Electronic Temperature

Measurement

Temperature Transmitters

Model TR12, TR24, TR32, TR48

Data sheet : TEMP-TX/2012

Contents

Page

Temperature Transmitter Overview

1

Model TR12 Digital Temperature Transmitters

4

Model TR24 Digital Temperature Transmitters

9

Model TR32.1/3S Digital Temperature Transmitters

13

Model TR48 Digital Temperature Transmitters

22

ATEX Classification Guide

25

Temperature transmitters are used to convert the primary sensing

signal, usually a resistance change for RTD sensors or EMF for thermocouples, into a standard current signal of 4-20mA.

These transmitters may be either head mounted Where the transmitter is installed into the housing (connection head) of the temperature

sensor or Din Rail Mounted where the transmitter is mounted to a DIN

rail and used for centralized control room installations.

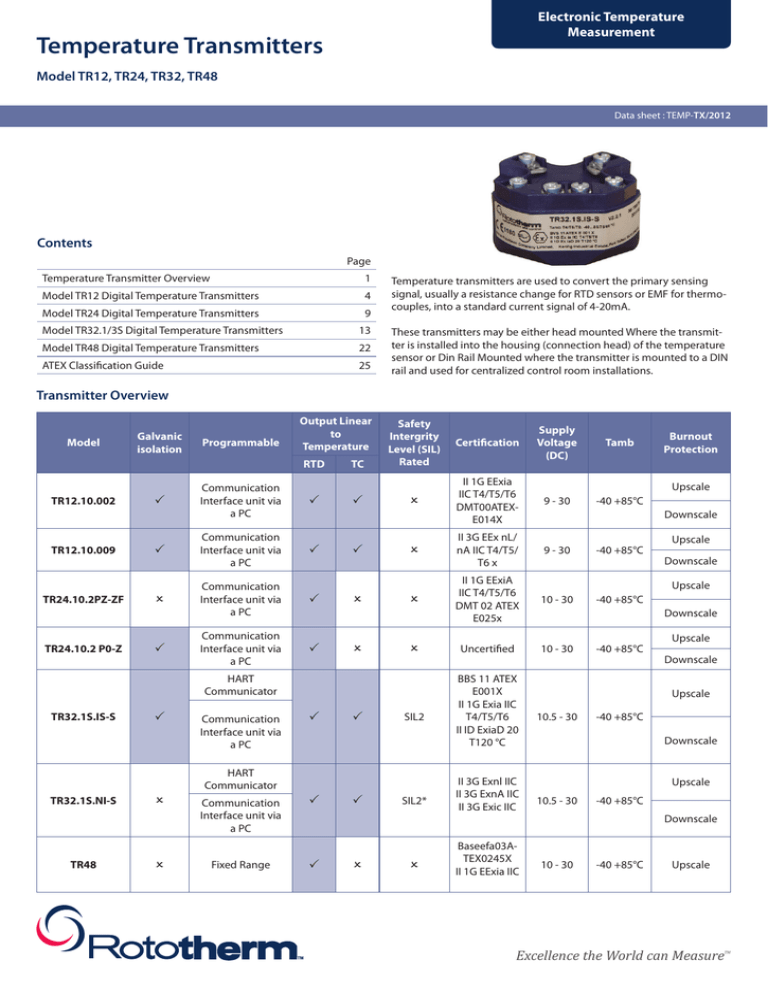

Transmitter Overview

Model

Galvanic

isolation

Programmable

Output Linear

to

Temperature

RTD

TR12.10.002

TR12.10.009

TR24.10.2PZ-ZF

TR24.10.2 P0-Z

Communication

Interface unit via

a PC

Communication

Interface unit via

a PC

Communication

Interface unit via

a PC

Communication

Interface unit via

a PC

TC

Safety

Intergrity

Level (SIL)

Rated

Certification

Supply

Voltage

(DC)

Tamb

II 1G EExia

IIC T4/T5/T6

DMT00ATEXE014X

9 - 30

-40 +85°C

II 3G EEx nL/

nA IIC T4/T5/

T6 x

9 - 30

-40 +85°C

II 1G EExiA

IIC T4/T5/T6

DMT 02 ATEX

E025x

10 - 30

-40 +85°C

Uncertified

10 - 30

HART

Communicator

TR32.1S.IS-S

Communication

Interface unit via

a PC

SIL2

HART

Communicator

TR32.1S.NI-S

TR48

Communication

Interface unit via

a PC

Fixed Range

SIL2*

BBS 11 ATEX

E001X

II 1G Exia IIC

T4/T5/T6

II ID ExiaD 20

T120 °C

II 3G Exnl IIC

II 3G ExnA IIC

II 3G Exic IIC

Baseefa03ATEX0245X

II 1G EExia IIC

Burnout

Protection

Upscale

Downscale

Upscale

Downscale

Upscale

Downscale

-40 +85°C

Upscale

Downscale

Upscale

10.5 - 30

-40 +85°C

Downscale

Upscale

10.5 - 30

-40 +85°C

Downscale

10 - 30

-40 +85°C

Upscale

Excellence the World can Measure

TM

TR Temperature Transmitters | 2

Protocol Setting

Setting

Decsription

TR12

TR24

TR32

TR48

HART (Highway

Addressable Remote

Transducer)

HART is a bi-directional communication protocol that provides data access between intelligent field instruments and host systems. A host can be any software

application from technician’s hand-held device or laptop to a plant’s process control, asset management, safety or other system using any control platform.

Communication

Interface unit via a PC

Transmitter is programmed though interface and computer via RS-232-C.

Non configurable

Transmitter range is pre-set and configurable

Transmitters Input Overview

Model

Code

Input

RTD

Thermocouple

Image

PT100

PT1000

Type K

Type J

Type T

Type N

Millivolt

TR12

TR24

TR32

TR48

Input Codes (table 1)

Code

Input

Type

Standards

1

PT100

RTD

BS EN 60751:2008

3

PT1000

RTD

BS EN 60751:2008

K

Type K

Thermocouple

BS EN 60584/2:1993

J

Type J

Thermocouple

BS EN 60584/2:1993

T

Type T

Thermocouple

BS EN 60584/2:1993

N

Type N

Thermocouple

BS EN 60584/2:1993

V

millivolt

N/A

N/A

Sensor Wiring Configurations (table 2)

Note: Thermocouple & millivolt inputs are always 2 wires, RTD inputs are 2, 3 & 4 wires

Code

Input

TR12

TR24

TR32

TR48

2

2 Wires

3

3 Wires

4

4 Wires

Transmitter Classification (table 3)

Code

Classification

IA

EExia Certified

XN

EExnL/nA Certified

UN

Uncertified

TR Temperature Transmitters | 3

Setting (table 4)

Code

Input

TR12

TR24

TR32

TR48

F

Fixed Range

P

Programmable (Programed)

U

Programmable (Un-Programed)

Sensor Burnout Protection (table 5)

Code

Burnout

F

Upscale

P

Downscale

Sensor Burnout Reference Table

Input / Burnout Protection

PT100

Model

Upscale

Downscale

Pt1000

Upscale

Downscale

Type K

Upscale

Downscale

Type J

Upscale

Downscale

Type T

Upscale

Downscale

Type N

Upscale

TR12

TR24

TR32

TR48

Temperature Range (table 6)

Model

RTD PT100

RTD PT1000

Thermocouple

Type K

Thermocouple

Type K

Thermocouple

Type K

Thermocouple

Type N

TR12

TR24

TR32

TR48

Minimum

-200 °C

-200 °C

-200 °C

-200 °C

Maximum

850 °C

850 °C

850 °C

600 °C

Minimum Span

25 °C

50 °C

10 °C

30 °C

Minimum

10 °C

Minimum

-180 °C

-270 °C

-200 °C

Maximum

1372 °C

1372 °C

1200 °C

Minimum Span

50 °C

10 °C

100 °C

Minimum

-100 °C

-210 °C

-200 °C

Maximum

1200 °C

1200 °C

1200 °C

Minimum Span

50 °C

10 °C

100 °C

Minimum

-200 °C

-270 °C

-200 °C

Maximum

400 °C

400 °C

400 °C

Minimum Span

50 °C

10 °C

100 °C

Minimum

-180 °C

-270 °C

Maximum

1300 °C

Minimum Span

100 °C

-200 °C

Minimum Span

Maximum

850 °C

1300 °C

10 °C

TR12 Temperature Transmitters | 4

Model TR12

ATEX

Digital Temperature Transmitter

APPROVED PRODUCTS

yy Universally programmable for

- RTDs

- Thermocouples

- Resistance - sensor

- mV - sensor

yy Output linear to temperature with input signal from RTDs and Thermocouples

yy Analog output 4 … 20 mA, invertible, 2 - wire design

yy Signalling configurable for sensor burnout and sensor short circuiting

yy Ex class protection, intrinsically safe ATEX

yy Approved

- EEx ia llC T4 / T5 / T6

- EExnA

- EExd (when fitted in H70 connection head)

yy EMC Conformity per

- EN 61326:1997/P1:1998/P2:2001

- NAMUR NE 21

yy Galvanic isolation

yy 100% Rh protection, moisture condensation permissible

yy Increased ambient temperature

yy PC configurable, Windows® programme

yy CE Conformity

DIN rail mounting version

(shown not to scale)

yy

yy

yy

General Description

The digital temperature transmitter TR12 range is designed for

universal industrial use.

Comprehensive configuration possibilities, for example, type of sensor,

measuring range and error signalling, high accuracy, galvanic isolation

and EMI protection characterize these transmitters. The compact head

mounting case fits in almost any DIN connecting head.

During configuration any one of 17 input signals can be selected.

Measured temperatures are from - 200 °C up to + 2300 °C.

The following sensors can be connected:

yy RTDs per EN60751, JIS C 1606, DIN 43 760 in 2, 3 and 4 - lead

connection, the connection system used is configurable and ensures an optimal lead wire compensation

Thermocouples per IEC 584 , DIN 43 710 and ASTM E988. Cold junction compensation (CJC) is built-in, the use of an external CJC is selectable via configuration.

