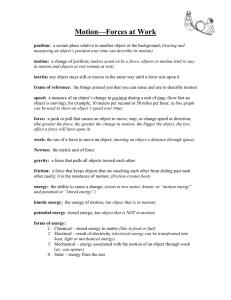

Tribological tests in the system of steel

advertisement

Janusz JANECKI, Jolanta DRABIK, Marek WOLSZCZAK, Zbigniew PAWELEC – Institute for Sustainable Technologies, National Research Institute, Radom, Poland Please cite as: CHEMIK 2013, 67, 4, 309-316 Introduction The studies on the application of regenerating materials and / or structural polymer composites as an alternative to metal engineering materials have been conducted for many years. The results of such studies were published in many papers, of which the most important are, among other things, the papers written by: J. Broś [1], J. Janecki [2], R. Marczak and S. Zawalski [3], J.M. Warda [4] and J. Sikora [5]. Attempts to employ adequate composites based on polymers in the regeneration processes of worn machine parts have produced good results, whereas the fact those mechanical properties of polymer composites are worse than the properties of metals used to produce the regenerating part somehow limit a wider range of their application. S. Banaszkiewicz [6], J. Szumniak [7, 8] and S. Zawalski [9] were involved in works on the effect of fillers on tribological properties of composite friction materials. An important issue that requires a particular consideration is a fact that the loads of friction nodes favour an increase in temperature, which then requires the maintenance of lubrication stability at higher temperatures, e.g. by introducing proper additives resulting in reduced friction and thus, temperature drop [10]. The papers on modifying tribological properties of composites indicated, inter alia, that a composite with solid lubricant additives had better tribological properties than the composites without such additives [11 ÷ 13]. The changes in tribological properties and the degree of wear of a composite produced from phenol formaldehyde resin by adding TiO2 nanopowder were described in the paper of F.-H. Su et al [14]. On the other hand S. S. Kim et al. used additives demonstrating self-lubricating properties in composites based on such a type of resin which additionally was characterized by the increased thermal resistance. The used additives counteracted seizing of co-operating mechanical elements [15]. The surface layer of co-operating elements is destroyed as a result of a series of complex phenomena leading to the lack of its cohesion, scaling or mass decrements. The destruction of surface layers in slide bearing depends mainly on the mutual velocity of rotating parts and the load value. For such machine parts, the degree of their wear depends on the temperature which adversely influences the non-homogeneous, previously regenerated, surfaces by reducing their operation period [2, 4, 13]. Regardless of the fact whether the durability of the surface layer was reduced as a result of the process of their natural wear, the faults in design or operational forces, it resulted in the damaged surface. Such changes are irreversible. However, their scope and occurrence intensity can be reduced as well as an attempt can be made to define a set of factors that decide on their significance, and to determine the area enclosed within boundary values describing operational strength of surfaces prone to abrasion. The above issue is connected with establishing criteria that are used to perform such nr 4/2013 • tom 67 assessments following the determination of significant operational features. The faced difficulty lies in ambiguous indicators for assessing operational systems, for which the wear of machine parts is observed and which require the renovation by replacing or regenerating [4]. As part of the performed research [17, 21, 22], the authors assumed that functional properties determined on the basis of tribological tests, were reliable indicators to assess the operational suitability of friction elements made of composite materials. Such test conditions as slide velocity of co-operating surfaces, loading and a temperature reached in the friction process, a type of lubrication considerably affect the condition of the surface layer of co-operating parts. For slide bearings with parts made of polymer materials, an adequate selection of a lubricant, inter alia, to avoid the impact of operational pollution which, with respect to composite materials, clearly affects the wear of a machine part and often results in the catastrophic degree of wear. Taking into account the above, while developing the composition of composite materials intended for parts of a sliding pair operating under the conditions