar Pressure in bar Pressure/temperature rating 60 Carbon steel 5" - 8" 50 60 Seat rating Stainless steel 5" - 8" 50 40 40 30 30 20 20 10 10 Body rating 300# 0 -29 0 Body rating 300# 0 38 93 149 200 230 -29 260 0 38 93 149 200 Temperature ºC 230 260 TemperatureºC F ØN2 H1 ØN1 H E Ød ØA 4 X ØO2 4 X ØO1 T L1 L DN 5" 6" 8" Ød 125 150 200 ØA 279,4 317,5 381,0 #E 27 27 27 F 27 27 27 H 183,0 202,0 252,5 H1 260,0 280,0 279,5 L 381 403 502 L1 160 176 221 M 600,0 800,0 - Ø N1 Ø N2 Ø O1 Ø O2 - 125 125 125 - 14 14 14 T 35,0 36,6 41,2 m[kg] 60,0 73,8 171,0 11 kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 12 Econ® 2-piece Ball Valves Automated Ball Valves Ball Valves can be used for open/close purposes only (not for regulating purposes). Because of the quarter turn construction Ball Valves are perfectly suited to automated processes. A great advantage of the Econ® two-piece flanged Ball Valves is the standard(1) Direct Mount top-flange according to ISO 5211 which enables direct mounting of an actuator - without mounting bracket and drive adapter - on top of the valve. This results in a considerable cost saving, a compact automated unit and a higher level of safety for operators. If required, the use of a mounting bracket is still possible. ) ASME 300# 1/2" - 4" has a ISO 5211 top-flange, but not Direct Mount 1 12 kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 13 Double acting pneumatic actuator • • • • • Compact Suitable for high duty cycles Fast opening and closing times Few moving parts: increases operational safety Modular design for easy mounting of accessories, like limit switches, (NAMUR) solenoid valves and bus communication systems • Can be combined with emergency operation (manual gearbox) • ISO 5211 mounting flange Single acting pneumatic actuator • Compact • Fail-safe function can easily be realized in spring closing or spring opening configuration • Suitable for high duty cycles • Fast opening and closing times • Few moving parts: increases operational safety • Modular design for easy mounting of accessories, like limit switches, (NAMUR) solenoid valves and bus communication systems • Can be combined with emergency operation (manual gearbox) • ISO 5211 mounting flange Electric actuator • Compact • Wide range of voltage options, not depended from availability of compressed air: large scope of applications • Quiet operation (open/close) prevents water hammering • Low noise • Self-locking reduction gear • Usual required options, like limit switches, visual open/close indication and even a emergency handwheel operator are often standard integrated in the actuator • ISO 5211 mounting flange Hydraulic actuator • • • • Extremely compact Heavy duty High operational safety Modular design for easy mounting of accessories, like limit switches or visual open/close indication • Suitable for submerged purposes (IP68) as option • ISO 5211 mounting flange 13 kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 14 Econ® 2-piece Ball Valves Torque values 1000 426 391 357 322 150 184 100 4" 107 80 3" 79 65 2½" 40 50 2" 28 40 1½" 20 32 1¼" 14 25 1" 7 6 20 15 3/4" 1/2" 64 52 23 12 6 0 Bar 13 12 7 7 6 17 15 15 10 25 23 23 15 12 37 33 30 30 7 7 6 6 5 10 20 30 40 75 150 300 450 600 PSI 0 Bar 50 PSI 750 Size Inch 46 46 Torque values in Nm 93 83 75 75 0 6" 5" 129 115 115 8" 150 125 Size DN 100 200 467 368 334 242 219 219 610 Torque values in Nm 322 558 495 426 Notes: • Break-away torque from close to open = 100% • Break-away torque from open to close = 70% • Running torque = 40% • Closing torque = 65% Example: (20 bar and 4") • Break-away torque from close to open 150Nm • Break-away torque from open to close 105Nm • Running torque 60Nm • Closing torque 98Nm Recommended safety margin is 40% at "normal" conditions (example: fluids -20°C tot 100°C) Recommended safety for actuator sizing incl. safety margin is 1.4 x 150 = 210Nm Consult Econosto for specific applications Kv and CV values DN 15 20 25 32 40 50 14 Kv 26 43 81 121 225 415 Inch ½ ¾ 1 1¼ 1½ 2 Cv 30 50 94 140 260 480 DN 65 80 100 125 150 200 Kv 649 1125 1990 3201 4671 8651 Inch 2½ 3 4 5 6 8 Cv 750 1300 2300 3700 5400 10000 Remarks Kv is the capacity in m3/h for water 20°C at a differential pressure of 1 bar. Cv is the capacity in US gallon per minute for water 60°F at a differential pressure of 1 psi. The Kv and Cv values are valid in fully opened position only. kogelkranen_uk_06_empty_backV3 12/6/05 10:49 AM Pagina 15 Options Gearbox Extended spindle • Visual open/close indication • Mechanical end stops for open/close position • ISO 5211 mounting flange • To clear Pipe Lagging • Standard length 100 mm Spring return handlever Extended bonnet for low temperature applications • Suitable for fail-safe applications • Suitable for cold media (< -30°C) Marking All Ball Valves have a nameplate, which shows the pressure class, size, materials, temperature range, ATEX group/category and serial number. Installation For protection purposes, all Econ® Ball Valves are supplied in open position and fitted with plastic flange covers. Automated Ball Valves are supplied in fail safe position. The flange covers should not be removed until the Ball Valve is being installed. During installation, Ball Valve should remain in open position. To prevent unnecessary damage, Econosto advises to flush the piping system prior to operation of the Ball Valve. Extended installation instructions can be found in the IOM (Installation & Operation Manual). Disclaimer The text, illustrations and technical data in this brochure have been compiled with great care. Responsibility is neither claimed nor accepted by Econosto for any possible errors or inaccuracies. 15