Electrical Power and Energy Systems 70 (2015) 70–82

Contents lists available at ScienceDirect

Electrical Power and Energy Systems

journal homepage: www.elsevier.com/locate/ijepes

Small signal stability enhancement of DFIG based wind power system

using optimized controllers parameters

Bhinal Mehta a,⇑, Praghnesh Bhatt a, Vivek Pandya b

a

b

Department of Electrical Engineering, C.S. Patel Institute of Technology, CHARUSAT, Changa, Gujarat, India

Department of Electrical Engineering, School of Technology, PDPU, Gandhinagar, Gujarat, India

a r t i c l e

i n f o

Article history:

Received 19 August 2014

Received in revised form 30 December 2014

Accepted 31 January 2015

Available online 21 February 2015

Keywords:

Wind turbine generators

Doubly fed induction generator

Particle swam optimization

Eigen value analysis

Low voltage ride through

a b s t r a c t

This paper presents the state space modelling of doubly fed induction generator (DFIG) for small signal

stability assessment. The gains of PI controller in torque and voltage control loop of rotor-side converter

(RSC) are optimized by particle swarm optimization (PSO) to improve the dynamic performance of DFIG.

These optimized parameters results in improved damping of DFIG and minimizes the oscillations in rotor

currents and electromagnetic torque. The nature of modes of oscillations for DFIG integrated to infinite

bus are analysed under different operating conditions such as varying wind speed and grid strength.

The transient analysis with optimized parameters shows the enhancement in LVRT capability during

voltage sag and three phase fault as desired by grid codes.

Ó 2015 Elsevier Ltd. All rights reserved.

Introduction

The use of wind power has increased significantly over recent

decades and its integration with the power system is now an

important topic of study. India ranks fifth amongst the wind energy producing countries of the world after USA, China, Germany and

Spain. The installed capacity of wind power in India has reached

about 20 GW by 2013. Estimated potential is around 49,130 MW

at 50 m above ground level and 102,788 MW at 80 m above ground

level [1].

The wind energy conversion system (WECS) could be

operationally classified into fixed speed and variable speed wind

turbine generating system (WTGS). In the early stage of wind power generations, most wind farms were equipped with fixed speed

induction generators (FSIG). The operation of FSIG is fairly simple

but it is unable to extract maximum power at varying wind speed

as its slip can be varied in a very small range. The development in

technology has encouraged to switch from the fixed speed WTGS

to variable speed WTGS mainly due to its advantages such as

improved efficiency for wider range of wind speeds, independent

control of active and reactive power, better fault ride through capability, etc. Currently the most common variable-speed wind turbine configurations are DFIG wind turbine and fully rated

converter (FRC) wind turbine based on a synchronous or induction

⇑ Corresponding author. Mobile: +91 9427045058.

E-mail address: bhinalmehta.ee@charusat.ac.in (B. Mehta).

http://dx.doi.org/10.1016/j.ijepes.2015.01.039

0142-0615/Ó 2015 Elsevier Ltd. All rights reserved.

Downloaded from http://www.elearnica.ir

generator. Amongst many variable speed concepts, the DFIG

equipped wind turbine is very popular as it has many advantages

over others like improved power quality, higher efficiency, the

power converter rating can be kept fairly low, approximately 25%

of the total machine power, more economical than a series configuration with a fully rated converter, the controllability of reactive power and thus it help DFIG equipped wind turbines play a

similar role to that of synchronous generators [2–5].

PI controllers are the most common controllers as they have

simple structure. Their performance greatly depends on an optimal

tuning of the gains. The tuning of the PI gains is very important

task and even more vital to have optimized performance for varying operating conditions. The sound knowledge of the dynamic

modelling of DFIG integrated to power system is required to adjust

the PI gains in order to have optimized performance of DFIG in normal operating conditions as well as under severe disturbance on

the system [6].

One of the major advantages of DFIG is to have decoupled

control of active and reactive powers with the use of different

control strategies for grid side and rotor side convertors. The

decoupled control of DFIG has the following controllers, namely

Pref; V sref ; V dcref , and qcref . These controllers are required to maintain

maximum power tracking, stator terminal voltage, dc voltage level,

and GSC reactive power level respectively. The coordinated tuning

of these controllers may or may not result into optimized performance of DFIG while adopting hit and trail method for tuning of

gains [7]. The coordinated tuning of the controllers to improve

71

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

the damping of the electromechanical mode in the DFIG was presented in [8] by replacing the DC link capacitor with battery energy

storage (BES) system which eliminated the oscillatory mode corresponding to DC link.

With increasing penetration level of DFIG type wind turbines

into the grid, it is very important to investigate the impacts of wind

turbine generating units on the power system stability [4,9]. The

wind farms are generally located far from demand centres where

the network is relatively weak and congested. Therefore, if the

integration and penetration of wind energy are not properly

assessed for the given network, it is difficult to maintain the reliability and stability [10]. In order to protect the security and operation of the transmission system, it is imperative to investigate the

impact of wind at various penetration levels.

A detailed investigation to analyse the small signal behaviour of

squirrel cage induction generator (SCIG), DFIG and permanent

magnet synchronous generator (PMSG) based wind turbines are

carried out in [11] to see how each turbine technology affects the

local, inter area, torsional and control modes of the system. The

comprehensive studies regarding the modelling of DFIG and to

identify their interaction with the power system have been reported in [12]. [13] shows the presence of DFIG can alter the local and

inter-area mode shapes and shows the improvement in dynamic

behaviour of multi machine power system.

Large voltage dip occurs as a result of a large network disturbance, such as a short circuit, and it may trigger a sequence of

other events in the network. Most of the countries have introduced

and implemented the gird code regulations to fulfil the fault ride

through requirements as the penetration level of wind power generation in the power system has increased drastically. In [14], the

importance of the correct design of the control system is discussed

where, an adequate adjustment of the PI gains helps to limit the

generator currents during a fault. Hence the operations of the

crowbar can be avoided and the convertors continuously remain

in operation.

PSO is an evolutionary computation technique, motivated by

the simulation of social behaviour. In searching the optimal solution of a problem, information of the best position of each individual particle and the best position among the whole swarm are

used to direct the searching. Hence, in comparison with GA, PSO

is quite immune to local optima and is reasonably efficient in solving problems with complex hyperspace [15].

This paper presents the state space model of DFIG to study its

small signal and transient performance. The dynamic performance

of DFIG under different wind speeds and system disturbances for

strong and weak grid are presented in the paper. Therefore, the

objectives of the paper are as follows:

1. To formulate the state space model of DFIG connected to infinite bus for small signal and transient stability assessment.

2. To optimize the controllers gains by PSO for dynamic performance improvement of DFIG.

3. To investigate the impact of optimized controllers’ gains on the

nature of modes of oscillations with varying wind conditions

and with different strength of transmission network.

4. To investigate the fault ride through capability of DFIG with

optimized controllers gains under fault and voltage sag

conditions.

The paper is organized in six sections. Section ‘Mathematical

modelling of DFIG’ presents the modelling concepts of wind turbine

generating system associated with DFIG along with its control

strategies. Interfacing of DFIG with infinite bus is discussed in Section ‘Interfacing of DFIG with infinite bus’. Section ‘Particle swarm

optimization’ defines the objective function and describes the PSO

algorithm for the optimization of the controller gains. Section

‘Results and discussions’ details the approach to analyse the impact

of DFIG on small signal and transient stability along with results and

discussions of different scenarios. The conclusion is drawn in

Section ‘Conclusion’.