of technical dry friction, plastic grease [16, 19, 20] was used as one of the components of metal-polymer composite [17]. This solved the problem of lubricating a sliding pair of composite material – steel, while only plastic grease contained in the composite material was used for lubrication. The tribological tests confirmed the positive impact of plastic grease in the composite on the wear, in comparison to the specimen of analogical composite without such grease [17]. This paper presents the results from experimental tests related to the analysis of the surface layer of metal-polymer composites with plastic grease additive and without it, after performing tribological tests under the conditions of technical dry friction. In these tests, the wear of tested composites was determined on the basis of friction – wear characteristics, and the surfaces after their testing were assessed regarding element composition employing the method of scanning electron microscope SEM and energy dispersive spectrometry EDS. Experimental part Methodology The tribological tests were conducted on a stand type T-05 [18] in a roller–block friction pair representing the real pin-bearing system in the slide bearing (Fig. 1). A distributed contact created by a rotating roller and a block pressed against the roller was a parameter characteristic for the friction node. The experiments were performed under the conditions of variable sliding velocity within the range of 0.1 m/s – 0.4 m/s under the constant unit pressure of 6 MPa. A block made of the tested composite material • 313 science Tribological tests in the system of steel-composite made of phenol formaldehyde resin and the analysis of the effect of plastic grease in resin on the state of surface layer science was the specimen, and a roller made of bearing steel 100Cr6 (ŁH15) of the hardness of 56-60 HRC was the counter specimen. For each pair, three research courses were performed. Table 1 Physical, chemical and lubricating properties of FS 1265 oil and F plastic grease [20] a) Properties Method Result Properties of fluorosilicone oil Molecular formula of FS oil 1265 (C4H7F3OSi)n poly [methyl (3,3,3-trifluoropropyl) siloxane Kinematic viscosity at 100°C, cST PN-EN ISO 3104:2004 74 PN-ISO 2909:2009 >220 PN-EN ISO 1516:2003 304 Flow temperature, °C PN-ISO 3016:2005 -40 Welding load, kG PN-C-04147:1976 160 Flaw diameter d, mm PN-C-04147:1976 0.63 Viscosity factor, VF Ignition temperature in a closed pot, °C b) Properties of F plastic grease a block made of a composite material a roller made of bearing steel Fig. 1. Photo of a) a stand type T-05 and friction node – association of a friction pair of roller-block type and b) a shape and dimensions of the specimen (composite block) and the counter specimen (a roller made of steel 100Cr6) The composite materials were prepared on the matrix of a thermosetting moulding compound FSzG-2 s– a mixture of phenol formaldehyde resin of novolac type, and fillers, which is usually used in the production of technical products of low friction coefficient (Fig. 2). Dropping point, °C PN-ISO2176:2011 230 Penetration, 10-1 mm PN-ISO 2137:2011 245 Consistency class acc. to NLGI PN-ISO 2137:2011 3 Flaw diameter d, mm PN-C-04147:1976 0.98 Welding load, kG PN-C-04147:1976 500 The tests on friction and wear of the prepared composite materials were carried out on a tribological stand type T-05 under the conditions of technical dry friction. During the test, the specimen temperature and friction force were recorded, and after completing the test, the worn mass was determined and the friction coefficient was calculated (Tab. 2). Table 2 Conditions for tribological tests [17] Test conditions Pin-bearing sliding pair Velocity, m/s Fig. 2. General formula of novolac resin Metallic filler – Fe metal powder of type NC 100 24 of Höganas company (FN specimen) and 1% m/m of plastic grease (FN 1S specimen) were added to the powdered moulding compound to obtain the specimens of composite materials. As part of research works performed in the Institute for Sustainable Technologies – National Research Institute , a high-temperature plastic grease was developed using DOW CORNING® fluorosilicone oil FS 1265 and Aerosil® type silica thickener [20]. It was characterized by very developed specific surface and high thermal stability. Some of the properties of base oil and the produced plastic grease are presented in Table 1. For the purpose of obtaining the composite material, after thorough mixing of the components, pressing process using a hydraulic press PHM-100 was conducted according to the developed procedure at a temperature of 160oC and at a pressure of 10 MPa [17]. Using mechanical working, blocks intended for frictional co-operation with the roller made of bearing steel were cut out from the obtained moulded pieces (Fig. 1 b). 