Bulletin No. 65013-004-11D

June 2000

Raleigh, NC, USA

Instruction Bulletin

Replaces 65013-004-11B dated 6/94

Standard and Push-to-Test Pilot Lights

and Illuminated Push Buttons

Class 9001, Types TP/TPM and TPK, Series H

Retain for future use.

INTRODUCTION AND

INSTALLATION PROCEDURE

This bulletin describes how to install Class 9001, Types TP/TPM and TPK

standard and push-to-test pilot lights and illuminated push buttons.

Refer to one of the following diagrams:

DANGER

HAZARDOUS VOLTAGE

Turn off all power supplying this equipment

before working on it.

Failure to follow this instruction will result in

death or serious injury.

Figure 1 for the Type TP/TPM standard pilot light

Figure 2 for the Type TP/TPM push-to-test pilot light

Figure 3 for the Type TP/TPM illuminated push button

Figure 4 for the Type TPK push-to-test pilot light

Figure 5 for the Type TPK illuminated push button

NOTE: If Class 9001, Type TPK push-to-test pilot lights or illuminated push

buttons are fitted in Class 9001, Type TY enclosures, Square D part no.

75030-765-50 insulator kit must be used to achieve correct electrical

clearance.

1. Remove the ring nut from the operator.

2. Insert the operator from the rear of the panel, making sure that the

locating dowel on the operator fits in the mating hole in the panel.

3. Thread the ring nut onto the operator and tighten with a Class 9001 Type

T1 ring nut wrench.

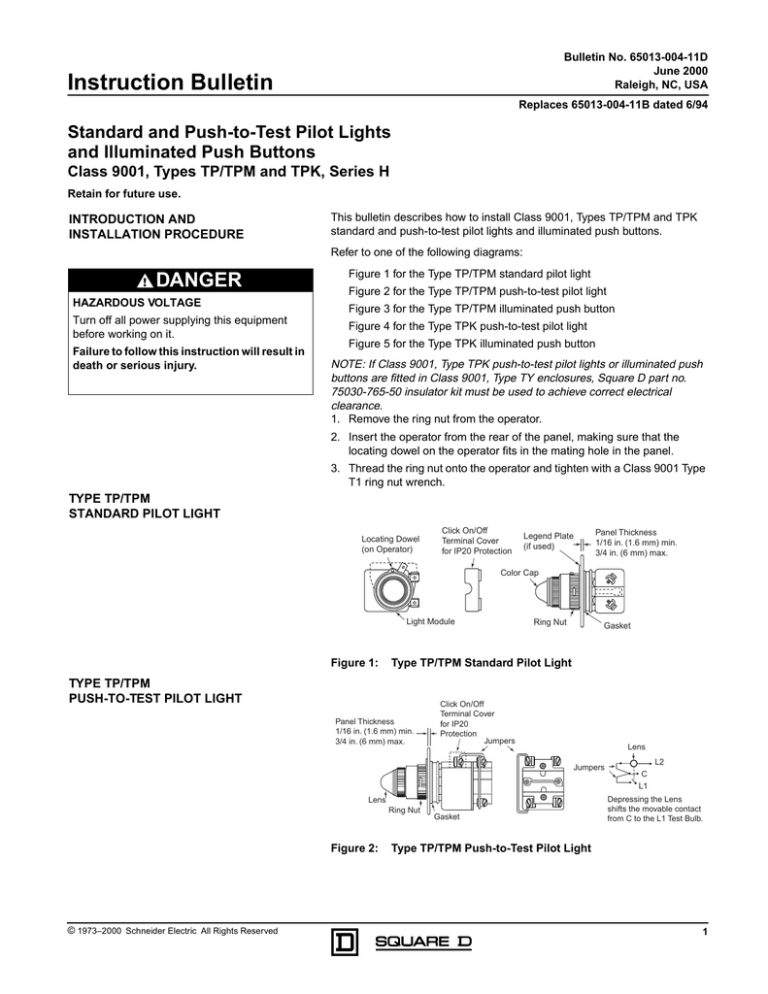

TYPE TP/TPM

STANDARD PILOT LIGHT

Locating Dowel

(on Operator)

Click On/Off

Terminal Cover

for IP20 Protection

Legend Plate

(if used)

Panel Thickness

1/16 in. (1.6 mm) min.

3/4 in. (6 mm) max.