Mathematical modelling of DFIG

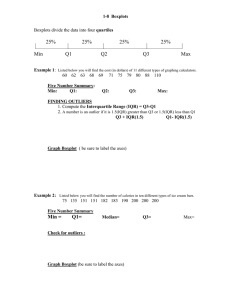

Fig. 1 shows the schematic of a DFIG connected to an infinite

bus through transmission line and transformer. The DFIG is wound

rotor induction generator whose stator is directly connected to a

power grid. The rotor of DFIG is connected to the power grid

through IGBT based controlled back-to-back voltage source converters. The rotor-side converter (RSC) controls the injected rotor

voltage that allows the control of the electromagnetic torque,

which must follow the reference speed provided by the control

system. It can also provide reactive power control and voltage control or power factor control of the machine. This ensures the variable speed operation of DFIG with maximum power point tracking

characteristics. The grid side converter (GSC) is connected to the

grid through a grid-side filter and is used to control dc-link voltage

and reactive power exchange with the grid. Thus GSC represents a

shunt power converter. As RSC can provide reactive power control,

GSC may offer additional voltage support capabilities in conditions

of excessive speed ranges or in transient operations. In this work

for the proposed model only the control of RSC is discussed and

it was assumed that the dc link voltage between the converters

is kept constant by converter. Thus in order to evaluate the performance of the DFIG based scheme proposed to control the RSC,

operational aspects concerning to the GSC control will not be

depicted in detail because it is not the main objective of this work.

Induction generator model

Assumptions:

The following assumptions are made while modelling the

induction generator.

(1) Stator current is negative when flowing toward the machine,

i.e. generator convection is used.

(2) Equations are derived in the synchronous reference frame.

(3) q-axis is 90° ahead of the d-axis.

The stator of the induction machine carries three-phase windings. The windings produce a rotating magnetic field which rotates

at synchronous speed. The dynamic equations for stator and rotor

in d–q reference frame rotating at synchronous speed [3,16,17] are

described in (1)–(3).

Stator voltage equations:

"

v ds ids

uqs

1 d uds

¼ Rs

þ xs

þ

xb dt uqs

v qs

iqs

uds

#

ð1Þ

Rotor voltage equations:

"

v dr idr

uqr

1 d udr

¼ Rr

þ s xs

þ

xb dt uqr

v qr

iqr

udr

#

ð2Þ

Flux equations:

uds ¼ X ss ids þ X m idr

uqs ¼ X ss iqs þ X m iqr

udr ¼ X rr idr X m ids

uqr ¼ X rr iqr X m iqs

ð3Þ

The expression for the stator and rotor currents as the state

variables are obtained by substituting the flux Eqs. (3), into the stator and rotor voltage Eqs. (1) and (2), respectively.

72

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

Three Winding

Transformer

MV

AC Side

Slip

Rings

V∞

HV

Re

Xe

LV

Gear

Box

Infinite Bus

AC low voltage and

Variable frequency

DC

PWM Converter I

(Rotor Side

Converter)

(RSC)

PWM Converter II

(Grid Side

Converter)

(GSC)

Fig. 1. Schematic of DFIG integrated with infinite bus.

and the rated value, the rotor speed reference can be obtained by

substituting k into (4) as follows:

Wind turbine model for DFIG

To complete the induction generator state model, it is necessary

to combine the equations that describe electrical voltage and current components of the machine with swing equation that provides rotor speed as state variable. In power system studies,

drive trains are modelled as a series of rigid disks connected via

mass less shafts.

Maximum Power Point Tracking (MPPT)

The aim of the DFIG wind turbine is to extract maximum power

from the wind. The mechanical power Pw extracted from the wind

is given by (4) [3,18].

Pw ¼

Tm ¼

q

cp ðk; bÞAr v 3w

2

Pw

xm

ð4Þ

ð5Þ

where q is the air density, v w is the wind speed, b is the pitch angle,

Ar is the area swept by the rotor, k is the blade tip speed ratio and b

is the blade pitch angle.

The power coefficient and the tip-speed ratio describe the performance of a wind turbine rotor. In fact, the maximum power

coefficient is only achieved at a single tip speed ratio kopt and if

can

the turbine is operated at variable speed, xr a maximum cmax

p

be achieved over a range of wind speeds [3,18].

The performance co-efficient or the power co-efficient cp is represented as follows:

c2

C p ¼ c1

c3 b c4 ec5 ki þ c6 k

ki

ð6Þ

where

ki ¼

1

0:035

b3 þ1

1

kþ0:08b

ð7Þ

C p ðk; bÞ has a maximum cmax

for a particular tip speed ratio kopt and

p

pitch angle b = 0. A typical wind turbine characteristics and maximum power point extraction curve is shown in Fig. 2(a). The speed

control of the DFIG is achieved by driving the generator speed along

the optimum power-speed characteristic curve (intersect cmax

for

p

each wind speed) shown in Fig. 2(a), which corresponds to the maximum energy capture from the wind. The complete generator torque speed characteristics in shown in Fig. 2(b). When generator

speed is less than the low limit or higher than the rated value, the

reference speeds is set to the minimal value or rated value,

respectively. When generator speed is between the lower limit

k¼

vt

2Rxr

¼g

v w GB pv w

ð8Þ

where v t is the blade tip speed, v w the wind speed, gGB is the gear

box ratio, p is the number of poles of the induction generator and R

is the wind turbine blade radius.

Lumped mass model

For small signal stability analysis of synchronous generators in

conventional power plants, the one mass or lumped mass model is

used because the drive train behaves as a single equivalent mass.

The participations of all inertias, which include the rotating masses

of turbine and generator rotor, are nearly equal. Hence the mode of

interest is non-torsional [16]. Similarly in case of WTGS, drive train

can be represented by the lumped mass system, where there is

only a single inertia which is equivalent to the sum of the generator rotor and the wind turbine. The mathematical equation of

a one-mass model is given by (9).

dxr

1

¼

ðT m T e Þ

2Htot

dt

ð9Þ

where Htot is the total inertia of generator rotor Hg and wind turbine

Ht ; T e is the electromagnetic torque and T m is the mechanical

torque, T e and T m are given by (10) and (11).

T e in terms of the state variables

T e ¼ X m ðidr iqs iqr ids Þ

Tm ¼

C pðpuÞ V 3wðpuÞ

xrðpuÞ

Vw

V w base

Cp

¼

C p nom

ð10Þ

ð11Þ

V wðpuÞ ¼

ð12Þ

C pðpuÞ

ð13Þ

Control strategies for a DFIG

The PVdq control scheme is employed for the control of DFIG.

The rotor current is split into two orthogonal components, d-axis

and q-axis. The q-axis component of the current is used to regulate

the torque and the d-axis component is used to regulate power factor or terminal voltage of DFIG [3].

Torque control scheme

The purpose of the torque controller is to modify the electromagnetic torque of the generator according to wind speed

73

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

Rated power

Generator power

v = 10 m/s

v = 8 m/s

v = 6 m/s

v = 4 m/s

v = 2 m/s

cut-in speed

speed

limit

Generator speed

Generator speed

(a)

(b)

Tsp

ωr

v = 12 m/s

Generator torque

Maximum

power curve

Rated

torque

Fig

2(b)

xss

v qr '

x1

iqr ,ref

+

xmωs vs

∫

K i1

−

shutdown

speed

+

vqr

+

+

+

Te Vs Wr

Characteristics

K p1

iqr

s

idr

vs

2

⎡⎛

xm vs ⎤

x ⎞

s ⎢⎜ xrr − m ⎟ idr +

⎥

xss ⎠

xssωs ⎦

⎣⎝

(c)

vs

x3

ref

+

vs

−

∫

K p3

x2

idr ,ref

+

+

+

∫

Ki 2

−

vdr

+

+

'

vdr

+

−

K p2

1

xmωs

idr

s

(d)

s

iqr

⎡⎛

2

xm ⎞ ⎤

−

x

⎜ rr

⎟ iqr

xss ⎠ ⎦

⎣⎝

⎢

⎥

Fig. 2. Control strategies for DFIG: (a) characteristic for Maximum Power Point Tracking (MPPT) and (b) generator torque speed characteristics (c) torque control scheme (d)

voltage control scheme.

variations and drive the system to the optimal operating point reference. Given a rotor speed measurement, the reference torque T sp

is provided by the wind turbine characteristic for maximum power

extraction as shown in Fig. 2(b). With this computed value of T sp , a

reference rotor current in the q axis i.e. iqr;ref can be found as shown

in Fig. 2(c). The rotor voltage v qr required to operate DFIG at the

reference torque set point T sp is obtained through a summation

of the term obtained by PI controller and the compensation term.

This compensation term is required to minimize cross-coupling

between speed and voltage control loops.