Resistance-sensors up to 5 k W in 2 - , 3 - and 4 - lead connection, configurable compensation of the connection cable

mV-sensors up to 800 mV

Configuration is carried out by means of a standard DOS PC using

the Configuration set. With the Configuration Software the required

parameters are defined. Data to the TR12 is down-loaded using a

Communication-Interface (Programming Unit). The bi-directional

communication enables display of the measured values on the PC.

Configuration can be effected whilst the transmitter is mounted in the

field. The Communication-Interface has an integral isolation barrier

which allows configuration whilst the transmitter is within hazardous

areas, and acts to protect the PC. Configuration sets are available as an

optional extra.

The transmitters are delivered with any customized configuration

within the given limits.

Input Types

Input Type

Code

TR12

RTD PT100

Type K

Thermocouple

Type J

Thermocouple

Type T

Thermocouple

Transmitter Classification

LJ8<bf^glbhgl

Code

Classification

IA

EExia Certified

XN

EExnL/nA Certified

Type N

Thermocouple

Millivolt

<ZmZ8Ka^^m8J^_^k^g\^88LJ¦

TR12 Load

Diagram

DhZ]8<bZ`kZf

The permissible load is dependant upon the loop power supply

voltage

Setting

Code

Input

TR12

F

Fixed Range

P

Programmable (Programed)

U

Programmable (Un-Programed)

<ZmZ8Ka^^m8J^_^k^g\^88LJ¦

TR12 Temperature Transmitters | 5

TR12 Dimensions

LJ8<bg8JZbe8Ehngmbg`8N^klbhg8<bf^glbhgl

DhZ]8<bZ`kZf

DIN Rail Mounting Version

LJ8<bf^glbhgl

L^fi^kZmnk^8LkZglfbmm^kl8888ñ8888

all dimensions are in mm

TR12 Wiring Scheme

LJ8Obkbg`8K\a^f^

Eh]^e8LJ8<bg8JZbe8Ehngmbg`8L^fi^kZmnk^8LkZglfbmm^kl

Receiving

8

8

8

8

8

8

8

8

Disconnect

Mgbo^klZeer8ikh`kZffZ[e^8_hk Equipment

¦8JL<l

¦8La^kfh\hnie^l

Input

¦8J^lblmZg\^8¦8l^glhk

¦8fN8¦8l^glhk

Gnminm8ebg^Zk8mh8m^fi^kZmnk^8pbma8bginm888888888888888888

lb`gZe8_khf8JL<l8Zg]8La^kfh\hnie^l

9gZeh`8hnminm8888f98bgo^kmb[e^88¦8pbk^8]^lb`g

Kb`gZeebg`8\hgy`nkZ[e^8_hk8l^glhk8[nkghnm8Zg]888

l^glhk8lahkm8\bk\nbmbg`

=q8\eZll8ikhm^\mbhg8bgmkbglb\Zeer8lZ_^89L=P8888888888

Ziikho^]

¦8==q8bZ8ee;8L8¥8L8¥8L

=E;8;hg_hkfbmr8i^k

¦8<AF8=F88¦

¦8<AF8=F88¦

¦8F9EMJ8F=8

AlheZmbhg8ohemZ`^88N9;8[^mp^^g8l^glhk8Zg]8888

\nkk^gm8ehhi

RS 232-C

H;8¦8\hgy`nkZ[e^8Obg]hplÜ8ikh`kZff^

;=8;hg_hkfbmr

TR12D

Yellow and green are connected only if configuration of the TR12.30.00 is to be made during

the operation. When configuring in the workshop, an external power supply is not required

as the Programming Unit provides the power.

Eh]^e8LJ8<b`bmZe8L^fi^kZmnk^8LkZglfbmm^k

?^g^kZe8<^l\kbimbhg

La^8]b`bmZe8m^fi^kZmnk^8mkZglfbmm^k8LJ8kZg`^8bl8]^lb`g^]8

_hk8ngbo^klZe8bg]nlmkbZe8nl^

TR12 Designation of Terminal Connectors

Þ

J^lblmZg\^8l^glhkl8ni8mh88d8 8bg88¦888¦8Zg]88¦8e^Z]8

\hgg^\mbhg8\hgy`nkZ[e^8\hfi^glZmbhg8h_8ma^8\hgg^\¦

mbhg8\Z[e^8

fN¦l^glhkl8ni8mh88fN8

;hfik^a^glbo^8

\hgy`nkZmbhg8 ihllb[bebmb^l8 _hk8 ^qZfie^8

LJ8<^lb`gZmbhg8h_8L^kfbgZe8;hgg^\mhkl

mri^8h_8l^glhk8f^Zlnkbg`8kZg`^8Zg]8^kkhk8lb`gZeebg`8ab`a8

Þ

mV Sensor

RTD/Resistance Sensor

Thermocouple

4..20mA Loop

Z\\nkZ\r8`ZeoZgb\8blheZmbhg8Zg]8=EA8ikhm^\mbhg8\aZkZ\m^k¦

bs^8ma^l^8mkZglfbmm^kl88La^8kZbe8fhngmbg`8\Zl^8yml8mh8Zgr8

;hgy`nkZmbhg8bl8\Zkkb^]8hnm8[r8f^Zgl8h_8Z8lmZg]Zk]8<GK8

lmZg]Zk]8kZbe8i^k8<AF8=F88¦

H;8 nlbg`8 ma^8 ;hgy`nkZmbhg8 l^m8 Obma8 ma^8 ;hgy`nkZmbhg8

Kh_mpZk^8ma^8k^jnbk^]8iZkZf^m^kl8Zk^8]^yg^]8<ZmZ8mh8ma^8

<nkbg`8 \hgy`nkZmbhg8 Zgr8 hg^8 h_8

8 bginm8 lb`gZel8 \Zg8 [^8

LJ8 bl8 ]hpg¦ehZ]^]8 nlbg`8 Z8 ;hffngb\Zmbhg¦Agm^k_Z\^8

l^e^\m^]8E^Zlnk^]8m^fi^kZmnk^l8Zk^8_khf8¦88·;8ni8mh8

ªHkh`kZffbg`8 Mgbm«8 La^8 [b¦]bk^\mbhgZe8 \hffngb\Zmbhg8

¸88·;8

^gZ[e^l8]blieZr8h_8ma^8f^Zlnk^]8oZen^l8hg8ma^8H;8

La^8_heehpbg`8l^glhkl8\Zg8[^8\hgg^\m^]8

;hgy`nkZmbhg8 \Zg8 [^8 ^__^\m^]8 pabelm8 ma^8 mkZglfbmm^k8 bl8

Þ

JL<l8i^k8<AF8A=;8

8k^li8<AF88

8bg88¦888¦8Zg]8

fhngm^]8bg8ma^8y^e]8La^8\hffngb\Zmbhgl8bgm^k_Z\^8aZl8Zg8

8 ¦8 e^Z]8 \hgg^\mbhg8 ma^8 \hgg^\mbhg8 lrlm^f8 nl^]8 bl8

bgm^`kZe8blheZmbhg8[Zkkb^k8pab\a8Zeehpl8\hgy`nkZmbhg8pabelm8

4 wire

3 wire

2 wire

\hgy`nkZ[e^8 Zg]8 ^glnk^l8 Zg8 himbfZe8 e^Z]8 pbk^8 \hf¦

ma^8mkZglfbmm^k8bl8pbmabg8aZsZk]hnl8Zk^Zl8Zg]8Z\ml8mh8ikh¦

i^glZmbhg

m^\m8ma^8H;8;hgy`nkZmbhg8l^ml8Zk^8ZoZbeZ[e^8Zl8Zg8himbhgZe8

Þ

La^kfh\hnie^l8 i^k8 A=;8 8 8 <AF8 8

8 Zg]8 9KLE8

^qmkZ

=8(DIN

;he]8

cng\mbhg8

\hfi^glZmbhg8

ª;B;«8

bl8 [nbem¦bg8 of Terminal Connectors

TR12

Rail

Mounted

Version)

Designation

LJ8ª<AF8JZbe8Ehngm^]8N^klbhg«8<^lb`gZmbhg8h_8L^kfbgZe8;hgg^\mhkl

ma^8nl^8h_8Zg8^qm^kgZe8;B;8bl8l^e^\mZ[e^8obZ8\hgy`nkZ¦

La^8 mkZglfbmm^kl8 Zk^8 ]^ebo^k^]8 pbma8 Zgr8 \nlmhfbs^]8 \hg¦

mbhg8

y`nkZmbhg8pbmabg8ma^8`bo^g8ebfbml

mV Sensor

RTD/Resistance Sensor

Thermocouple

4..20mA Loop

4 wire

3 wire

2 wire

If cold junction compensation is used with an external RTD (2

wire) Terminal 1 +ve Terminal 4 -ve

DhZ]8<b

TR12 Temperature Transmitters | 6

TR12 - Input Types

Sensor Type

RTD

Thermocouple

Max. Measuring Range

Min Measuring Span(1)

PT 100

EN60751

-200 to +850°C

25 K

JPt 100

JIS C 1606

-200 to +500°C

25 K

Ni 100

DIN 43760 : 1987-09

-60 to +500°C

25 K

Type T Cu-CuNi

IEC 584

-200 to +400°C

50 K

Type E NiCr-CuNi

IEC 584

-100 to +1000°C

50 K

Type J Fe-CuNi

IEC 584

-100 to +1200°C

50 K

Type L Fe-CuNi

DIN 43710 : 1985-12

-100 to +900°C

50 K

Type K NiCr-Ni

IEC 584

-180 to +1372°C

50 K

Type N NiCrSi-NiSi

IEC 584

-180 to +1300°C

100 K

Type U Cu-CuNi

DIN 43710 : 1985-12

-200 to +600°C

75 K

Type R PtRh-Pt

IEC 584

-50 to +1760°C

200 K

Type S PtRh-Pt

IEC 584

-50 to +1760°C

200 K

Type B PtRh-PtRh

IEC 584

+400 to +1820°C(2)

