16506-1 11/13 SECTION 16506 LIGHTING OCCUPANCY

advertisement

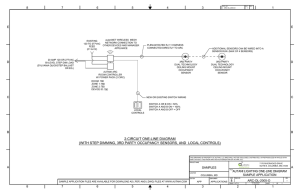

SECTION 16506 LIGHTING OCCUPANCY SENSORS PART 1 - GENERAL 1.01 REQUIREMENTS A. 1.02 1.03 1.04 The general provisions of the Contract, including General and Supplementary Conditions and General Requirements, apply to the work specified in this Section. SCOPE A. The work covered under this Section shall include furnishing and installing a complete operational occupancy sensor based lighting control system as shown on the Drawings, detailed in the manufacturer’s submittal and as herein specified. B. Work described in this section shall be coordinated with all applicable plans and specifications, including by not limited to interfacing with microprocessor based Lighting Control Systems, wiring, raceways, boxes and fittings, luminaires, and HAVC systems. QUALITY ASSURANCE A. Occupancy sensors shall conform to the requirements of the National Electrical Code (NEC), state and local codes, and these Specifications. B. All components shall be listed by Underwriter's Laboratories, Inc. (UL) for their intended use and shall bear the UL label. C. Products supplied shall be from a single manufacturer that has been continuously involved in manufacturing of occupancy sensors for a minimum of five (5) years. Mixing of manufacturers shall not be allowed. D. Products shall be manufactured by an ISO 9002 certified manufacturing facility and shall have a defect rating of less than 1/3 of 1%. E. Wall switch products must be capable of withstanding the effects of inrush current. Submittals shall clearly indicate the method used. SUBMITTALS A. Submittals are required in accordance with SECTION 16010 of these specifications. Submittals shall include, but not be limited to the following for 16506-1 11/13 LIGHTING OCCUPANCY SENSORS SECTION 16506 review. Submittals not containing all of the information listed below will be rejected. 1.05 1.06 1. Manufacturers shall substantiate conformance to this specification by providing the necessary documents, performance data and wiring diagrams. Any deviations to the specifications must be clearly stated by letter and submitted. 2. Submit a scaled building lighting plan (minimum size of 1/16” = 1’-0”) clearly marked by the manufacturer showing proper product, location and orientation of each sensor and power pack (switch pack). Plans shall show detection coverage patterns. If necessary for clarity, provide a 1/8” = 1’-0” scaled plan or one plan with coverage areas shown and another plan with the other information shown. Illegible drawings will be rejected. 3. Submit interconnections diagrams per major subsystem and interfacing with Lighting Control Panels (LCP) [Refer to SECTION 16505], showing proper wiring. 4. Submit standard catalog literature which includes specifications indicating compliance to the specification. 5. Catalog sheets must clearly state any load restrictions when used with electronic ballasts. performance SYSTEM DESCRIPTION A. The objective of this specification section is to ensure the proper installation of the occupancy sensor based lighting control system so that lighting is turned off automatically after reasonable time delay when a room or area is vacated by the last person to occupy said room or area. B. The occupancy sensor based lighting control shall accommodate all conditions of space utilization and irregular work hours and habits. SYSTEM TEST AND ACCEPTANCE A. Prior to the Architect/Engineer’s final site visitation, and acceptance of each construction phase, this Contractor shall conduct a complete operation test of each system including each device. The systems shall test free from grounds, shorts, and other faults. All connections shall be thoroughly checked for mechanical and electrical connection. All equipment shall be demonstrated to operate in accordance with the requirements set forth in these Specifications and as shown on the Drawings. B. This Contractor shall perform all tests in the presence of the Owner. This 16506-2 11/13 LIGHTING OCCUPANCY SENSORS SECTION 16506 Contractor shall furnish all personnel for use in the tests. C. 1.07 Training A. 1.08 When the work on the system has been completed and is ready for final review, a visit shall be made by the Owner at which time the Contractor shall demonstrate that the requirements of the Contract as it applies to this system have been carried out and that the system has been adjusted and operated in accordance herewith. Upon completion of the project, the Contractor and manufacturer’s factory authorized representative shall provide a minimum of four (4) hours of training to familiarize the Owner with the operation, use, adjustment, and problem solving diagnosis of the occupancy sensing devices and systems. WARRANTY A. This Contractor shall warrant all equipment furnished in accordance with this specification to be undamaged, free of defects in materials and workmanship, and in conformance with these specifications. The warranty shall include repair or replacement, and testing without charge to the Owner on all or any parts of equipment which are found to be