Color Cap

Light Module

Figure 1:

Ring Nut

Gasket

Type TP/TPM Standard Pilot Light

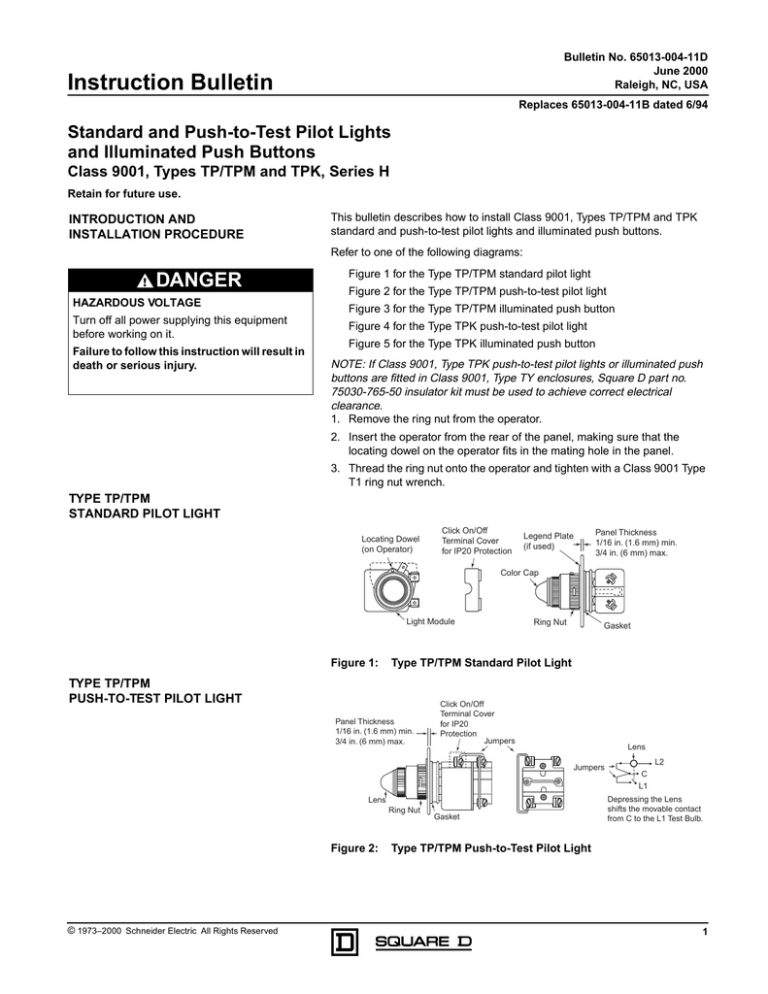

TYPE TP/TPM

PUSH-TO-TEST PILOT LIGHT

Panel Thickness

1/16 in. (1.6 mm) min.

3/4 in. (6 mm) max.

Click On/Off

Terminal Cover

for IP20

Protection

Jumpers

Lens

Jumpers

Lens

Ring Nut

Figure 2:

© 1973–2000 Schneider Electric All Rights Reserved

Gasket

L2

C

L1

Depressing the Lens

shifts the movable contact

from C to the L1 Test Bulb.

Type TP/TPM Push-to-Test Pilot Light

1

Standard and Push-to-Test Pilot Lights and Illuminated Push Buttons

Class 9001, Type TP/TPM and TPK, Series H

Bulletin No. 65013-004-11D

June 2000

TYPE TP/TPM

ILLUMINATED PUSH BUTTON

Panel Thickness

1/16 in. (1.6 mm) min.

3/4 in. (6 mm) max.

Panel Drilling

(All Units)

Click On/Off Terminal

Cover for IP20 Protection

Legend Plate (if used)

Ring Nut with Guard

DIA = 0.136 in. (3.5 mm)

Min. 1/16 in. (1.6 mm) deep

3/4 in.

(19 mm)

Color Cap

Ring Nut

(Operator

without Guard)

Figure 3:

DIA = 1-7/32 in. (31 mm)

Gasket

Type TP/TPM Illuminated Push Button

TYPE TPK

PUSH-TO-TEST PILOT LIGHT

Panel Thickness

1/16 in. (1.6 mm) min.

3/4 in. (6 mm) max.

Click On/Off

Terminal Cover

for IP20

Protection

Jumpers

Lens

Jumpers

L2

C

L1

Depressing the Lens

shifts the movable contact

from C to the L1 Test Bulb.

Lens

Ring Nut

Figure 4:

Gasket

Type TPK Push-to-Test Pilot Light

TYPE TPK

ILLUMINATED PUSH BUTTON

Panel Thickness

1/16 in. (1.6 mm) min.

3/4 in. (6 mm) max.

Click On/Off Terminal

Cover for IP20 Protection

DIA = 0.136 in. (3.5 mm)

Min. 1/16 in. (1.6 mm) deep

Ring Nut withGuard

3/4 in.

(19 mm)

Color Cap

Ring Nut

(Operator

without Guard)

Figure 5:

Square D Company

8001 Hwy 64 East

Knightdale, NC 27545 USA

1-888-SquareD (1-888-778-2733)

www.squared.com

2

Panel Drilling

(All Units)

DIA = 1-7/32 in. (31 mm)

Gasket

Type TPK Illuminated Push Button

Electrical equipment should be serviced only by qualified personnel. No responsibility is assumed

by Schneider Electric for any consequences arising out of the use of this material.

© 1973–2000 Schneider Electric All Rights Reserved