Neglecting the stator resistance and stator transients from (1)

and use of uqs and uds from (3) into (1), we get d-axis and q-axis

stator voltages as follows:

v ds ¼ xs ðX ss iqs þ X m iqr Þ

v qs ¼ xs ðX ss ids þ X m idr Þ

ð14Þ

ð15Þ

With the use of (14) and (15) and q-axis and d-axis stator current

are obtained as (16) and (17), respectively

Xm

iqr

X ss

1

X

¼

v þ mi

xs X ss qs X ss dr

iqs ¼

ids

1

xs X ss

v ds þ

ð16Þ

ð17Þ

Eq. (16) can be represented by (18) after considering d-axis component of stator voltage v ds ¼ 0 as stator flux oriented reference frame

is used.

iqs ¼

Xm

iqr

X ss

ð18Þ

With the use of (17) and (18) in (10), the electromagnetic magnetic

torque of DFIG is derived in (19).

74

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

Xm

1

X

T e ¼ X m idr

iqr iqr v qs þ m idr

X ss

xs X ss

X ss

ð19Þ

With the help of the reference torque set point T sp , the reference qaxis current iqr;ref is given by (20).

iqr;ref ¼

xs X ss

T sp

X m v qs

ð20Þ

The complete block diagram of torque control scheme is shown in

Fig. 2(c). All the variables shown in the block diagram are in per

unit.

The use of udr from (3) and ids from (17) in (2), the final

equation of q-axis rotor voltage v qr can be obtained as (21) after

neglecting the transient term from (2).

!

v qr ¼ Rr iqr þ sxs

X rr X 2m

Xm

idr v

X ss

xs X ss qs

ð21Þ

From Fig. 2(c), (22) can be obtained as follows

v 0qr ¼ x1 þ K p1 ðiqr;ref iqr Þ

idr;ref ¼ x3 þ

X m xs

x3 ¼ K p3 ðv s;ref v s Þ

v ds ¼ v d1 X T iqs þ RT ids

v qs ¼ v d1 þ X T ids þ RT iqs

ð31Þ

ð32Þ

where

X T ¼ X TR þ X e

ð33Þ

RT ¼ Re þ RS

ð34Þ

where v q1 and v d1 are q and d axis components of infinite bus

voltage.

State variables for control loops of DFIG shown in Fig. 2(c) and

(d) are represented by (35)–(37)

x_ 1 ¼ K i1 iqr þ ðK i1 X ss =xs X m Þ

ð22Þ

Voltage control scheme

The voltage control or power factor control at the terminal of

DFIG is achieved through the rotor side converter. The terminal

voltage will increase or decrease with the change in reactive power

delivered to the grid. The voltage controller should fulfil the following requirements in such a situation: (i) the reactive power consumed by the DFIG should be compensated and (ii) if the terminal

voltage is too low or too high compared with the reference value

then idr;ref , for d axis rotor current should be adjusted appropriately.

The required d-axis rotor voltage v dr is obtained through the output

of a PI controller, v 0dr minus a compensation term to eliminate

cross-coupling between control loops [3]. The complete block diagram of the DFIG terminal voltage controller is shown in Fig. 2(d).

All the variables shown in the block diagram are in per unit.

v 0dr ¼ x2 þ K p2 ðidr;ref idr Þ

vs

System matrix A, Control matrix B, Output matrix C and Feed

forward matrix D for the induction machine are represented in

Appendix C.

In order to consider the integration of DFIG to the transmission

network, the stator voltage equations are represented in (31) and

(32).

ð23Þ

ð24Þ

ð25Þ

T sp

ð35Þ

vs

x_ 2 ¼ K i2 x_ 3 K i2 idr þ ðK i2 =xs X m Þv s

ð36Þ

x_ 3 ¼ K p3 v s þ K p3 v sref

ð37Þ

The state variables and control inputs for DFIG after the integration

to transmission network are given in (38) and (39), respectively.

T

x_ ¼ ½ids iqs idr iqr xr x2 x1 x3 u1 ¼ ½idr iqr

v s v s;ref

T sp ð38Þ

T

ð39Þ

The complete system matrix Asys of DFIG connected to the infinite

bus for small signal stability analysis is represented in (40). All

the elements of system matrix Asys are listed in Appendix D.

2

Asys

3

A11

A12

A13

A14

A15

A16

A17

A18

6 A21

6

6

6 A31

6

6A

6 41

¼6

6 A51

6

6A

6 61

6

4 A71

A22

A23

A24

A25

A26

A27

A32

A33

A34

A35

A36

A37

A42

A43

A44

A45

A46

A47

A52

A53

A54

A55

A56

A57

A62

A63

A64

A65

A66

A67

A72

A73

A74

A75

A76

A77

A28 7

7

7

A38 7

7

A48 7

7

7

A58 7

7

A68 7

7

7

A78 5

A81

A82

A83

A84

A85

A86

A87

A88

ð40Þ

Interfacing of DFIG with infinite bus

Particle swarm optimization

The test system for the analysis is shown in Fig. 1 where DFIG is

integrated to the infinite bus through the transmission line. The

infinite bus is considered as voltage source of constant voltage

and constant frequency. To carry out the small signal stability analysis of the system shown in Fig. 1, the linearization of the induction machine equations given in (1) and (2) and the rotor

mechanical equation given in (9) are presented in (26) and (27).

The system state space representation can be described by (26)

and (27). The system state matrix after the integration of DFIG to

infinite bus is represented in (40) and its elements are listed

Appendix D. The eigenvalues of this state matrix Asys is used to

design the objective function.

Design of the objective function

x_ ¼ Ax þ Bu

ð26Þ

y ¼ Cx þ Du

ð27Þ

where

T

x_ ¼ ½ids iqs idr iqr xr ð28Þ

In general, input and output vectors for the system under considerations are defined as follows:

u ¼ ½v ds

v qs v dr v qr T

y ¼ ½idr iqr T

ð29Þ

ð30Þ

The PI gains of the RSC controller are to be optimized in such a

manner that some degree of relative stability and damping of electromechanical modes of oscillations can be achieved. Therefore, a

multi-objective optimization function, OF (Figure of Demerit) is

designed as given in (41) to have minimized undershoot, minimized overshoot and faster settling time of oscillations in the transient responses.

P

OF1 ¼ i ðr0 ri Þ2 , if ri P 0, r0 = 2.0, ri is the real part of the

th

i eigenvalue. The relative stability is determined by r0 . By optimizing OF1, closed loop system poles are thus consistently pushed

further left of jx axis with simultaneous reduction in imaginary

75

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

i

0

Table 2

Original and optimized controller parameters.

j

0

K p1

K i1

K p2

K i2

K p3

0

Original parameters

Optimized parameters

0.05

10

0.05

10

7

0.7

11.3367

0.5761

13.4624

10

Particle swarm optimization

0

The PSO was first introduced by Eberhart and Shi [22]. It is an

evolutionary optimization technique based on swarm intelligence.

The PSO is a population-based optimization technique, where the

population is called ‘swarm’. Based on PSO concept, mathematical

equations for the searching process are:

Velocity updating equation:

Fig. 3. D-shaped sector in the negative half of s – plane.

v kþ1

¼ v ki þ c1 r1 i

parts also, thus increasing the damping ratio above f0 (0.3). Finally,

all closed loop system poles should lie within a D-shaped sector

shown in Fig. 3.

P

OF2 = ðf0 fi Þ2 , if (imaginary part of the ith eigenvalue) > 0.0,

i

fi is the damping ratio of the ith eigenvalue and fi < f0 . Minimum

damping ratio considered, f0 = 0.3. Minimization of this objective

function will minimize maximum overshoot.

P

OF3 = i (imaginary part of ith eigenvalue), if ri P 1:0. High

value of imaginary part of ith eigenvalue to the right of vertical line

r0 = 2.0 is to be prevented. OF3 will be high if imaginary part of

ith eigenvalue is large.

OF4 = an arbitrarily chosen very high fixed value (say, 106),

which will indicate some ri values P 0.0. This means unstable

oscillation occurs for the transient responses.