damaged, defective or non-conforming. There shall be no deductibles applied to such warranty. Satisfactory warranty documents shall be furnished. Refer to SECTION 01740 WARRANTIES AND BONDS. PART 2 - PRODUCTS 2.01 2.02 MANUFACTURERS A. The lighting occupancy sensors shall be manufactured by THE WATT STOPPER, as listed or equal by GREENGATE (COOPER CONTROLS), HUBBELL, or SENSOR SWITCH. B. The listing of any manufacturer as “equal” does not imply automatic approval. This Contractor shall ensure submittals made are for sensors and associated equipment which meets or exceeds the specifications included herein. LIGHTING OCCUPANCY SENSORS A. Occupancy sensors shall consist of, but not be limited to the following: 1. Sensing technology shall be passive infrared (PIR), ultrasonic (or microphonics™), dual technology having both PIR and ultrasonic (or microphonics™). 16506-3 11/13 LIGHTING OCCUPANCY SENSORS B. SECTION 16506 2. Passive infrared sensors shall provide high immunity to false triggering form RFI (hand-held radios) and EMI (electrical noise in the line). The PIR sensors shall have a multiple segmented Fresnel lens, in multi-tier configuration, with grooves-in to eliminate dust and residue build-up. 3. Ultrasonic sensors shall be able to adjust the detection threshold dynamically to compensate for constantly changing levels of activity and air flow throughout controlled spaces. Ultrasonic operating frequency shall be crystal controlled at 32 kHz within + 0.002% tolerance, or 40 kHz within + 0.002% tolerance to assure reliable performance and eliminate sensor cross-talk. Sensors using multiple frequencies are not acceptable. Microphonic™ sensors shall be able to operate within set tolerances that will mimic ultrasonic to ensure reliable performance. 4. Dual technology sensors shall consist of PIR and ultrasonic (or microphonics™) technologies for occupancy detection. 5. All sensors shall be capable of operating normally with electronic ballasts, PL lamp systems and rated motor loads. 6. Coverage of sensors shall remain constant after sensitivity control has been set. No automatic reduction shall occur in coverage due to the cycling of air conditioner or heating fans. 7. All sensors shall have readily accessible, user adjustable settings for time delay and sensitivity. Settings shall be located on the sensor (not the control unit) and shall be recessed to limit tampering. 8. In the event of failure, a bypass manual override shall be provided on each sensor. When bypass is utilized, lighting shall remain on constantly or control shall divert to a wall switch or lighting control panel until the sensor is replaced. This control shall be recessed to prevent tampering. 9. All sensors shall provide an LED as a visual means of indication at all times to verify that motion is being detected during both testing and normal operation. Ceiling mounted room occupancy sensors shall be low voltage dual technology type consisting of passive infrared (PIR) and ultrasonic (or microphonics™) technologies with 360° coverage for large classrooms, open office spaces or areas up to 1600 square feet; WATT STOPPER Model DT-300. Sensors shall operate on 12 to 24 VAC or VDC and NEC Class 2 wiring. Each sensor shall be complete with one (1) power pack or two (2) power packs for rooms requiring two (2) lighting branch circuits. Rooms requiring multiple sensors may only require one (1) power pack for multiple sensors, where shown on the Drawings. Sensors shall also be equipped with an additional isolated relay. 16506-4 11/13 LIGHTING OCCUPANCY SENSORS 1. C. SECTION 16506 Occupancy sensors shown on the Drawings to be powered from a Lighting Control Panel generally will not require a power pack. Ceiling mounted (or wall mounted where shown on the Drawings) room occupancy sensors shall be low voltage dual technology type consisting of passive infrared (PIR) and ultrasonic (or microphonics™) technologies for directional one-way coverage for classrooms, offices or areas up to 1000 square feet; WATT STOPPER Model DT-200. Sensors shall operate on 12 to 24 VAC or VDC and NEC Class 2 wiring. Each sensor shall be complete with one (1) power pack or two (2) power packs for rooms requiring two (2) lighting branch circuits. Rooms requiring multiple sensors may only require one (1) power pack for multiple sensors, where shown on the Drawings. Sensors shall also be equipped with an additional isolated relay. 1. Occupancy sensors shown on the Drawings to be powered from a Lighting Control Panel generally will not require a power pack. D. Corridor ceiling mounted occupancy sensors shall be low voltage ultrasonic (or microphonics™) technology type with coverage of approximately ten (10) feet by ninety (90) linear feet; WATT STOPPER Model WT-2250. Corridor lobbies or areas wider than ten (10) feet shall have ceiling mounted low voltage ultrasonic technology type sensors with 360° coverage of approximately 2200 square feet; WATT STOPPER Model WT-2200. Sensors shall operate on 12 to 24 VAC or VDC and NEC Class 2 wiring. Sensors shall be powered from a lighting control panel or power pack and/or as shown on the Drawings. Sensors shall also be equipped with an additional isolated relay. E. Wall switch occupancy sensors shall be line voltage ultrasonic (or microphonics™) technology type with coverage of approximately 30 to 40 square feet for use in small utility/storage rooms, small toilet rooms, etc. as shown on the Drawings; WATT STOPPER Model UW-100. Sensors shall operate on 120 or 277 volts. Load rating shall be 0 to 800 watts ballast or tungsten at 120 volts and 0 to 1200 watts ballast at 277 volts. Sensor shall use zero-cross circuitry to detect when the sine wave crosses at the “zero-point” so as to minimize wear on the switching contact. 