200 K

Type W3, W3Re/W25Re

ASTM E988

0 to +2300°C

200 K

Type W5, W5Re/W26Re

ASTM E988

0 to +2300°C

200 K

0 to +5 kOhm

30 Ohm

-10 to +800 mV

5 mV

Resistance Sensor

mV Sensor

TR12 - Input Specification

Measuring deviation per DIN IEC 770,

23ºC ±5K

RTD

± 0.2 K or (3) ±(0.025% FS + 0.1) K

Resistance Sensor

± 0.07 W or (3) ± 0.03% FS in W

Sensor current

Approx. 0.2 mA

Temperature coefficient Tc

RTD/Resistance Sensor

RTD

± (0.025% FS + 0.09) K/10 K Tamb

Resistance Sensor

± (0.025% FS + 0.01) W / 10 K Tamb

Lead wire connection

Connection Leads

Configurable: 2=lead, 3-lead, 4-lead

Max. resistance

30 W each lead, 3-lead symmetric

Effect

±0.02 W / 10 W

Signalling of sensor error

Configurable

Measuring deviation per DIN IEC 770, 23ºC ± 5K

± 0.5 K or (3) ± 10 mV or (3) ±0.05%

Cold junction compensation

± 1.0 K

(4)

Temperature coefficient Tc

Thermocouple

Connection Leads

mV Sensor

T, E, J, L, K, N, U

± (0.05% FS + 0.1) K 10 K Tamb

or (3) ± 0.5 K / 10 K Tamb

R, S, B, W3, W5

± 2 K / 10 K

Max. resistance

250 W

Effect

± 0.5 uV / 10 W

Tamb

Signalling of sensor error

Configurable

Measuring deviation per DIN IEC 770, 23ºC ± 5K

± 10 mV or (3) ± 0.05% FS in mV

Temperature coefficient Tc

± (0.05% FS + 0.02) mV / 10 K Tamb

Connection Leads

Max. resistance

250 W

Effect

± 0.5 mV / 10 W

TR12 - Output Specification

RTD

Linear to temperature per EN60751 / JIS C 1606 / DIN 43 760 : 1987-09

Thermocouple

Linear to temperature per DIN IEC 584 / DIN 43 710 : 1985-12 / ASTM E988

Simulation Mode

Independant from input signal, simulation value configurable from 3.5 mA up to 23 mA

Output Limits

Application specification

Configurable from 3.6 mA up to 21.5 mA

NAMUR NE 43

Lower limit: 3.8 mA upper limit: 20.5 mA

Not active

Lower limit: 3.6 mA upper limit: 21.5 mA

Load RA

RA < (UB - 9V) / 0.023 A with RA in Ohm and UB in Volt

Load effect

< ± 0.01% of measuring span / 100 W

Measuring deviation per DIN IEC 770, 23º, ± 5 K

< ± 0.05% or measuring span

Temperature coefficient

< ± 0.1 % of measuring span / 10 K Tamb

Damping

Configurable: minimal 0.5 s , 1 s up to 60 s

Measured value update

Approx. 2/s

Power supply effect

< 0.005 % of measuring span / V

TR12 Temperature Transmitters | 7

TR12 - Power Supply UB

Model TR12 without Ex-protection

DC 9 … 36 V

Model TR12 with Ex-protection

DC 9 … 30 V

Protection EC Type Test DMT 00 ATEX E014X

Model TR12.10.002

II 1G EEx ia IIB / IIC T4/T5/T6

Model TR12.10.004

EExnA IIC T4/T5/T6

Permissible ambient temperature

-20 °C … +70 °C with T4

-20 °C … +70 °C with T5

-20 °C … +60 °C with T6

Maximum values for connection of the sensor

circuit (connections + and -)

Ui = 30V

Maximum values for connection of the sensor

circuit (connections 1- 4)

UO = 11.5V

IO = 31mA

Group IIB:

CO = 11 mF

LO = 8.6mH

Group IIC:

CO = 1.5 mF

LO = 8.6mH

Ii = 100mA Pi = 705mW Li = 0.65mH Ci = 25nF

PO = 87mW

Li = 0.65mH

CI = 125nF

TR12 - Total Measuring Deviation

Sum of input and output per DIN IEC 770, 23ºC ±5K

TR12 - Signalling - analogue output with sensor error or internal malfunction

Substitue value

Configurable from 3.5 mA up to 23.0 mA

Up-scale NAMUR NE 43

> 21.0 mA

Down-scale NAMUR NE 43

< 3.6 mA

TR12 - Case for head mounting

Material

Plastic

Cross section of terminal connections

max. 1.5 mm2, screws captive

Weight

Approx. 70 g

TR12 - Case for rail mounting per DIN EN 50 022-35

Material

Degree of protection

Plastic

Case

IP56 IEC 529 / EN 60529

Terminal Connections

IP20 IEC 529 / EN 60529

Cross section of terminal connections

0.25 mm2 up to 2.5 mm2

Weight

Max. 0.2 kg

TR12 - Special Features

Isolation Voltage (input versus analog output)

1500 VAC, 60 s

Electric protection

Protected against reverse polarity

Ambient and

storage temperature

Standard

-40 … +85 °C

Optional

Min. -50 °C max. +105 °C

Humidity

100 % relative humidity (unlimited with isolated sensor connection wires), moisture condensation permissible IEC 68 2-30 Var. 2

Vibration

10 … 2000 Hz 5 g DIN IEC 68 2-6

Shock

DIN IEC 68 2-27 gN = 30

Salt fog

DIN IEC 68 2-11

Configuration and calibration data

Permanently stored in EEPROM

Self-monitoring

Automatic execution of initial test after connection to power supply,

thereafter monitoring due to internal malfunction

Warm-up time

Approx. 5 Min.

Power consumption with UB 24 V

Max. 552 mW

Electromagnetic Compatibility

EMC Directive 89/336/EEC. EN61326:1997/A1:1998/A2:2001

Communication-interface

Programming Unit (part of the configuration-set available as an accessory)

Guarantee

5 years when used within standard ambient range. Rototherm standard terms of warranty apply.

1) Beginning of measuring range maximum 50% of end of measuring range

2) Technical data only valid only for configured measuring range > 400ºC

3) Whichever is greater

4) Valid only for configured measuring range beginning > -150ºC

FS

UB R A

TC Tamb - full scale value of configured measuring range

- loop power supply voltage, see power supply

- load

- temperature coefficient

- ambient temperature

TR12 Temperature Transmitters | 8

TR12 - Ordering Code

Model TR12 PUCK Style

TR12(P)

Model TR12 DIN Rail Mounting

TR12(D)

Input (table 1)

RTD PT100

Thermocouple Type K

Thermocouple Type J

Thermocouple Type T

Thermocouple Type N

Millivolt

1

K

J

T

N

V

Sensor Wiring Configuration (table 2)

2 wire

3 wire

4 wire

2

3

4

Transmitter Classification (table 3)

EExia Certified

EExnl/nA Certified

IA

XN

Setting (table 4)

Programmable (Programmed)

Pragrammable (Un-Programmed)

P

U

Sensor Burnout Protection (table 5)

Upscale

Downscale

U

D

Range (table 6)

Enter Minimum Range (Negative starts with N)

XXXX

Enter maximum Range (Positive starts with P)

XXXX

Unit of Measure

Degree C (ºC)

Degree F (ºF)

Millivolt (mV)

C

F

V

Clips

G Style DIN Rail Clip (Nylon)

M4 Top hat DINN Clip (Steel)

No Clip

Example Order Code

yy

yy

yy

yy

yy

yy

yy

yy

yy

yy

TR12 Transmitter (PUCK style)

PT100 input

2 wire wiring

EExiA Classification

Programmable (Programmed)

Upscale Burnout Protection

-100 Minimum Temperature

+100 Maximum Temperature

Degree C

No Clip

G

T

X

TR12(P)

1

2

IA

P

U

N100

P100

C

X

TR24 Temperature Transmitters | 9

Model TR24

Digital Temperature Transmitter

yy

yy

yy

yy

yy

yy

yy

Configurable with Windows® PC without sensor simulation

Analogue signal processing, ideal for multiplex systems

Quick response <1 ms to 90%

Sensor burnout signalling according to NAMUR NE 43

Electromagnetic compatibility according to NAMUR NE 21

Measuring span from 20 K

Compact design

General Description

Temperature transmitter for Pt100 in 2 or 3 wire connection with

4...20mA analogue output (loop powered 2 wire technique)

The TR24 temperature transmitter combines the known quick response

of an analogue transmitter with the flexibility of configuration by

means of a Windows PC.

The quick stabilisation of the output current after excitation voltage has

been applied enables the use of this transmitter in multiplex systems.

Setting of the measuring range, type of sensor and sensor burnout behavior takes only a matter of seconds thanks to the easy to use Windows configuration software. Time consuming adjustments and sensor

simulation are not required for this transmitter.

The TR24 can be remotely configured from the control room via the

current loop. Possible measuring errors which might for example, result

from poor thermometer position, can be compensated by means of the

function ‘sensor correction’.

Write protection and an increased ambient temperatures range complete the spectrum of features offered by the temperature transmitter.

Due to its flexibility and reliability the TR24 temperature transmitter

is suited for a wide range of applications in the machine industry and

plant construction.

As a result of its extremely compact design this TR24 temperature

transmitter can be fitted into any DIN connection head of form B.

The transmitters are delivered with a basic configuration. Alternatively,

upon request, transmitters can be delivered with a customized configuration within the given limits.

Input Types

Input Type

Code

TR24

RTD PT100

Type K

Thermocouple

Type J

Thermocouple

Type T

Thermocouple

Type N

Thermocouple

Millivolt

Setting

Code

Input

TR24

F

Fixed Range

P

Programmable (Programed)

U

Programmable (Un-Programed)

TR24 Dimensions

All dimensions are in mm. Drawings are for illustration purposes only

TR24 Temperature Transmitters | 10

TR24

Wiring Scheme

LJ8;hgg^\mbhg8h_8Hkh`kZffbg`8Mgbm

Receiving

Equipment

Disconnect

Input

Yellow and green are

connected only if

configuration of the

transmitter is to be made

8888ñ8888L^fi^kZmnk^8Hkh]n\m8;ZmZeh`n^

when the transmitter is

on-line.

