APPLICATION OF THE MIPS CONCEPT IN ITALY: TWO CASE

advertisement

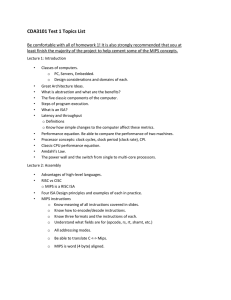

APPLICATION OF THE MIPS CONCEPT IN ITALY: TWO CASE STUDIES A.Federico1 , F. Hinterberger2, F.Musmeci1 1 ENEA: Agenzia per lo Sviluppo sostenibile Lgt.Thaon de Revel 72, 00169 Rome, Italy, FAX +39 06 30486410 e-mail federico@casaccia.enea.it 2 SERI Sustainable Europe Research Institute Schwarzspanierstr. 4/8 A-1090 Vienna, Austria, FAX +43 1 969 07 28 e-mail Fritz@seri.at Keywords MATERIAL FLOW, MIPS, SCRAPPING, MOBILE TELEPHONE, DEMATERIALIZATION Abstract The massive use of material and energy extracted from the environment is estimated, in EU, to be about 45 Tons/year per capita. This flow comes from a variety of different activities offering a growing set of products and services. A deeper insight is gained when the flow is analyzed for each product or service. The material flow in our economy is a measure of the human pressure on the environment. Concepts like the Total Material Requirement are already included in EU guide lines and assessments of sustainability of national economies. The Material Input per Unit Service (MIPS) is an index of pressure that can be computed for different products or services. To achieve the necessary dematerialization, decision-makers in politics and economics, but especially the individual consumers, need valid, understandable, and internationally compatible information about the ecological qualities of goods and services on the market. The MIPS is the sum of the primary natural resources including their "hidden flows" or ecological rucksacks. The computation can be extended to the phases of production, use and disposal of products. The paper present the MIPS concept applied to two case studies in Italy. The aim is to give an operational view of this index. The first studied case is related to the scrapping cars scheme adopted during the period 1997-1998. This case is related to the ecological assessment of politics aimed to preserve the environment and, in this particular case, to reduce Greenhouse Gas emissions. The second case, a MIPS application for the Italian mobile telephone network, is related to the analysis of new trends of the information society. The MIPS for cars are estimated to be around 0.2 Kg/(passenger Km). A first comparison of the business as usual and the scrapping scheme scenario shows a negative impact of the politic with around 3% of increasing the MIPS. The rucksacks of the mobile telephone devices and of the network are of the same order of magnitude. As service as units we consider both the minute of telephone call and the SMS message. This gives estimated Material Input per Unit of Service (MIPS) of 0.207 Kg/(minute of telephone call) and 0.632 Kg/SMS. If we assume one SMS is the substitute of 10 sec of telephone call then a final MIPS of 0.196 Kg/minute can be obtained. Introduction The current unsustainable production and consumption pattern in our society is characterized by a massive use of material and energy extracted from the environment. There is agreement now that this flow can be used as a proxy for estimating the roaring human pressure on the environment. This flow comes from a variety of different activities offering a growing set of products and services. A deeper insight is gained when the flow is analyzed for each product or service. A reduction of the material throughput in OECD countries by an average of a Factor 10 during the coming decades is imperative, especially when taking into account the expected economic and demographic increases in the "Third World". In order to reliably achieve the necessary dematerialization, decision-makers in politics and economics, but especially the individual consumers, need valid, understandable, and internationally compatible information about the ecological qualities of goods and services on the market. This kind of effort brought to the development of several useful concepts like the following: • Material Input (MI): the sum of all material requested for giving a service, such as a mobile telephone call. It is the sum of the primary natural resources including their "hidden flows" or ecological rucksacks. The unit used is kg. • Material Input per Unit Service (MIPS): the material input of a system or product can be compared with the service it offers. Products, services and infrastructures must be compared and designed from the beginning under the aspect of ecological criteria of resource efficiency. This is where the MIPS concept can play a decisive role. The used unit will depend on the service offered. For the mobile telephony could be Kg/(sec of conversation), Kg/(passenger km) for transportation. 1 Dematerialization requires diminishing the material throughput of our economy while keeping many of the services it offers. On one side private transportation is a key issue for an Italian sustainable development with more than 30 millions vehicles on the roads. On the other side the Information and Communication Technology (ICT) can play an important role in the dematerialization. It can reduce unnecessary travel e.g. in vehicles traveling to and from the workplace, and diminish the stress and pollution associated with commuting. It can also facilitate the access to information that, many believe, is a key issues for a democratic achievement of a sustainable development path. For these reasons the ENEA effort to apply the MIPS concept to the Italian case was focused on these two aspect. In particular we focus on the recent car scrapping scheme and on the mobile telephone service as two examples of our society trends and environmental policies. For both the studies data sets of materials used were multiplied with factors that account for the ecological rucksack of each material. Tables of this kind of data are available from Wuppertal Institut publications and on the Manstein Data Base. What they give is the Material Input Factor (MIF) that is used as a multiplier for the physical weight of material used in each product. Car Scrapping Scheme The car scrapping scheme was applied in Italy during the period 1997-1998. A bonus was given to replace an at least 10 years old car for a new