So, multi-objective optimization function (Figure of Demerit),

OF ¼ 10 OF1 þ 10 OF2 þ 0:01 OF3 þ OF4

ð41Þ

pBesti xki þ c2 r2 gBest xki

ð42Þ

Position updating equation:

xkþ1

¼ xki þ v kþ1

i

i

ð43Þ

The following modifications help to enhance the global search ability of PSO algorithm.

Position and velocity updating

In (42), the second term on the right hand side represents the

personal behavior whereas the third term represents the social

behavior of the particles. As numbers r1 and r2 are generated randomly, they could be too large or too small. In such cases personal

and social experiences will be over used or not fully utilized.

Hence, to strike a balance between two, the velocity and position

equations are modified as follow.

v kþ1

¼ r2 signðr3Þ v ki þ ð1 r2Þ c1 r1

i

pBesti xki þ ð1 r2Þ c2 ð1 r1Þ

gBest xki

The weighting factors ‘10’ and ‘0.01’ are chosen to impart more

weight to OF1 and OF2 and to reduce high value of OF3, to make

them mutually competitive during optimization. All the closed

loop poles lie in the negative half plane of jx axis for which

ri 2:0, fi 0:3.

In (44), sign(r3) may be defined as,

Table 1

Initial condition for test system.

signðr3Þ ¼

1 ðr3 6 0:05Þ

ðr3 > 0:05Þ

1

ð44Þ

ð45Þ

Initial condition for test system

Scenario

Scenario 1 (40 MVA)

Scenario 2 (16 MVA)

Case

a

b

C

a

b

c

wr0

ids0

iqs0

idr0

iqr0

vds0

vqs0

vdr0

vqr0

vdsinf

vqsinf

Dvds

Dvqs

Te

vs0

Dvs

iqrref

0.8

0.024

0.35

0.229

0.367

0.035

0.999

0.02

0.206

0

1

0.0351

1.001

0.3516

0.9996

1.0016

0.3676

1.1

0.055

0.661

0.197

0.693

0.066

0.998

0.02

0.098

0

1

0.0664

1.0010

0.6653

1.0001

1.0032

0.6954

1.29

0.097

0.977

0.154

1.024

0.098

0.995

0.085

0.286

0

1

0.0984

0.9999

0.9873

0.9998

1.0047

0.9586

0.8

0.035

0.343

0.217

0.367

0.06

0.998

0.025

0.206

0

1

0.0604

0.9998

0.3449

0.9998

1.0016

0.3675

1.1

0.084

0.649

0.166

0.693

0.114

0.993

0.025

0.097

0

1

0.1146

0.9965

0.6559

0.9995

1.0031

0.6962

1.29

0.151

0.959

0.096

1.024

0.1169

0.986

0.105

0.28

0

1

0.1698

0.9902

0.9751

0.9929

1.0033

0.9706

The steps of proposed PSO based algorithms as implemented for

optimization of PI gains of RSC controller are listed below:

Generation of population.

Evaluation of Figure of Demerit of each particle as per (41).

Search for individual minimum Figure of Demerit and corresponding individual best particle (pBest).

Search for global minimum Figure of Demerit and its corresponding global best particle (gBest).

Velocity and position updating.

Searching for Individual best position updating and global best

position updating.

Iteration updating and stopping criteria.

The parameters used are c1 = 2.15, c2 = 2.05. The chosen maximum population size np = 50, maximum allowed iteration

cycles = 500.

76

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

Table 3

Results of small signal stability analysis of DFIG using original controller parameters for Scenario 1 at different wind speed.

Strong connection (VAsc = 40 MVA)

Mode No.

Frequency of oscillation in Hz

Damping ratio

Most influential states in the control of the Mode with their % participation

CASE (a) Wr = 0.8 p.u.

k1, k2

53.42 ± 485.82i

k3, k4

29 ± 131.56i

k5, k6

24.15 ± 76.38i

k7

0.1

k8

0.68

Eigen values

77.24

20.92

12.14

0.00

0.00

0.11

0.22

0.30

1.00

1.00

ids = 26, iqs = 25.8, idr = 24.1, iqr = 24

ids = 23.5, iqs = 23.8, idr = 25.3, iqr = 25.7, x2 = 0.7, x1 = 0.8

ids = 22.5, iqs = 21, idr = 24.7, iqr = 23, x2 = 4.3, x1 = 4.1

wr = 99, x1 = 0.9

x3 = 99.7

CASE (b) Wr = 1.1 p.u.

k1, k2

46.42 ± 484.29i

k3, k4

39.11 ± 121.04i

k5, k6

20.77 ± 82.03i

k7

0.1

k8

0.67

76.99

19.24

13.04

0.00

0.00

0.10

0.31

0.25

1.00

1.00

ids = 26, iqs = 25.6, idr = 24.3, iqr = 24

ids = 23.2, iqs = 23.4, idr = 25, iqr = 25.3, x2 = 1.4, x1 = 1.5

ids = 23.6, iqs = 23, idr = 25.2, iqr = 24.5, x2 = 1.8, x1 = 1.8

wr = 99.5

x3 = 99.6

CASE (c) Wr = 1.29 p.u.

k1, k2

43.18 ± 483.58i

k3, k4

47.73 ± 160.93i

k5, k6

15.13 ± 61.96i

k7

0.07

k8

0.66

76.88

25.59

9.85

0.00

0.00

0.09

0.28

0.24

1.00

1.00

ids = 26, iqs = 25.5, idr = 24.4, iqr = 23.9

ids = 24.1, iqs = 23.2, idr = 25.9, iqr = 25, x2 = 0.8, x1 = 0.8

ids = 22.7, iqs = 22.8, idr = 24.2, iqr = 24.2, x2 = 2.8, x1 = 2.8

wr = 98.9

x3 = 99.4

Table 4

Results of small signal stability analysis of DFIG using original controller parameters for Scenario 2 at different wind speed.

Weak connection (VAsc = 16 MVA)

Mode No.

Frequency of oscillation in Hz

Damping ratio

Most influential states in the control of the mode with their % participation

CASE (a) Wr = 0.8 p.u.

k1, k2

75.91 ± 610.31i

k3, k4

22.8 ± 120.97i

k5, k6

19 ± 67.53i

k7

0.1

k8

1.17

Eigen values

97.03

19.23

10.74

0.00

0.00

0.12

0.19

0.27

1.00

1.00

ids = 26.3, iqs = 26.1, idr = 23.8, iqr = 23.6

ids = 23.2, iqs = 23.4, idr = 25.5, iqr = 26, x2 = 1, x1 = 1

ids = 22.1, iqs = 20.2, idr = 24.6, iqr = 22.4, x2 = 5.4, x1 = 5.1

wr = 98.9, x1 = 0.9

x3 = 99.3

CASE (b) Wr = 1.1 p.u.

k1, k2

68.83 ± 607.92i

k3, k4

32.3 ± 112.52i

k5, k6

15.95 ± 71.46i

k7

0.11

k8

1.14

96.65

17.89

11.36

0.00

0.00

0.11

0.28

0.22

1.00

1.00

ids = 26.2, iqs = 25.8, idr = 24.1, iqr = 23.7

ids = 23, iqs = 23.1, idr = 25.1, iqr = 25.3, x2 = 1.6, x1 = 1.7

ids = 23, iqs = 22.3, idr = 25.3, iqr = 24.3, x2 = 2.5, x1 = 2.4

wr = 99.3

x3 = 99.1

CASE (c) Wr = 1.29 p.u.

k1, k2

65.34 ± 606.6i

k3, k4

39.84 ± 153.62i

k5, k6

11.53 ± 52.35i

k7

0.08

k8

1.13

96.44

24.42

8.32

0.00

0.00

0.11

0.25

0.22

1.00

1.00

ids = 26.3, iqs = 25.6, idr = 24.3, iqr = 23.6

ids = 24, iqs = 23, idr = 26, iqr = 25, x2 = 0.8, x1 = 0.9

ids = 21.9, iqs = 22, idr = 23.8, iqr = 23.9, x2 = 4.1, x1 = 4.1

wr = 98.8, x1 = 0.5

x3 = 98.7

Results and discussions

Case a. rotor speed = 0.8 p.u. Case b. rotor speed = 1.1 p.u.