1. F. Wall switch occupancy sensors shall have stainless steel cover plates, not the plastic cover plates that may be included in the switch packaging. See Specification Section 16130 for type. Wall switch occupancy sensors, with dual ON/OFF button switches and dual relays for controlling two lighting loads or circuits, shall be line voltage ultrasonic (or microphonics™) technology type with coverage of approximately 30 to 40 square feet for use in small utility/storage rooms, small toilet rooms, etc. as shown on the Drawings; WATT STOPPER Model UW-200. Sensors shall 16506-5 11/13 LIGHTING OCCUPANCY SENSORS SECTION 16506 operate on 120 or 277 volts. Load rating shall be 0 to 800 watts ballast or tungsten at 120 volts and 0 to 1200 watts ballast at 277 volts. Sensor shall use zero-cross circuitry on both relays to detect when the sine wave crosses at the “zero-point” so as to minimize wear on the switching contact. 1. 2.03 2.04 Wall switch occupancy sensors shall have stainless steel cover plates, not the plastic cover plates that may be included in the switch packaging. See Specification Section 16130 for type. POWER PACKS AND AUXILIARY RELAY PACKS CONTROL UNITS A. Power packs shall accept 120 or 277 volts, be plenum rated, and provide Class 2 power to a minimum of two (2) occupancy sensors. Power packs shall be able to externally mount through a 1/2” knock-out on a standard electrical enclosure (junction box) and be an integrated, self-contained unit consisting internally of an isolated load switching control relay (load rated 20 amperes at 120 or 277 volts) and a transformer to provide low voltage power; WATT STOPPER Model BZ100. Power pack shall provide a minimum of 150mA at 24 VDC to drive occupancy sensors and auxiliary relay packs. B. Power packs shall use zero-cross circuitry to detect when the sine wave crosses at the “zero-point” so as to minimize wear on the switching contact. C. Auxiliary relay packs shall be the same self-contained type unit as the power pack hereinbefore described, except shall not include a transformer; WATT STOPPER Model S120/277/347E-P. The auxiliary relay pack shall be used to control another lighting load with a different line voltage than the power pack. Auxiliary relay packs shall be powered from a power pack with 24 VDC. ISOLATED RELAY A. Sensors hereinbefore described to include an isolated relay shall have the relay be internal with Normally Open, Normally Closed and Common outputs for use with Lighting Control Panels (LCP), HVAC control, and other control options as shown on the Drawings. Sensors utilizing separate components or specially modified units to achieve this function shall not be acceptable. B. Corridor and other location occupancy sensors indicated on the Drawings to interface with a Lighting Control Panel (LCP) shall have the isolated relay send a contact closure signal to the Lighting Control System. These sensors shall be powered from the LCP and not by a power pack. Operation of sensors in corridors and other areas where sensors are interfaced with the lighting control system shall operate in a manner such the lighting in the controlled areas is “held-on” during normal school operating hours. After normal schools hours, these controlled areas shall respond to the occupancy sensors for lighting control. See the Drawings and details for the sequence of operations via the 16506-6 11/13 LIGHTING OCCUPANCY SENSORS SECTION 16506 LCP. 2.05 WIRING A. Low voltage wiring between occupancy sensors and power packs shall be three (3) conductor, No. 18 AWG, unshielded, plenum rated with a temperature range for dry locations of minus ten (10) degrees C to sixty (60) degrees C. A cable that will meet this specification is WEST PENN Cat. No. 25234B. B. Low voltage wiring between occupancy sensors and Lighting Control Panels (LCP) shall be three (3) conductor, No. 18 AWG, unshielded, plenum rated with a temperature range for dry locations of minus ten (10) degrees C to sixty (60) degrees C. A cable that will meet this specification is WEST PENN Cat. No. 25234B. PART 3 - EXECUTION 3.01 INSTALLATION A. It shall be the Contractor’s responsibility to provide the quantity of occupancy sensors required for complete and proper volumetric coverage to completely cover the controlled areas. Rooms shall have ninety (90) to one hundred (100) percent volumetric coverage to completely cover the controlled areas to accommodate all occupancy habits of single or multiple occupants at any location within the rooms. Proper