When configuring

LJ8¦8Ki^\by\Zmbhgl

8888ñ8888L^fi^kZmnk^8Hkh]n\m8;ZmZeh`n^

in the workshop, an external

Aginm

power supply is not required

LJ8¦8Ki^\by\Zmbhgl E^Zlnkbg`8kZg`^8\hgy`nkZ[e^8pbma8Obg]hplÜ8H;

888Eh]^e8LJ

Hm888888<AF8=F88

888pbk^88pbk^

as the Programming Unit

E^Zlnkbg`8kZg`^8\hgy`nkZ[e^8pbma8Obg]hplÜ8H;

Aginm

888E^Zlnkbg`8kZg`^8fZqbfnf

LJ8888¦Å;¸Å;

provides the power.

888Eh]^e8LJ

Hm888888<AF8=F88

888pbk^88pbk^

888E^Zlnkbg`8liZg

LJ88888fbgbfnf88C

RS 232-C

888E^Zlnkbg`8kZg`^8fZqbfnf

LJ8888¦Å;¸Å;

888AgbmZe8oZen^8h_8f^Zlnkbg`8kZg`^8\hgy`nkZ[e^

888E^Zlnkbg`8liZg

888:Zlb\8\hgy`nkZmbhg

LJ88888¦Å;¸Å;

8pbk^88Å;

888AgbmZe8oZen^8h_8f^Zlnkbg`8kZg`^8\hgy`nkZ[e^

Ziikhq88f9

888:Zlb\8\hgy`nkZmbhg

=__^\m

Æ8C8¥888^Z\a8pbk^8ª«

888K^glhk8\nkk^gm

888;hgg^\mbhg8e^Z]l

888K^glhk8\nkk^gm

H^kfbllZ[e^8ehZ]8k^lblmZg\^

888;hgg^\mbhg8e^Z]l

9gZeh`n^8Gnminm

LJ88888¦Å;¸Å;

8pbk^88Å;

88^Z\a8pbk^88pbk^8lrff^mkb\ Ziikhq88f9

=__^\m

Æ8C8¥888^Z\a8pbk^8ª«

8f988pbk^8]^lb`g

H^kfbllZ[e^8ehZ]8k^lblmZg\^

ª«

ÆË8

888E^Zlnkbg`8]^obZmbhg8i^k8<AF8=F8

8Å;8ÆC

LJ88888fbgbfnf88C

88^Z\a8pbk^88pbk^8lrff^mkb\

8f988pbk^8]^lb`g

Dbg^Zk8mh8m^fi^kZmnk^8i^k8<AF8=F8

888E^Zlnkbg`8]^obZmbhg8i^k8<AF8=F8

8Å;8ÆC

ÆË8ª«

ÆË8ª«

9gZeh`n^8Gnminm

888Dbg^ZkbsZmbhg

888Dbg^Zkbmr8^kkhk

888L^fi^kZmnk^8\h^_y\b^gm888888

888LC

s^kh888Dbg^ZkbsZmbhg

888Dbg^Zkbmr8^kkhk

liZg

ÆË8¥88C LZ8hk8ª«8ÆC¥8C LZ Dbg^Zk8mh8m^fi^kZmnk^8i^k8<AF8=F8

ÆË8ª«

ÆË8¥88C

888Jblbg`8mbf^8888888888m

888L^fi^kZmnk^8\h^_y\b^gm888888

s^kh

ÆË8¥88C LZ8hk8ª«8ÆC¥8C LZ

í8fl

888LC

liZg

ÆË8¥88C LZ

í88fl

888Jblbg`8mbf^8888888888m

í8fl

ª«

l^glhk8[nkghnm

;hgy`nkZ[e^888F9EMJ8]hpgl\Ze^888í8f98ªmrib\Ze88f9«8

TR24 Designation of Terminal Connectors

LZ

LJ8<^lb`gZmbhg8h_8L^kfbgZe8;hgg^\mhkl

888Kpbm\a¦hg8]^eZr8^e^\mkb\

888Kb`gZeebg`

888Kpbm\a¦hg8]^eZr8^e^\mkb\ ;hgy`nkZ[e^888F9EMJ8nil\Ze^888î88f98ªmrib\Ze88f9«8

í88fl

l^glhk8lahkm8\bk\nbm

888Kb`gZeebg`

Fhm8\hgy`nkZ[e^8bg8`^g^kZe8F9EMJ8]hpgl\Ze^8í8f98

l^glhk8[nkghnm

;hgy`nkZ[e^888F9EMJ8]hpgl\Ze^888í8f98ªmrib\Ze88f9«8ª«

ªmrib\Ze88f9«8ª«

;hgy`nkZ[e^888F9EMJ8nil\Ze^888î88f98ªmrib\Ze88f9«8

input

4..20mA Loop

888DhZ]8888J9

J98í8ªM:8¦8N«8¥898pbma8J

8bg888Zg]8M

8bg8N

l^glhk8lahkm8\bk\nbm

Fhm8\hgy`nkZ[e^8bg8`^g^kZe8F9EMJ8]hpgl\Ze^8í8f98

9

:

ªmrib\Ze88f9«8ª«

Æ8Ë8¥88

888DhZ]8^__^\m

888Hhp^k8lniier8^__^\m

888DhZ]8888J9

ÆË8¥8N

J98í8ªM:8¦8N«8¥898pbma8J98bg888Zg]8M:8bg8N

Hhp^k8Kniier

888DhZ]8^__^\m

:r8ma^8f9¦ehhi

Æ8Ë8¥88

RTD/Resistance

Sensor

888Hhp^k8lniier8^__^\m

888Eh]^e88LJ8888ªpbmahnm8=q¦ikhm^\mbhg«

888Aginm8ihp^k8lniier8ikhm^\mbhg

4..20mA Loop

ÆË8¥8N

<;888N

:r8ma^8f9¦ehhi

Hhp^k8Kniier

J^o^kl^8iheZkbmr

888Eh]^e88LJ8888ªpbmahnm8=q¦ikhm^\mbhg«

8pbma8N8¥8fZqbfnf8ehZ]88<;888N

888Aginm8ihp^k8lniier8ikhm^\mbhg

J^o^kl^8iheZkbmr

=e^\mkhfZ`g^mb\8;hfiZmb[bebmr8ª=E;«

i^k8=E;8<bk^\mbo^8¥¥=O?88<AF8=F888Zg]8

888EZq8i^kfbllb[e^8kbiie^

888EZq8i^kfbllb[e^8kbiie^

9f[b^gm8Zg]8lmhkZ`^8m^fi^kZmnk^l

9f[b^gm8;hg]bmbhgl

;ebfZm^8\eZll

EZqbfnf8i^kfbllb[e^8anfb]bmr

Kah\d

KZem8_h`

3 wire

TR24 Load Diagram

DhZ]8<bZ`kZf

i^k8=E;8<bk^\mbo^8¥¥=O?88<AF8=F888Zg]8

Z]]bmbhgZe8F9EMJ8F=88ª9n`nlm8«

KmZg]Zk]8kZg`^8¦8mh8¸Å;

=qm^g]^]8kZg`^8ªhimbhg«8¦8mh8¸Å;8hk8¦8mh8¸Å;8ª«

;qª¦8mh8¸Å;8Ë8ni8mh8Ë8k^eZmbo^8anfb]bmr«88<AF8=F88¦

9f[b^gm8Zg]8lmhkZ`^8m^fi^kZmnk^l

KmZg]Zk]8kZg`^8¦8mh8¸Å;

=qm^g]^]8kZg`^8ªhimbhg«8¦8mh8¸Å;8hk8¦8mh8¸Å;8ª«

Ë8k^eZmbo^8anfb]bmr8fhlbmnk^8\hg]^glZmbhg8i^kfbllb[e^8

;ebfZm^8\eZll

Nb[kZmbhg

8pbma8N8¥8fZqbfnf8ehZ]88

Z]]bmbhgZe8F9EMJ8F=88ª9n`nlm8«

=e^\mkhfZ`g^mb\8;hfiZmb[bebmr8ª=E;«

9f[b^gm8;hg]bmbhgl

<AF8=F8¦¦8NZk8

;qª¦8mh8¸Å;8Ë8ni8mh8Ë8k^eZmbo^8anfb]bmr«88<AF8=F88¦

8mh88@s888`888<AF8=F88¦¦

EZqbfnf8i^kfbllb[e^8anfb]bmr

Ë8k^eZmbo^8anfb]bmr8fhlbmnk^8\hg]^glZmbhg8i^kfbllb[e^8

2 wire

<AF8=F8¦¦8NZk8

<AF8=F88¦¦

Nb[kZmbhg

8mh88@s888`888<AF8=F88¦¦

<AF8=F88¦¦

Kah\d

<AF8=F88¦¦

KZem8_h`

<AF8=F88¦¦

888888lniier

L;88m^fi^kZmnk^8\h^_y\b^gm

M:88ehhi8ihp^k8lniier8ohemZ`^8l^^8ihp^k8

Obk^8Fnf[^kWire Number: 888888lniier

ehZ]8J98bg8

ehZ]8J98bg8

Specifications in % refers to the measuring span.

