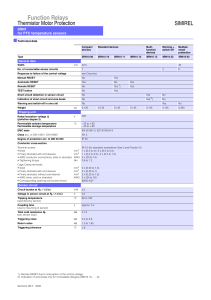

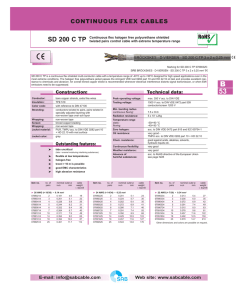

Miniature Circuit Breakers (MCBs) RCCBs/RCBOs Distribution Boards

advertisement