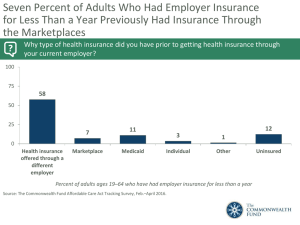

the occupational safety, health

advertisement