The

permissible load is dependant upon the loop power supplyKi^\by\Zmbhgl8bg8Ë8k^_^kl8mh8ma^8f^Zlnkbg`8

La^8i^kfbllb[e^8ehZ]8bl8]^i^g]^gm8nihg8ma^8ehhi8ihp^k

DhZ]8<bZ`kZf

RA Load

voltage

liZg

lniier8ohemZ`^

J988DhZ]

Ta ambient temperature

Ki^\by\Zmbhgl8bg8Ë8k^_^kl8mh8ma^8f^Zlnkbg`8

La^8i^kfbllb[e^8ehZ]8bl8]^i^g]^gm8nihg8ma^8ehhi8ihp^k

LZ88Zf[b^gm8m^fi^kZmnk^

lniier8ohemZ`^

TC temperatureliZg

coefficient

L;88m^fi^kZmnk^8\h^_y\b^gm

J988DhZ]

M:88ehhi8ihp^k8lniier8ohemZ`^8l^^8ihp^k8

UB loop power Lsupply

voltage, see power supply

88Zf[b^gm8m^fi^kZmnk^

Z

Obk^8Fnf[^k

Fh8

Fh8

Fh8

ohemZ`^8M:8bg8N

ohemZ`^8M:8bg8N

Fh8

Fh8

Fh8

TR24 Temperature Transmitters | 11

TR24 - Specification

Input

Measuring range configurable with Windows® PC

Model TR24

Pt100

Measuring range maximum

TR24 -150ºC...+850ºC

Measuring span

TR24

minimum 20 K

Inital value of measuring range, configurable

TR24

-150ºC...+150ºC

Basic configuration

3 wire 0...150ºC

Sensor current

approx. 0.5 mA

Connection leads

DIN EN 60 751 2 wire, 3 wire

Effect

±0.2 K / 10 W each wire (1)

Permissable load resistance

30 W each wire, 3 wire symmetric

Analogue Output

4...20 mA, 2 wire design

Measuring deviation per DIN EN 60770, 23ºC ±5K

±0.2% (2)

Linearization

Linear to temperature per DIN EN 60751

Linearity error

±0.1% (3)

Temperature coefficient

TK

Rising time

zero

±0.1% / 10 KTa or (4) ±0.15K/10 KTa

span

±0.15% / 10 KTa

t90

< 1ms

Switch-on delay, electric

Signalling

< 10 ms

sensor burnout

Configurable NAMUR downscale < 3.6mA (typical 3 mA) (5)

Configurable NAMUR upscale > 21.0 mA (typical 23 mA)

sensor short circuit

Not configurable, in general NAMUR downscale < 3.6mA

(typical 3 mA) (5)

Load RA

RA < (UB - 10V) / 0.022A with RA in W and UB in V

Load effect

± 0.05% / 100 W

Power supply effect

±0.025% / V

Power Supply

By the 4...20mA-loop

Model TR24 (without Ex-protection)

DC 10....36 V

Input power supply protection

Reverse polarity

Max. permissible ripple

10 with 24V / maximum load 300 W

Electromagnetic Compatibility (EMC)

per EMC Directive 89/336/EWG DIN EN 61 326:2002 and

additional NAMUR NE 21 (August 98)

Ambient Conditions

Ambient and storage temperatures

Standard range -40 to +85ºC

Extended range (option): -50 to +85ºC or -40 to +105ºC (6)

Climate class

Cx(-40 to +85ºC, 5% up to 95% relative humidity) DIN EN 60 654-1

Maximum permissible humidity

100% relative humidity, mositure condensation permissible

DIN EN 60068-2-30 Var. 2

Vibration

10 to 2000 Hz 10g DIN EN 60 068-2-6

Shock

DIN EN 60 068-2-27

Salt fog

DIN EN 60 068-2-11

Special features

Temperature units

Configurable: ºC, ºF, K

Resistance Sensor

Linear resistance sensors are connectable

Sensor connection

Configurable: 3 wire or 2 wire

configurable compensation of lead resistance with 2 wire connection

Info data

TAG-N0., descriptor and Message via configuration storeable in

transmitter

Configuration and calibration data

Permanently stored in EEPROM

Case

Head Mounting design, including spring loaded mounting screws

Material

Plastic, PBT, glass fibre reinforced

Ingress protection

case

IP 50 IEX 529 / EN 60 529

terminal connections

IP 00 IEX 529 / EN 60 529

Cross section of terminal connectors

0.14 to 1.5 mm2

Weight

Approx. 0.04 kg

(1) (2)

(3)

(4)

(5)

(6)

For 3 wire sensor connection, with 2 wire connection a total lead resistance up to 20 W is compensatable, otherwise the lead resistance causes additional error

For measuring span lower than 50K additional: 0.1 K

For measuring span higher than 550K additional: 0.1%

±0.2% with measuring ranges with initial value lower than 0ºC or measuring span higher than 800K

Whichever is greater between the standard range of ambient temperature -40ºC <Ta<±+85ºC, with option “extended range of ambient temperature” the double value is valid outside the standard range

Temperature value, in case of short between wire no. 2 and no. 3 (operation of sensor in 2 wire connection)

-40 to +105ºC only without EX-protection

TR24 Temperature Transmitters | 12

TR24 - Ordering Code

Model TR24

TR24

Input (table 1)

RTD PT100

1

Sensor Wiring Configuration (table 2)

2 wire

3 wire

2

3

Transmitter Classification (table 3)

EExia Certified

Uncertified

IA

UN

Setting (table 4)

Programmable (Programmed)

Pragrammable (Un-Programmed)

P

U

Sensor Burnout Protection (table 5)

Upscale

Downscale

U

D

Range (table 6)

Enter Minimum Range (Negative starts with N)

XXXX

Enter maximum Range (Positive starts with P)

XXXX

Unit of Measure

Degree C (ºC)

Degree F (ºF)

Millivolt (mV)

C

F

V

Clips

G Style DIN Rail Clip (Nylon)

M4 Top hat DINN Clip (Steel)

No Clip

G

T

X

Example Order Code

TR24

yy

yy

yy

yy

yy

yy

yy

yy

yy

yy

TR24 Transmitter

PT100 input

2 wire wiring

EExiA Classification

Programmable (Programmed)

Upscale Burnout Protection

-100 Minimum Temperature

+100 Maximum Temperature

Degree C

No Clip

1

2

IA

P

U

N100

P100

C

X

TR32 Temperature Transmitters | 13

Model TR32.1/3S

ATEX

Digital Temperature Transmitter

APPROVED PRODUCTS

yy HART® Protocol

yy ATEX Approved

yy Universally programmable for 1 or 2 sensors

- RTDs / Resistance - sensor

- Thermocouples / mV – sensor

- Potentiometers

yy Output linear to temperature with input signal from RTDs and

. Thermocouples

yy Custom specific linearisation with max. 30 points for sensors with Ω or mV output

yy Analog output 4 … 20 mA, invertible, 2 - wire design

yy Signalling in accordance with NAMUR NE43

yy Sensor break detection in accordance with NAMUR NE89

yy Ex class protection, intrinsically safe

- II 1G Ex ia llC T4 / T5 / T6

- II 1D Ex iaD 20 T120 ºC

- II (1G) 2G Ex ia llC T4 / T5 / T6

- II (1D) 2D Ex iaD 20/21 T120 ºC

yy EMC Conformity per

- EN 61326-1:2006

- EN 61326-2-3:2006

- NAMUR NE 21

yy Isolation voltage 1200 VAC between sensor and current loop

yy 95 % Rh protection, moisture condensation permissible

yy TÜV certified SIL for protective equipment developed per . .

. . IEC 61508

yy Configurable via

- HART® Communicator

- PC Windows® programme

yy Terminal connections with captive screws

yy CE Conformity

General Description

The TR32.xS transmitters are designed for universal use in the process

industry. They offer high accuracy, galvanic isolation and excellent EMI

protection.

Via HART® protocol, the TR32.xS temperature transmitters are configurable with a variety of open configuration tools. In addition to the different sensor types (e.g. sensors in accordance with DIN EN 60751, JIS

C1606, DIN 43760, IEC 60584 or DIN 43710), customer specific sensorcurves can also be defined, through the input of value pairs (user defined linearisation).

When configured for a sensor with redundancy (Dual sensor), on a sensor failure it will automatically change over to the working sensor.

Furthermore there is the possibility to activate Sensor Drift Detection.

With this, an error signal occurs when the magnitude of the temperature difference between Sensor 1 and Sensor 2 exceeds a user-selectable value.

The TR32 transmitter also has additional sophisticated supervisory functionality such as monitoring of the sensor wire resistance and sensorbreak detection in accordance with NAMUR NE89 as well as monitoring

of the measuring range. Moreover, this transmitter has comprehensive

cyclic self monitoring functionality.

The dimensions of the head-mounted transmitter match the Form-B

DIN connecting heads with extended mounting space, e.g. Rototherm’s

H70.

The rail-mounted transmitters can be used for all standard rack systems

in accordance with IEC 60715.

The transmitters are delivered with either a basic configuration or configured according to customer specifications.

Input Types

Input Type

Code

TR32

RTD PT100

RTD PT1000

Type K

Thermocouple

Type J

Thermocouple

Type T

Thermocouple

Type N

Thermocouple

Millivolt

Setting

Code

Input

TR24

F

Fixed Range

P

Programmable (Programed)

U

Programmable (Un-Programed)

TR32 Temperature Transmitters | 14

Specifications of Model TR32.1S head mounting version and Model TR32.3S rail mounting version

Temperature Transmitter Input

Resistance sensor

Max. Configurable

measuring range 1)

Standard

α values

Pt100

-200 °C ... +850 °C

IEC 60751:2008

α = 0.00385

4)

PT(x) 10...1000

-200 °C ... +850 °C

IEC 60751:2008

α = 0.00385

JPt100

-200 °C ... +500 °C

JIS C1606:1989

α = 0.003916

Ni100

-60 °C ... +250 °C

Resistance sensor

Potentiometer

9)

DIN 43760:1987

α = 0.00618

0 ... 8370 Ω

Minimum

measuring span

14)

}

10 K or 3.8 Ω

whichever is

greater

4Ω

0 ... 100%

Typical measuring

deviation 2)

≤ ± 0.12 °C

5)

≤ ± 0.0094 °C

6) 7)

≤ ± 0.12 °C

5)

≤ ± 0.0094 °C

6) 7)

≤ ± 0.12 °C

5)

≤ ± 0.0094 °C

6) 7)

≤ ± 0.12 °C

5)

≤ ± 0.0094 °C

6) 7)

≤ ± 1.68 Ω

10%

Temperature

coefficient per °C

typical 3)

≤ 0.50 %

8)

10)

≤ ± 0.1584 Ω

8)

≤ ± 0.0100 %

10)

Sensor current at the measurment

maximum 0.3 mA (Pt100)

Connection type

1 sensor 2- /4- /3-wire or 2 sensors 2-wire

(for further information, please refer to Designation of Terminal Connections)

Maximum wire resistance

50 Ω each wire, 3-/4-wire

Thermocouple

Max. Configurable

1)

measuring range

Standard

Type J (Fe-CuNi)

-210 °C ... +1200 °C

IEC 60584-1: 1995

Type K (NiCr-Ni)

-270 °C ... +1372 °C

IEC 60584-1: 1995

Type L (Fe-CuNi)