314 • Determined parameters Distributed contact 0.1 0.2 0.3 Friction distance, m 2400 Unit pressure, MPa 6 Type of lubrication during tests: 0.4 • Friction force, N • temperature of friction node, oC after tests: • worn mass of the specimen, g without external • friction coefficient lubricant (technical dry) The surface layer of the composite specimen was subjected to the analysis of X-ray radiography using the SEM/EDS technique before and after the tribological tests. The measurements were performed to test the changes in the content of carbon, oxygen, iron and silicon in the friction traces of the composite surface layer depending on the conditions of the tribological test [17]. The Noran energy dispersive X-ray (EDS) microanalyser with Norvar window, SiLi crystal and the resolution of 133eV, electronically coupled to the Hitachi scanning electron microscope (SEM) S 2460N with the option of conducting tests in rough vacuum range, was employed to identify elements present in the area of friction trace. Linear scanning of friction traces was performed at a 40-fold enlargement, at an accelerating voltage of 15 kV and a detection angle of 25o under the conditions of high vacuum. Discussion on results The tribological tests showed that adding plastic grease to the metal-polymer composite affected the stabilisation of the tribosystem nr 4/2013 • tom 67 Fig. 3. Effect of sliding velocity on the change in friction coefficient in tests performed under constant pressure of 6 MPa (FN – specimen of phenol formaldehyde resin composite with lubricant, FN 1S – specimen of phenol formaldehyde resin composite containing 1% by weight of plastic grease) On the basis of the obtained results, it was found that the dependence of friction coefficient in the function of sliding velocity was non-linear. For FN specimens at the velocities of 0.2 and 0.3 m/s, the friction coefficient was created at a lower level when compared to its values obtained at the velocities of 0.1 and 0.4 m/s. However, adding 1% of plastic grease to that composite caused that the friction coefficient was stabilised within the range of tested velocities. After completing the tribological tests conducted at a variable velocity within the range from 0.1 to 0.4 m/s and under the constant unit pressure of 6 MPa, the worn mass of the specimens were assessed (Fig. 5). An increase in sliding velocity under the constant unit pressure, under the conditions of technical dry friction deteriorated the wear resistance of the FN metal-polymer composite. At increased velocities, the clear increase in worn mass of the FN specimen was observed. Adding the plastic grease to the composite (FN 1S specimen) resulted in reduced worn mass of the specimen, and this reduction was distinct. The greatest difference in worn mass for the assessed composites was found at the sliding velocity of 0.3 m/s. Under such conditions, worn mass of the FN 1S specimen was considerably reduced by ca. 40% when compared to the FN specimen (Fig. 5). The determined characteristics of friction and wear confirmed the positive impact of the plastic grease contained in the metal-polymer composite on the conditions of the co-operation of composite-steel pair. After performing the tribological tests, the surface layer of the composite was assessed to observe any impact of the test conditions on changes in the material structure. The tests consisted in analysing element composition of the composite surface layer in the area of visible friction traces. Fig. 6 illustrates the exemplary test results for deposits formed on the composite surface following the friction process taking place under the pressure p = 6 MPa and the velocity v = 0.3 m/s. a) c) e) b) d) f) Fig. 4. Effect of sliding velocities on the change in temperature recorded during tribological tests performed under the constant pressure of 6 MPa The temperature in the friction node recorded during the tribological tests was increasing as the velocity, both for FN and FN 1S composites, was increasing. It was observed that the presence of lubricant in the composite provided better conditions for the cooperation of the FN 1S composite – steel pair, which reduced the temperature in the friction node. Fig. 5. Effect of sliding velocities on the change