one. Half of the cost was covered by the State while the other was covered by the car selling firms. The policy was aimed by the attempt to reduce the emissions by the car fleet substituting old gross emitters with greener new cars. Following the MIPS approach, in this study the aim is at the material entering the system and not to its outputs. In other words the spot is on the effect on material flow of such policy, and not on the emission reduction. The comparison can be made with data from a FIAT study released just before the policy took place. This study gives a case base scenario to be compared with the observed one. We consider a typical car from the eighties, named CAR80, as that one being scrapped and a typical car of the nineties, CAR90, as sample of the replacement. We estimate the Material Input as sum of the contribution of the production stage and of the using phase. Recover material from scrapping has been considered taking into account that the Material Input for recycled steel is 41% of the new one. Considering that a car is not made only by steel, other losses, etc., we assume a factor of 33% of material recovering from scrapping. Considering the car materials, from FIAT documents, and the related MIF, we get 14901 Kg for CAR80 and 14379 Kg for CAR90 for the production of a 980 kg car. For Material Input needed for usage we assume an old car traveling less than a new one and we estimate (ANPA 2000) a mileage of 10000 km/year for CAR80 and 14000 Km/year for CAR90. Given 2.9 as Material Factor for gasoline and a consumption of 10.7 liters/100 Km, for CAR80 and 7 litres/100 Km for CAR90, we get an estimate for the Material Input during an year of car use. Here the service is km passenger. We assume 1.55 average car occupancy. Year Registered Scrapped MIProd (Kg) MIRec. (Kg) MIUsage (Kg) MI Kg Service MIPS 1997 2389937 2037425 34364904123 10018691075 85048957749 1.0939E+11 5.48E+11 0.199626 1998 2437721 1506219 35051990259 7406575875 87143095295 1.1479E+11 5.75E+11 0.199402 1999 2285802 1210247 32867546958 5951183881 89722133561 1.1664E+11 6.05E+11 0.192875 TABLE 1: MIPS for the observed period Year Registered Scrapped MIProd (Kg) MIRec. (Kg) MIUsage (Kg) MI Kg 1997 1924474 1405280 27672011646 6910225502 85698237923 1.065E+11 1998 2009151 1503817 28889582229 7394764449 86625193473 1.081E+11 1999 2097554 1640133 30160728966 8065075205 87379335225 1.0947E+11 TABLE 2: MIPS for the case base scenario Service MIPS 5.48E+11 0.1942491 5.67E+11 0.1907580 5.85E+11 0.1870534 We observe the material flow to maintain and to operate the Italian car fleet is of the order of 100 Millions Tons per year. The adopted scrapping scheme altered this number of about 10%. Due to the increased mileage of new cars, in 1999, the MIPS change was only 3% greater than the case base. The decrease in gasoline consumption for the new cars was overcome by the increment in the mobility. The contribution of production and usage are of the same order of magnitude. MIPS is of the order of 200 grams per km passenger. 2 Mobile Telephone Service The analysis of the mobile telephone service in Italy was carried out mainly using data from the T28 Ericsson device. For the network we also considered the other components such as the radio base station, the Mobile service Switching Center etc. Data on these components were gathered from an industrial construction company and from the three telephones companies operating in Italy. Energy consumption during the production, transportation and operation phases was considered. The estimation for the mobile device gives 75 Kg/Telephone. Taking into account the network structure, especially considering the Radio Base Station building phase and its energy consumption during operation, an hidden flow of 2.416 Millions tons a year is required by the network to operate. Considering the 41.4 millions Italian subscribers, this gives 183.85 Kg/user. The rucksacks of the mobile telephone of the network are of the same order of magnitude. As service units we consider both the minute of telephone call and the SMS message. The estimate communications are 26815 millions of minutes of telephone calls and 8774 millions of SMSes. This gives estimated Material Input per Unit of Service (MIPS) of 0.207 Kg/(minute of telephone call) and 0.632 Kg/SMS. If we assume one SMS is the substitute of 10 sec of telephone call then a final MIPS of 0.196 Kg/minute can be obtained. This gives a MIPS of about 200 grams MIPS. The same number observed for the mobility of one passenger per one km. References Albert Adriaanse and others. Resource Flows: The Material Basis of industrial economies. Wuppertal Institute, aprile 1997. Anpa Le immissioni in Atmosfera da trasporto stradale, Rome 2000 S.Bringezu and others. Analysis for Action: Support for Policy towards Sustainability by Material Flow Accounting. Wuppertal Special 6 ,1997. S. Bringezu and others, The Con Account Action on Material Flow Analysis and its Research & Development Agenda. Wuppertal Special 8, 1998. S. Bringezu, R.Beherensmeier, H. Schutz, Material Flow Accounts Part I MFS/97/6 General Aspects, EUROSTAT doc. S. Bringezu, H. Schutz, Material Flow Accounts Part II EUROSTAT Doc. MFS/97/6 C. Delle Fratte Sviluppo Sostenibile e modelli di produzione: l’indice MIPS nel settore automobilistico e l’efficacia della rottamazione, Dissertation thesis, Rome 1999 A.Federico, F.Musmeci, D.Proietti Mancini: MIPS of the Italian Telephone Network, paper presented at the "Environmental Impact of Telecumunication System and Services" Discussion Forum (Lausanne 25 aptril 2001) and as poster at the "Challenges of a Changing Earth" Conference, 10-13 July 2001, Amsterdam F. Hinterberger (1993), Reduction of material inputs: an economic foundation of the MIPS concept, Fresienus Environmental Bulletin. F. Hinterberger, F. Schmidt-Bleek (1999), Dematerialization, MIPS and Factor 10 physical sustainability indicators as a social device, ecological Economics, April, Germany. C. Manstein, F. Musmeci: Material Input Calculator . ENEA, Factor 4+, SERI software. F. Schmidt-Bleek: MIPS BOOK 1994 .H.Spangenberg, F. Hinterberger, A. Femia and others Material Flow Indicators, Wuppertal Institute, 1997 3