judgment must be exercised in executing the work so as to ensure the best possible installation in the available space and to overcome local difficulties due to space limitations, interference of structural components, or furnishings in the rooms or spaces. The locations and quantities of sensors shown on the Drawings are based on coverage patterns of THE WATT STOPPER sensors. Sensors of other approved manufacturers may require different quantities of sensors for full coverage of spaces being controlled. The sensors shown on the drawings are diagrammatic and do not necessarily show the exact locations of the sensors. This contractor shall confirm with the occupancy sensors manufacturer the exact quantities of sensors and power packs at time of bid. This Contractor shall provide additional sensors if required to properly and completely cover the respective rooms at no additional cost to the Owner. B. Line voltage wall switch type occupancy sensors shall be installed in a suitable wall outlet box in a method recommended by the equipment manufacturer similar to a standard line voltage light switch. C. Low voltage occupancy sensors shall be securely mounted to a ceiling or wall mounted junction box in a method recommended by the sensor manufacturer. Ceiling mounted junction boxes shall be supported from the building structure with no less than one (1) ¼” threaded rod. Sensors shall be wired as detailed on 16506-7 11/13 LIGHTING OCCUPANCY SENSORS SECTION 16506 the Drawings and as recommended by the equipment manufacturer. D. Power packs shall be located in accessible ceiling spaces and securely mounted to a standard electrical enclosure (junction box) through a standard 1/2” chase nipple. Plastic clips into the junction box shall not be acceptable. Junction box shall be supported from the building structure with no less than one (1) ¼” threaded rod. All Class 1 wiring shall pass through the chase nipple into the junction box without any exposure of wire leads. Low voltage Class 2 wiring to the sensors shall not be exposed in finished spaces. Power packs shall be wired as detailed on the Drawings and as recommended by the equipment manufacturer. E. Supports shall not terminate or be fastened directly to the roof decking except where specifically approved by the Owner. F. Wiring: 1. All low voltage field wiring in finished and unfinished spaces shall be installed by this Contractor in 1/2-inch conduit and/or surface metal raceway as shown on the Drawings or hereinbefore specified elsewhere. Conduit fill shall not exceed the conduit space capacity. 2. All low voltage field wiring to be installed in areas without a ceiling or in areas without an accessible ceiling shall be installed by this Contractor in 1/2-inch conduit. 3. All low voltage field wiring to be installed in areas with accessible ceilings shall be installed by this Contractor bundled together and run exposed above the ceilings. Bundles shall be supported by "J" hooks mounted not more than four (4) feet on center. “J” hooks shall be dedicated to the wiring specified in this specification section. 4. All low voltage field wiring shall be run at right angles to the building structure. 5. All low voltage field wiring shall be installed below the roof/floor structural supports (joists, beams, girders, etc.). Wiring installed between the structural supports mentioned above and the roof or floor deck will not be acceptable. 6. All low voltage field wiring penetrations through new and/or existing walls shall be sleeved. Minimum sleeve size shall be one (1) inch. All sleeves shall be bushed both sides. 7. All low voltage field wiring for the occupancy sensor systems shall be 16506-8 11/13 LIGHTING OCCUPANCY SENSORS SECTION 16506 furnished and installed by this Contractor. All junction box covers shall be stenciled for distinct identification. G. 3.02 8. All wiring connections shall be made by this Contractor as shown on the Drawings and as recommended by the equipment manufacturer. Splices shall be made only in junction boxes. 9. All occupancy sensor system wiring shall be checked and tested by this Contractor to insure the system is free from grounds, opens, and shorts. 10. Contractor shall test all low voltage cable for integrity and proper operation of the system. The Contractor shall arrange a pre-installation meeting with the occupancy sensors manufacturer’s factory authorized representative, at the project facility to verify proper placement of sensors and installation criteria. TESTING A. Sensor Testing and Adjustment: 1. At the time of installation, the Contractor shall be responsible for testing and adjusting each sensor for proper detection of motion appropriate to room usage. The Contractor shall follow the testing and adjustment procedures as written in the installation instructions for each sensor model. Note: Due to room conditions it may be necessary for the Contractor to make adjustments, change the location or type of sensor to obtain proper operation and coverage of the system in each room and should therefore make labor and material allowances for such changes and adjustments. END OF SECTION 16506-9 11/13