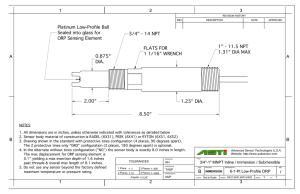

pH/ORP HART® Analyzer/Controller

advertisement