Case c. rotor speed = 1.29 p.u.

Test scenario

Small signal stability analysis

The impacts of DFIG on dynamic behaviour of power system

under different wind conditions have been evaluated for the test

system shown in Fig. 1. It has been observed that the dynamic performance of the power system is also affected by the strength of

the transmission network to which the wind farms are connected.

Hence, the effect of strong and weak transmission network are

considered with short circuit level of 40 MVA and 16 MVA, respectively. The DFIG model along with torque and voltage control

strategies as discussed in Section ‘Interfacing of DFIG with infinite

bus’ is implemented in MATLAB/Simulink [19]. The parameters

used for simulation are given in Appendices A and B. The following

two scenarios are simulated for the analysis.

Scenario1: Strong grid with short circuit level of 40 MVA.

Scenario2: Weak grid with short circuit level of 16 MVA.

The dynamic behaviour of the DFIG is also analysed for the following rotor speeds considering above both scenarios.

Modal analysis or small signal analysis has been popularly used

in power system for identification of low frequency oscillation.

Small signal stability studies are based on linearization of system

equations around the operating point and modes of oscillations of

system response can be derived from the eigenvalues of the system

state matrix. The analysis of the Eigen properties of system state

matrix provides valuable information regarding the stability characteristics of the system [16]. The states associated in the eigenvalue

analysis for above scenarios are given in (38). The dynamic performance of DFIG is evaluated under different operating conditions

such as varying wind speed and varying network strength. The

steady state initial operating points for these varying operating conditions are tabulated in Table 1. Table 2 shows the original controller

parameters [18] and optimized controller parameters obtained after

minimizing the objective function given in (41) with the help of PSO.

The results of eigenvalue analysis including frequency of oscillation, damping ratio and percentage participation of all the states

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

77

Table 5

Results of small signal stability analysis of DFIG using optimized controller parameters for Scenario 1 at different wind speed.

Strong connection (VAsc = 40 MVA)

Mode No.

Frequency of oscillation in Hz

Damping ratio

Most influential states in the control of the mode with their % participation

CASE (a) Wr = 0.8 p.u.

k1, k2

1017.82 ± 195.21i

k3, k4

40.41 ± 319.21i

k5

23.04

k6

17.83

k7

0.24

k8

0.19

Eigen values

31.04

50.75

0.00

0.00

0.00

0.00

0.98

0.13

1.00

1.00

1.00

1.00

ids = 23.2, iqs = 25.9, idr = 21.3, iqr = 29.3

ids = 28, iqs = 22.6, idr = 27.2, iqr = 22

ids = 20.6, iqs = 1.4, idr = 22.5, iqr = 1.6, x2 = 50.6, x1 = 2.8

ids = 0.4, iqs = 13.6, idr = 0.5, iqr = 14.8, wr = 3, x2 = 3.3, x1 = 64

wr = 94.9, x1 = 4.4

x3 = 99.1, wr = 0.6

CASE (b) Wr = 1.1 p.u.

k1, k2

1002.23 ± 47.64i

k3, k4

55.56 ± 323.75i

k5

23.94

k6

17.62

k7

0.19

k8

0.36

7.57

51.47

0.00

0.00

0.00

0.00

1.00

0.17

1.00

1.00

1.00

1.00

ids = 25, iqs = 21.8, idr = 23.9, iqr = 29

ids = 28.2, iqs = 22.6, idr = 27.4, iqr = 21.6

ids = 26.5, idr = 28.3, x2 = 44.1

iqs = 14.1, iqr = 15.1, wr = 7.7, x1 = 62.4

wr = 88.1, x1 = 11

x3 = 98.9, wr = 0.7

CASE (c) Wr = 1.29 p.u.

k1

1092.94

k2

893.80

k3, k4

64.60 ± 328.32i

k5

22.30

k6

18.74

k7

0.19

k8

0.43

0.00

0.00

52.20

0.00

0.00

0.00

0.00

1.00

1.00

0.19

1.00

1.00

1.00

1.00

ids = 33, iqs = 8.4, idr = 33.1, iqr = 25

ids = 16.3, iqs = 27.8, idr = 27.8

ids = 28.2, iqs = 22.6, idr = 27.4, iqr = 21.5

ids = 25.7, iqs = 2, idr = 27.1, iqr = 2.2, wr = 0.5, x2 = 39.3, x1 = 2.9

ids = 0.9, iqs = 13.2, idr = 0.8, iqr = 14.2, wr = 10, x2 = 2.7, x1 = 57.9

wr = 84.5, x1 = 14.4, x3 = 0.5

x3 = 99, wr = 0.6

Table 6

Results of small signal stability analysis of DFIG using optimized controller parameters for Scenario 2 at different wind speed.

Weak connection (VAsc = 16 MVA)

Mode No.

Frequency of oscillation in Hz

Damping ratio

Most influential states in the control of the mode with their % participation

CASE (a) Wr = 0.8 p.u.

k1, k2

995.37 ± 334.99i

k3, k4

73.39 ± 313.83i

k5

22.60

k6

18.21

k7

0.24

k8

0.33

Eigen values

53.26

49.89

0.00

0.00

0.00

0.00

0.95

0.23

1.00

1.00

1.00

1.00

ids = 25, iqs = 24.4, idr = 23.7, iqr = 26.6

ids = 28, iqs = 22.1, idr = 27.8, iqr = 21.9

ids = 20, iqs = 2.1, idr = 22.2, iqr = 2.3, x2 = 48.2, x1 = 4.7

ids = 1, iqs = 13.2, idr = 1.1, iqr = 14.7, wr = 2.9, x2 = 5.6, x1 = 61

wr = 94.8, x1 = 4.4

x3 = 98.5, wr = 0.7

CASE (b) Wr = 1.1 p.u.

k1, k2

963.21 ± 220.86i

k3, k4

104.85 ± 319.01i

k5

24.13

k6

17.77

k7

0.34

k8

0.34

35.11

50.72

0.00

0.00

0.00

0.00

0.97

0.31

1.00

1.00

1.00

1.00

ids = 29.5, iqs = 20, idr = 27.1, iqr = 23

ids = 28.3, iqs = 22.1, idr = 28, iqr = 21.3

ids = 26.7, iqs = 0.4, idr = 29, iqr = 0.5, x2 = 42.5, x1 = 0.6

ids = 0.2, iqs = 14.1, idr = 0.2, iqr = 15.5, wr = 7.7, x1 = 61.4

wr = 87.6, x1 = 11.1, x3 = 1

x3 = 97.8, wr = 1.1

CASE (c) Wr = 1.29 p.u.

k1

1051.1

k2

760.1

k3, k4

129.5 ± 345i

k5

22.2

k6

13.8

k7

2.1

k8

1.7

0.00

0.00

54.85

0.00

0.00

0.00

0.00

1.00

1.00

0.35

1.00

1.00

1.00

1.00

ids = 36.5, iqs = 10.1, idr = 36.5, iqr = 16.7

ids = 24, iqs = 33.8, idr = 8.9, iqr = 32.7, wr = 0.5

ids = 28.4, iqs = 22.3, idr = 27.8, iqr = 21.2

ids = 23.6, iqs = 3.8, idr = 25.3, iqr = 4.1, wr = 1, x2 = 37, x1 = 4.8

ids = 1.4, iqs = 13.3, idr = 1.3, iqr = 14.5, wr = 10, x2 = 4.3, x1 = 54.8

wr = 83.6, x1 = 14.9, x3 = 1

x3 = 97.6, wr = 1

for two scenarios and all three cases under considerations are

tabulated in Tables 3–6. The results shown in Tables 3–6 reveal

that system exhibit the stable behaviour for all the scenarios with

varying wind speeds. Tables 3 and 4 shows the results with using

original parameters of PI gains and Tables 5 and 6 with optimized

parameters of controllers. As per Tables 3 and 4, for scenario 1 and

2, respectively, five stable modes have been identified for each

wind speed, two of which are non-oscillating modes. The physical

nature of the modes can be identified by observing the participation factors: Mode 1 (k1;2 Þ and mode 2 (k3;4 Þ are oscillating modes

associated with the stator and the rotor electrical dynamics,

respectively. Mode 3 (k5;6 Þ is also oscillating mode associated with

rotor electrical and mechanical dynamics (rotor currents and gen-

erator speed) and therefore it is referred as electromechanical

mode. Mode 4 (k7 Þ is non oscillating mode associated with rotor

speed. k8 is also the non oscillating mode associated with voltage

controller. The stator mode (k1;2 Þ has a large real part magnitude

and the much higher frequency of oscillations which results in

lowest damping ratio. As the wind speed increases, damping ratio

of mode 1 and mode 3 is slightly reduced while that of mode 2

increases up to the synchronous speed and then again reduces.