in the specimen wear after performing tribological tests under the constant pressure of 6 MPa nr 4/2013 • tom 67 Fig. 6. Surfaces of composite wear scars subjected to energy dispersive X-ray (EDS) analysis following the friction process: a, b) SEM images of FN and FN 1S specimens respectively; c, d) images of oxygen atoms distribution in FN and FN 1S specimens respectively; e, f) images of silicon atoms distribution in FN and FN 1S specimens respectively Depending on the test conditions, the intensity of signals and the percentage content of tested elements were changing in the surface layers of the tested composites FN and FN 1S (Fig. 7). The conducted SEM/EDS analysis of the surface layer of FN 1S composite following the friction under the conditions of various sliding velocities confirmed that signals indicating the presence of such elements as oxygen and silicon in the surface layer probably came from the components of the plastic grease used as the composite modifier. The obtained results indicated that lubricants were absorbed in friction traces, which directly influenced the reduction in friction coefficient and in the temperature of the sliding pair of steel–FN 1S composite and thus, its wear resistance increased under the test conditions (Figs 3÷5). • 315 science operation within the whole range of the conducted tests; both the temperature and friction force was created at a lower level than for the composite (FN) without the lubricant additive (Figs 3, 4). science Fig. 7. Results from the energy dispersive X-ray analysis of surface layers of FN and FN 1S composites after conducting tribological tests at various velocities (0.1–0.4 m/s) and under the constant unit pressure of 6 MPa The obtained results were used to identify the content of carbon, iron, oxygen and silicon in the surface layer. Carbon, iron and oxygen could originate from the components of FN composite, whereas the increased content of silicon and oxygen could only come from the plastic grease contained in the FN 1S specimen. During the tests carried out under the conditions of technical dry friction, it was also found that the surface layer of the composite containing lubricant was changing the co-operation conditions of the composite-steel pair. On the basis of the X-ray analysis of friction traces,improved conditions for the co-operation and the smaller worn mass of the tested specimen were observed as the content of elements present in the surface layer and originating from the plastic grease was increasing (Fig. 7). Under the experimental conditions, adding the plastic grease to the friction surface was likely to release grease dispergated in the composite, which effectively protected the surface layer against wearing. Summary By conducting the tribological tests at the constant load and at various sliding velocities, it was found that the co-operation conditions of friction elements in polymer composite – steel system were improved by adding the plastic grease to the polymer – steel composite. The performed tests demonstrated that the increase in sliding velocity considerably influenced the change in the friction coefficient and the temperature in the friction node, and at the same time it influenced the degree of wear of the tested composite materials. The analysis of the surface layer of the specimen, after performing the tribological tests, showed that the increase in wear resistance of the composite containing the plastic grease can be assessed on the basis of the quantity and intensity of signals characteristic for silicon and oxygen, originating from the oxosilane group of the plastic grease present in the phenol formaldehyde resin, which were identified in the energy dispersive X-ray spectrum. An increase in the content of these groups in the surface layer of the FN 1S composite indicated that the self-lubricating layer resistant to the wear process was properly shaped and thus, this layer had a positive impact on the co-operation conditions of the sliding pair of polymer composite – steel. This research work has been financed from the Polish science budget for years 2010‒2012 – Project No. N N508 481138. Literature 1. Broś J.: Mechanika, z. 20. Politechnika Krakowska Kraków, 1965. 2. Janecki J. i in.: Sprawozdanie z pracy wykonanej na zlecenie Funduszu Na Rzecz Nauki Polskiej – program PONT. WITPiS Sulejówek, 1992. 3. Marczak R., Zawalski S.: Materiały XI Szkoły Tribologicznej. Rynia, 1992. 4. Ward J.M.: Mechaniczne właściwości polimerów jako tworzyw konstrukcyjnych. PWN Warszawa. 1973. 