-200 °C ... +900 °C

DIN 43760: 1987

Minimum measuring span

Type U (Cu-CuNi)

-200 °C ... +600 °C

DIN 43710: 1985

}

Type R (PtRh-Pt)

-50 °C ... +1768 °C

IEC 60584-1: 1995

150 K

Type E (NiCr-Cu)

-270 °C ... +1000 °C

IEC 60584-1: 1995

Type N (NiCrSiNiSi)

-270 °C ... +1300 °C

IEC 60584-1: 1995

Type T (Cu-CuNi)

-270 °C ... +400 °C

IEC 60584-1: 1995

Type S (PtRh-Pt)

-50 °C ... +1768 °C

Type B (PtRh-Pt)

0 °C ... +1820 °C

mV-Sensor

15)

14)

50 K or 2 mV whichever is greater

Typical measuring

deviation 2)

≤ ± 0.91 °C

11)

≤ ± 0.98 °C

11)

≤ ± 0.91 °C

11)

≤ ± 0.91 °C

≤ ± 1.02 °C

11)

11)

11)

≤ ± 0.92 °C )

≤ ± 0.92 °C

11)

≤ ± 1.66 °C

11)

11)

IEC 60584-1: 1995

150 K

≤ ± 1.66 °C

IEC 60584-1: 1995

200 K

≤ ± 1.73 °C 12)

4 mV

≤ ± 0.33 mV 13)

-500 mV ... +1800 mV

Temperature

coefficient per °C

typical 3)

11)

≤ ± 0.0217 °C 7)

≤ ± 0.0238 °C 7)

≤ ± 0.0203 °C 7)

11)

≤ ± 0.0224 °C 7)

≤ ± 0.0238 °C 7)

11)

≤ ± 0.0191 °C 7)

≤ ± 0.0191 °C 7)

11)

≤ ± 0.0338 °C 7)

≤ ± 0.0338 °C 7)

11)

11)

11)

11)

11)

≤ ± 0.0500 °C 7)

≤ ± 0.0311 mV 7)

12)

13)

Connection type

1 sensor or 2 sensors

(for further information, please refer to Designation of Terminal Connections)

Max. wire resistance

5 kΩ each wire

Cold Junction Compensation, configurable

compensation; internal or external with Pt100 or with thermostat or off

1)

Other units e.g. ºF and K on request

Measuring deviation(input+output) at ambient temperature 23

ºC ±3K, without

influence of lead resistance; example calculation see page 4.

3)

Temperature coefficient (input+output) per ºC

4)

x configurable between 10 ... 1000

5)

Based on 3-wire Pt100, Ni100, 150 ºC MV

6)

Based on 150 ºC MV

7)

In ambient temperature range -40 ... +85 ºC

8)

Based on a sensor with max. 5KΩ

9)

2)

10)

Rtotal: 10 ... 100 KΩ

Based on a potentiometer value of 50%

11)

Based on 400 ºC MV with cold junction compensation error

12)

Based on 1000 ºC MV with cold junction compensation error

13)

Based on measuring range 0 ... 1 V, 400 mV MV

14)

The transmitter can be configured below these limits but not recommended due to

loss of accuracy

15)

Specification valid only for measuring range between 450 ... 1820 ºC

MV = Measuring value (temperature measuring value in ºC)

TR32 Temperature Transmitters | 15

User linearisation

Via software, customer-specific sensor curves can be stored in the

transmitter, so that further sensor types can be used.

Number of data points: minimum 2; maximum 30

Monitoring functionality with 2 sensors connected (dual sensors).

Redundancy

During a sensor failure (sensor break, wire resistance too high or

below the sensor measuring range) of one of the two sensors, the

process value is based only on the error free sensor. Once the error is

resolved, the process value (output) is once again based on both sensors, or on Sensor 1.

Ageing-control (sensor-drift-monitoring)

An error signal is activated if the magnitude of the temperature difference between Sensor 1 and Sensor 2 exceeds a user selected value.

This monitoring function only signals a failure when two valid sensor

values are measured and the temperature difference exceeds the

selected limit value. (Not available for the sensor functionality “difference”, since the output signal is already defined by this value).

Sensor functionality with 2 sensors connected (dual sensor)

Sensor 1, Sensor 2 redundant

The 4 ... 20 mA output signal delivers the process value from Sensor 1.

If Sensor 1 fails, the process value is taken from Sensor 2 (Sensor 2 is

redundant).

Average

The 4 ... 20 mA output signal delivers the average value from Sensor

1 and Sensor 2. If one sensor fails, the process value is taken from the

error-free sensor.

Minimum

The 4 ... 20 mA output signal delivers the minimum value with respect

to Sensor 1 and Sensor 2. If one sensor fails, the process value is taken

from the error-free sensor.

Maximum

The 4 ... 20 mA output signal delivers the maximum value

with respect to Sensor 1 and Sensor 2. If one sensor fails, the process

value is taken from the error-free sensor.

Difference *)

The 4 ... 20 mA output signal delivers the difference between Sensor 1

and Sensor 2. If one sensor fails, an error signal will be activated.

*) This operating mode is not allowed at option SIL (TR32.xS.xx-S).

Note:

The transmitter can be configured below these limits but is not recommended

due to loss of accuracy.

Analogue output / Output limits / Signalling / Isolation resistance

Analogue output, configurable

linear to temperature per IEC 60751 / JIS C1606 / DIN 43760

(for resistance sensors) or

linear to temperature per IEC 584 / DIN 43710 (for thermocouples)

4 ... 20 mA or 20 ... 4 mA, 2-wire design

Output limits, configurable

to NAMUR NE43

customer specific, adjustable

Option SIL (TR32.xS.xx-S)

lower limit

3.8 mA

3.6 mA ... 4.0 mA

3.6 mA ... 4.0 mA

upper limit

20.5 mA

20.0 mA ... 21.5 mA

20.0 mA ... 20.5 mA

Current value for Signalling, configurable

to NAMUR NE43

default value

Option SIL (TR32.xS.xx-S)

down scale

< 3.6 mA (3.5 mA)

3.5 mA ... 12.0 mA

3.5 mA ... 3.6 mA

up scale

> 21.0 mA (21.5 mA)

12.0 mA ... 23.0 mA

21.0 mA ... 23.0 mA

In simulation mode, independent from input signal, simulation value configurable from 3.5 mA up to 23.0 mA

Load RA (without HART®)

RA ≤ (UB -10.5 V) / 0.023 A with RA in Ω and UB in V

Load RA (with HART®)

RA ≤ (UB -11.5 V) / 0.023 A with RA in Ω and UB in V

Isolation voltage (input to analogue output)

1200 V AC, (50 Hz / 60 Hz); 1 s

Isolation specification to DIN EN 60664-1:2003

Overvoltage Category III

Rise time / Damping / Measuring rate

Rise time t90

approx. 0.8 s

Damping, configurable

off; configurable between 1 s and 60 s

Turn on time (time to get the first measured value)

max. 15 s

Measuring rate

measured value update approx. 3/s

1)

1) Valid only for single RDT/Thermocouple sensor

TR32 Temperature Transmitters | 16

Measuring deviation / Temperature coefficient / Long-term stability

Effect of Load

not measurable

Power supply effect

not measurable

Warm-up time

after approx. 5 minutes the instrument will function to the specified technical data (accuracy)

Input

Measuring deviation per

DIN EN 60770, 23 °C ± 3 K

Average temperature coefficient (TC) for each

10 K ambient temperature change in the

range -40 ... +85 °C 1)

Connection lead

effects

Long-term

stability 1 year

Resistance

thermometer

Pt100/JPt100/

Ni100 2)

-200 °C ≤ MV ≤ 200 °C: ±0.10 K

MV > 200 °C: ±(0.1 K + 0.01 % IMV -200

K|) 3)

±(0.06 K + 0.015 % MV)

Resistance sensor 5)

≤ 890 Ω: 0.053 Ω 6) or 0.015% MV 7)

≤ 2140 Ω: 0.128 Ω 6) or 0.015% MV 7)

≤ 4390 Ω: 0.263 Ω 6) or 0.015% MV 7)

≤ 8380 Ω: 0.503 Ω 6) or 0.015% MV 7)

±(0.01 Ω + 0.01 % MV)

4-wire: no effect

(0 to 50 Ω each wire)

3-wire: ±0.02 Ω /

10 Ω

(0 to 50 Ω each wire)

2-wire: resistance

of the connection

leads 4)

±60 mΩ or 0.05 %

of MV, whichever is

greater

Potentiometer 5)

Rpart/Rtotal is max. ±0.5 %

±(0.1 % MV)

Thermocouple

Type E, J

-150 °C < MV < 0 °C: ±(0.3 K + 0.2 % IMVI)

MV > 0 °C: ±(0.3 K + 0.03 % MV)

Type E: MV > -150 °C: ±(0.1 K + 0.015 % |MV|)

Type J: MV > -150 °C: ±(0.07 K + 0.02 % |MV|)

Type T, U

-150 °C < MV < 0 °C: ±(0.4 K + 0.2 % IMVI)

MV > 0 °C: ±(0.4 K + 0.01 % MV)

-150 °C < MV < 0 °C: ±(0.07 K + 0.04 % MV)

MV > 0 °C: ±(0.07 K + 0.01 % MV)

Type R, S

50 °C < MV < 400 °C:

±(1.45 K + 0.12 % IMV-400 KI)

400 °C < MV < 1600 °C:

±(1.45 K + 0.01 % IMV-400 KI)

Type R: 50 °C < MV < 1600 °C:

±(0.3 K + 0.01 % |MV - 400 K|)

Type S: 50 °C < MV < 1600 °C:

±(0.3 K + 0.015 % |MV - 400 K|)

450 °C < MV < 1000 °C:

±(1.7 K + 0.2 % |MV - 1000 K|)

MV > 1000 °C: ±1.7 K

450 °C < MV < 1000 °C:

±(0.4 K + 0.02 % |MV - 1000 K|)

MV > 1000 °C: ±(0.4 K + 0.005 % (MV - 1000 K))

Type K

-150 °C < MV < 0 °C: ±(0.4 K + 0.2 % |MV|)

0 °C < MV < 1300 °C: ±(0.4 K + 0.04 % MV)