Tables 5 and 6 show the results obtained with optimized controller

parameters for both the scenarios in which different rotor speeds

as represented in cases a–c above are considered. The results

revealed that for speed below the synchronous and just above

the synchronous speed, only two oscillating modes exist, i.e. mode

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

Comparison of Damping Performance for Scenario 1

λ1,2

λ3,4

λ5,6

λ7

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

λ1,2

λ8

Case (a) Wr=0.8 p.u Original Parameters

Case (a) Wr=0.8 p.u Optimized Parameters

λ3,4

λ5,6

λ7

λ8

Case (a) Wr=0.8 p.u Original Parameters

Case (a) Wr=0.8 p.u Optimized Parameters

λ3,4

λ5,6

λ7

λ8

Comparison of Damping Peformance for Scenario 2

1

Damping Ratio

Damping Ratio

λ1,2

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

λ1,2

Case (b) Wr=1.1 p.u Original Parameters

Case (b) Wr=1.1 p.u Optimized Parameters

Comparison of Damping Peformance for Scenario 2

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Comparison of Damping Performance for Scenario 1

Damping Ratio

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Damping Ratio

Damping Ratio

Comparison of Damping Performance for Scenario 1

0.8

0.6

0.4

0.2

0

λ1,2

λ3,4

λ5,6

λ7

λ8

Case (b) Wr=1.1 p.u Original Parameters

Case (b) Wr=1.1 p.u Optimized Parameters

λ3,4

λ5,6

λ7

λ8

Case (c) Wr=1.29 p.u Original Parameters

Case (c) Wr=1.29 p.u Optimized Parameters

Comparison of Damping Peformance for Scenario 2

Damping Ratio

78

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

λ1,2

λ3,4

λ5,6

λ7

λ8

Case (c) Wr=1.29 p.u Original Parameters

Case (c) Wr=1.29 p.u Optimized Parameters

Fig. 4. Comparison of damping performance of all three cases for Scenario 1 and Scenario 2.

1 and mode 2. For the rotor speeds much above the synchronous

speed results in more stabilized operations for both scenarios

and left with only one oscillating mode.

Fig. 4 show the comparative performance of the damping ratio

of all three cases for scenarios 1 and 2, respectively, with and

without optimized controller parameters. The improvement in

the damping performance with use of optimized parameter can

be clearly noticed from Fig. 4.

Transient response of DFIG for short circuit

As the penetration of wind power in electrical power system

increases, the behaviour of wind turbine (WT) under faults, voltage

dips and disturbances becomes more important, especially for

those with power electronic converters, such as DFIGs. The grid

voltage dips imposed at the connection point of the DFIG due to

short circuit results in high rotor current. This high rotor current

can damage the RSC and may cause large increases in the dc-link

voltage. Such large rotor current, dc-link over voltage and torque

oscillations occurring due to grid faults are quite harmful for the

DFIG-based WTs. In these conditions either the DFIG may be disconnected from the grid, or the rotor-side converter may be deactivated using the crowbar resistors. A sudden loss of wind power

during grid faults results in rapid rate of change of frequency

(ROCOF) in the system. In addition DFIG will behave as squirrel

cage induction generator after the deactivation of RSC. Thus DFIG

consumes more reactive power and caused the voltage instability

problem. Thus, it is desired that the wind turbines must remain

connected and actively contribute to the system stability during

and after the faults and disturbances. The ability of WT to stay

connected to the grid during the faults and voltage dips is termed

as low voltage ride through (LVRT) capability [20]. Nowadays, in

order to ensure the security of power system, most of the countries

have introduced and implemented their grid codes for LVRT

capability while integrating WTGs into the utility grid. The grid

code for LVRT capability of DFIG as demanded by UK TSO is given

in [18,21].

Three phase fault

The transient performance of DFIG connected to infinite bus has

been analyzed for three phase balanced fault applied at the terminal

of DFIG. The fault is applied at 5 s which persists for 140 ms and after

that the normal operation is restored. The comparative transient

responses, of stator currents ðids; iqs Þ , rotor currents ðidr; iqr Þ and electromagnetic torque (T e Þ for both the scenarios are shown in Figs. 5

and 6, for original controller parameters and optimized controller

parameters. It is clearly depicted in Figs. 5 and 6 that the currents

and electromagnetic torque were operating at their initial settled

value as indicated in Table 1 before the application of fault. The sudden application of three phase fault causes the significant excursions in transient responses of currents and electromagnetic

torque. The optimized parameters of the controllers successfully

limit the peak values in these excursions and suppress them very

quickly as per the grid code requirements. The systems regain its

original operating points after the removal of the fault and all the

parameters are restored back to their initial steady state value.

Voltage sag

The LVRT capability specified in grid codes also requires the

WTGs to operate at reduced voltage for a few hundreds of ms to

several seconds. It can be seen, from the requirement specified

by the TSO of UK [18,21] that wind turbines should ride through

a 50% fault for 710 ms. This condition is also investigated, for both

the scenarios by reducing the terminal voltage of DFIG from its

nominal value to 50% of its nominal value for the duration of

710 ms. The comparative transient responses shown in Figs. 7

79

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

6

4

original

original

optimized

Te

Te

optimized

2

original

4

optimized

Te

2

2

0

0

5.2

5.3

5.4

5.5

5.6

4.9

5.7

4

4

2

2

0

-2

5.1

5.2

5.3

5.5

5.4

5.6

4.9

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5

0

0

-2

-4

-5

-4

4.9

5

5.1

5.2

5.3

5.4

5.5

5.6

4.9

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

4.9

5.7

4

4

2

4

0

2

iqs

2

iqs

iqs

0

5

ids

5.1

5

ids

ids

-2

4.9

0

0

-2

-4

-2

5

5.1

5.2

5.3

5.4

5.5

5.6

4.9

5.7

4

2

2

idr

4

0

5

5.1

5.2

5.3

5.4

5.5

5.6

4.9

5.7

5

idr

4.9

idr

-2

0

0

-2

-2

-4

-4

4.9

5

5.1

5.2

5.3

5.4

5.5

5.6

4.9

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

-5

4.9

5.7

4

4

4

2

0

2

iqr

iqr

iqr

2

0

0

-2

-2

-2

-4

4.9

5

5.1

5.2

5.3

5.4

5.5

5.6

4.9

5.7

5

5.1

Time in Seconds

5.2

5.3

5.4

5.5

5.6

4.9

5.7

Time in Seconds

Time in Seconds

Fig. 5. Comparative transient response of all three cases for Scenario 1 considering three phase fault.

3

original

Te

Te

optimized

1

3

original

2

2

optimized

Te

2

1

0

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

-1

5

5.1

5.2

5.3

5.4

5.5

5.6

5.1

5.2

5.3

5.4

5.5

5.6

5.7

-4

4.9

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5

5.1

5.2

5.3

5.4

2

2

ids

2

-4

4.9

0

5

5.1

5.2

5.3

5.4

5.5

5.6

-4

4.9

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

3

2

0

iqs

iqs

2

1

0

0

-1

-2

4.9

0

-2

-2

2

iqs

5

4

-2

5

5.1

5.2

5.3

5.4

5.5

5.6

4.9

5.7

5

5.1

5.2

5.3

5.4

5.5

5.6

-2

4.9

5.7

4

4

2

2

2

0

0

-2

-2

4.9

idr

4

idr

idr

4.9

5.7

4

0

optimized

1

4

ids

ids

4.9

original

optimized

0

0

-1

-1

4.9

original

5

5.1

5.2

5.3

5.4

5.5

5.6

-4

4.9

5.7

0

-2

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

4.9

3

2

0

2

iqr

iqr

iqr

2

1

0

0

-1

-2

4.9

5

5.1

5.2

5.3

5.4

Time in Seconds

5.5

5.6

5.7

4.9

5

5.1

5.2

5.3

5.4

Time in Seconds

5.5

5.6

5.7

-2

4.9

Time in Seconds

Fig. 6. Comparative transient responses of all three cases for Scenario 2 considering three phase fault.