5. Sikora J.: Wybrane problemy tribologii. PWN Warszawa, 1990. 6. Banaszkiewicz S.: Praca doktorska. Politechnika Krakowska Kraków, 1980. 7. Szumniak J.: Informator WITPiS – Prace Naukowe. Sulejówek, 1986. 316 • 8. Szumniak J. i zespół: Część I i II. Sprawozdanie. WITPiS Sulejówek, 1994. 9. Zawalski S.: Praca doktorska. Archiwum WITPiS, 1973. 10. Gatzen M.M. et al. : Tribology International 2010, 43, 981-989. 11. Muratore C., Hu JJ., Voevodin AA.: Thin Solid Films 2007, 515, 3638-43. 12. Hu JJ., Muratore C., Voevodin AA.: Comp. Sci. Technol. 2007, 67, 336-347. 13. Voevodin AA., Zabinski JS. : Comp. Sci. Technol. 2005, 65, 741-748. 14. Su F.-H. et al.: Wear 2008, 264, 562-570. 15. Kim S.S. et al.: Composite Structures 2009, 88, 26-32. 16. Drabik J., Trzos M.: J Therm Anal Calorim 2012, 109, 521-527. 17. Janecki J. i inni: Sprawozdanie z realizacji projektu badawczego. ITeE-PIB Radom, 2012. 18. Wulczyński J., Bator A., Lech J., Michalczewski R., Piekoszewski W., Szczerek M.: Opracowanie modyfikacji zespołu urządzeń tribologicznych i metod badania procesów tarcia i zużycia. Sprawozdanie z prac naukowo-badawczych Zakładu Tribologii, ITE Radom, 1996. 19. Drabik J., Trzos M.: Improvement of the resistance to oxidation of the ecological greases by the additives. J Therm Anal Calorim 2013 (po recenzji, przyjęty do druku). 20. Drabik J. i inni: Nietoksyczne, biodegradowalne materiały smarowe przeznaczone do zastosowań specjalnych. Zadanie badawcze realizowane w ramach Programu Strategicznego pn. „Innowacyjne systemy wspomagania technicznego zrównoważonego rozwoju gospodarki” w Programie Operacyjnym Innowacyjna Gospodarka”. ITE-PIB Radom, 2010-2014. Janusz Tytus JANECKI – (Sc.D., Eng), Full Professor obtained a university degree in 1954. He obtained an academic degree of doctor in 1961, and habilitated doctor of technical sciences in the field of tribology in 1969. He was awarded the title of the Associate Professor in 1972, and the title of the Full Professor in 1984. Professor J.T. Janecki is a member of the Polish Tribology Society, a full member of the Academy of Engineering in Poland, a member of the European Materials Research Society in Strasbourg, an honorary member of the Russian National Committee of Tribology, the laureate of many departmental and university distinctions, including the distinctions of the Poznań University of Technology and Military University of Technology (WAT). Professor J. T. Janecki is a researcher at the Institute for Sustainable Technologies – National Research Institute in Radom. He is the author and co-author of over 250 Polish and foreign publications, a co-author of many papers and announcements presented at the conferences, a co-author of monographs, patents and patent applications. Jolanta DRABIK - Ph.D., (Eng)g., graduated from the Faculty of Chemistry and Chemical Technology at the University of Technology and Agriculture in Bydgoszcz in 1981. She has been working in the Institute for Sustainable Technologies – National Research Institute in Radom since 1990, currently as an assistant professor. She was granted the degree of Doctor at the Air Force Institute of Technology in Warsaw in 1995. She is the author and co-author of 127 Polish and foreign publications, 45 papers and announcements and 10 posters presented at the national and international conferences, a coauthor 9 of patents and 8 patent applications. email: Jolanta.Drabik@itee.radom.pl Marek WOLSZCZAK – Eng., graduated from the School of Engineering in Radom in 1981. He has been working in the Institute for Sustainable Development – National Research Institute in Radom since 1986. He is co-author of 12 papers, 2 patents and studies elaborated on the basis of scientific and research works. Research interests: materials for the recovery of machines and equipment, pro-ecological technologies and equipment for the production, operation and utilisation of operational fluids. Zbigniew PAWELEC – Ph.D,. (Eng), graduated from the Faculty of Materials Science at the Radom University of Technology. In 1998, he was granted the degree of Doctor in the field of construction and operation of machines, specialisation in tribology, at the Military Institute of Armour and Car Technology (WITPiS). He works at the Institute for Sustainable Technologies – National Research Institute in Radom, currently as an assistant professor. He is the author and co-author of 60 papers on the composition and operational properties of materials containing a polymer matrix, and a co-author of 4 patents and 2 patent claims. nr 4/2013 • tom 67