-150 °C < MV < 1300 °C: ±(0.1 K + 0.02 % |MV|)

Type L

-150 °C < MV < 0 °C: ±(0.3 K + 0.1 % |MV|)

MV > 0 °C: ±(0.3 K + 0.03 % MV)

-150 °C < MV < 0 °C: ±(0.07 K + 0.02 % |MV|)

MV > 0 °C: ±(0.07 K + 0.015 % MV)

Type N

-150 °C < MV < 0 °C: ±(0.5 K + 0.2 % |MV|)

MV > 0 °C: ±(0.5 K + 0.03 % MV)

-150 °C < MV < 0 °C: ±(0.1 K + 0.05 % |MV|)

MV > 0 °C: ±(0.1 K + 0.02 % MV)

mV-Sensor 5)

≤1160 mV: 10 µV +0.03% |MV|

>1160 mV: 15 µV +0.07% |MV|

2 μV + 0.02 % |MV|

100 μV + 0.08 % |MV|

Cold Junction

Compensation

(CJC) 9)

±0.8 K

±0.1 K

±0.2 K

Output

±0.03 % of measuring span

±0.03 % of measuring span

±0.05% of span

Type B

Total measuring deviation

Addition: input + output per DIN EN 60770, 23 ºC ± 3 K

MV = Measuring value (temperature measuring value in ºC)

“Measuring span = configurable upper limit of measuring range - configurable lower

limit of measuring range”

1) TR32.1S: With the extended ambient temperature range (-50 ... -40 ºC) the value is

doubled

2) For sensor Ptx (x = 10 ... 1000) applies:

for x ≥ 100: permissible error, as for Pt100

for x ≤ 100: permissible error, as for Pt100 with a factor (100/x)

3) Additional error for resistance thermometers in a 3-wire configuration with zerobalanced cable: 0.05 K

Example calculation

Pt100 / 4-wire / measuring range 0 ... 150 ºC / ambient temperature 33 ºC

Input Pt100, MV < 200 ºC

±0.100 K

Output ±(0.03 % of 150 K)

±0.045 K

TC 10 K - input ±(0.06 K + 0.015 % of 150 K) ±0.083 K

TC 10 K - output ±(0.03 % of 150 K)

±0.045 K

Measuring deviation - typical

±0.145 K

(√ (input2+output2+TCinput2+TCoutput2))

Measuring deviation - maximum

±0.273 K

(input+output+TCinput+TCoutput)

6 μV / 1000 Ω 8)

±20

μV or 0.05 %

of MV, whichever is

greater

4) The specified resistance value of the sensor wire can be subtracted from the

calculated measured sensor resistance.

Dual sensor: configurable for each sensor separately.

5) This operating mode is not allowed at option SIL (TR32.xS.xx-S)

6) Double value at 3-wire

7) Greater value applies

8) Within a range of 0 ... 10 KΩ wire resistance.

9) Only for thermocouple

Basic configuration:

Input signal: Pt100 in 3-wire connection, measuring range: 0 ... 150 °C

Thermocouple type K / measuring range 0 ... 400 ºC / internal compensation

(cold junction) / ambient temperature 23 ºC

Input type K, 0 ºC < MV < 1300 ºC

±0.56 K

±(0.4 K + 0.04 % of 400 K)

Cold junction ±0.8 K

±0.80 K

Output ±(0.03 % of 400K)

±0.12 K

Measuring deviation - typical

±0.98 K

(√ (input2+Cold junction2 + output2)

Measuring deviation - maximum

±1.48 K

(input+Cold junction + output)

TR32 Temperature Transmitters | 17

Monitoring

Test current for sensor monitoring 1)

nom. 20 μA during test cycle, otherwise 0 μA

Monitoring NAMUR NE89 (monitoring of input lead resistance)

Resistance thermometer (Pt100, 4-wire)

RL1 + RL4 > 100 Ω with hysteresis 5 Ω

RL2 + RL3 > 100 Ω with hysteresis 5 Ω

Thermocouple

RL1 + RL4 + RThermocouple > 10 kΩ with hysteresis 100 Ω

Sensor burnout monitoring

Activated

Self monitoring

active permanently, e.g. RAM/ROM Test, logical program operating checks

and validity check

Measuring range monitoring

monitoring of the set measuring range for upper/lower deviations

Monitoring of input lead resistance (3-wire)

monitoring for resistance difference between lead 3 and 4; an error will be set, if

there is a difference (> 0,5 Ω) between leads 3 and 4

1)

Valid for thermocouple only

Explosion protection / power supply

Model

Approvals

TR32.xS.00

TR32.1S.IS

EC-type examination certificate:

BVS 11 ATEX E 001 X

Zone 0, 1: II 1G Ex ia IIC T4/T5/T6

Zone 20, 21: II 1D Ex iaD T120 °C

intrinsically safe per directive 94/9/EC

(ATEX)

Permissible Ambient/Storage

temperature

(per temperature codes

and classes)

Safety-related maximum vales for

Sensor

(connections 1 up to 4)

Current loop

(connections ±)

{-50 °C} -40 °C...+85°C

-

-

10.5 ... 42 V

Gases, category 1 and 2

{-50 °C} -40 °C ... +85 °C (T4)

{-50 °C} -40 °C ... +75 °C (T5)

{-50 °C} -40 °C ... +60 °C (T6)

Uo = DC 6.5 V

Io = 9.3 mA

Po = 15.2 mW

Ci = 208 nF

Li = negligible

Gases, category 1

and 2

Ui = DC 30 V

Ii =130 mA

Pi = 800 mW

Ci = 7.8 nF

Li = 100 μH

10.5 ... 30 V

TR32.3S.IS

Zone 0, 1: II (1G) 2G Ex ia IIC T4/T5/T6

Zone 20, 21: II (1D) 2D Ex iaD T120 °C

intrinsically safe per directive 94/9/EC

(ATEX)

Dust, category 2

{-50 °C} -40 °C ... +40 °C

(Pi<750 mW)

{-50 °C} -40 °C ... +75 °C

(Pi<650 mW)

{-50 °C} -40 °C ... +100 °C

(Pi<550 mW)”

TR32.1S.NI/

TR32.3S.NI

II 3G Ex nL IIC T4/T5/T6

II 3G Ex nA IIC T4/T5/T6

II 3G Ex ic IIC T4/T5/T6

{-50 °C} -40 °C ... +85 °C (T4)

{-50 °C} -40 °C ... +75 °C (T5)

{-50 °C} -40 °C ... +60 °C (T6)

Gases, category 1 and 2

IIC: Co = 24 μF 3)

Lo = 365 mH

Lo/Ro = 1.44 mH/Ω

IIA: Co = 1000 μF 3)

Lo = 3288 mH

Lo/Ro = 11.5 μH/Ω

Dust, category 2

IIB iaD:

Co = 570 μH 3)

Lo = 1644 mH

Lo/Ro = 5.75 μH/Ω

Uo = DC 3.1 V

Io = 0.26 mA

Ci = 208 nF

Li = negligible

Co ≤ 1000 µF

Lo ≤ 1000 mH

ratio Lo/Ro (for ignition

protection type ic)

Lo/Ro ≤ 9 mH/Ω (for IIC)

Lo/Ro ≤ 39 mH/Ω (for IIB)

Lo/Ro ≤ 78 mH/Ω (for IIA)

Power

supply UB

(DC) 2)

Dust, category 2

Ui = DC 30 V

Ii =130 mA

Pi = 750/650/550 mW

Ci = 7.8 nF

Li = 100 μH

Ui = 40 V

Ii = 23 mA *)

Pi = 1 W

Ci = 7.8 nF

Li = 100 µH

10.5 ... 40 V

2) Power supply input protected against reverse polarity: Load RA ≤ (UB - 10.5V)/0.023 A with RA in Ω and UB in V (without HART®)

On switch on, an increase in the power supply of 2V/s is needed; otherwise the temperature transmitter will remain in a safe condition at 3.5 mA.

3) Ci already considered

{} Items in curved brackets are options for additional price, not for rail mounting TR32.3S

*) The maximum operating current is limited by the TR32. The maximum output current of the associated energy-limited apparatus does not have to be ≤ 23 mA.

TR32 Temperature Transmitters | 18

Ambient conditions

Permissible ambient temperature range

{-50} -40 ... +85 °C

Climate class per IEC 654-1: 1993

Cx (-40 ... +85 °C, 5 ... 95 % relative air humidity)

Maximum permissible humidity

■■ Model TR32.1S per IEC 60068-2-38: 1974

Test max. temperature cycling 65 °C and -10 °C, relative humidity 93 % ±3 %

■■ Model TR32.3S per IEC 60068-2-30: 2005

Test max. temperature 55 °C, relative humidity 95 %

Vibration per IEC 60068-2-6: 2007

Test Fc: 10 ... 2000 Hz; 10 g, Amplitude 0.75 mm

Shock per IEC 68-2-27: 1987

Test Ea: acceleration Type I 30 g and Type II 100 g

Salt mist per IEC 60068-2-52

Severity level 1

Freefall in accordance with IEC 60721-3-2: 1997

Drop height 1500 mm

Electromagnetic compatibility (EMC)

EMC Directive 2004/108/EC, DIN EN 61326 Emission (Group 1, Class B)

and immunity (industrial application), as well as per NAMUR NE21

{} Items in curved brackets are options for additional price, not for trail mounting TR32.3S

Case

Transmitter model

Material

Weight

Ingress protection 1)

Terminal connections

(screws captive)

TR32.1S head mounting version

Plastic PBT,

glass fibre reinforced

0.07 kg

IP 00

electronics completely

potted

Cross-section head and rail min. 0.14mm2

wire cross-section max. 1.5 mm2

TR32.3S rail mounting version

Plastic

0.2 kg

IP 20

wire cross-section max. 2.5 mm2

1) Ingress protection per IEC 529 / DIN EN 60529

HART® Communication Protocol Rev. 5 including burst mode, Multidrop

Compatibility between components from different manufacturers is imperative with HART®-Devices.