5.5

5.6

5.7

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

optimized

optimized

2

original

optimized

0.5

3

2

original

1

1

Te

Te

1.5

Te

80

0

0

0

-0.5

-1

5

5.2

5.4

5.6

5.8

6

6.2

5

5.4

5.6

5.8

6

6.2

0

-2

0

5.2

5.4

5.6

5.8

6

5

6.2

2

5.2

5.4

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

6.2

0

-2

-2

5

5

2

ids

ids

ids

5.2

2

2

5.2

5.4

5.6

5.8

6

6.2

3

2

2

0

0

iqs

iqs

1

-1

5

5.2

5.4

5.6

5.8

6

5

6.2

5.2

5.4

5.6

5.8

6

-1

6.2

2

2

idr

idr

2

1

0

-2

idr

iqs

original

1

0

0

0

-2

-2

5

5.2

5.4

5.6

5.8

6

5

6.2

2

5.2

5.4

5.6

5.8

6

-2

6.2

3

2

0

2

1

iqr

iqr

iqr

1

0

1

0

-1

-1

5

5.2

5.4

5.6

5.8

6

5

6.2

5.2

5.4

5.6

5.8

6

6.2

Time in Seconds

Time in Seconds

Time in Seconds

Fig. 7. Comparative transient responses of all three cases for Scenario 1 considering voltage sag.

1.5

1.5

optimized

Te

0

5

5.2

5.4

5.6

5.8

6

5

5.2

5.4

5.6

5.8

6

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

iqs

iqs

0

5.2

5.4

5.6

5.8

6

1

6.2

5.4

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

6.2

5

5.2

5.4

5.6

5.8

6

6.2

2

0

5

5.2

0

-2

6.2

2

1

5

2

0

-2

6.2

2

-1

5.4

ids

0

-2

5.2

2

ids

ids

2

1

0

5

6.2

iqs

Te

0.5

0

-0.5

original

original

1

original

0.5

optimized

2

optimized

Te

1

1

0

5

5.2

5.4

5.6

5.8

6

6.2

2

2

idr

0

idr

idr

2

0

0

-2

5

5.2

5.4

5.6

5.8

6

-2

6.2

2

5

5.2

5.4

5.6

5.8

6

-2

6.2

2

2

iqr

iqr

iqr

1

1

1

0

0

-1

5

5.2

5.4

5.6

5.8

Time in Seconds

6

6.2

0

5

5.2

5.4

5.6

5.8

6

6.2

Time in Seconds

Fig. 8. Comparative transient responses of all three cases for Scenario 2 considering voltage sag.

Time in Seconds

81

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

and 8 demonstrate that the DFIG exhibits the superior performance

with the optimized controller parameters for the voltage sag

considerations.

Conclusion

With increasing wind penetration in power systems, grid codes

demand complete dynamic models of WTGs and its simulation

studies under different operating conditions to prevent any detrimental impact of these energy sources on the network to which

it is connected. In this paper, a dynamic model of DFIG and its associated controllers with the reduced order representation is presented, which is suitable to capture its impact on small signal

and transient stability of power system. The RSC of DFIG is controlled by q-axis and d-axis rotor currents through torque and voltage controller loop respectively. It is observed from the eigenvalue

analysis that the dynamic behaviour of DFIG has been significantly

improved by optimizing the gains of torque and voltage control

loops for different network strength and also over a wide range

of rotor speed variations. The transient analysis of DFIG for three

phase fault and voltage sag reveals that the optimized gains plays

a vital role to improve the LVRT capability of DFIG.

Appendix A. Parameter of DFIG (in p.u. otherwise specified)

Dsh = 0.01, K sh = 10, Htot = 3.5, Hg = 0.5, Ht = 3, V w base = 9 m/s,

k = 8.1, cp = 0.48, Pnom = 2 MVA, P mec = 2 MVA, Pnom1 = 2.2222 MVA,

P elec base = 2.2222 MVA,

P wind base = 1,

c1 = 0.5176,

c2 = 116,

c3 = 0.4, c4 = 5, c5 = 21, c6 = 0.0068, pitch_rate = 2, pitch_max = 45,

K opt = 0.56, K p = 5, K i = 25, V b = 690 V, Sb = 2 MVA, F b = 50, Ws = 1,

W b ¼ 2 pi F b ,

X tr = 0.05,

Rs = 0.00488,

X ls = 0.09241,

Rr = 0.00549, X lr = 0.09955, X m = 3.95279, X rm = 0.02, W s = 1,

X ss = 4.0452 (X ss ¼ X ls þ X m Þ, X rr ¼ X lr þ X m , vdsinf = 0, vqsinf = 1.

2

Rs

6 x X

6

e

ss

6

6

0

F ¼ 6

6

6 s x X

e

m

4

X m iqr0

VAsc

X/R

Ze

Re

Xe

Rt

Xt

Scenario 2 weak grid

40 MVA

10

0.05

0.0050

0.0498

0.0099

0.0998

16 MVA

10

0.125

0.0124

0.1244

0.0173

0.1744

0

0

0

X rr

Xm

0

0

0

0

X rr

0

0

0

2Hxb

3

7

7

7

7

7

7

5

X m iqs0

X m ids0

Feed forward matrix D;

3

7

7

7

7

7

xb

7

X m ids0 X rr idr0 7

5

xb

0

X rr iqr0 X m iqs0

1 0 0

0 1 0

0 0 0

0 0 0

Appendix D. Elements of system matrix Asys

The elements of system matrix are as follows:

A11 ¼

A12 ¼

xb

X rr X ss X 2m

xb

X rr X ss X 2m

fRT X rr þ ðK p2 =v s0 xs ÞðRT v ds0 þ X T v qs0 Þg

f X rr X ss s0 X 2m xs þ X T X rr þ ðK p2 =v s0 xs ÞðRT v qs0

X T v ds0 Þg

A13 ¼

A14 ¼

A21 ¼

xb

X rr X ss X 2m

xb

X rr X ss X 2m

xb

X rr X ss X 2m

xb X m

X rr X ss X 2m

xb

X rr X ss X 2m

fX m ðRr þ K p2 Þg;

fðX m X rr þ s0 X m X rr Þxs g

fðX m iqs0 X rr iqr0ÞX m g;

A17 ¼ 0;

;

A18 ¼

xb X m K p2

X rr X ss X 2m

f X rr X ss þ s0 X 2m xs X T X rr

þ ðK p1 K opt X ss xs x2r0 =v 3s0 ÞðRT v ds0 þ X T v qs0 Þg

A22 ¼

xb

X rr X ss X 2m

fRT X rr þ ðK p1 K opt X ss xs x2r0 =v 3s0 ÞðRT v qs0

X T v ds0 Þg

A31 ¼

0

Rr

X m idr0

Output matrix C;

A32 ¼

A24 ¼

xb

X rr X ss X 2m

A26 ¼ 0;

0

s xe X rr

B ¼ ðEÞ1

0 0

C¼

0 0

0 0

D¼

0 0

A25 ¼

Xm

s xe X rr

Control matrix B;

Appendix C. Derivation of A, B, C and D matrices

d

x ¼ Fx þ u

dt

2

X ss

0

6

X ss

6 0

1 6

6 X m

E¼

0

xb 6

6

X m

4 0

Rr

0

A ¼ ðEÞ1 F

A23 ¼ A14 ;

E

s xe X m

System matrix A;

A16 ¼

Scenario 1 strong grid

Rs

0

0

y ¼ Cx þ Du

A15 ¼

Type of grid

xe X m

0

0

xe X m

x_ ¼ Ax þ Bu

Appendix B. System parameters

Parameters

xe X ss

xb

X rr X ss X 2m

fðX m ids0 þ X rr idr0ÞX m g

A27 ¼ A16 ;

xb

X rr X ss X 2m

xb

X rr X ss X 2m

fX m ðRr þ K p1 Þg;

A28 ¼ 0;

fRT X m þ ðK p2 X ss =X m v s0 xs ÞðRT v ds0 þ X T v qs0 Þg

fðX m X ss s0 X m X ss Þxs þ X T X rr

þ ðK p2 X ss =X m v s0 xs ÞðRT v qs0 X T v ds0 Þg

A33 ¼

A34 ¼

xb

X rr X ss X 2m

xb

X rr X ss X 2m

fX ss ðRr þ K p2 Þg;

f X 2m þ s0 X ss X rr xs g;

82

B. Mehta et al. / Electrical Power and Energy Systems 70 (2015) 70–82

A35 ¼

A36 ¼

A41 ¼

xb

X rr X ss X 2m

xb X ss

X rr X ss X 2m

xb

X rr X ss X 2m

References

fðX m iqs0 X rr iqr0ÞX ss g;

;

A37 ¼ 0;

A38 ¼

xb X ss K p2

X rr X ss X 2m

fðX m X ss þ s0 X m X ss Þxs X T X rr

þ ðK p1 X ss K opt X ss xs x2r0 =v 3s0 X m ÞðRT v ds0 þ X T v qs0 Þg

A42 ¼

xb

X rr X ss X 2m

fRT X m þ ðK p1 X ss K opt X ss xs x2r0 =v 3s0 X m ÞðRT v qs0

X T v ds0 Þg

A43 ¼

A44 ¼

A45 ¼

xb

X rr X ss X 2m

xb

X rr X ss X 2m

xb

X rr X ss X 2m

A46 ¼ 0;

n

X 2m s0 X ss X rr xs g;

)

fX ss ðRr þ K p1 Þ

fðX m ids0 þ X rr idr0ÞX ss þ 2ðK p1 X ss =X m Þg;

A47 ¼ A36 ;

A48 ¼ 0;

A51 ¼

X m iqr0

2H

X m idr0

X m iqs0

X m ids0

; A53 ¼

; A54 ¼

;

2H

2H

2H

¼ 0; A56 ¼ 0; A57 ¼ 0; A58 ¼ 0;

A52 ¼

A55

A61 ¼ ðK i2 =v s0 xs X m ÞðRT v ds0 þ X T v qs0 Þ;

A62 ¼ ðK i2 =v s0 xs X m ÞðRT v qs0 X T v ds0 Þ;

A65 ¼ 0;

A66 ¼ 0; A67 ¼ 0;

A71 ¼ ðK i1 K opt X ss xs x

A63 ¼ K i2 ;

A68 ¼ K i2 ;

v

2

3

r0 = s0 X m ÞðRT

v ds0 þ X T v qs0 Þ

A72 ¼ ðK i1 K opt X ss xs x2r0 =v 3s0 X m ÞðRT v qs0 X T v ds0 Þ;

A73 ¼ 0;

A74 ¼ K i1 ;

A75 ¼ ð2K i1 K opt X ss xs xr0 =X m v s0 Þ;

A78 ¼ 0;

A76 ¼ 0;

A77 ¼ 0;

A81 ¼ ðK p3 =v s0 ÞðRT v ds0 þ X T v qs0 Þ

A82 ¼ ðK p3 =v s0 ÞðRT v qs0 X T v ds0 Þ;

A85 ¼ 0;

A86 ¼ 0;

A87 ¼ 0;

A64 ¼ 0;

A83 ¼ 0;

A88 ¼ 0

A84 ¼ 0;

[1] http:www.windpowerindia.com.

[2] Lei Y, Mullane A, Lightbody G, Yacamini R. Modeling of the wind turbine with a

doubly fed induction generator for grid integration studies. IEEE Trans Energy

Convers 2006;21(1):257–64.

[3] Anaya-Lara O, Jenkins N, Ekanayake JB, Cartwright P, Hughes M. Wind energy

generation. Modelling and control. Hoboken, NJ: Wiley; 2009.

[4] Yang Lihui, Xu Zhao, Østergaard Jacob, Dong Zhao Yang, Wong Kit Po, Ma Xikui.

Oscillatory stability and eigenvalue sensitivity analysis of a DFIG wind turbine

system. IEEE Trans Energy Convers 2011;26(1):328–39.

[5] Elkington Katherine, Knazkins Valerijs, Ghandhari Mehrdad. On the stability of

power systems containing doubly fed induction generator-based generation.

Electr Power Syst Res 2008;78:1477–84.

[6] de Almeida Rogério G, Peças Lopes JA, Barrei JAL. Improving power system

dynamic behavior through doubly fed induction machines controlled by static

converter using fuzzy control. IEEE Trans Power Syst 2004;19(4):1942–50.

[7] Mishra Y, Mishra S, Li Fangxing, Dong ZY, Bansal RC. Small-signal stability

analysis of a DFIG-based wind power system under different modes of

operation. IEEE Trans Energy Convers 2009;24(4):972–82.

[8] Mishra Y, Mishra S, Li Fangxing. Coordinated tuning of DFIG-based wind

turbines and batteries using bacteria foraging technique for maintaining

constant grid power output. IEEE Syst J 2012;6(1):16–24.

[9] Slootweg JG, Kling WL. The impact of large scale wind power generation on

power system oscillations. Electr Power Syst Res 2003;67(1):9–20.

[10] Ackermann T. Wind power in power systems. West Sussex, England: John

Wiley & Sons, Ltd; 2005.

[11] Kong SY, Bansal RC, Dong ZY. Comparative small-signal stability analyses of

PMSG-, DFIG and SCIG-based wind farms. Int J Ambient Energy

2012;33(2):87–97.

[12] Holdsworth L, Wu XG, Ekanayake JB, Jenkins N. Comparison of fixed-speed and

doubly-fed induction wind turbines during power system disturbances. IEE

Proc Gener Transm Distrib 2003;150(3):343–52.

[13] Mehta Bhinal, Bhatt Praghnesh, Pandya Vivek. Small signal stability analysis of

power systems with DFIG based wind power penetration. Int J Electr Power

Energy Syst 2014;58:64–74.

[14] Ekanayake JB, Holdsworth L, Wu X, Jenkins N. Dynamic modelling of doubly

fed induction generator wind turbines. IEEE Trans Power Syst

2003;18(2):803–9.

[15] Wu F, Zhang X-P, Godfrey K, Ju P. Small signal stability analysis and optimal

control of a wind turbine with doubly fed induction generator. IET Gener

Transm Distrib 2007;1(5):751–60.

[16] Kundur P. Power system stability and control. The EPRI power system

engineering series. New York: McGraw-Hill, Inc; 1994.

[17] Krause PC, Wasynczuk O, Sudhoff SD. Analysis of electric machinery and drive

systems. 2nd ed. A John Wiley and Sons, Inc. Publication; 2002.

[18] Ugalde-Loo Carlos E, Ekanayake Janaka B, Jenkins Nicholas. State-space

modeling of wind turbine generators for power system studies. IEEE Trans

Ind Appl 2013;49(1):223–32.

[19] MATLAB Help Tutorial, The Math Works, Inc. Version 7.8.0.347, 2009.

[20] Rahimi Mohsen, Parniani Mostafa. Grid-fault ride-through analysis and control

of wind turbines with doubly fed induction generators. Electr Power Syst Res

2010;80:184–95.

[21] Grid Code—Extra High Voltage, Tennet TSO GmbH; 2010. <http://www.

tennettso.de/site/binaries/content/assets/transparency/

publications/gridconnection/tennetnar2010eng.pdf>.

[22] Eberhart RC, Shi Y. Particle swarm optimization: developments, applications

and resources. In: Proceedings of the 2001 congress on evolutionary

computation, vol. 1; 27–30 May, 2001. p. 81–6.