The TR32 can be compatible with almost every open software and hardware tool; among other things with:

1. User-friendly Rototherm Configuration Software, contact Rototherm sales

2. HART® Communicator HC275 / FC375 / FC475 / MFC4150: TR32 Device Description (device object file) is integrated and upgradable with old

HC275 versions

3. Asset Management Systems

Note:

For direct communication via the serial / USB interface of a PC / Notebook, a HART® modem is needed.

Parameters, which are defined in the scope of the universal HART® commands (e.g. the measuring range) can, in principle, be edited with all

HART® configuration tools.

Load diagram

The permissible load is dependent upon the loop power supply voltage.

Load RA ≤ (UB - 10.5 V) / 0.023 A with RA

in Ω and UB in V

(without HART®)

Designation of Terminal Connections

TR32 Temperature Transmitters | 19

Dimensions in mm

TR32.1S

TR32.3S

Typical connection for hazardous areas

Typical connection for non-hazardous areas

TR32 Temperature Transmitters | 20

TR32 Temperature Transmitters | 21

TR32 - Ordering Code

Model TR32 PUCK Style

TR32(P)

Model TR32 DIN Rail Mounting

TR32(D)

Input (table 1)

RTD PT100

RTD PT1000

Thermocouple Type K

Thermocouple Type J

Thermocouple Type T

Thermocouple Type N

Millivolt

1

2

K

J

T

N

V

Sensor Wiring Configuration (table 2)

2 wire

3 wire

4 wire

2

3

4

Transmitter Classification (table 3)

EExia Certified

EExnl/nA Certified

IA

XN

Setting (table 4)

Programmable (Programmed)

Pragrammable (Un-Programmed)

P

U

Sensor Burnout Protection (table 5)

Upscale

Downscale

U

D

Range (table 6)

Enter Minimum Range (Negative starts with N)

XXXX

Enter maximum Range (Positive starts with P)

XXXX

Unit of Measure

Degree C (ºC)

Degree F (ºF)

Millivolt (mV)

C

F

V

Clips

G Style DIN Rail Clip (Nylon)

M4 Top hat DINN Clip (Steel)

No Clip

G

T

X

Example Order Code

TR32(P)

yy

yy

yy

yy

yy

yy

yy

yy

yy

yy

TR32 Transmitter (PUCK style)

PT100 input

2 wire wiring

EExiA Classification

Programmable (Programmed)

Upscale Burnout Protection

-100 Minimum Temperature

+100 Maximum Temperature

Degree C

No Clip

1

2

IA

P

U

N100

P100

C

X

TR48 Temperature Transmitters | 22

Model TR48

ATEX

Temperature Transmitter

yy

yy

yy

yy

yy

yy

yy

APPROVED PRODUCTS

ATEX Approval

EExia / EExd (when fixed in H70 Head)

Radio Frequency Immunity from 20 to 1000 MHz

Thermocouple and RTD Inputs

Differential Transmitters

Open Circuit Protection

Cold Junction Compensated

General Description

The model TR48 temperature transmitter offers a convenient method

of increased system accuracy, while reducing costs through the

elimination of long runs of expensive compensating cables. The

transmitter requires only two wires which carry both supply voltage

and current signal, and has a high degree of immunity to interference

and noise pick-up.

II 1G EExia IIC T4/5

Input Types

Input Type

Code

RTD PT100

TR48

RTD PT1000

Type K

Thermocouple

Type J

Thermocouple

Type T

Thermocouple

Type N

Thermocouple

Millivolt

Setting

Code

Input

TR24

F

Fixed Range

P

Programmable (Programed)

U

Programmable (Un-Programed)

Dimensions

DIN Rail Mounted Version

Loop Drive Capability

The TR48 temperature transmitter is also available in a DIN rail

mounted version. Manufactured to the same high specification with

easily adjustable zero and span potentiometers, this model is ideal

when larger numbers are required to be rack mounted.

TR48 Temperature Transmitters | 23

Wiring Details

TR48TC Thermocouple Input

TR48SW Slidewire input

The slidewire input version of the TR48 produces a linear output

proportional to the position of the wiper of a slidewire or potentiometer. This provides a convenient way of remotely indicating

or controlling the position of any motorised actuator fitted with a

re-transmission potentiometer.

TR48R Platinum Resistance Input TR48RD Differential Input

Differential transmitters produce an output proportional to the

difference between two precision Platinum Resistance

Thermometers.

A typical application might be to monitor the efficiency of a piece

of plant by detecting the heat loss or gain between input and

output. In such applications it is often necessary to measure very

small differences. Using a differential transmitter with a span of

20ºC, a resolution of 0.01ºC can easily be achieved using only a

low cost digital panel meter.

Specifications

Input

Thermocouple

RTD

Slidewire

Output

4 to 20 mA (minimum 2.2 mA, maximum 27 mA)

Power Supply

7.5 to 36 VDC (reverse polarity protected) 24 VDC nominal

Ambient Temperature Range - Working

-25 to +85ºC (high 125ºC version available)

Ambient Temperature Range - Storage

-55 to +125ºC

Humidity

0 to 95% Rh non-condensing

Sensor Open Circuit Protection

Upscale standard

(downscale to order)

Upscale only

Cold Junction

Compensation

Fitted as standard

N/A

Linearity

Not linearised (linear to Linear to temperature

mV input)

<0.05%

Zero and Span

Adjustment

+10% nominal (wider spans are available)

Turn on Time

Less than 20 ms to 1% of final reading

Differential RTD

N/A

Up or Down depending on

which sensor fails

Linear to position

<0.01%

Linear to temperature

difference <0.05%

TR48 Performance

Repeatability ±0.05% of span

Accuracy

Hysteresis ±0.02% of span

Stability ±0.02% of span

Zero < ±0.01% of span

Ambient Temperature Effect (per ºC change)

Span ±0.01% of span

CJC (TC only) ±0.01ºC/ºC

Long Term Drift

< ±0.1% of span/year

Power Supply

7.5 to 36 VDC

Power Supply Effect

< ±0.01% of span/Volt change

Output Ripple

< 0.04% of span RMS

CMMR

-110 db

Sensor Lead Resistance Effect (RTD)

< ±0.001% of span per Ohm. Equal change in lead resistance.

Excitation Current

0.8 mA

Sensor Lead Resistance Effect (TC)

Up to 1000 Ohm lead resistance has no

measurable effect

Input Impedance

10 G Ohm

Radio Frequency Interference Effect

CE conformity per EN50081-1(1992) and EN50082-1(1992) over the frequency range 20

MHz to 1000 MHz at a field strength of 10 V/metre

TR48 Temperature Transmitters | 24

TR48 - Ordering Code

Model TR48

TR48

Input (table 1)

RTD PT100

Thermocouple Type K

Thermocouple Type J

Thermocouple Type T

1

K

J

T

Sensor Wiring Configuration (table 2)

3 wire

3

Transmitter Classification (table 3)

EExia Certified

EExnl/nA Certified

Uncertified

IA

XN

UN

Setting (table 4)

Fixed Range

F

Sensor Burnout Protection (table 5)

Upscale

U

Range (table 6)

Enter Minimum Range (Negative starts with N)

XXXX

Enter maximum Range (Positive starts with P)

XXXX

Unit of Measure

Degree C (ºC)

Degree F (ºF)

Millivolt (mV)

C

F

V

Clips

G Style DIN Rail Clip (Nylon)

M4 Top hat DINN Clip (Steel)

No Clip

G

T

X

Example Order Code

TR48

yy

yy

yy

yy

yy

yy

yy

yy

yy

yy

TR48 Transmitter

PT100 input

3 wire wiring

Uncertified

Programmable (Programmed)

Upscale Burnout Protection

-100 Minimum Temperature

+200 Maximum Temperature

Degree C

No Clip

1

3

UN

P

U

N0100

P0200

C

X

TR48 Temperature Transmitters | 25

Classification Guide (According to 94/9/EC)

II 2G EEx ia IIC T6

Device Group

Category

Identify

Ignition Protection

Class

Explosion Group

Temperature Class

Symbol

Symbol

Description

EU explosion atmosphere symbol

Device Group

Group

Description

Group I

for use in underground mine and their above ground equipment

Group II

for use above ground at risk of explosion

Category

Group

Equivalent to Zone

Description

Safety

Category 1G

Zone 0

Inflammable gasses, vapours or mists

Very high level of safety

Category 2G

Zone 1

Inflammable gasses, vapours or mists

High level safety

Category 3G

Zone 2

Inflammable gasses, vapours or mists

Normal level safety

Category 1D

Zone 20

Inflammable dust

Very high level of safety

Category 2D

Zone 21

Inflammable dust

High level safety

Category 3D

Zone 22

Inflammable dust

Normal level safety

Identifier

Identifier

Description

EEx

Define that this is an electrical device

Ignition Protection Class

Class

Ignition protection category

Can be used

in Zone

Safety Principle

EExia Certified

Intrinsically safe (Special requirements)

Zone 0

Limits the energy of the spark and temperature of the surface

EExd Certified

Explosion Proof, Pressurised encapsulation

Zone 1

Controls an internal explosion and extinguishes the flame.

EExnA Certified

Non sparking equipment

Zone 2

No arcs, sparks or hot surfaces

EExnL Certified

Energy limiting equipment

Zone 2

Limits the energy of the spark and temperature of the surface

EExe Certified

Increased safety

Zone 1

No arcs, sparks or hot surfaces

Explosion Gas Group

Explosion Gas Group

Sample Gas

I

Methane (mining only)

IIA

Propane

IIB

Ethylene

IIC

Hydrogen

Temperature Class

Temperature Class

Maximum permissible surface temperature of the equipment

T1

450°C

T2

300°C

T3

200°C

T4

135°C

T5

100°C

T6

85°C

TM

ISO9001:2008

British Rototherm Company Limited

Kenfig Industrial Estate, Margam, Port Talbot SA13 2PW United Kingdom

Excellence the World can Measure

TM

T: +44 (0) 1656 740 551 E: sales@rototherm.co.uk

F: +44 (0) 1656 745 915

W: www.rotothermgroup.com

In keeping with British Rototherm’s policy for continual product development and improvement, we reserve the right to amend specifications without notice.

©2012 Rototherm Group. All rights reserved. Company registered in Wales : 2570730. Registered office as above.